Treatment process for improving surface hydrophilicity of implant

A treatment process and implant technology, applied in the direction of metal material coating process, prosthesis, manufacturing tools, etc., can solve the problems of poor hydrophilicity and stability, and achieve the promotion of adsorption, osseointegration, and morphology uniformity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this example, the steps of processing the hydrophilic TA4 dental implant are:

[0049] A. After the TA4 dental implant is finely ground, use Micro90 ultrasonic cleaning for 25 minutes, rinse with tap water for 2 minutes, and wash with purified water for 20 minutes to clean and remove oil, and then dry it.

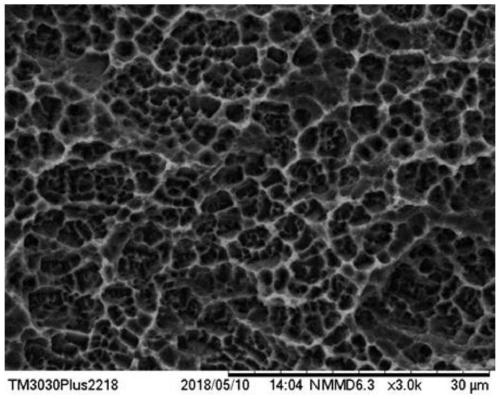

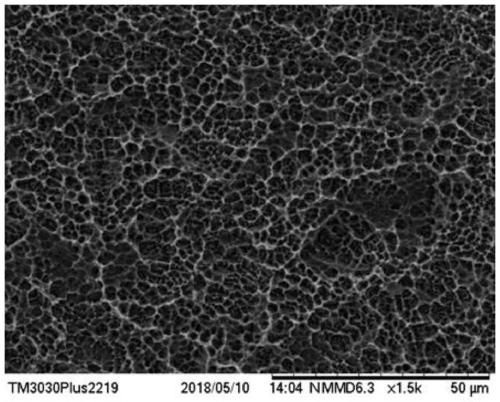

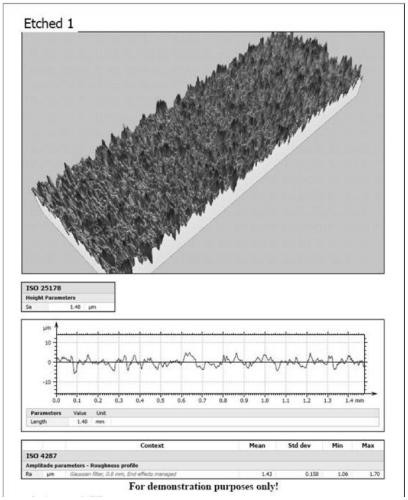

[0050] B. Sandblast the surface of the dental implant with 30 mesh white corundum particles for 10 seconds, the sandblasting pressure is 0.3MPa, and the spray distance is 10cm, until the surface forms a uniform gray, so that the surface of the dental implant forms a three-dimensional porous structure, the first grade The pit diameter is between 20 and 60 μm. Perform Micro90 ultrasonic cleaning for 15 minutes in sequence, rinse with tap water, ultrasonically clean with purified water, and dry.

[0051] C. Acid Etching Treatment: Place the sandblasted dental implant in 60wt% H 2 SO 4 , 18wt% HCl and pure water mixed acid solution, in which 60wt% H 2 SO 4 , 10wt...

Embodiment 2

[0065] In this example, the steps of processing the hydrophilic TA4 dental implant are:

[0066] A. After the TA4 dental implant is finely ground, use Micro90 ultrasonic cleaning for 20 minutes, rinse with tap water for 5 minutes, and wash with purified water for 10 minutes to clean and remove oil, and then dry it.

[0067]B. Sandblast the surface of the dental implant with 50 mesh white corundum particles for 5 seconds, the sandblasting pressure is 0.2MPa, and the spray distance is 5cm, until the surface forms a uniform gray color, so that a three-dimensional porous structure is formed on the surface of the dental implant. The pit diameter is between 20 and 60 μm. Perform Micro90 ultrasonic cleaning for 15 minutes in sequence, rinse with tap water, ultrasonically clean with purified water, and dry.

[0068] C. Acid Etching Treatment: Place the sandblasted dental implant in 98wt% H 2 SO 4 , 36wt% HCl and pure water mixed acid solution, in which 98wt% H 2 SO 4 , 36wt% HCl ...

Embodiment 3

[0074] In this example, the steps of processing the hydrophilic TC4 dental implant are:

[0075] A. After the TC4 dental implant is finely ground, use Micro90 ultrasonic cleaning for 50 minutes, rinse with tap water for 1 minute, and wash with purified water for 40 minutes to clean and remove oil, and then dry it.

[0076] B. Use 100-mesh white corundum particles to sandblast the surface of the dental implant for 60 seconds, the sandblasting pressure is 0.6MPa, and the spray distance is 15cm, until the surface forms a uniform gray, so that the surface of the dental implant forms a three-dimensional porous structure, the first grade The pit diameter is between 20 and 60 μm. Perform Micro90 ultrasonic cleaning for 15 minutes in sequence, rinse with tap water, ultrasonically clean with purified water, and dry.

[0077] C. Acid Etching Treatment: Place the sandblasted dental implant in 49wt%H 2 SO 4 , 18wt% HCl and pure water mixed acid solution, in which 49wt% H 2 SO 4 , 18w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com