Polyester-cotton anti-static functional fabric

An anti-static and functional technology, applied in the field of textile fabrics, can solve the problems of poor anti-static effect and poor functional durability, and achieve the effects of improving wetting performance, enhancing wearing performance and enhancing anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

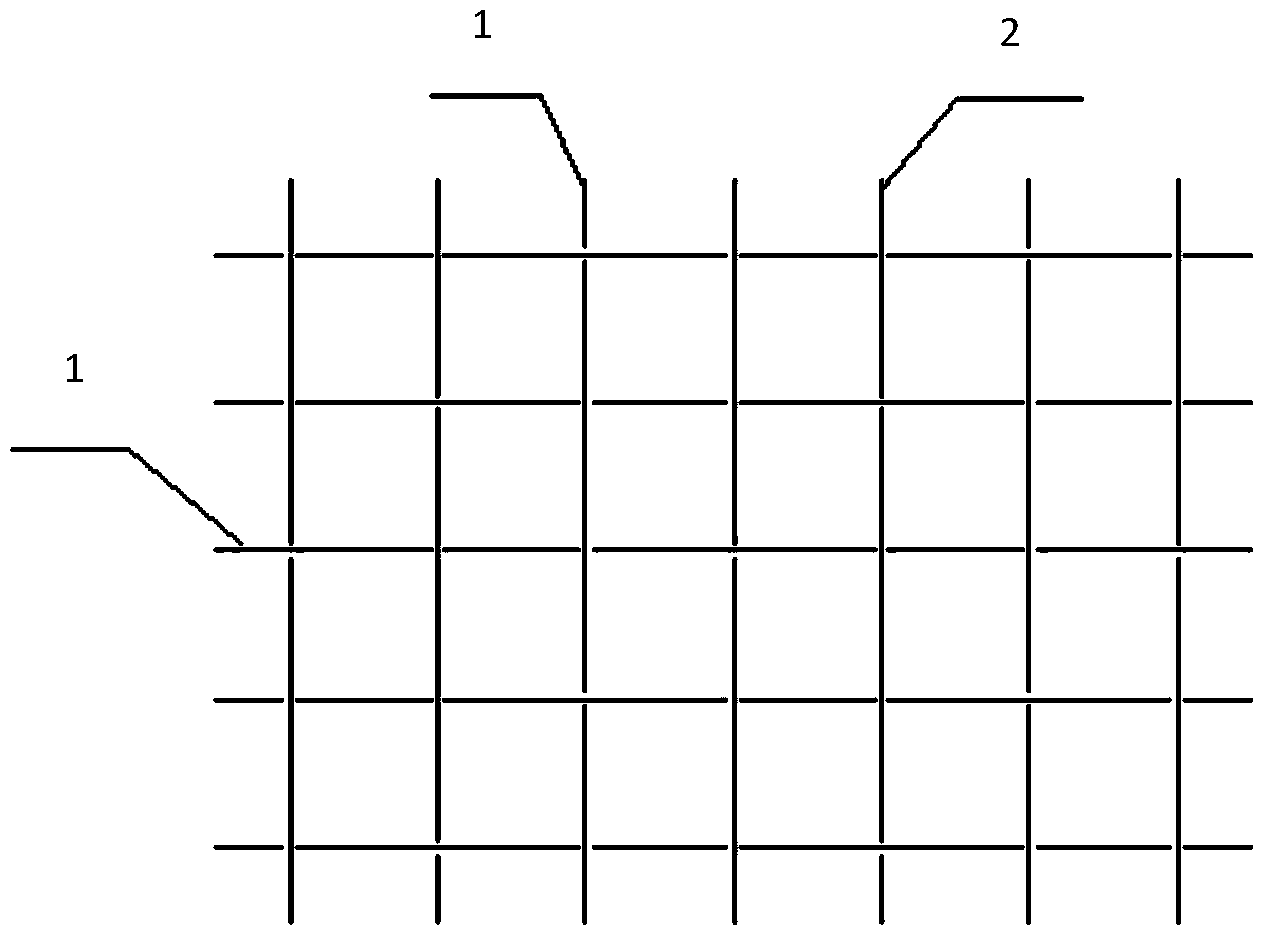

[0030] Polyester-cotton blended yarn 1, its linear density is 18tex×2, and its blending ratio is 65% cotton fiber / 35% polyester fiber; polyester-cotton blended yarn / carbon fiber filament wrapping yarn 2 is used as functional embedded yarn, and carbon fiber The filament and the polyester-cotton blended strand are wrapped to obtain a wrapped yarn with a yarn number of 15.4tex.

[0031] The specific design of the warp arrangement cycle is 40 warp yarns as a cycle, 39 of which are polyester-cotton blended strands 18tex×2, and one polyester-cotton blended yarn / carbon fiber filament wrapping yarn is embedded in each cycle. The weft yarns are all polyester-cotton blended strands 18tex×2.

[0032] The fabric finishing process adopts biological enzyme treatment method, wherein the enzyme treatment process is as follows: 1. fabric; 2. esterase enzyme washing (pH=7, enzyme content 2g / L, room temperature, 30min); 3. boiling inactivation; 4. Washing; 5, drying.

[0033] One of the antist...

Embodiment 2

[0035] Polyester-cotton blended yarn 1, its linear density is 18tex×2, and its blending ratio is 65% cotton fiber / 35% polyester fiber; polyester-cotton blended yarn / carbon fiber filament wrapping yarn 2 is used as functional embedded yarn, and carbon fiber The filament and the polyester-cotton blended strand are wrapped to obtain a wrapped yarn with a yarn number of 15.4tex.

[0036] The specific design of the warp arrangement cycle is 40 warp yarns as one cycle, 35 of which are polyester-cotton blended strands 18tex×2, and 5 polyester-cotton blended yarns / carbon fiber filament wrapping yarns are embedded in each cycle. The weft yarns are all polyester-cotton blended strands 18tex×2.

[0037] The fabric finishing process adopts biological enzyme treatment method, and the enzyme treatment process is as follows: 1. Fabric; 2. Esterase enzyme washing (pH=6.5, enzyme content 1.5g / L, room temperature, 50min) 3. Boiling inactivation; 4. Washing; 5, drying.

[0038] One of the anti...

Embodiment 3

[0040] Polyester-cotton blended yarn 1, its linear density is 18tex×2, and its blending ratio is 65% cotton fiber / 35% polyester fiber; polyester-cotton blended yarn / carbon fiber filament wrapping yarn 2 is used as functional embedded yarn, and carbon fiber The filament and the polyester-cotton blended strand are wrapped to obtain a wrapped yarn with a yarn number of 15.4tex.

[0041] The specific design of the warp arrangement cycle is 40 warp yarns as a cycle, 32 of which are polyester-cotton blended strands 18tex×2, and 8 polyester-cotton blended yarns / carbon fiber filament wrapping yarns are embedded in each cycle. The weft yarns are all polyester-cotton blended strands 18tex×2.

[0042]The fabric finishing process adopts biological enzyme treatment method, and the enzyme treatment process is as follows: 1. Fabric; 2. Esterase enzyme washing (pH7.5, enzyme content 2.5g / L, room temperature, 25min); 3. Boiling inactivation; 4. , washing; 5, drying.

[0043] One of the antis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com