Soft leather filling agent and preparation method thereof

A technology for fillers and leathers, applied in biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as lack of antibacterial properties, unstable performance, hardening of leather, etc., and achieve excellent oiliness Effect, softness improvement, permeability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

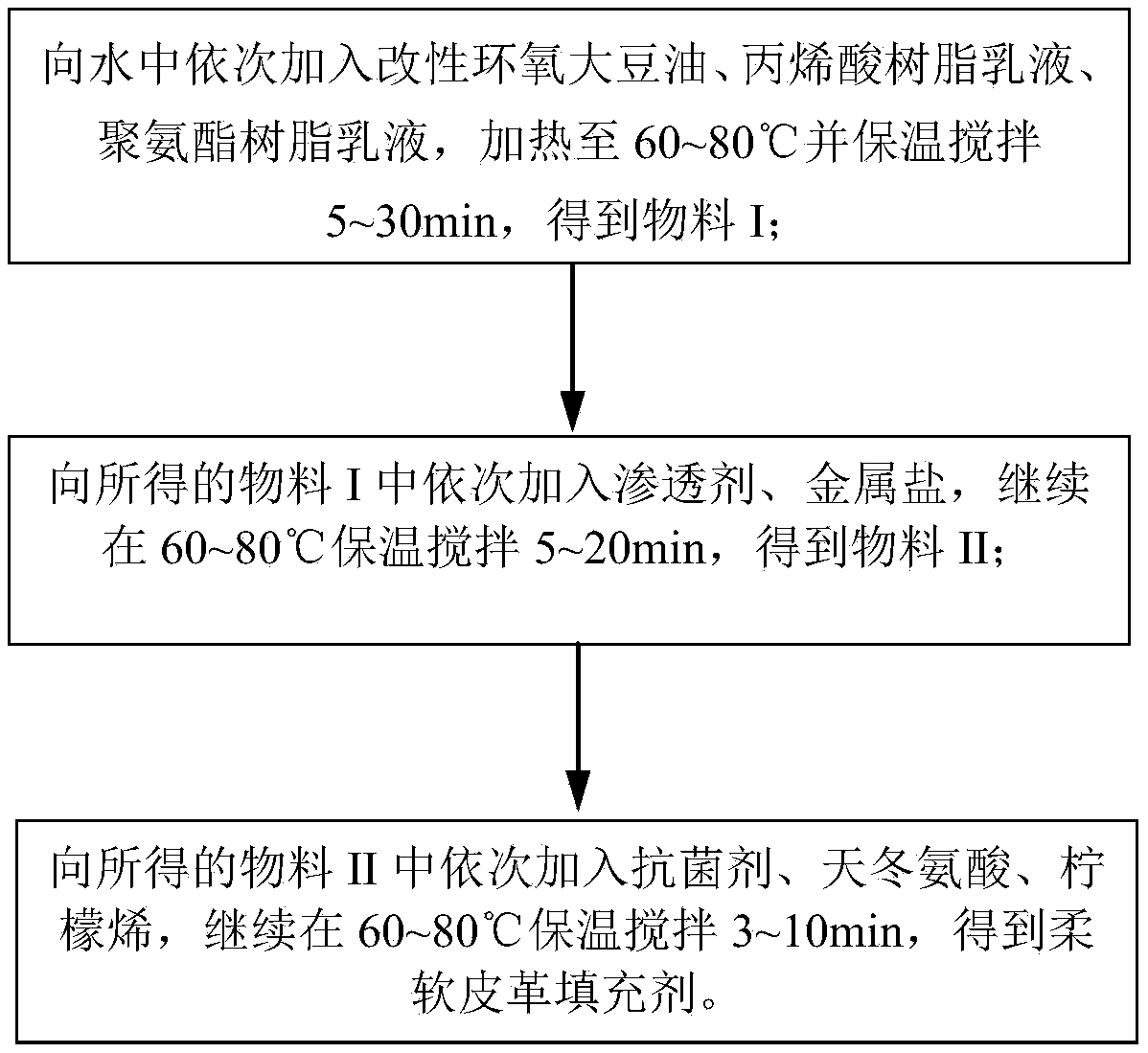

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the soft leather filler of the present embodiment, comprises the steps:

[0031] Get the following raw materials in parts by weight:

[0032] 35 parts of acrylic resin emulsion, 33 parts of polyurethane resin emulsion, 24 parts of modified epoxy soybean oil, 4 parts of sodium dioctyl maleate sulfonate, 2 parts of fatty alcohol polyoxyethylene ether, 0.4 part of white clove extract 0.8 parts of camphor wood extract, 2 parts of peppermint extract, 0.2 parts of nano-lanthanum fluoride, 0.6 parts of nano-yttrium fluoride, 2 parts of aspartic acid, 3 parts of limonene, and 18 parts of deionized water.

[0033] (1) Add modified epoxy soybean oil, acrylic resin emulsion, and polyurethane resin emulsion to water in sequence, heat to 70° C. and keep stirring for 12 minutes to obtain material I;

[0034] (2) Add successively in the material I of step (1) gained dioctyl maleate sulfonate, fatty alcohol polyoxyethylene ether, nanometer lanthanum fluoride,...

Embodiment 2

[0037] The preparation method of the soft leather filler of the present embodiment, comprises the steps:

[0038] Get the following raw materials in parts by weight:

[0039] 40 parts of acrylic resin emulsion, 35 parts of polyurethane resin emulsion, 28 parts of modified epoxy soybean oil, 2.5 parts of sodium dioctyl maleate sulfonate, 2.5 parts of fatty alcohol polyoxyethylene ether, 0.3 part of white clove extract 0.3 parts of camphor wood extract, 1 part of peppermint extract, 0.3 parts of nano-lanthanum fluoride, 0.6 parts of nano-yttrium fluoride, 2 parts of aspartic acid, 3 parts of limonene, and 20 parts of deionized water.

[0040] (1) Add modified epoxy soybean oil, acrylic resin emulsion, and polyurethane resin emulsion to water successively, heat to 65° C. and keep stirring for 15 minutes to obtain material I;

[0041] (2) Add successively in the material I of step (1) gained dioctyl maleate sulfonate, fatty alcohol polyoxyethylene ether, nanometer lanthanum fluor...

Embodiment 3

[0044] The preparation method of the soft leather filler of the present embodiment, comprises the steps:

[0045] Get the following raw materials in parts by weight:

[0046]45 parts of acrylic resin emulsion, 38 parts of polyurethane resin emulsion, 25 parts of modified epoxy soybean oil, 5 parts of sodium dioctyl maleate sulfonate, 2 parts of fatty alcohol polyoxyethylene ether, 0.4 part of white clove extract 0.6 parts of camphor wood extract, 2 parts of peppermint extract, 0.1 part of nano-lanthanum fluoride, 0.5 part of nano-yttrium fluoride, 2 parts of aspartic acid, 2 parts of limonene, and 22 parts of deionized water.

[0047] (1) Add modified epoxidized soybean oil, acrylic resin emulsion, and polyurethane resin emulsion to water successively, heat to 75° C. and keep stirring for 8 minutes to obtain material I;

[0048] (2) Add successively in the material I of step (1) gained dioctyl maleate sulfonate, fatty alcohol polyoxyethylene ether, nanometer lanthanum fluorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com