Sliding component

A sliding part and sliding surface technology, applied in engine components, engine seals, mechanical equipment, etc., can solve the problem of easy lubrication of seal blocking parts, and achieve the effect of ensuring lubricity, reducing sliding torque, and maintaining tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

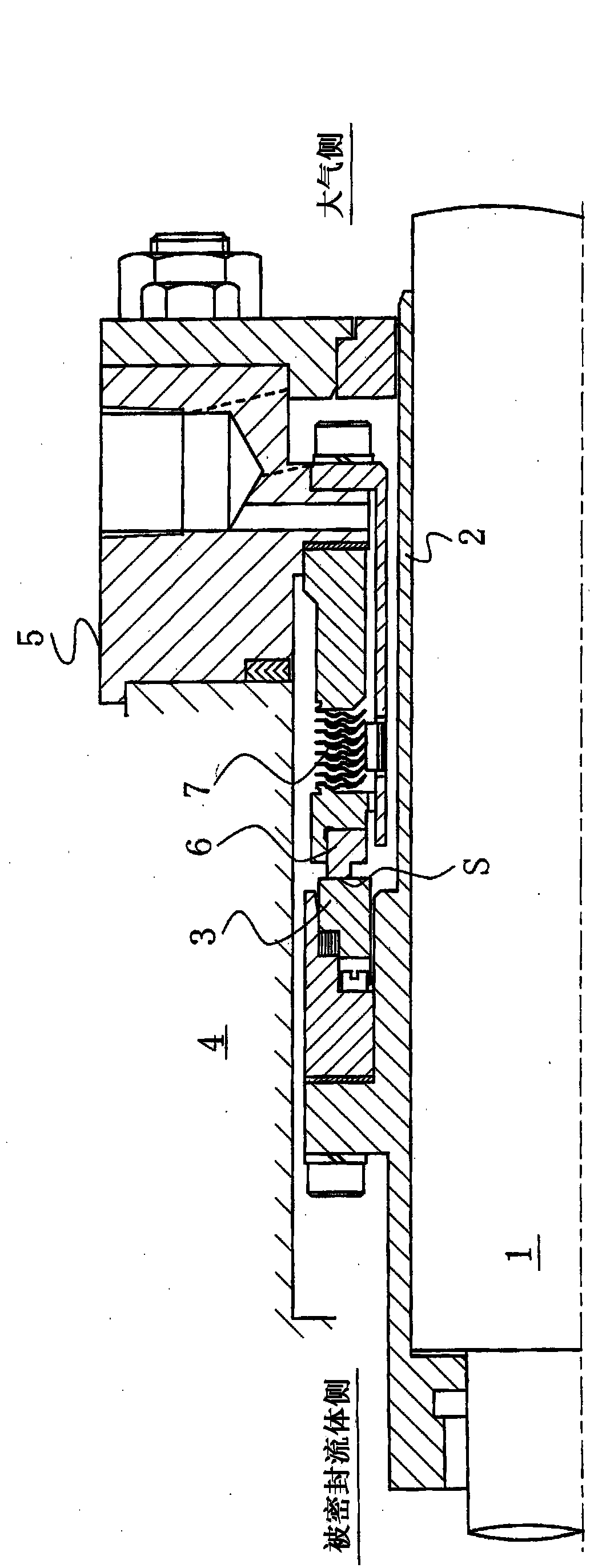

Embodiment approach 1

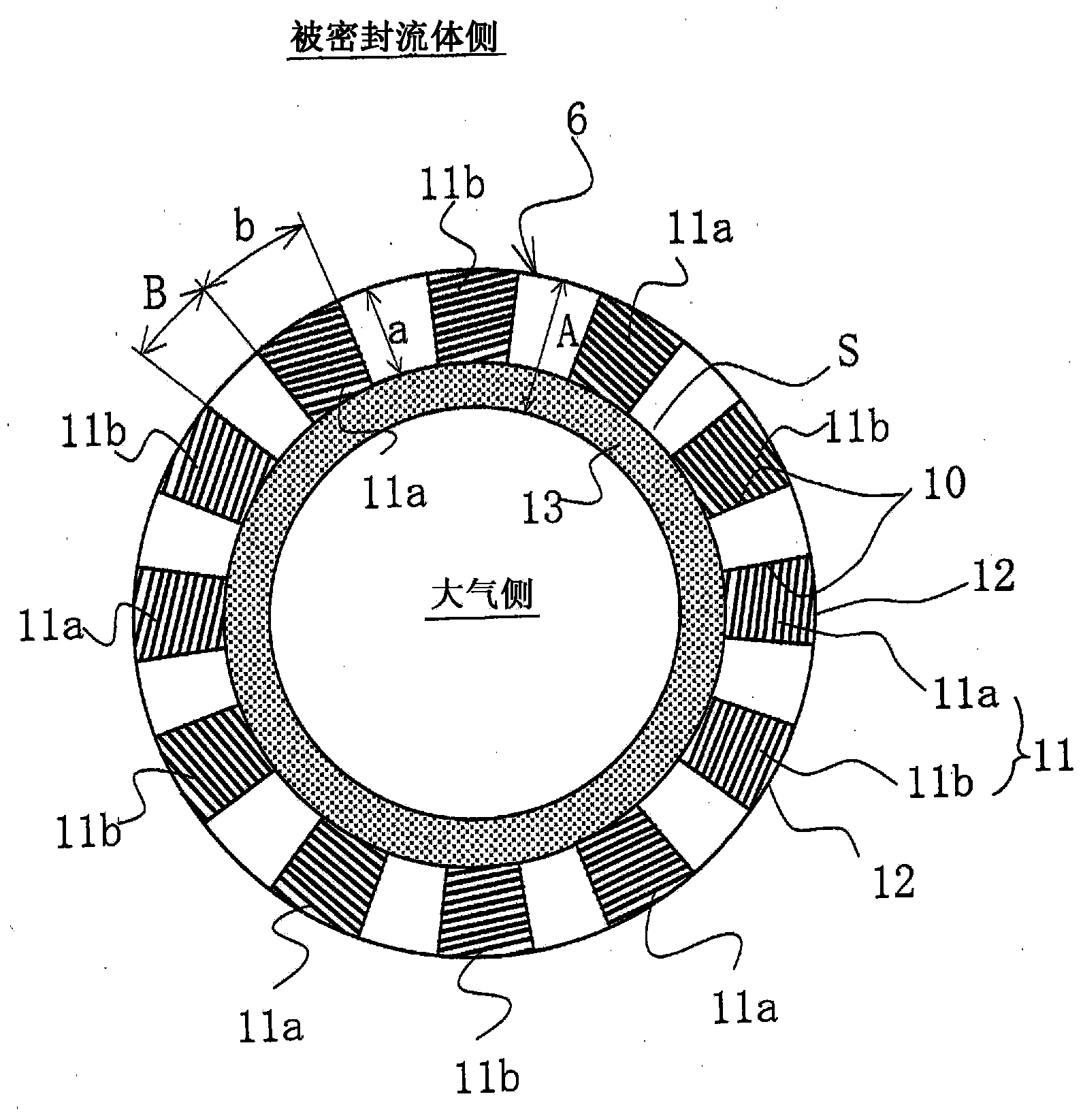

[0044] image 3 is shown in figure 1 and figure 2 Among the sliding surfaces of the stationary ring 6 and the rotating ring 3, the sliding surface S of the stationary ring 6, which has a smaller radial width, is formed with a sealed fluid receiving area, a suction portion, and a seal barrier portion with excellent lubricity. A top view of one embodiment of the case.

[0045] exist image 3 Among them, the fixing ring 6 is called a sealing ring, and is mostly formed of carbon (soft material). A plurality of sealed fluid storage areas 10 separated in the circumferential direction are formed on the sliding surface S of the stationary ring 6. The sealed fluid storage areas 10 are formed on a part of the radial direction of the sliding surface S, and are sealed with the outer peripheral side 12. The fluid storage space is directly connected.

[0046] In addition, in the case of an outer type mechanical seal in which the sealed fluid side exists inside the rotating ring 3 and...

Embodiment approach 2

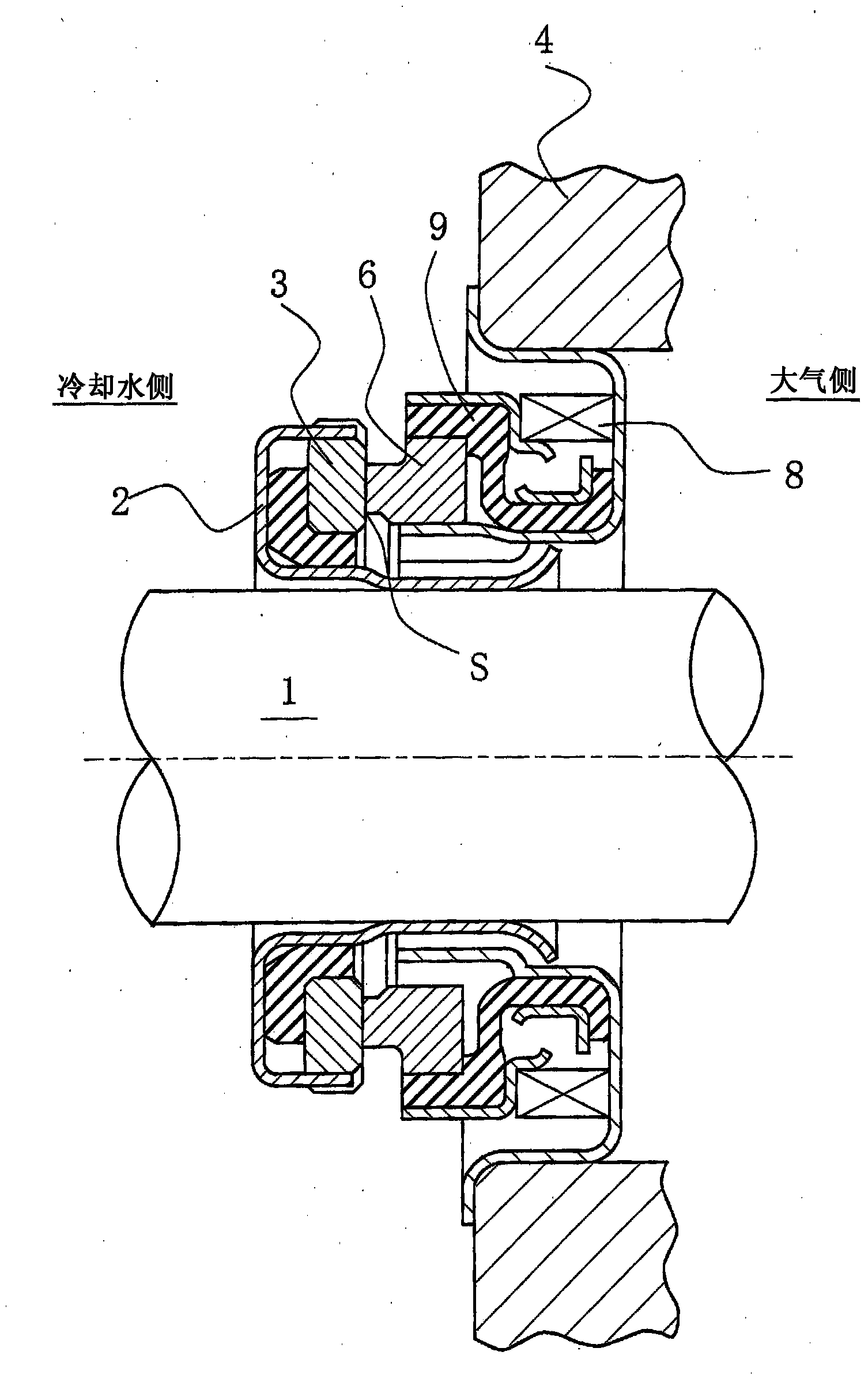

[0083] Image 6 is in figure 1 and 2 Among the mechanical seals of the fixed ring and the rotating ring, one of the cases where the sliding surface of the rotating ring with a large radial width is formed with a sealed fluid receiving area, a suction portion, and a seal stopper portion excellent in lubricity The drawing of the embodiment is a sectional view taken along a plane perpendicular to the sliding surface.

[0084] exist Image 6 Among them, the rotating ring 3 is called an adapter ring, and it is mostly formed of SiC (hard material). On the sliding surface S of the rotary ring 3, a plurality of sealed fluid storage areas 10 separated in the circumferential direction are formed. These plurality of sealed fluid storage areas 10 are formed on a part of the sliding surface S with spaces left outside and inside in the radial direction of the sliding surface S, and a part of the sealed fluid storage area 10 on the sealed fluid side It is formed so as not to be covered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com