Grinding auxiliary and grinding liquid for coarse grinding of sapphire and preparation methods of grinding auxiliary and grinding liquid

A grinding aid, sapphire technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as poor suspension of abrasive particles, thermal stress cracks, poor lubricity, etc., to increase cycle life and lubricity , the effect of increasing the grinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

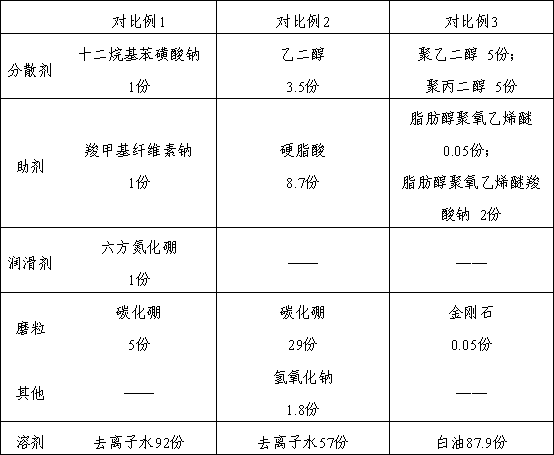

[0038] A rough sapphire grinding aid, which is prepared from the following components by weight, as shown in Table 1.

[0039] Table 1. Preparation of grinding aids for rough grinding of sapphire

[0040]

[0041] The filler can finally be dissolved in the grinding aid to play the role of lubrication and heat dissipation during the grinding process.

Embodiment 6

[0043] The present embodiment provides the preparation method of the grinding aid described in embodiment 1, comprising the steps of:

[0044] (1) Preparation of component A:

[0045] ① Add ethanol, zinc stearate, and magnesium stearate in proportion to the reaction kettle, and stir at 50°C for 0.5h;

[0046] ②Put the dispersant polymaleic acid into the above reaction kettle, stir for 0.5h at room temperature, defoam, discharge, and package;

[0047] (2) Preparation of component B:

[0048] Add xanthan gum and fumed silicon dioxide into the ball mill in proportion, then add ethanol, Tween 20, triethanolamine and sodium hydroxide in proportion, ball mill and stir for 0.5h, mix evenly, discharge and package.

[0049] When in use, mix components A and B at a weight ratio of 4:1 at room temperature.

Embodiment 7

[0051] The present embodiment provides the preparation method of the grinding aid described in embodiment 2, comprising the steps of:

[0052] (1) Preparation of component A:

[0053] ① Add ethylene glycol, zinc stearate, and magnesium stearate in proportion to the reaction kettle, and stir at 50°C for 1 hour;

[0054] ②Add polyamino acid into the above reaction kettle, stir for 0.5h at room temperature, defoam, discharge, and package;

[0055] (2) Preparation of component B:

[0056] Add fumed silicon dioxide into the ball mill in proportion, then add ethylene glycol, Tween 40, diethanolamine, and ammonia water in proportion, and stir in the ball mill for 0.5h, mix evenly, discharge and package.

[0057] When in use, mix components A and B at a weight ratio of 4:1 at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com