Coating for directional electromagnetic steel plate and preparation method of coating

An electromagnetic steel plate and directional technology, applied in the coating, metal material coating process, etc., can solve the problems of insulating coating tension, insulation and corrosion resistance degradation, etc., and achieve excellent slipperiness and good covering property Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

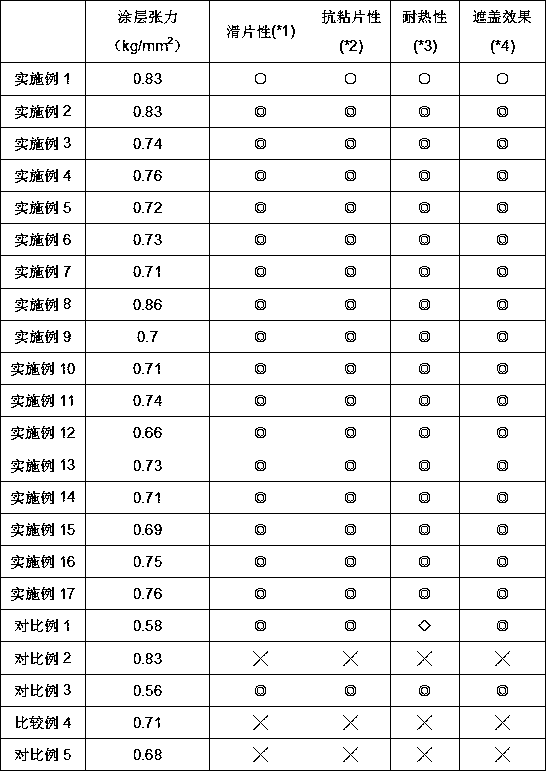

Examples

Embodiment 1

[0027] A coating for directional electrical steel sheets, the proportion of which is:

[0028] 100g aluminum dihydrogen phosphate (calculated as phosphate radical);

[0029] 90g silica sol (as SiO 2 meter), the particle size is 10nm;

[0030] 20gCrO 3 ;

[0031] 1g Ti 4 o 7 , the particle size is 10nm;

[0032] 20g boric acid;

[0033] Add boric acid and titanium compound powder to the silica sol according to the above ratio, form a stable mixed solution by mechanical dispersion or ultrasonic dispersion, mix and stir the mixed solution with phosphate to obtain a coating for oriented electrical steel sheets.

[0034] Use a high magnetic induction oriented electrical steel sheet with a thickness of 0.23mm and a glass film bottom layer, and after shearing, it will be heated at 3%H 2 SO 4 Carry out light pickling at 80°C for 10s in aqueous solution and then dry. Apply the coating on the surface of the steel plate by roller coating. After the coating is dried, carry out si...

Embodiment 2

[0036] A coating for directional electrical steel sheets, the proportion of which is:

[0037] 100g aluminum dihydrogen phosphate (calculated as phosphate radical);

[0038] 90g silica sol (as SiO 2 meter), the particle size is 10nm;

[0039] 20gCrO 3 ;

[0040] 5g Ti 4 o 7 , the particle size is 10nm;

[0041] 20g boric acid;

[0042]Add boric acid and titanium compound powder to the silica sol according to the above ratio, form a stable mixed solution by mechanical dispersion or ultrasonic dispersion, mix and stir the mixed solution with phosphate to obtain a coating for oriented electrical steel sheets.

[0043] Use a high magnetic induction oriented electrical steel sheet with a thickness of 0.23mm and a glass film bottom layer, and after shearing, it will be heated at 3%H 2 SO 4 Carry out light pickling at 80°C for 10s in aqueous solution and then dry. Apply the coating on the surface of the steel plate by roller coating. After the coating is dried, carry out sin...

Embodiment 3

[0045] A coating for directional electrical steel sheets, the proportion of which is:

[0046] 100g aluminum dihydrogen phosphate (calculated as phosphate radical);

[0047] 90g silica sol (as SiO 2 meter), the particle size is 10nm;

[0048] 20gCrO 3 ;

[0049] 10g Ti 4 o 7 , the particle size is 100nm;

[0050] 20g boric acid;

[0051] Add boric acid and titanium compound powder to the silica sol according to the above ratio, form a stable mixed solution by mechanical dispersion or ultrasonic dispersion, mix and stir the mixed solution with phosphate to obtain a coating for oriented electrical steel sheets.

[0052] Use a high magnetic induction oriented electrical steel sheet with a thickness of 0.23mm and a glass film bottom layer, and after shearing, it will be heated at 3%H 2 SO 4 Carry out light pickling at 80°C for 10s in aqueous solution and then dry. Apply the coating on the surface of the steel plate by roller coating. After the coating is dried, carry out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com