Novel threshing and redrying process based on tobacco mechanics characteristic differences

A technology of mechanical properties, threshing and redrying, which is applied in the fields of tobacco, food science, and tobacco preparation, can solve problems such as ineffective control, improve the processing technology level, improve the overall quality of tobacco sheets, and reduce the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further described by the following specific examples, but does not limit the present invention.

[0047] ① Threshing and redrying process setting

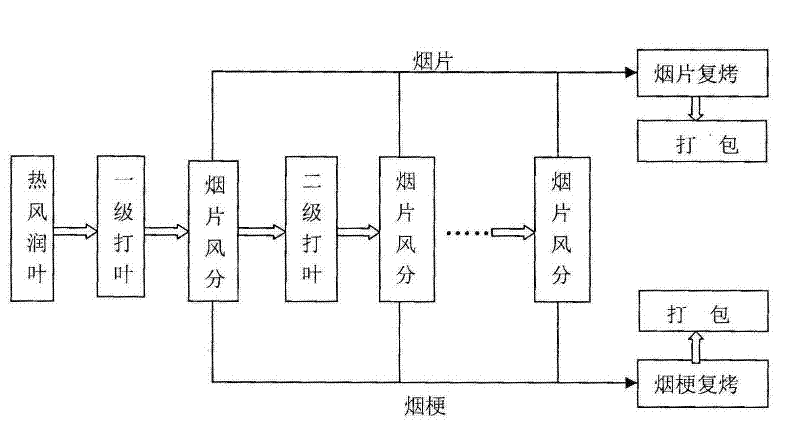

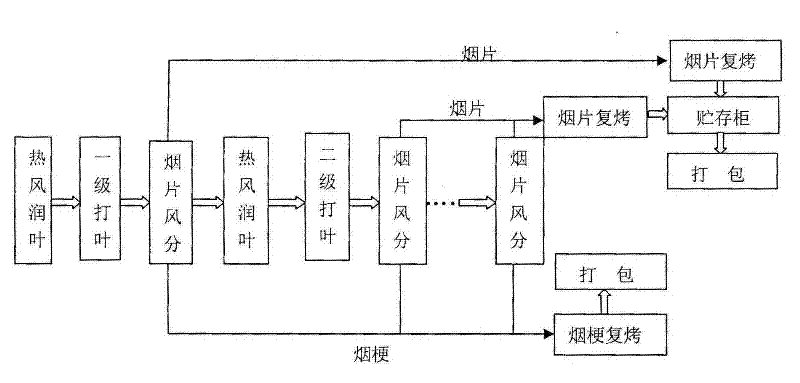

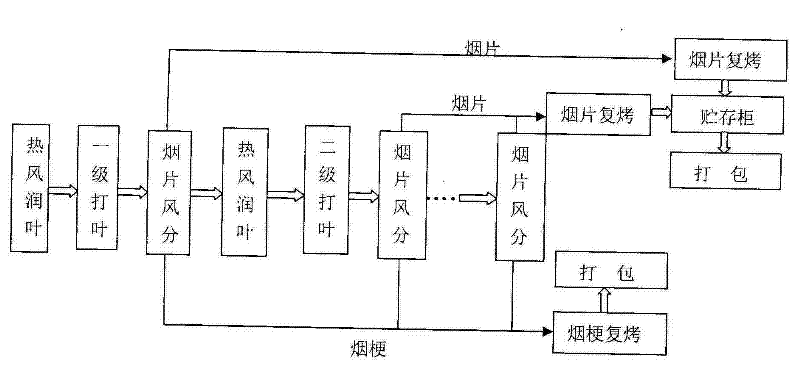

[0048] According to the present invention figure 2 Threshing leaves and re-roasting according to the technological process.

[0049] ② Determination of mechanical properties such as tobacco leaf adhesion

[0050] Table 2 shows the measurement results of mechanical indicators such as adhesion force of tobacco leaves from a certain domestic origin, grade C3F.

[0051] It can be seen from Table 2 that the mechanical property indicators such as adhesion force of this grade tobacco leaf meet the requirements for Class I tobacco leaf in the present invention.

[0052] Table 2 Adhesion force and tensile strength index of C3F tobacco leaves from a domestic production area

[0053] Tobacco Grade Adhesion (g) Pull force (N) C3F 567.456 1.875

[0054] ③Moisture content of tobacco ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com