Novel polyether ester nonionic surfactant and preparation method thereof

A surfactant and non-ionic technology, applied in the field of new polyetherester non-ionic surfactant and its preparation, can solve the problems of complex treatment process, water pollution, high cost, and achieve good biodegradability and mutual solubility. Good and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

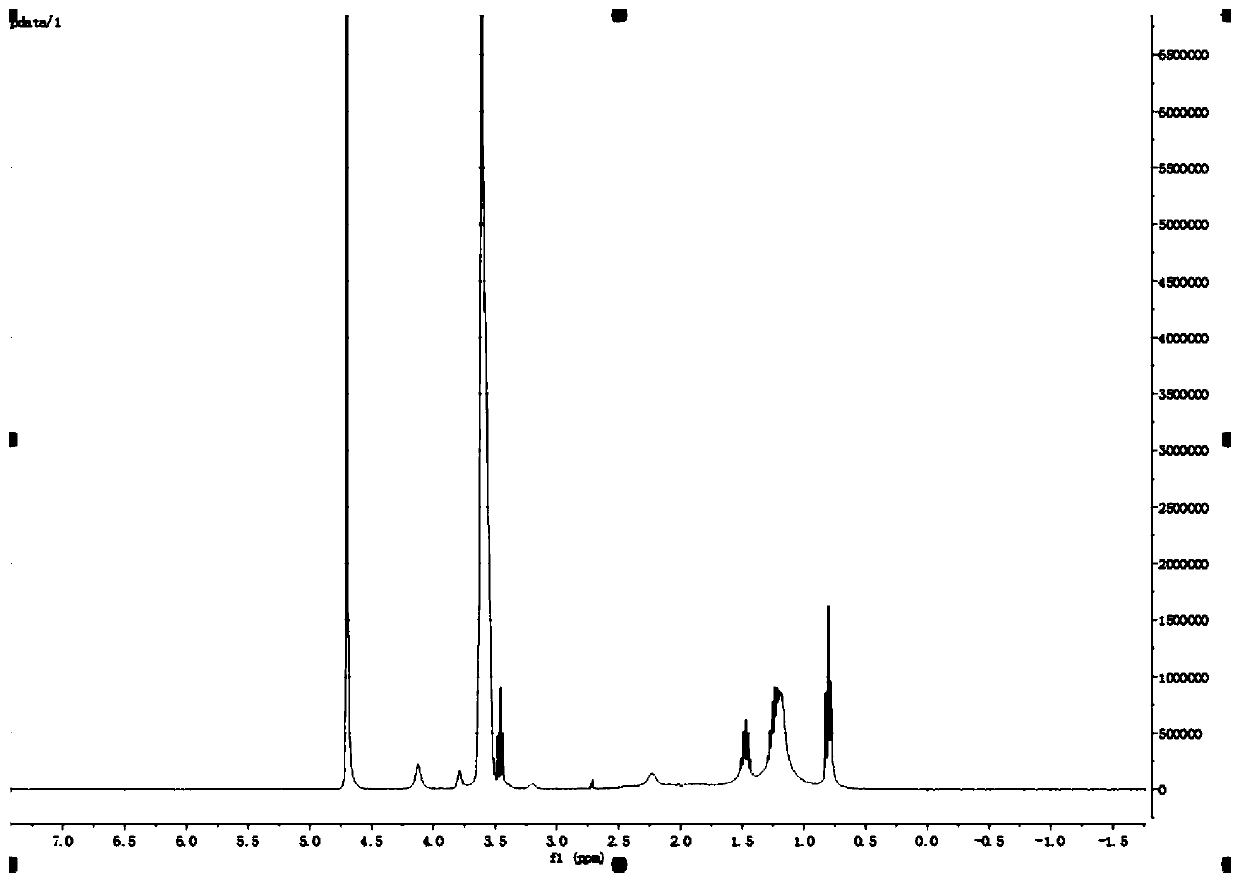

Image

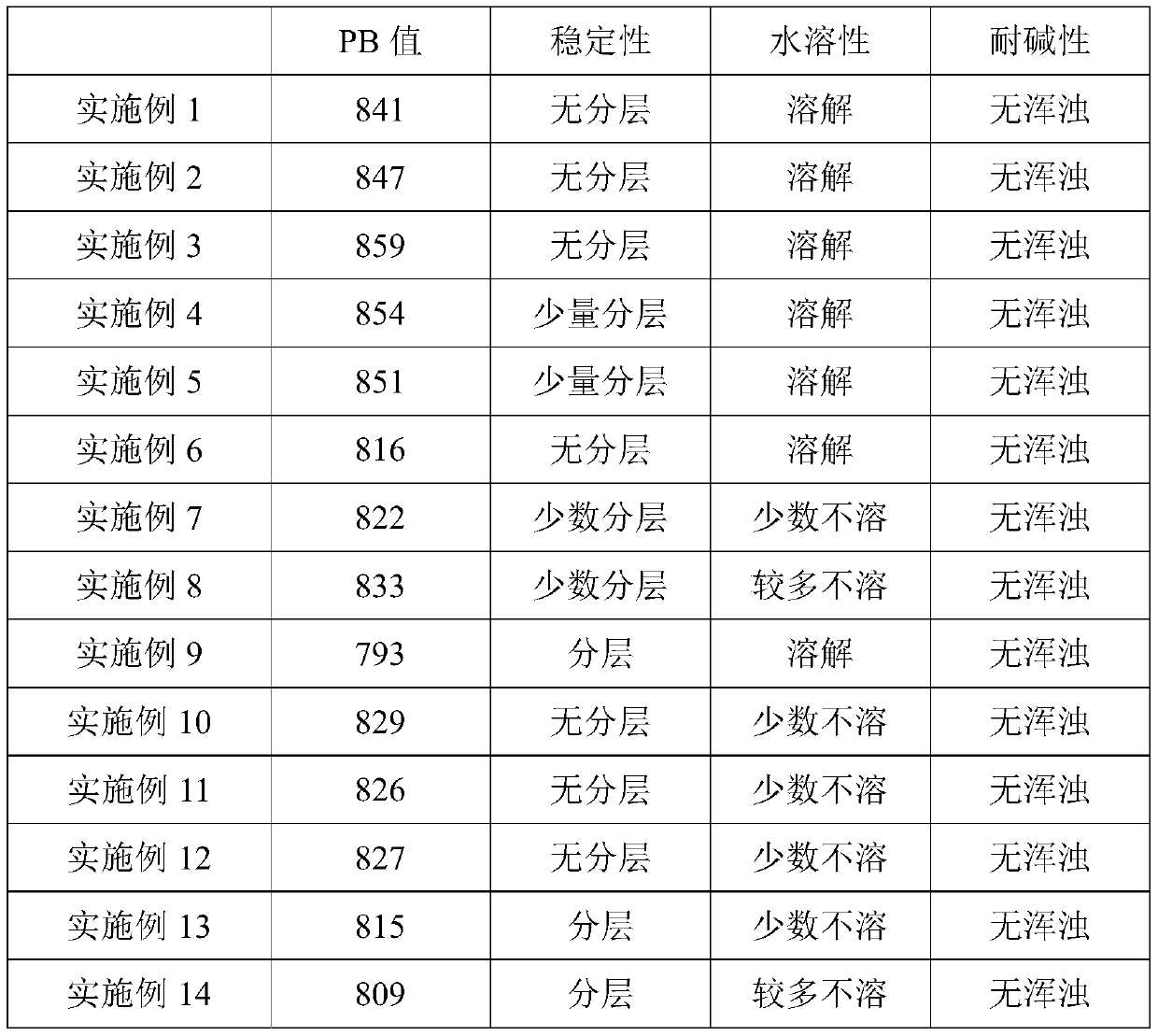

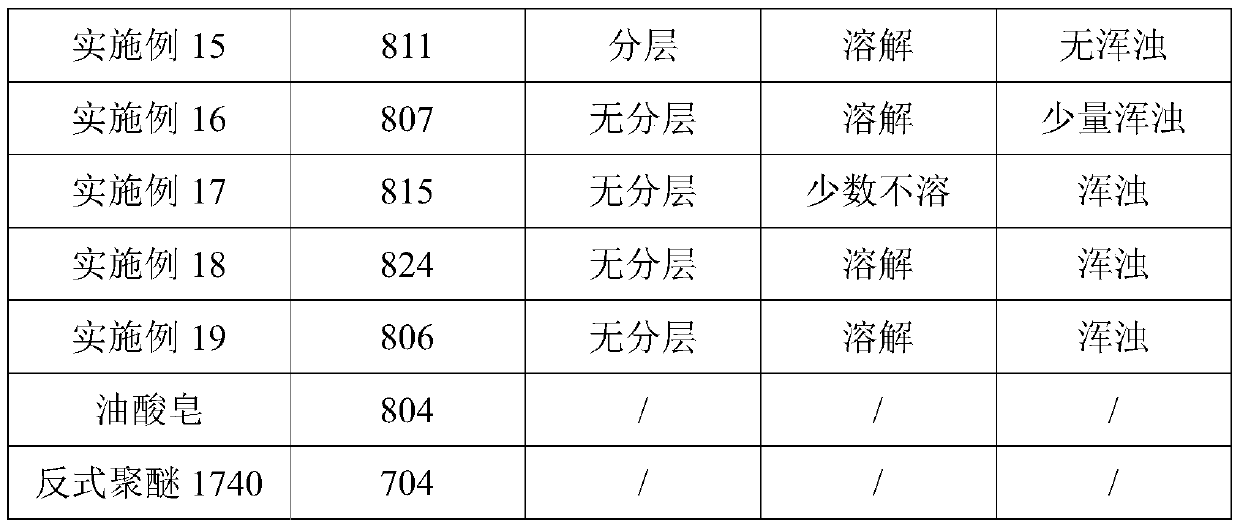

Examples

preparation example Construction

[0023] The first aspect of the present invention provides a preparation method of a novel polyether ester nonionic surfactant, which at least includes the following steps: mixing polyether and fatty acid, adding a catalyst, and reacting under reduced pressure to obtain a novel polyether ester nonionic surfactant. Ionic surfactant.

[0024] In one embodiment, the molar ratio of the polyether to the fatty acid is (1.1-1.5):1.

[0025] In a preferred embodiment, the molar ratio of the polyether to the fatty acid is 1.3:1.

[0026] polyether

[0027] In the present invention, the polyether is a linear polymer prepared by ring-opening homopolymerization or copolymerization with ethylene oxide, propylene oxide, butylene oxide, etc. as raw materials under the action of a catalyst.

[0028] In one embodiment, the polyether is selected from fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether, fatty amine polyoxyethylene ether, fatty acid polyoxyethylene ether, et...

Embodiment 1

[0093] Example 1 provides a preparation method of a novel polyetherester nonionic surfactant, comprising the following steps: mixing polyether and fatty acid, adding a catalyst, and reacting under reduced pressure at 100°C and 0.15MPa for 10 hours to obtain New polyether ester non-ionic surfactant;

[0094] The molar ratio of the polyether to the fatty acid is 1.1:1; the molar ratio of the fatty acid to the catalyst is 1:0.01;

[0095] The polyether is a compound of block polymer Pluronic RPE 1740 and emulsifier E-1310 of ethylene oxide and propylene oxide, and the molar ratio of Pluronic RPE 1740 and emulsifier E-1310 is 0.8:1; The molecular weight of the Pluronic RPE1740 is 2650, purchased from BASF (China) Co., Ltd.; the hydroxyl value of the emulsifier E-1310 is 83-93mgKOH / g, purchased from Jiangsu Haian Petrochemical;

[0096] The fatty acid is a compound of neodecanoic acid (CAS No. 26896-20-8) and palmitic acid (CAS No. 57-10-3), and the molar ratio of neodecanoic acid...

Embodiment 2

[0099] Example 2 provides a preparation method of a novel polyetherester nonionic surfactant, comprising the following steps: mixing polyether and fatty acid, adding a catalyst, and reacting under reduced pressure at 130°C and 0.25MPa for 10h to obtain New polyether ester non-ionic surfactant;

[0100] The molar ratio of the polyether to the fatty acid is 1.5:1; the molar ratio of the fatty acid to the catalyst is 1:0.05;

[0101] The polyether is a compound of block polymer Pluronic RPE 1740 and emulsifier E-1303 of ethylene oxide and propylene oxide, and the molar ratio of Pluronic RPE 1740 and emulsifier E-1303 is 1.2:1; The molecular weight of the Pluronic RPE1740 is 2650, purchased from BASF (China) Co., Ltd.; the emulsifier E-1303, with a hydroxyl value of 165-175mgKOH / g, purchased from Jiangsu Haian Petrochemical;

[0102] The fatty acid is a compound of neodecanoic acid (CAS No. 26896-20-8) and palmitic acid (CAS No. 57-10-3), and the molar ratio of neodecanoic acid t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com