Eccentric swing type speed reduction device

A technology of reduction gear and eccentric swing, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problem of cost and other problems, and achieve the effect of high lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, an example of an embodiment of the present invention will be described in detail with reference to the drawings.

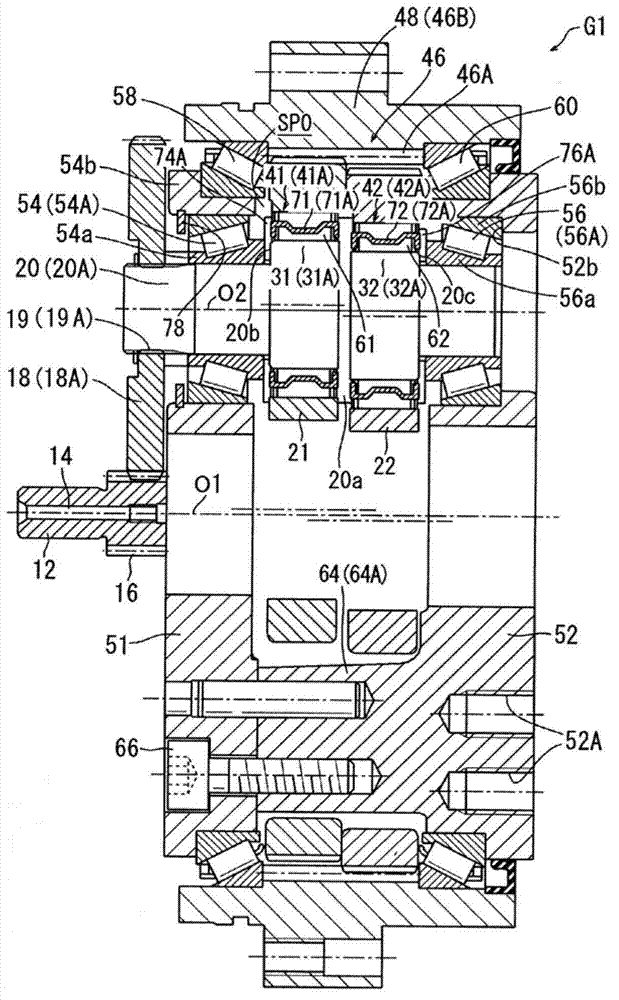

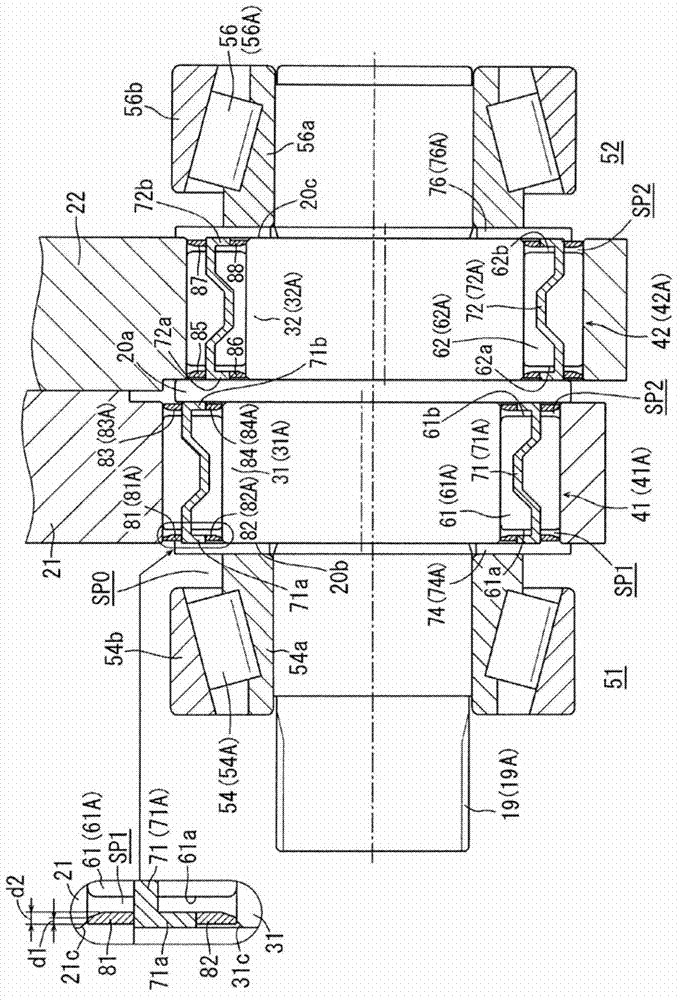

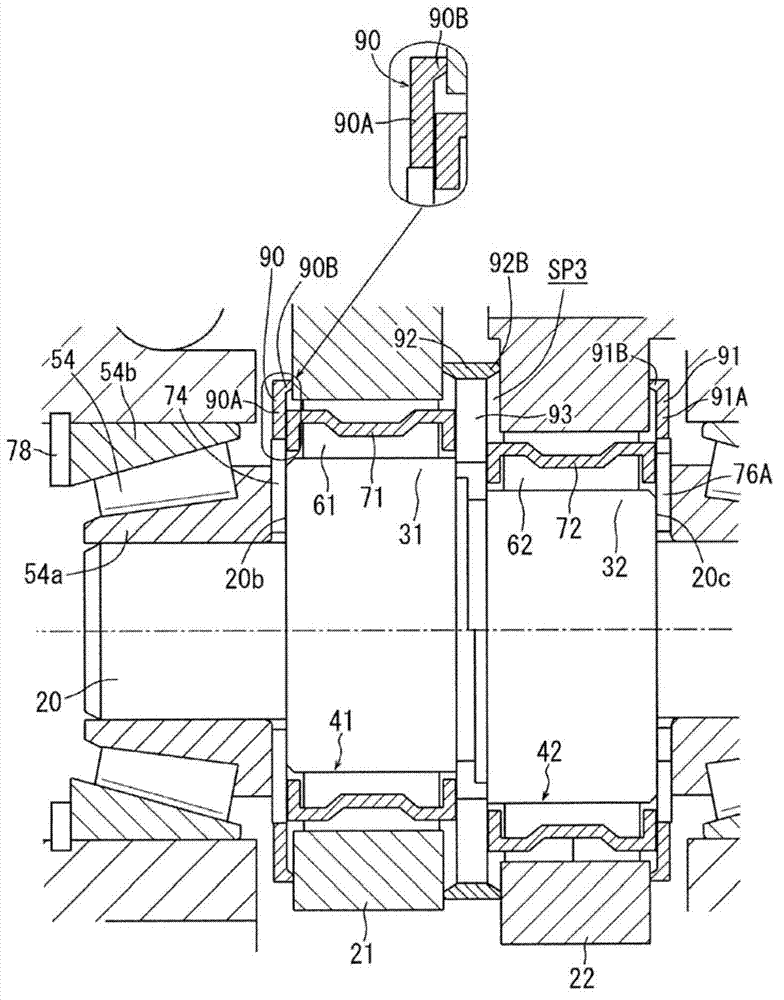

[0023] figure 1 It is a cross-sectional view showing a structural example of an eccentric oscillating type reduction gear G1 called a so-called sorting type according to an example of an embodiment of the present invention, figure 2 is the cross-sectional view of its main part.

[0024] Hereinafter, a description will be given starting from the schematic configuration of the reduction gear G1.

[0025] The input shaft 12 is connected to an unillustrated motor via a key 14 . A pinion gear 16 is formed at the front end of the input shaft 12 . The pinion gear 16 meshes with three distribution gears 18 ( 18A to 18C: only 18A is shown). The respective distribution gears 18 are respectively fixed to three eccentric body shafts 20 ( 20A to 20C: only 20A in the drawing) via splines 19 ( 19A to 19C: only 19A in the drawing). According to this con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com