Water-based lubricant for drilling fluid as well as preparation and application of water-base lubricant

A water-based lubricant and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as unfavorable environmental protection, the lubricating effect of pure water-based lubricants cannot reach the lubricating effect of oil-based lubricants, etc. , to achieve the effect of improving lubricity, reducing wear resistance of drilling tools, and reducing rotation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 26.5 parts of distilled water

[0051] 26.5 parts of ethylene glycol

[0052] 42.2 parts of methyl oleate

[0053] Emulsifier: 3.2 parts Span 85, 1.6 parts Tween 60 (total 4.8 parts)

[0054] Preparation:

[0055] (1) Take each raw material according to the above-mentioned parts by weight;

[0056] (2) Stir and dissolve the ethylene glycol and distilled water taken by weighing;

[0057] (3) The emulsifier and methyl oleate taken by weighing are stirred and dissolved in another 200mL beaker;

[0058] (4) Mix the raw material liquid prepared in step (2) with the raw material liquid prepared in step (3) with the emulsifying shearing machine turned on at a rotational speed of 10,000 to 15,000 rpm, and then continue shearing and emulsifying for 5 minutes to obtain a milky white solution.

Embodiment 2~9

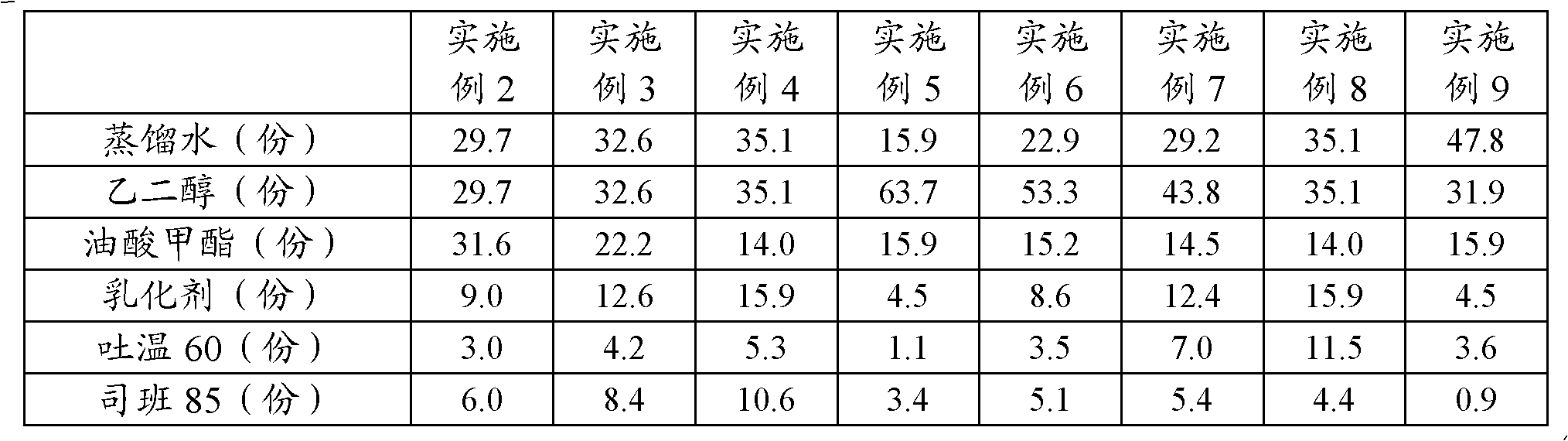

[0060] The preparation method is the same as in Example 1, and the amounts of each material are shown in the table below.

[0061]

Embodiment 10

[0063] 26.5 parts of glycerol

[0064] 26.5 parts of distilled water

[0065] 42.2 parts of chloromethyl oleate

[0066] Emulsifier: 1.5 parts Span 85, 3.3 parts Tween 80 (total 4.8 parts)

[0067] Preparation:

[0068] (1) Take each raw material according to the above parts by weight and place it in a 200mL beaker;

[0069] (2) Emulsify and shear the raw material solution in step (1) for 240 minutes with an emulsifier at a rotational speed of 8000-9000 rpm to obtain a milky white solution.

[0070] Performance evaluation:

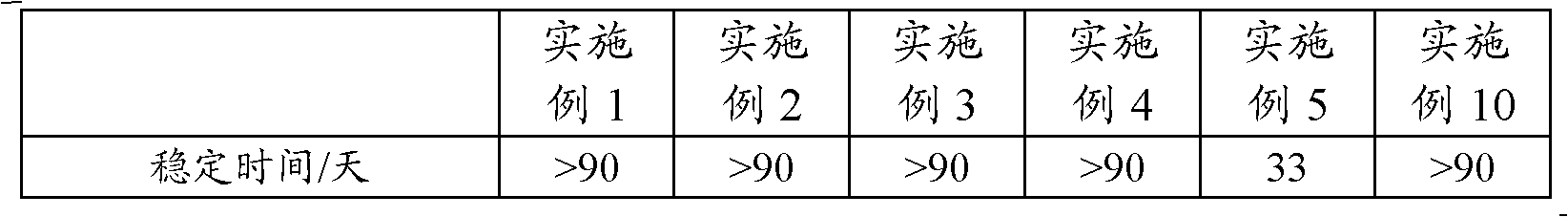

[0071] 1. Stability performance evaluation

[0072] Measure 100mL of sample and place it in a 100mL colorimetric tube, and observe its stability at room temperature. The result is as follows:

[0073]

[0074] 2. Lubrication performance evaluation

[0075] (1) Determination of lubrication coefficient in fresh water bentonite slurry

[0076] Prepare 2 parts of 3% fresh water base slurry: add 9g of sodium bentonite for drilling fluid test to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com