Composite magnetic material and process for producing the composite magnetic material

A technology of composite magnetic materials and bonding materials, applied in the fields of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve problems such as difficult heat treatment, and achieve the effects of low breaking strength, high filling and excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

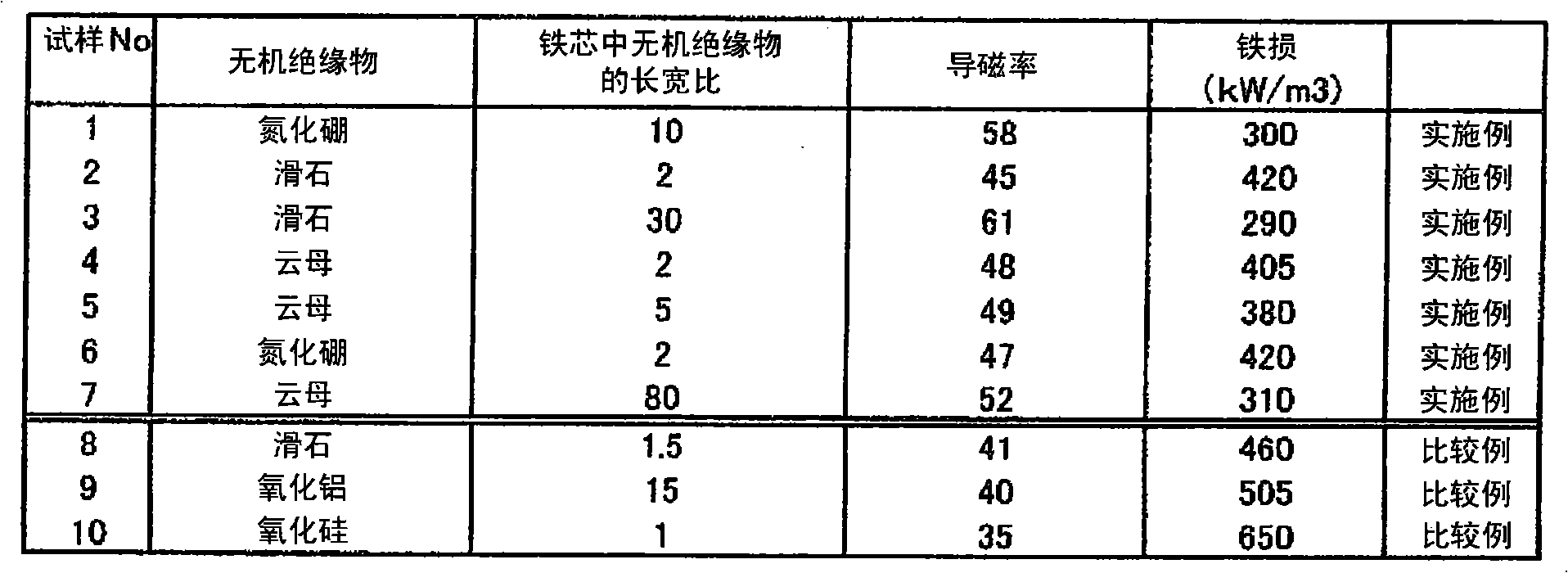

[0043] An Fe—Si—Al-based metal magnetic powder having an average particle diameter of 24 μm, containing 8.9% by weight of Si, and 5.9% by weight of Al was prepared. To 100 parts by weight of the prepared metal magnetic powder, 0.8 parts by weight of various inorganic insulators described in Table 1 having an average mixed major axis length of 4 μm and various aspect ratios were added to prepare a mixed powder. After adding 1.0 parts by weight of the silicone resin to 100 parts by weight of the obtained mixed powder, a small amount of toluene was added to carry out kneading and dispersion to prepare a mixture. at 10ton / cm 2 The obtained mixture was press-molded and heat-treated at 850° C. for 1.0 h in an argon atmosphere. In addition, the shape of the prepared sample was a toroidal core with an outer shape of 14 mm, an inner diameter of 10 mm, and a height of about 2 mm.

[0044] The obtained samples were evaluated for DC superposition characteristics, iron loss, and aspect r...

Embodiment 2

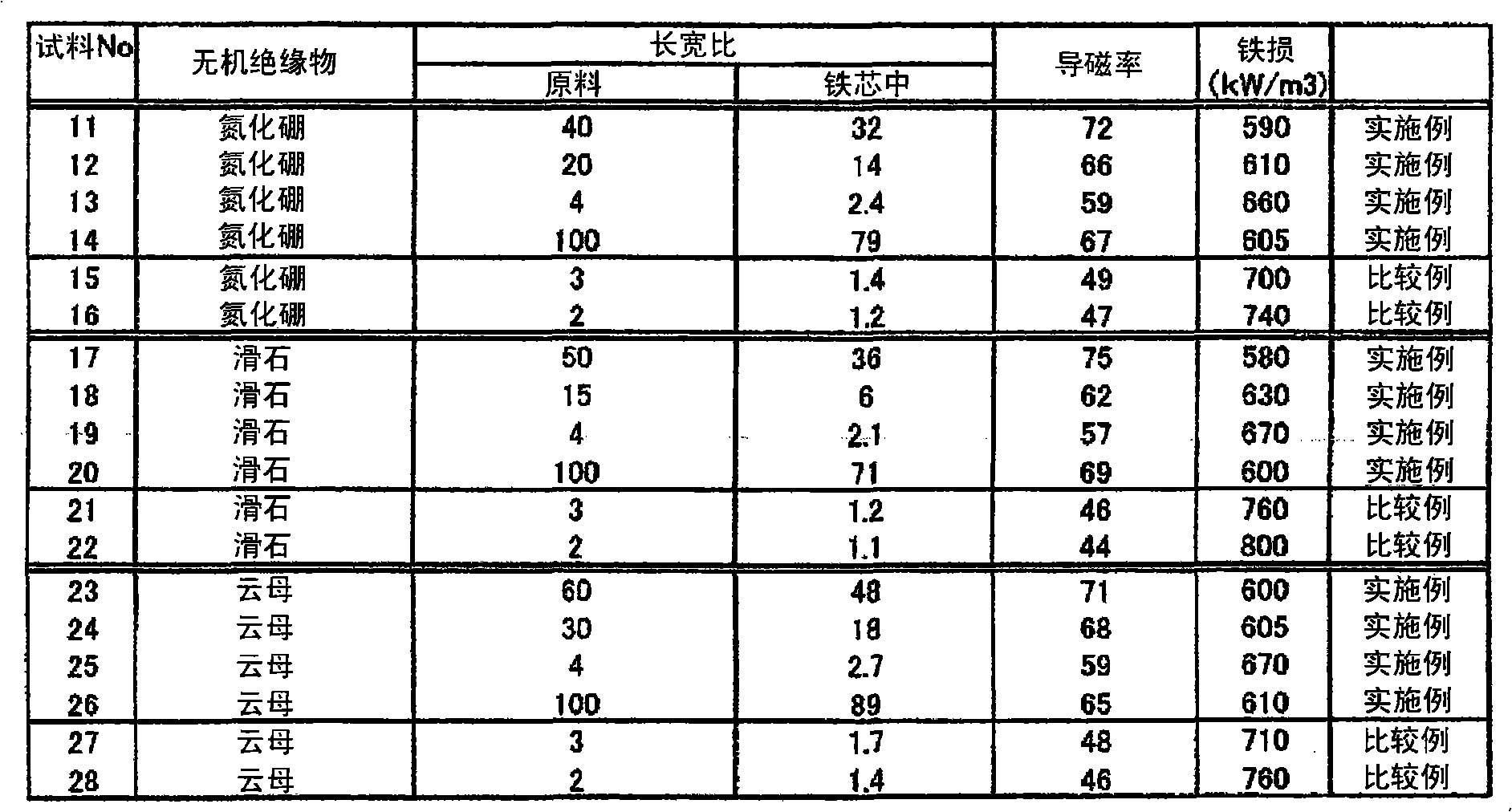

[0049] An Fe—Ni-based metal magnetic powder having an average particle diameter of 15 μm and containing 49.5% by weight of Ni was prepared. To 100 parts by weight of the prepared metal magnetic powder, 1.0 part by weight of various inorganic insulating materials described in Table 2 having an average mixed long axis length of 3 μm and various aspect ratios was added to prepare a mixed powder. After adding 0.7 parts by weight of an aluminum-based coupling agent and 0.6 parts by weight of a butyral resin to 100 parts by weight of the obtained mixed powder, a small amount of ethanol was added for uniform dispersion to prepare a mixture. at 9ton / cm 2 The obtained mixture was press-molded, and heat-treated at 790° C. for 0.5 h in a nitrogen atmosphere. In addition, the shape of the prepared sample was a ring core with an outer shape of 14 mm, an inner diameter of 10 mm, and a height of about 2 mm.

[0050] The obtained samples were evaluated for DC superposition characteristics, ...

Embodiment 3

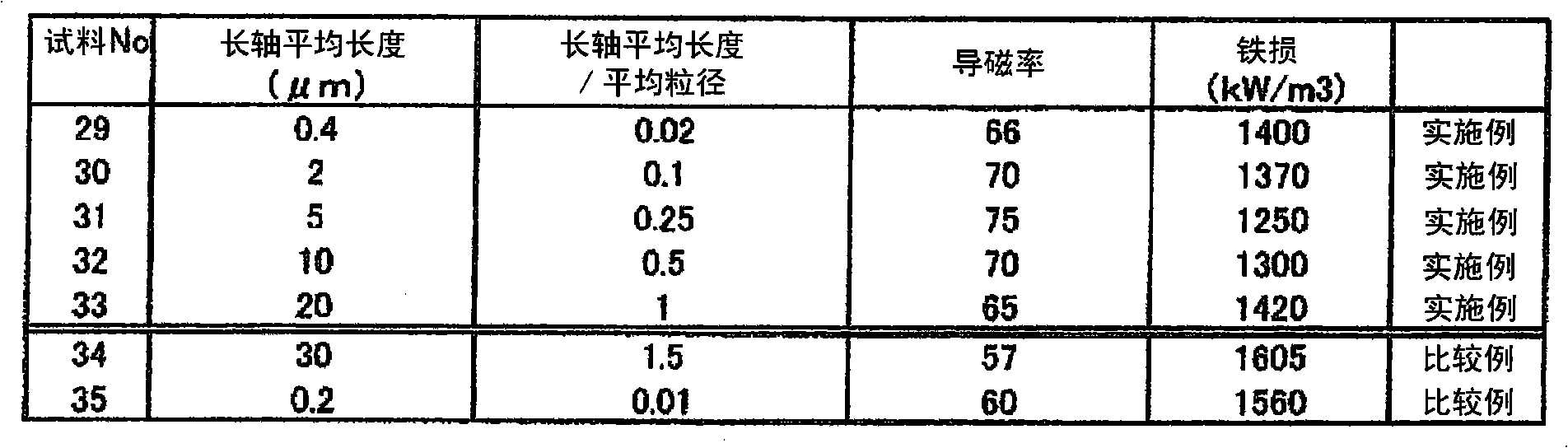

[0055] An Fe—Si-based metal magnetic powder having an average particle diameter of 20 μm and containing 4.9% by weight of Si was prepared. To 100 parts by weight of the prepared metal magnetic powder, 2 parts by weight of various mica (mica) described in Table 3 with an aspect ratio of 5 and various average lengths of major axes were added as an inorganic insulator to prepare a mixed powder. . After adding 1.0 parts by weight of the silicone resin to 100 parts by weight of the obtained mixed powder, a small amount of toluene was added to carry out kneading and dispersion to prepare a mixture. at 15ton / cm 2 The obtained mixture was press-molded, and heat-treated at 900° C. for 1.0 h in an argon atmosphere. In addition, the shape of the prepared sample was a ring core with an outer shape of 14 mm, an inner diameter of 10 mm, and a height of about 2 mm.

[0056] The obtained samples were evaluated for DC superposition characteristics and iron loss. Regarding the DC superposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com