Engine oil system with oil pressure regulator to increase cam phaser oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

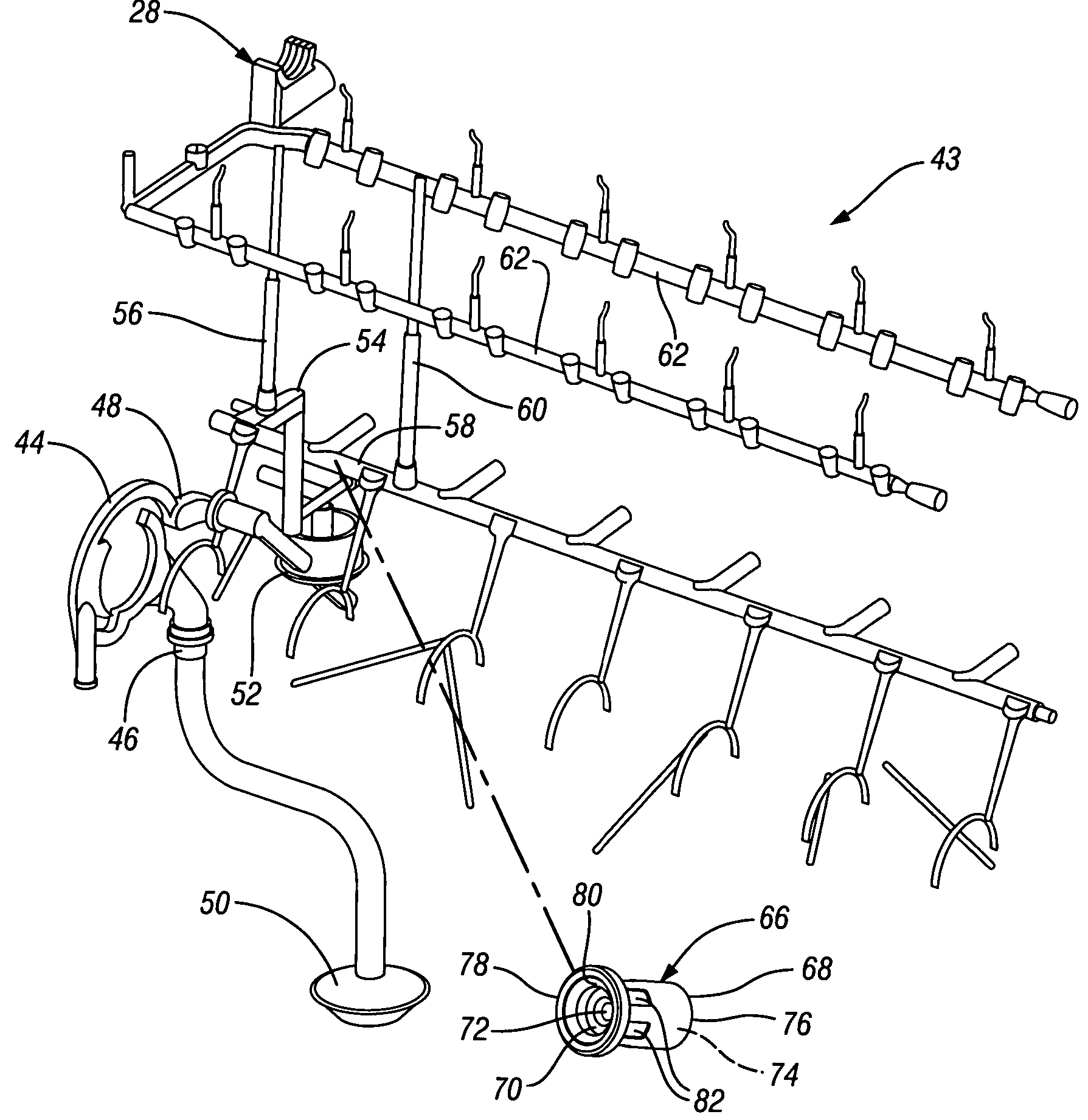

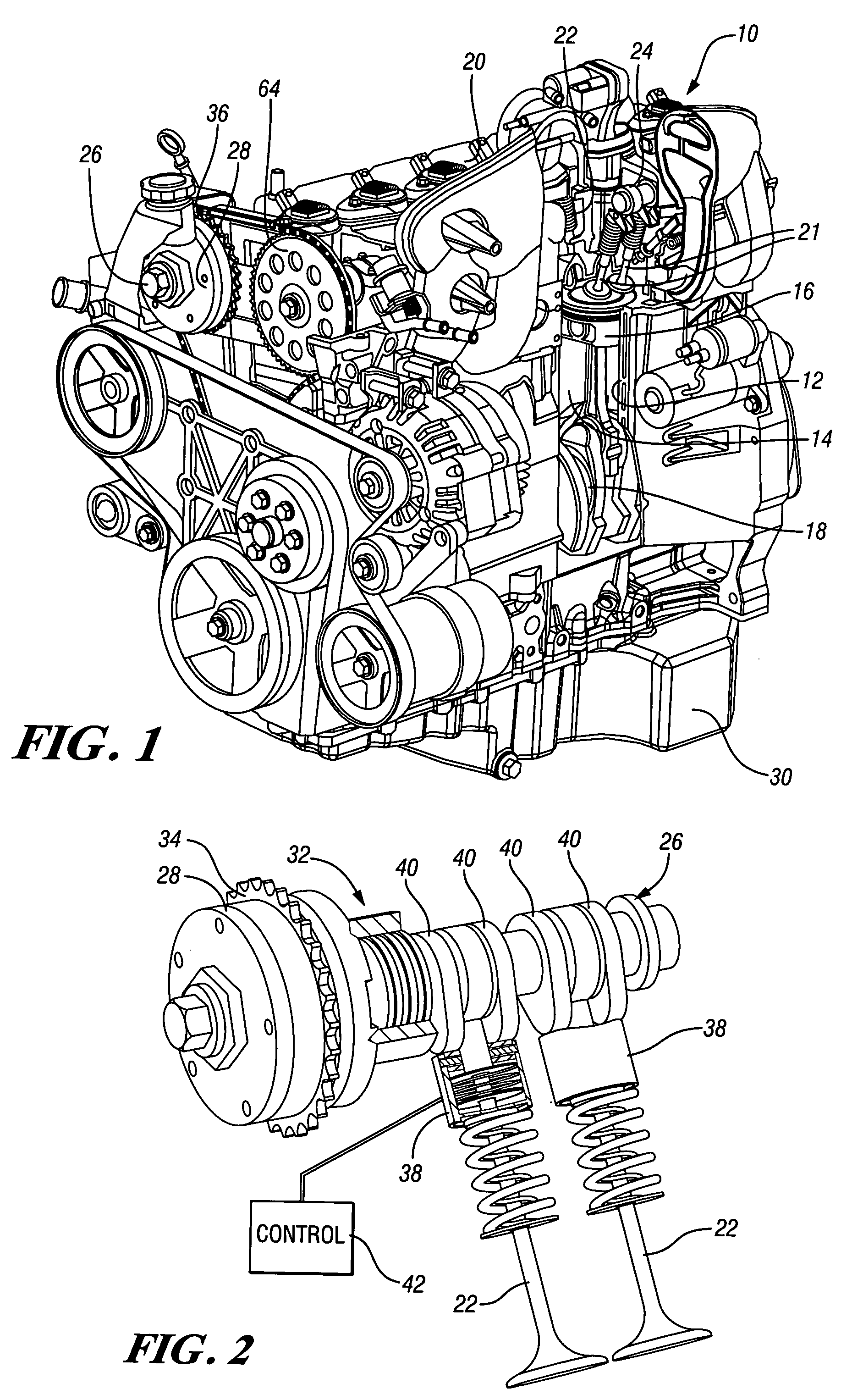

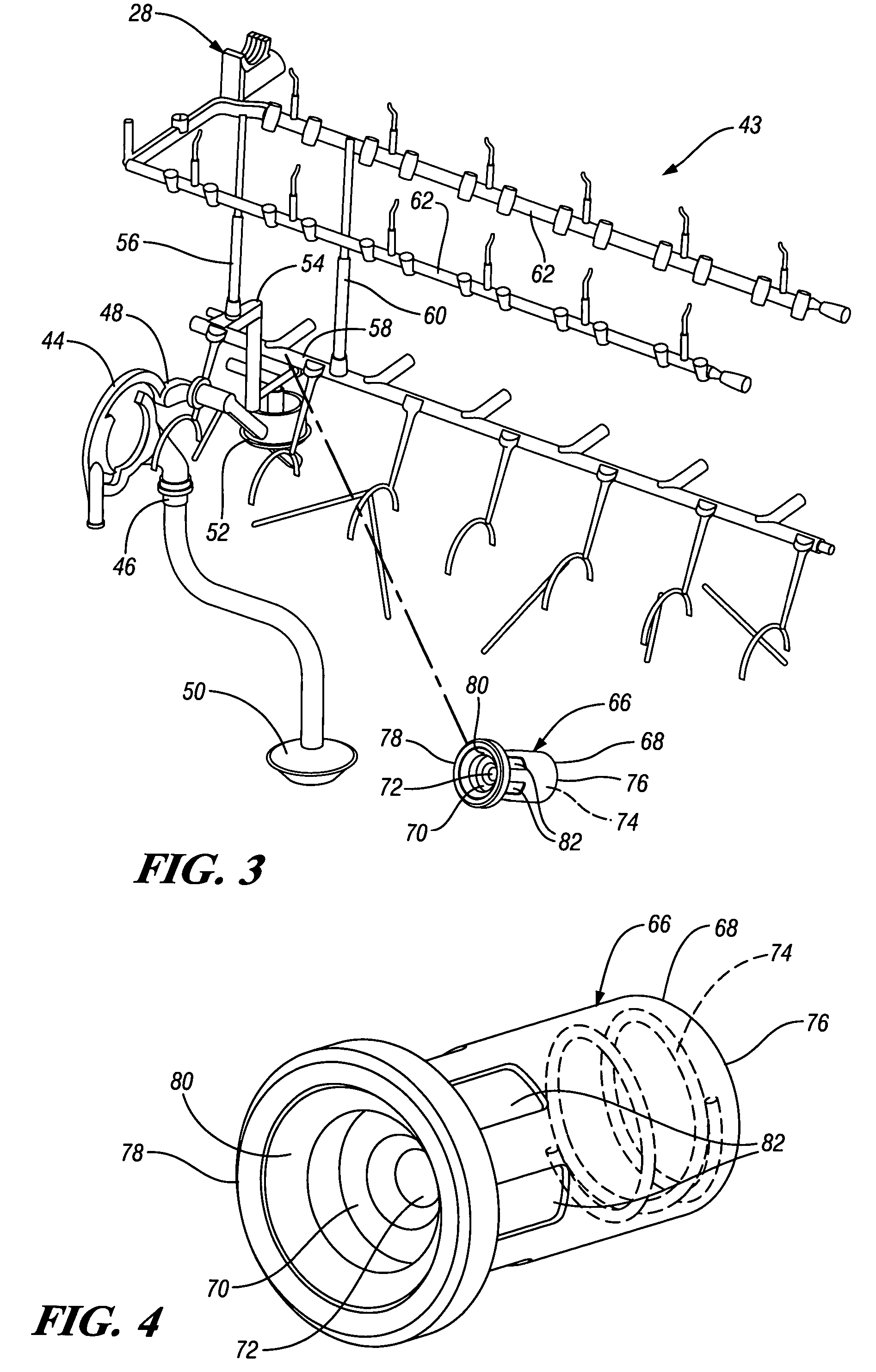

[0016] Referring now to FIG. 1 of the drawings in detail, numeral 10 generally indicates an internal combustion engine. The engine includes a cylinder block 12 having a bank of cylinders 14 containing pistons 16 connected with a crankshaft 18. A cylinder head 20 carries intake and exhaust valves 21, 22 actuated by camshafts 24, 26. A cam phaser 28 is mounted on the exhaust camshaft 26 to vary the exhaust valve timing. An oil pan 30 below the block forms an oil sump for the engine.

[0017]FIG. 2 illustrates an exhaust portion of an engine valve train 32 for use in an overhead cam piston type engine. The valve train 32 includes exhaust camshaft 26 which is driven through a drive sprocket 34 connected by a chain 36 with the engine crankshaft 18. Cam phaser 28 is connected between the sprocket 34 and the camshaft 26 in order to vary the timing of the camshaft relative to the piston motion and other operating functions of the engine and relative to other camshafts of the engine.

[0018] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com