Hydraulic engine valve actuator

a technology for hydraulic engine valves and actuators, which is applied in the direction of machines/engines, non-mechanical valves, valve arrangements, etc., can solve the problems of increasing the complexity affecting the service life of the valve actuator, etc., and reducing the cost of changes required in the design and manufacture of the manifold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

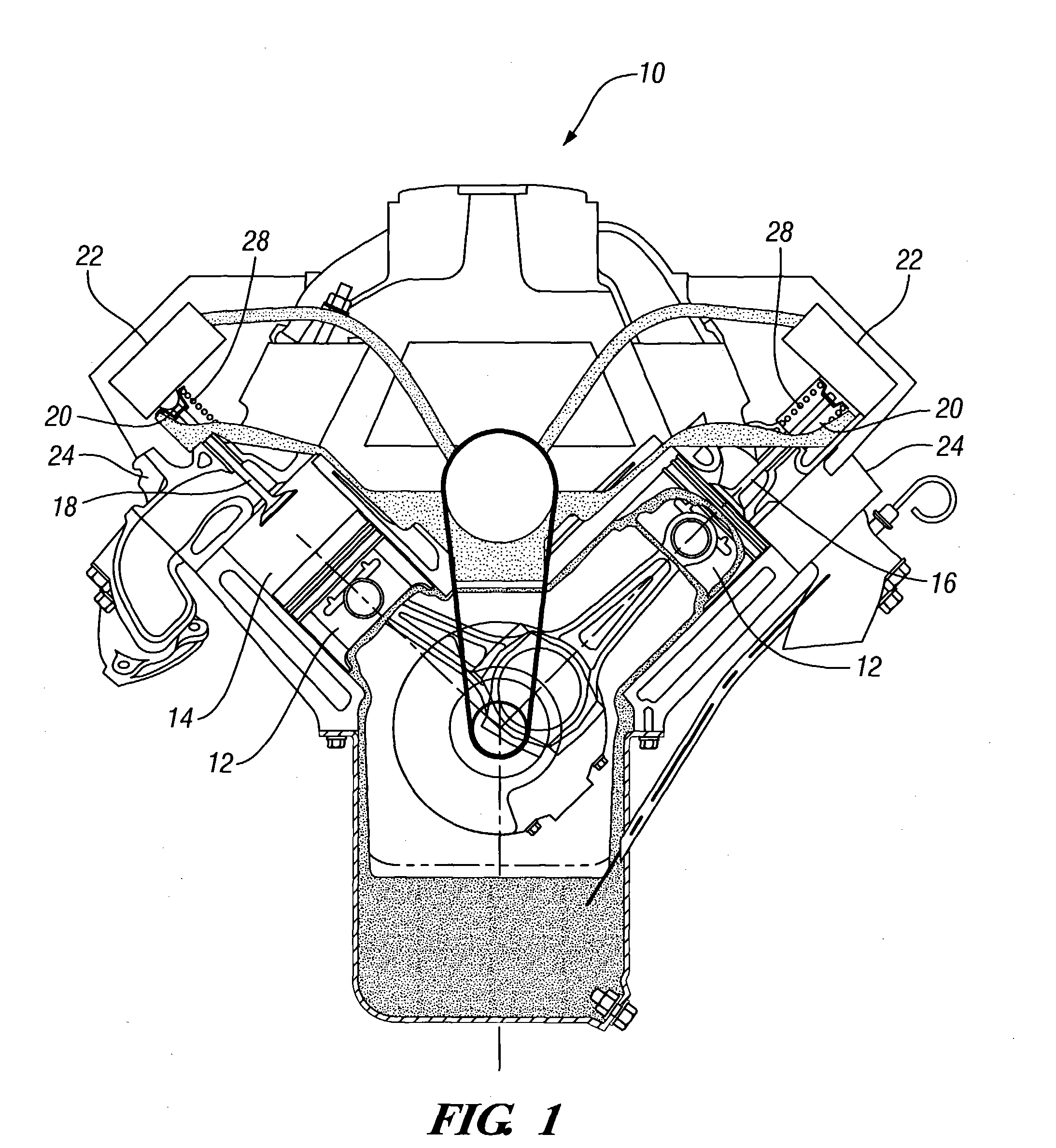

[0016] Referring now to FIG. 1 of the drawings in detail, numeral 10 generally indicates a camless internal combustion engine. Engine 10 has a plurality of pistons 12, reciprocable within engine cylinders 14. Each cylinder 14 has associated intake and exhaust valves 16, 18. The valves 16, 18 are hydraulically actuated by valve actuators 20 (FIG. 2) fixed to hydraulic supply manifolds 22 mounted on cylinder heads 24 and closing upper ends of the cylinders 14. The actuators 20 are controlled by oil distributor valves 26 (FIGS. 3,4) which are activated by a controller 27 to deliver pressure oil to or cut off pressure oil from the valve actuators 20. Specifically, the valves 16, 18 are opened by hydraulic actuator pistons, not shown, and are closed by valve springs 28 conventionally mounted on the cylinder heads 24.

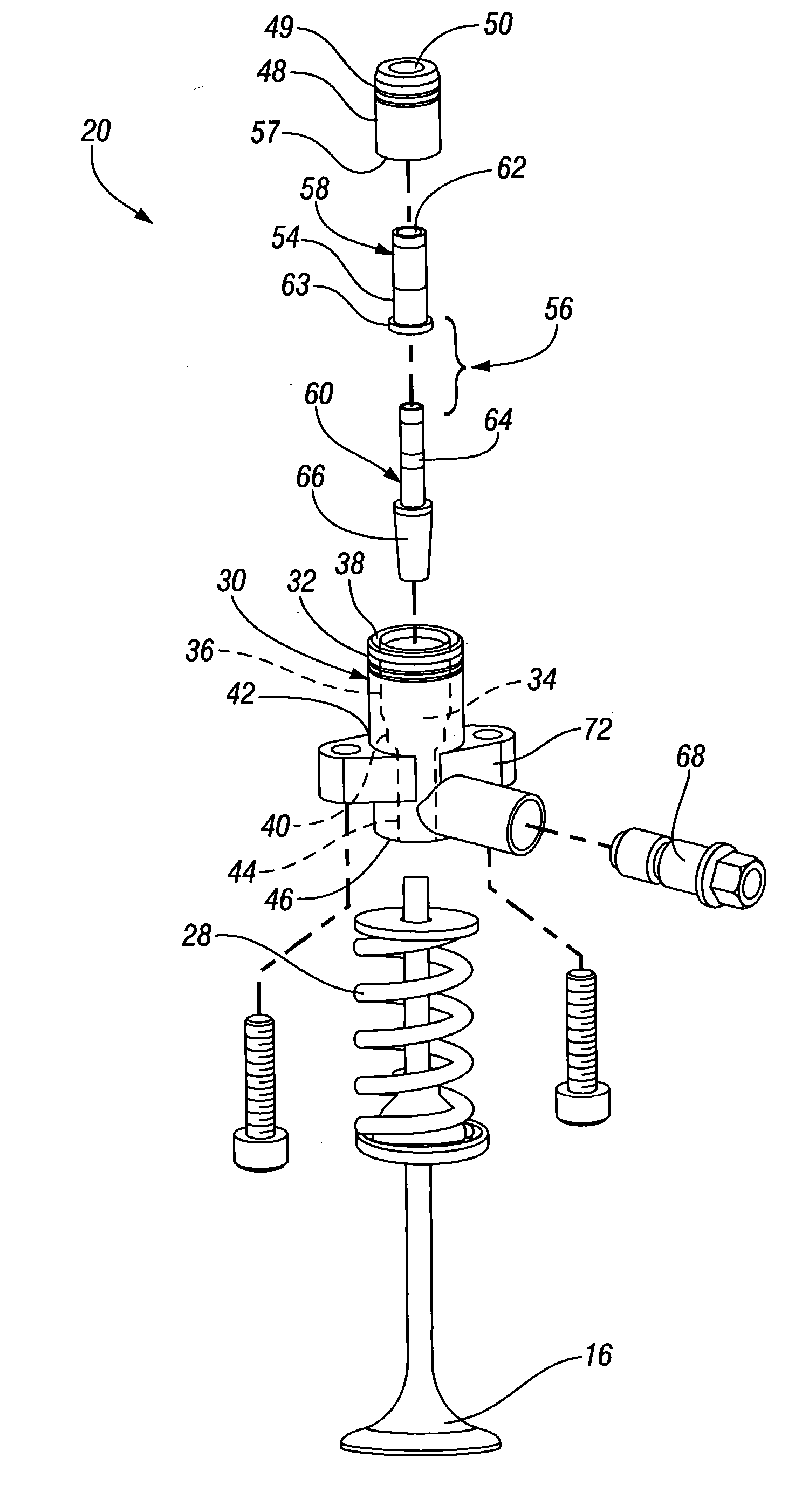

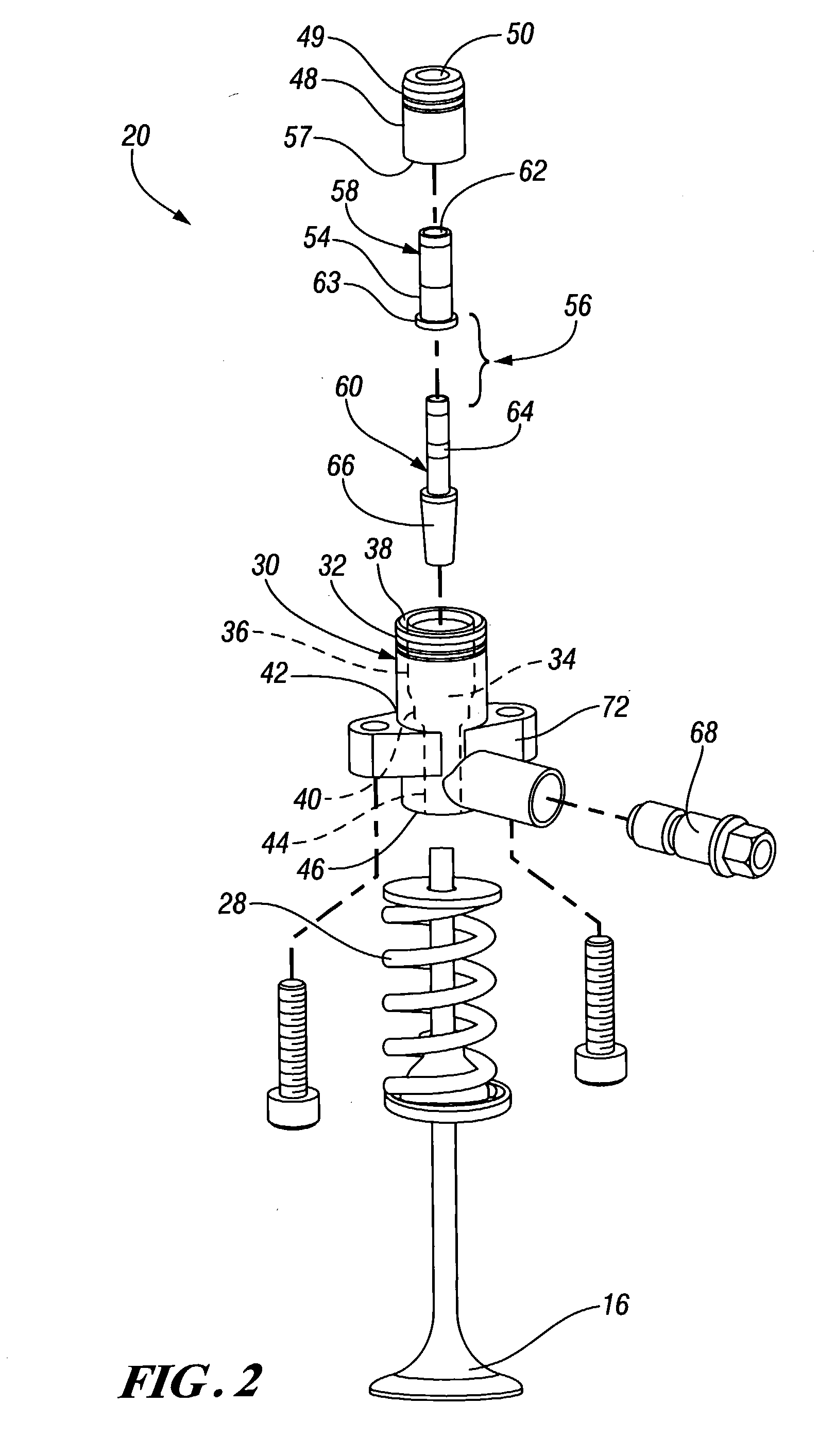

[0017] In accordance with the present invention, the valve actuators 20 comprise integral assemblies, as shown in FIG. 2. Each actuator 20 includes a cylindrical housing 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com