Patents

Literature

39results about "Engine revolutions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

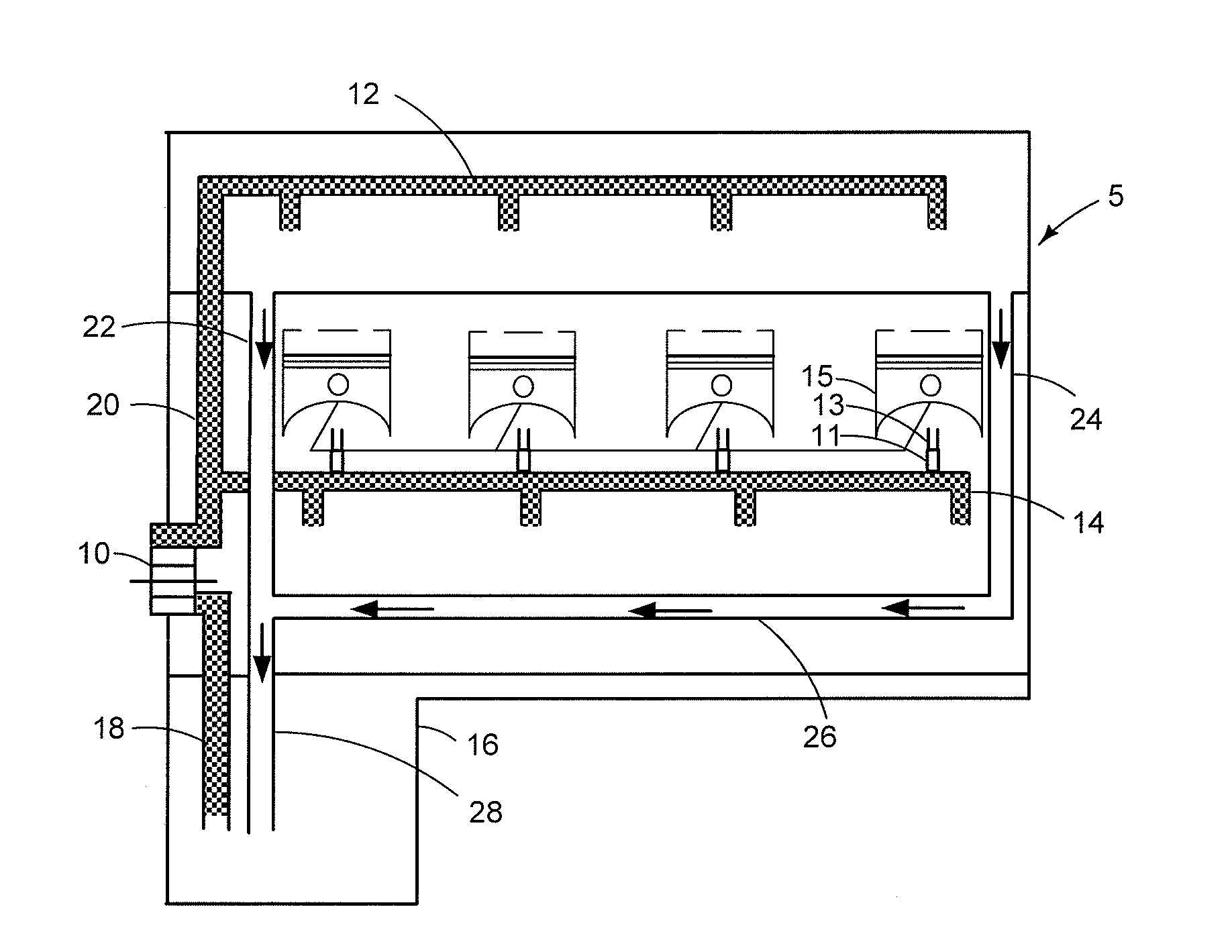

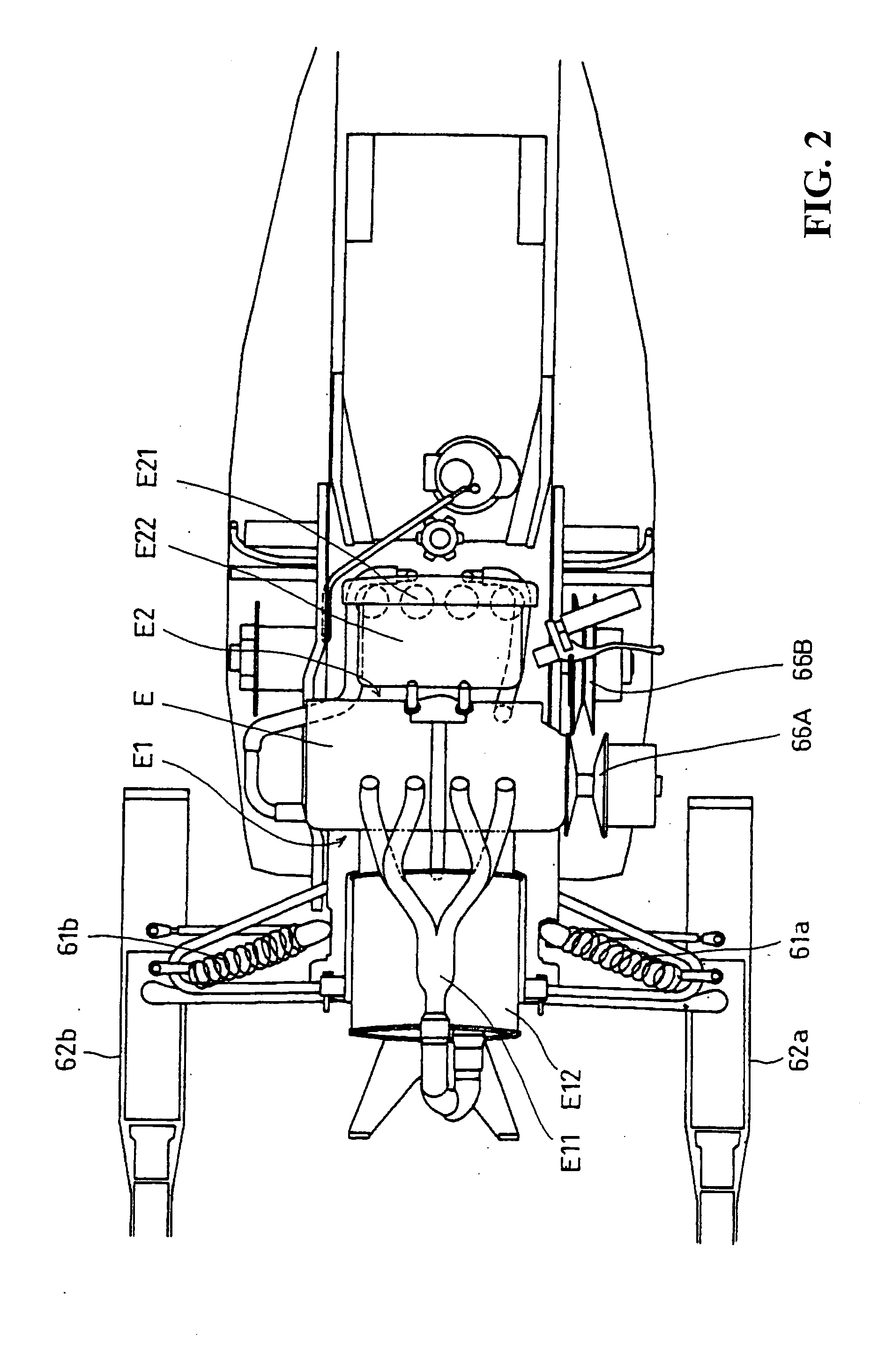

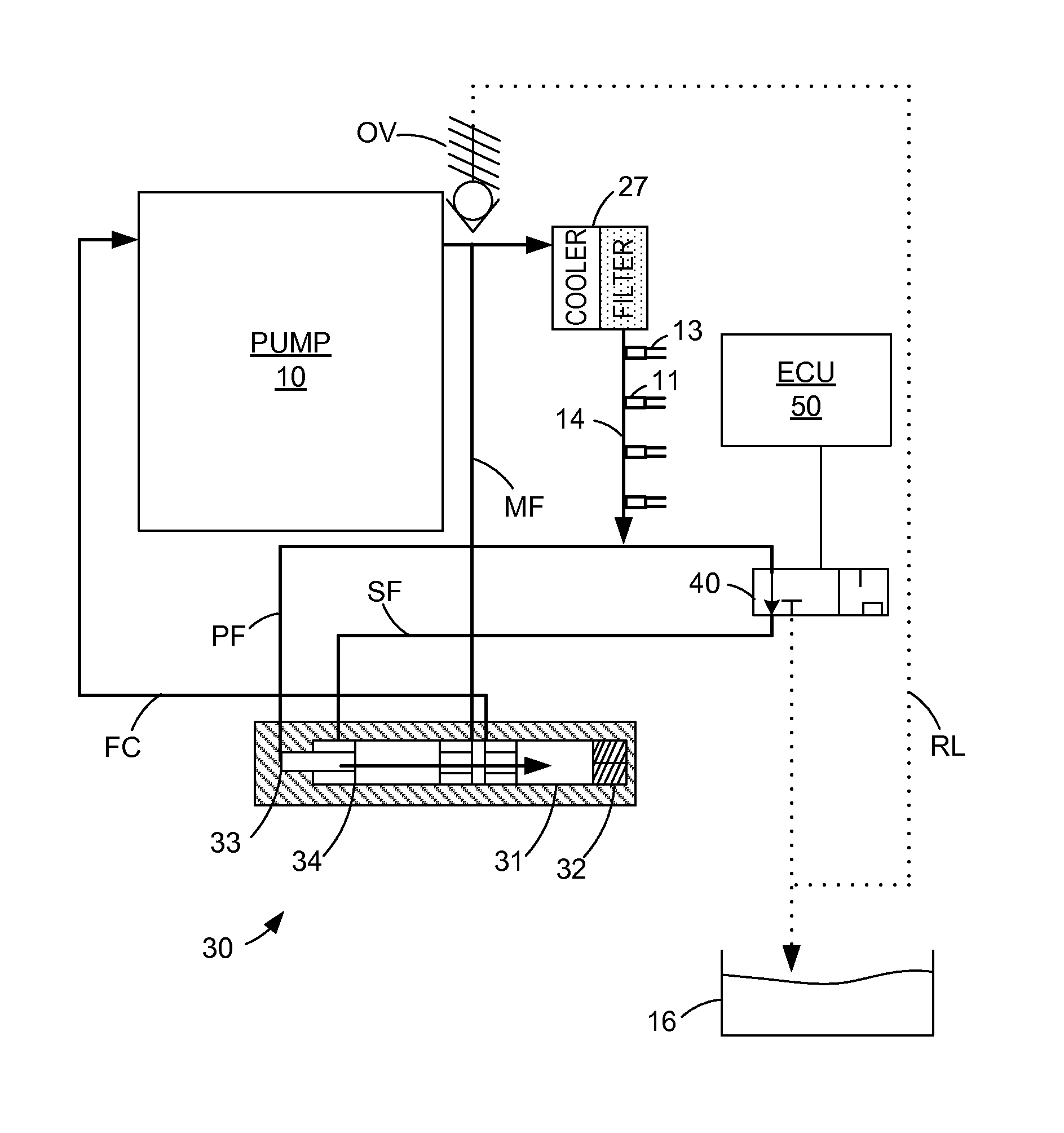

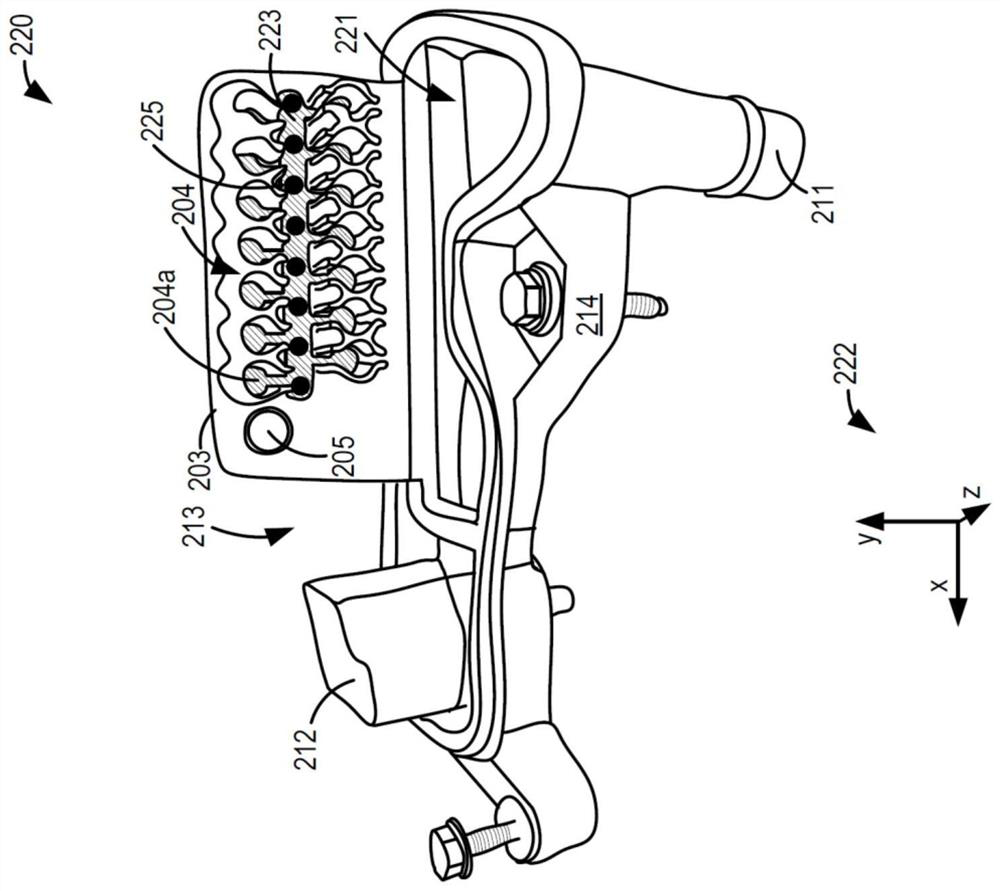

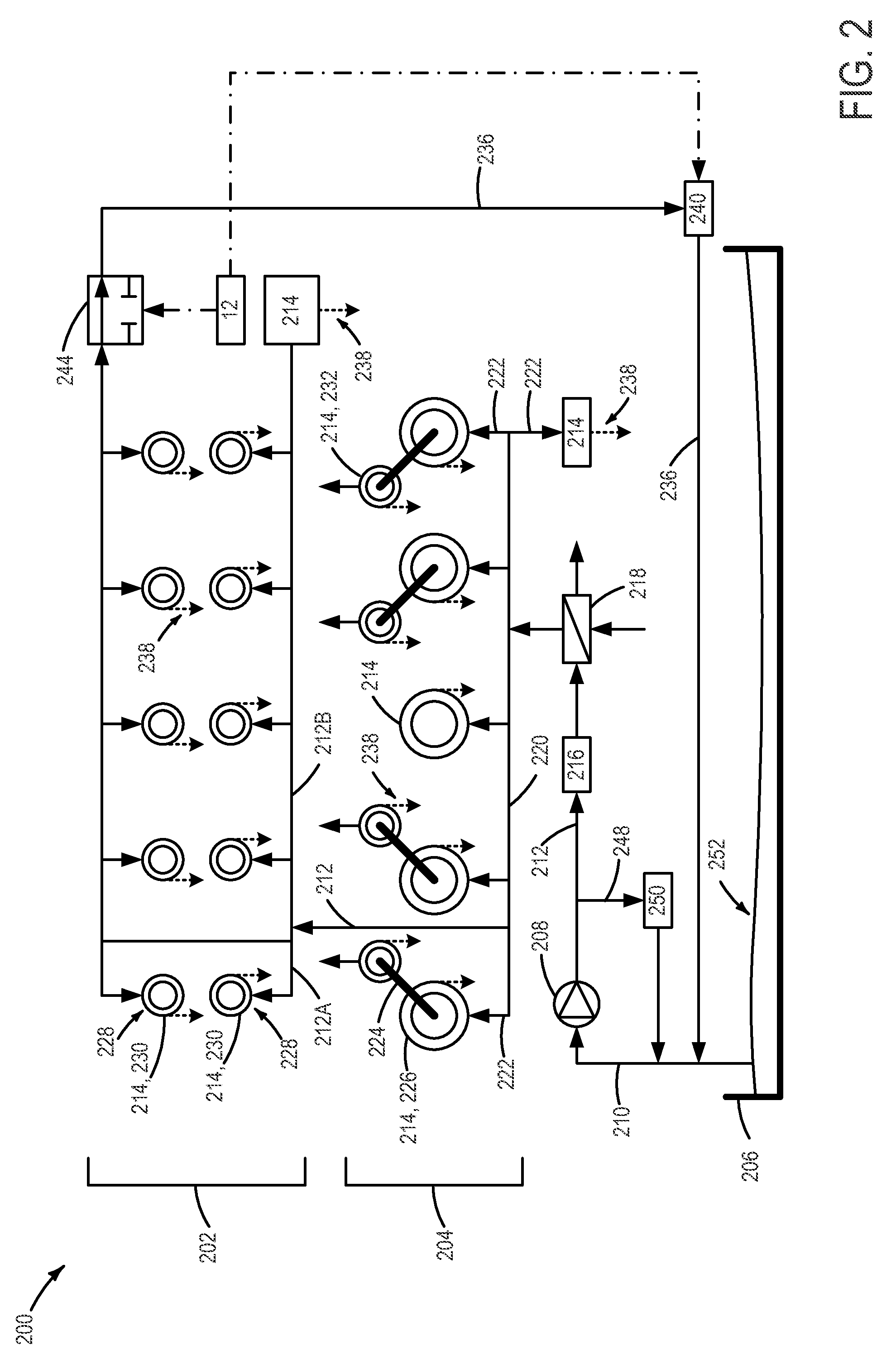

Oil supply system for an engine

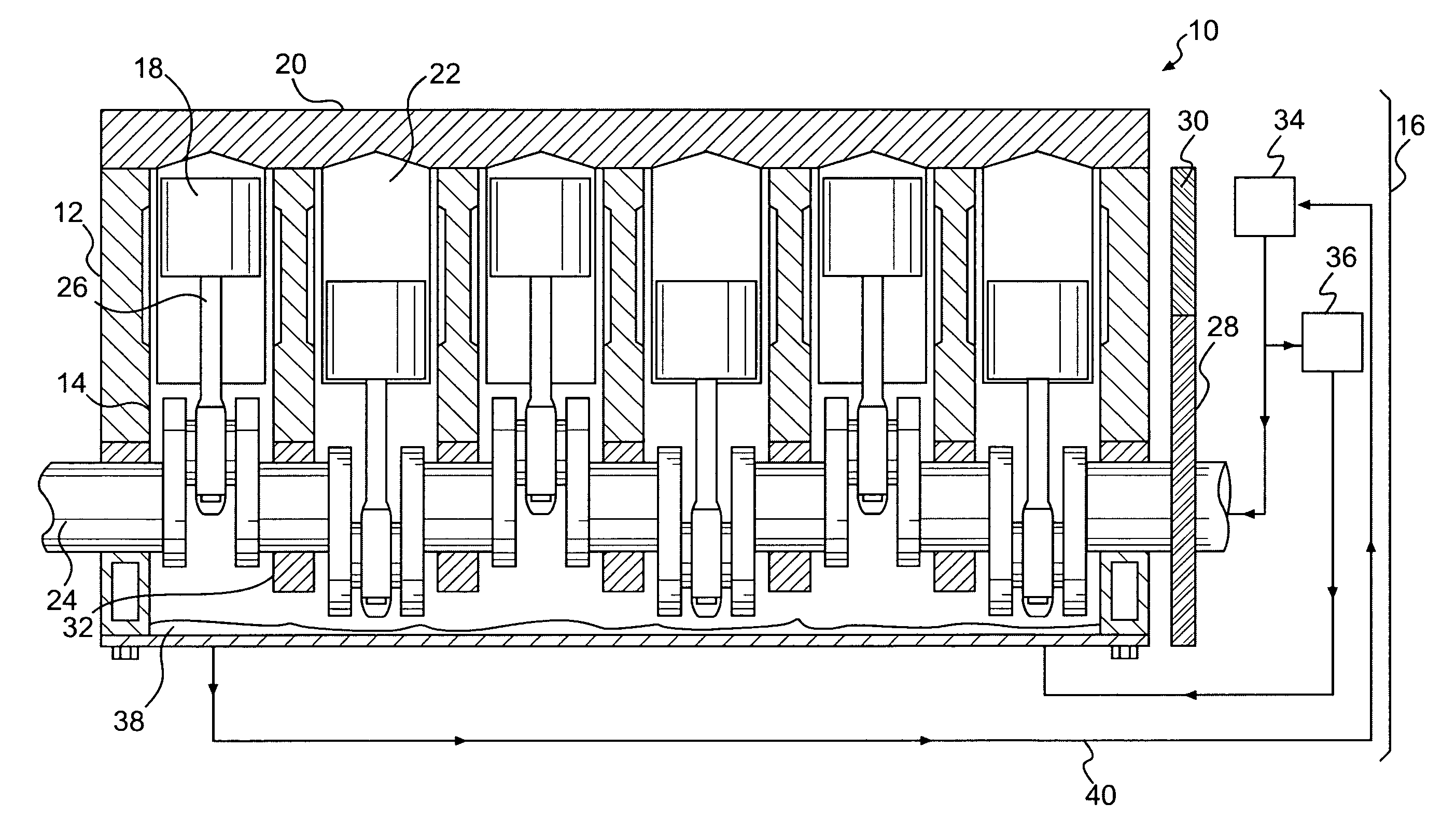

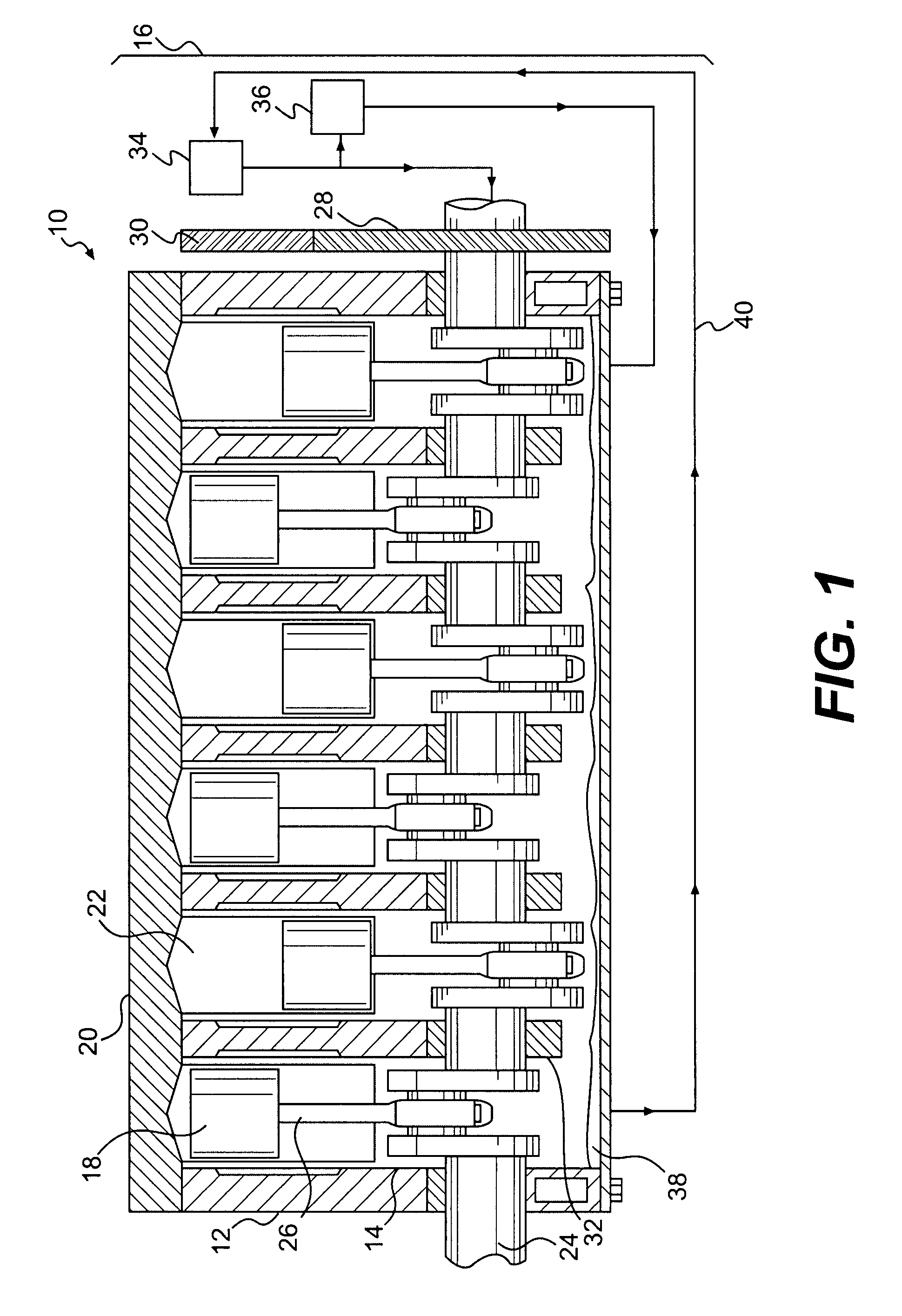

ActiveUS20110283968A1Reduce fuel usageLiquid coolingLubrication of auxillariesInternal combustion enginePiston

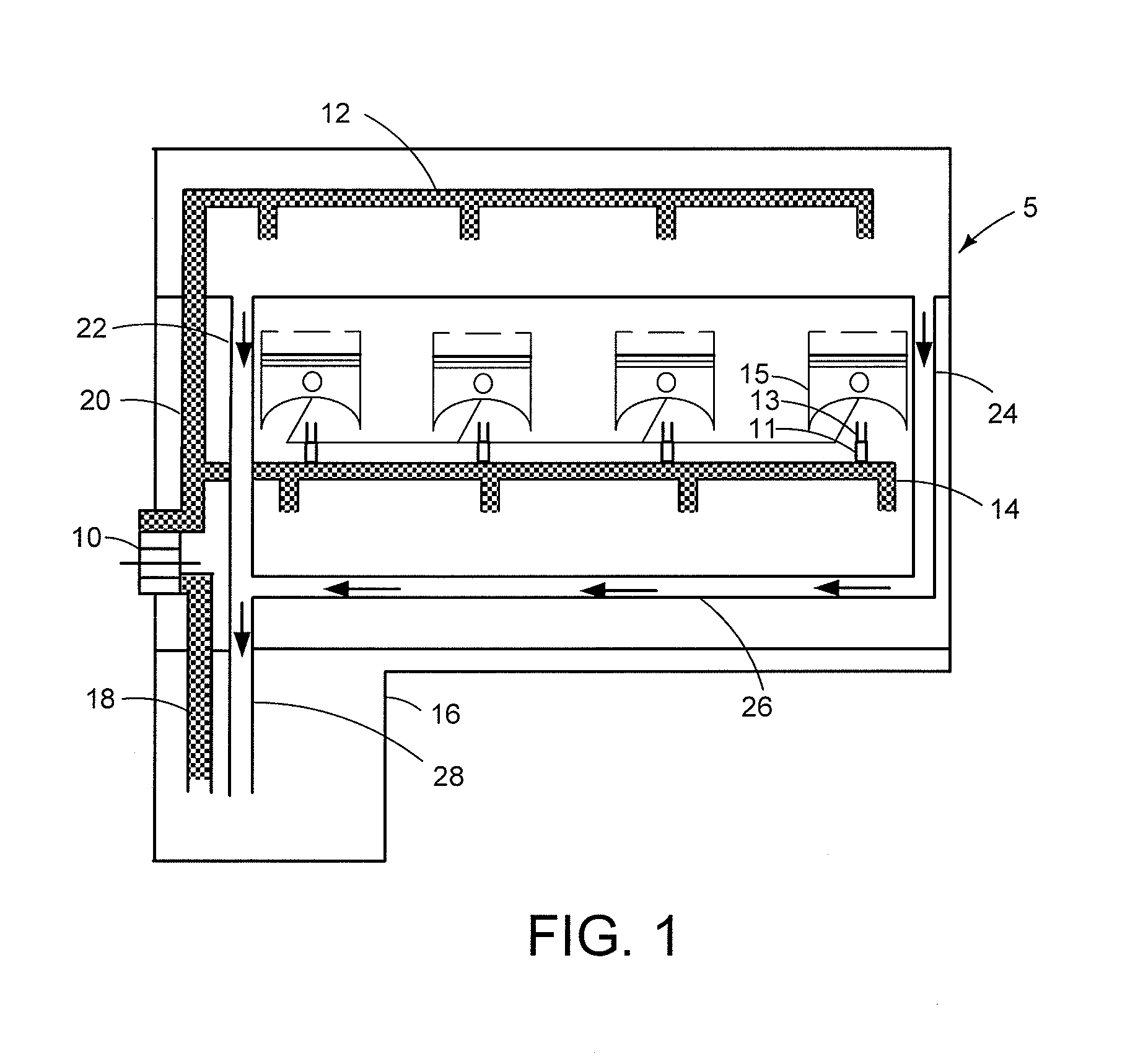

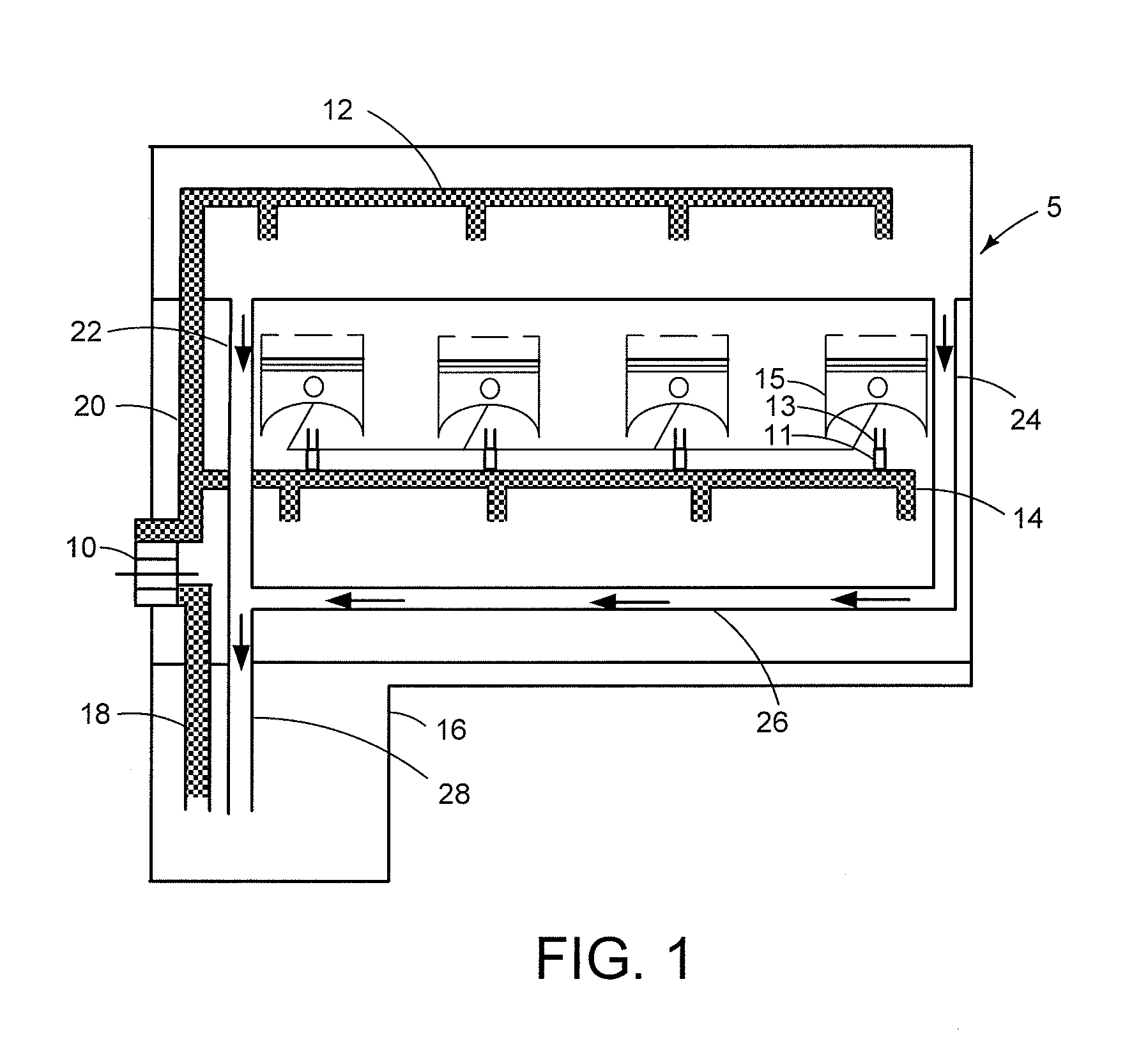

An oil supply system for a reciprocating piston internal combustion engine is disclosed in which the supply of oil to piston cooling jets is controlled by pressure operated valves designed to open at a pre-defined valve opening pressure. The pressure of oil supplied by a pump is controlled to be below this pre-defined valve opening pressure during operation of the engine in which piston cooling is not required, and the pressure of oil is controlled to above the pre-defined valve opening pressure when piston cooling is required. The control of the pump is by an electronic control unit based upon a combination of engine speed and engine load.

Owner:FORD GLOBAL TECH LLC

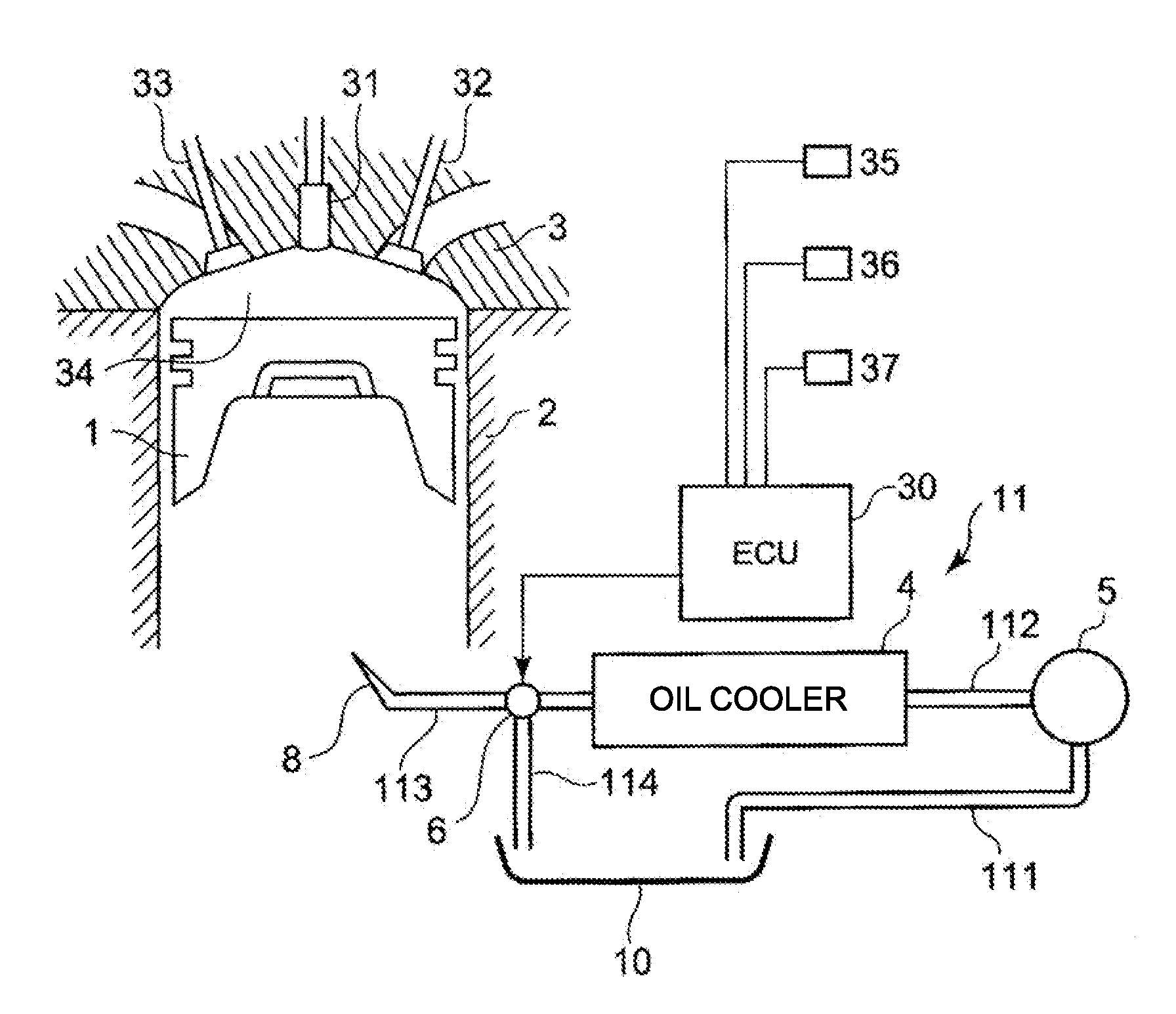

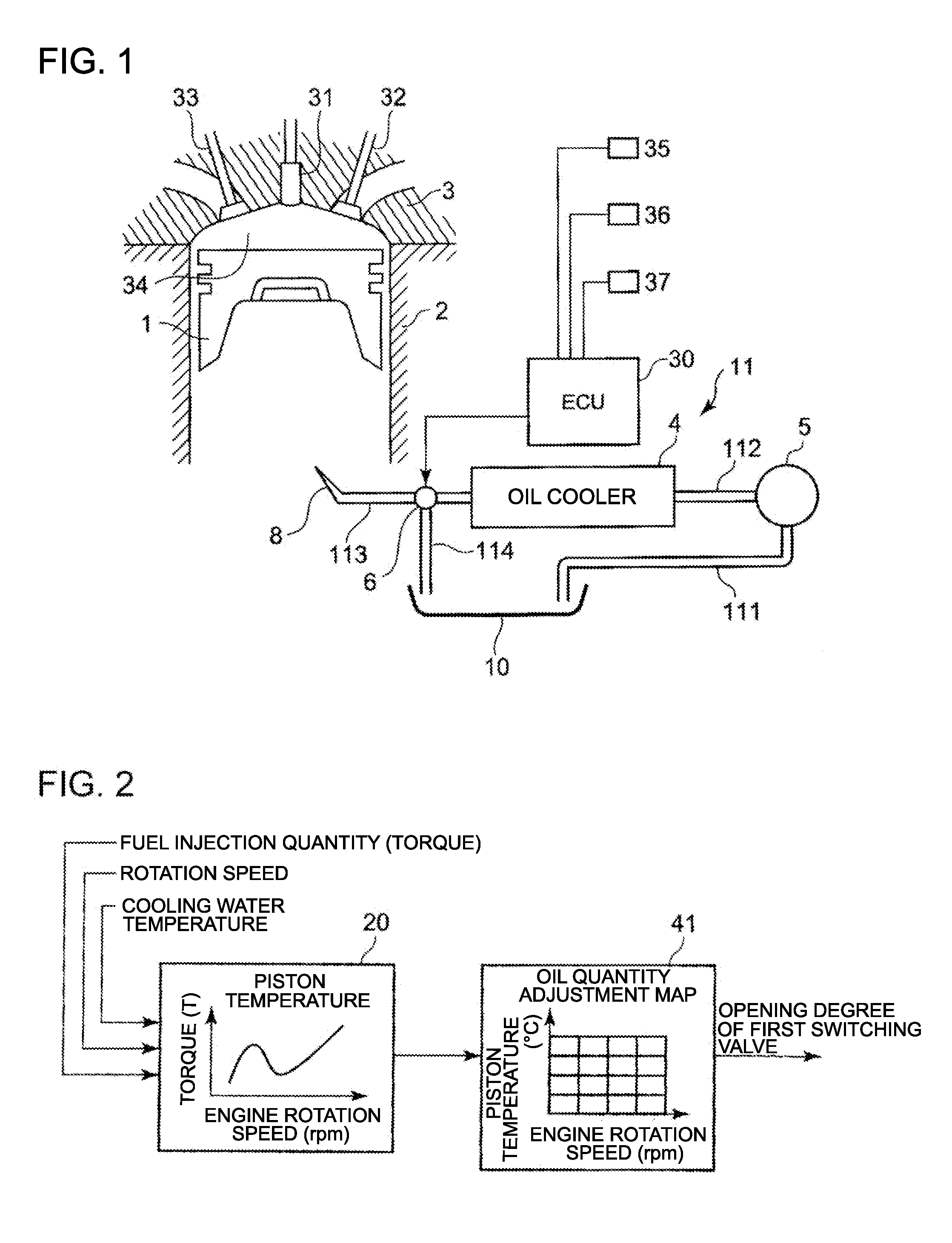

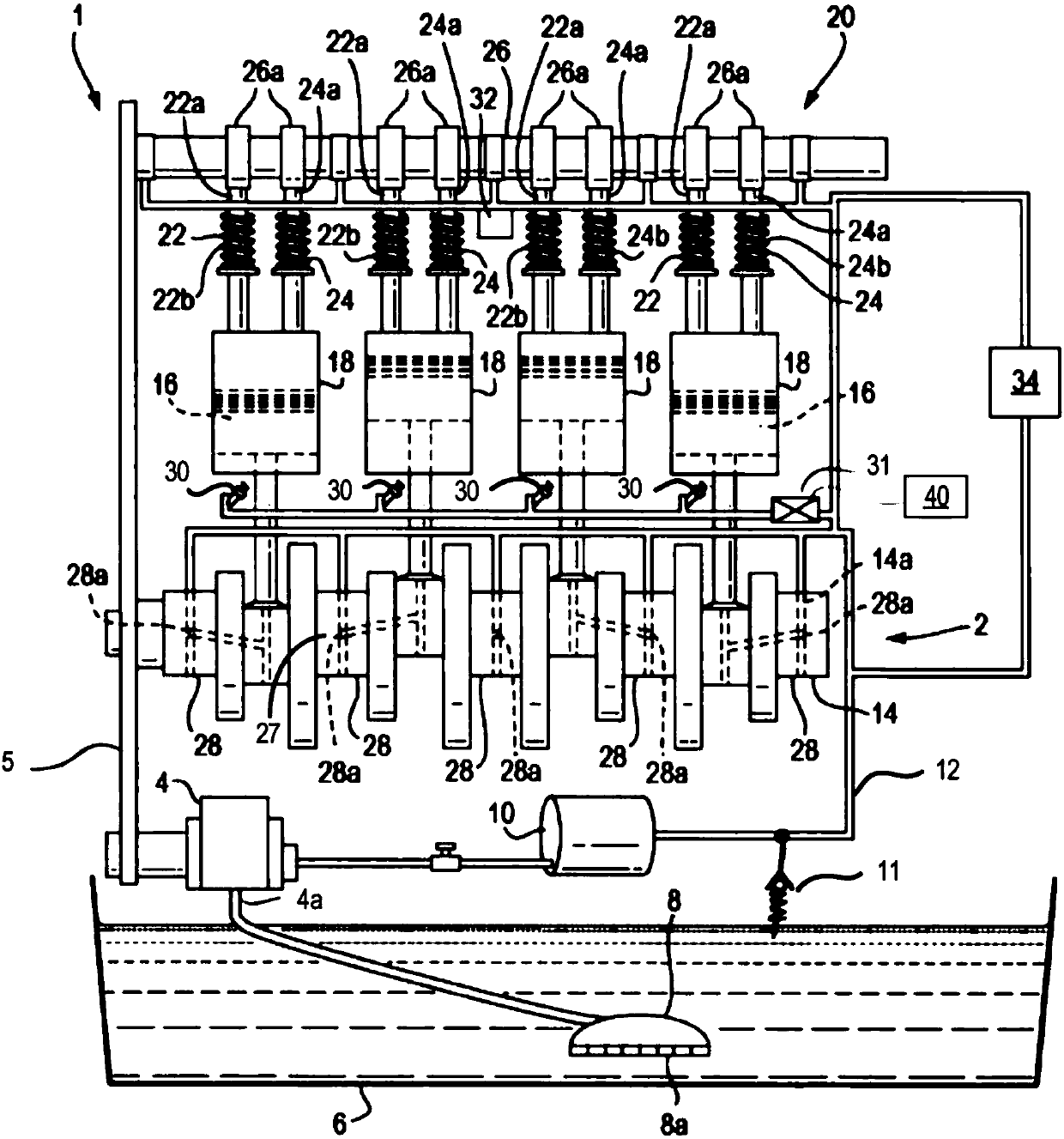

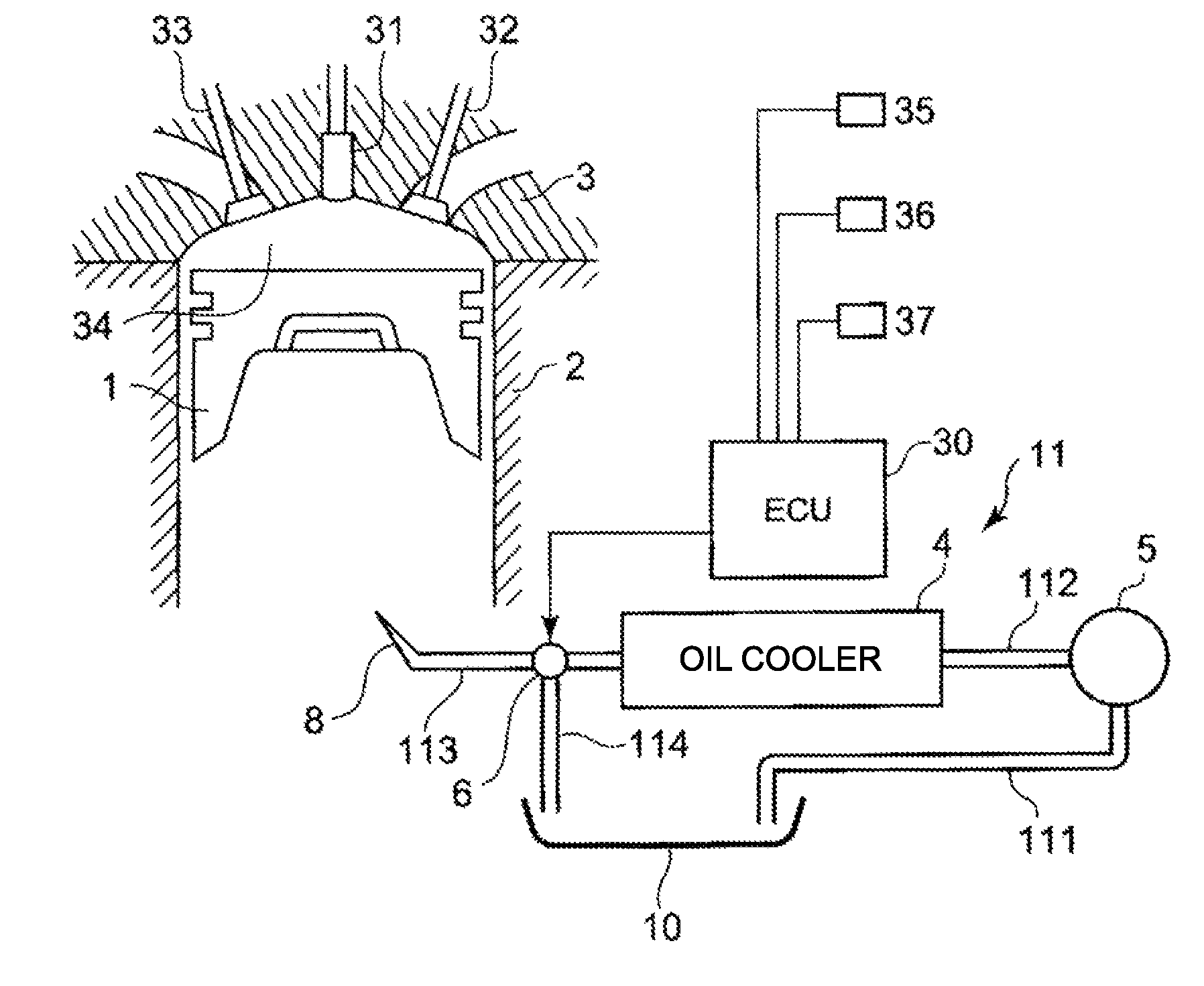

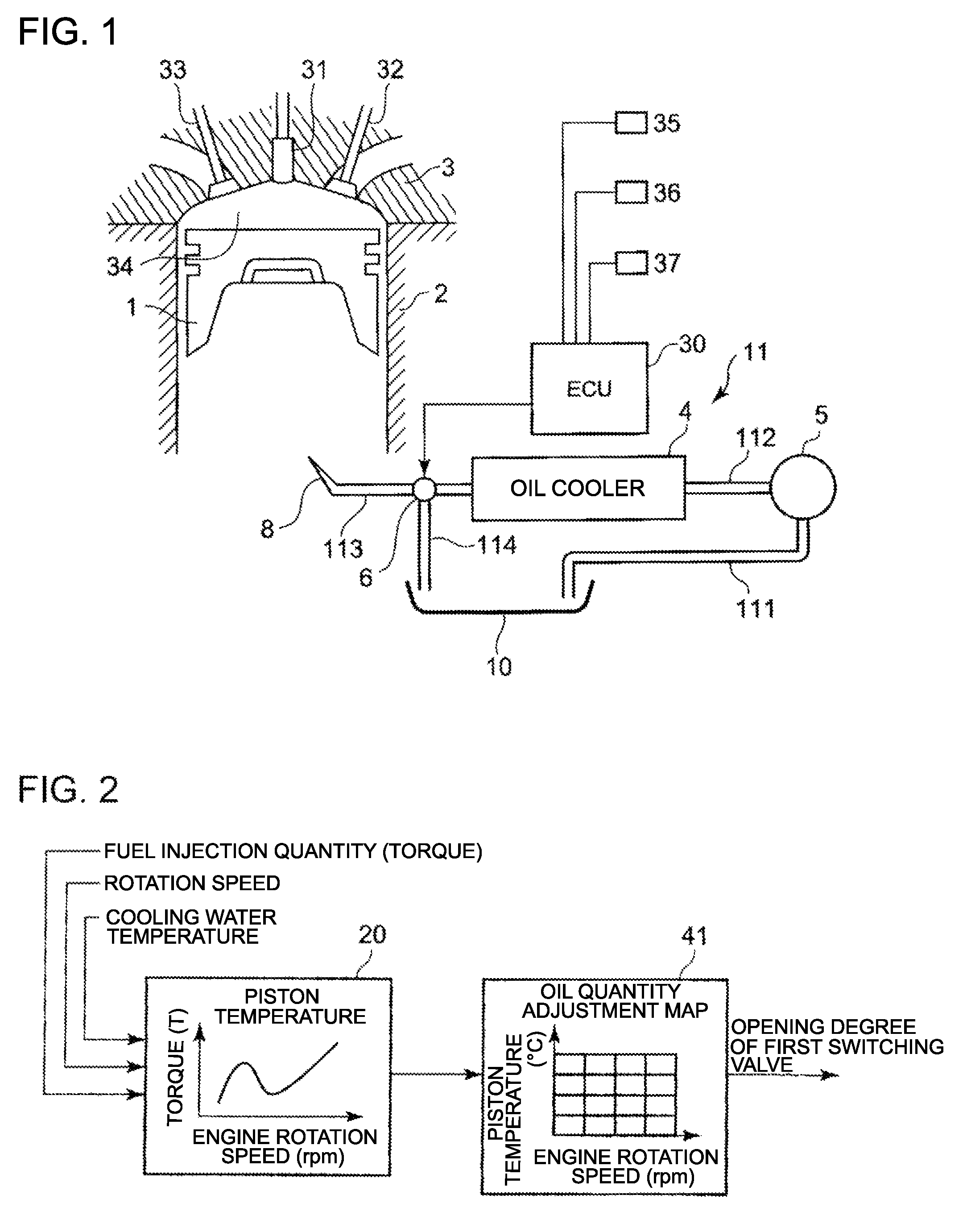

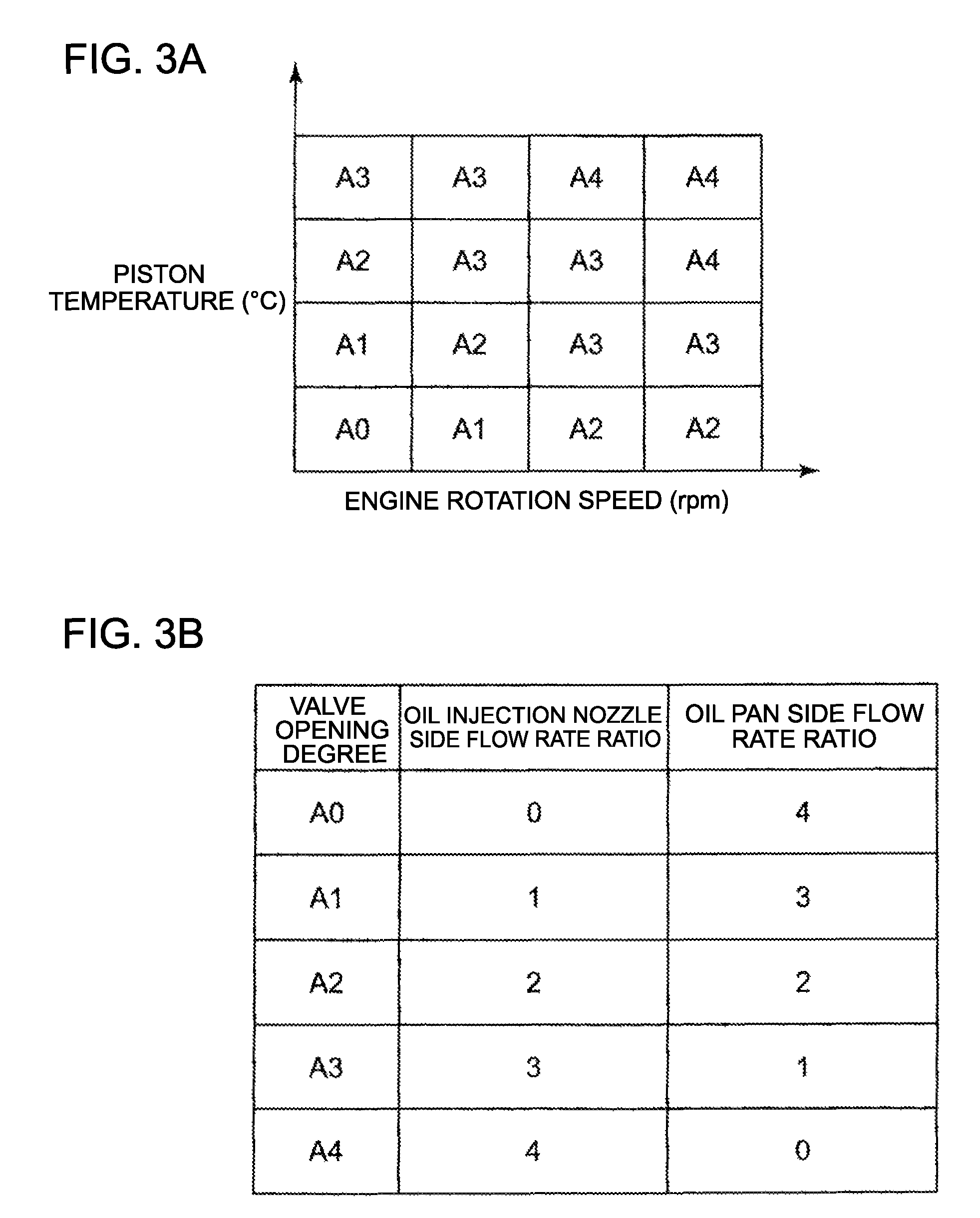

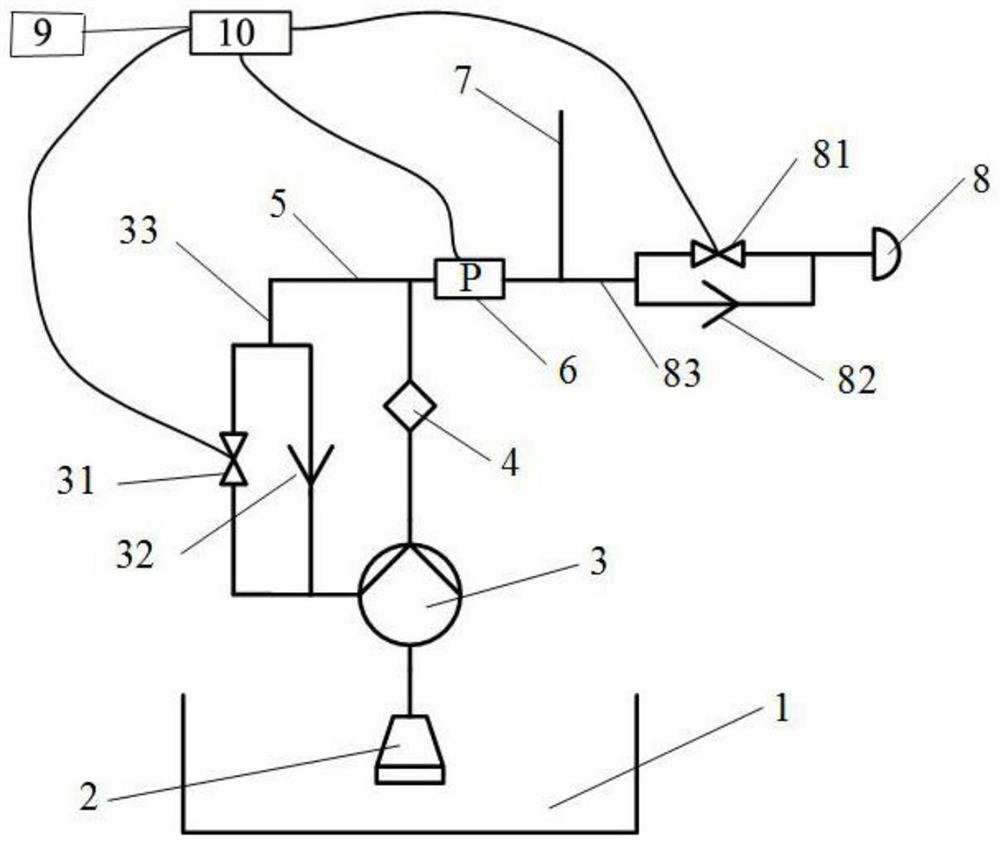

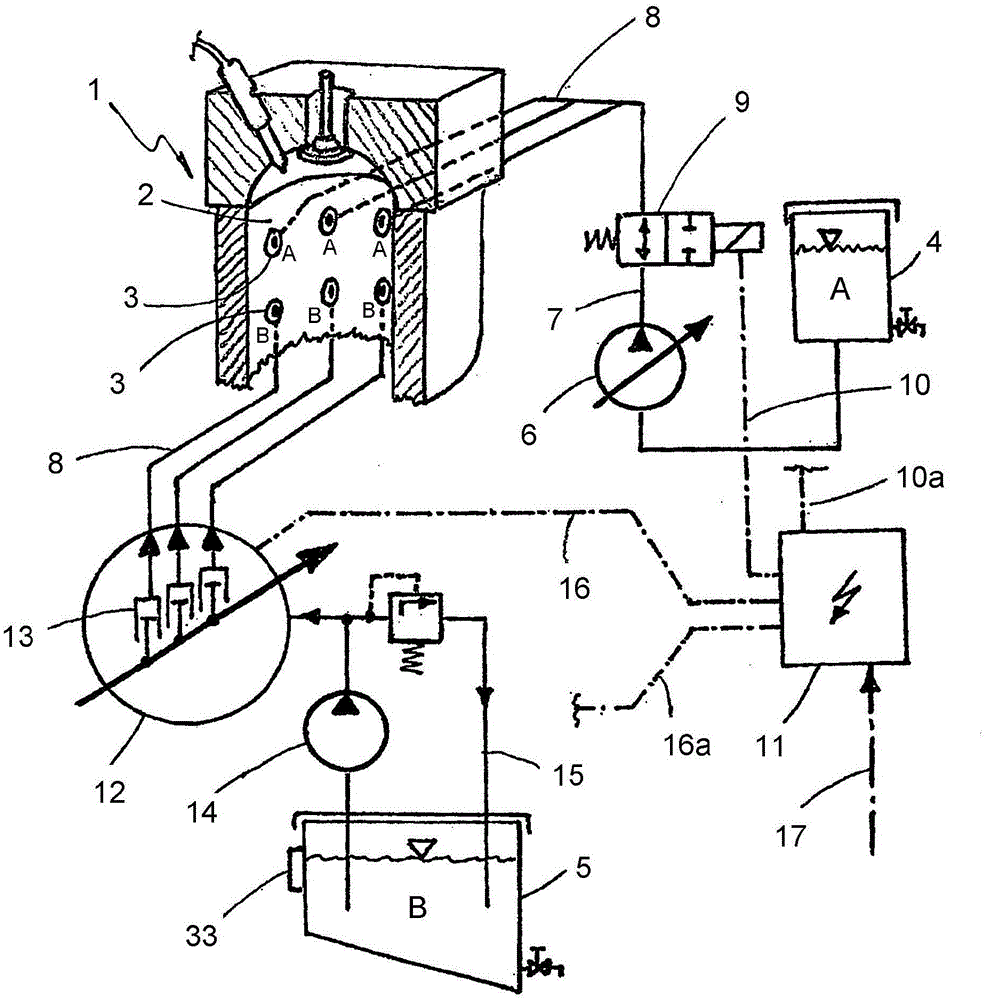

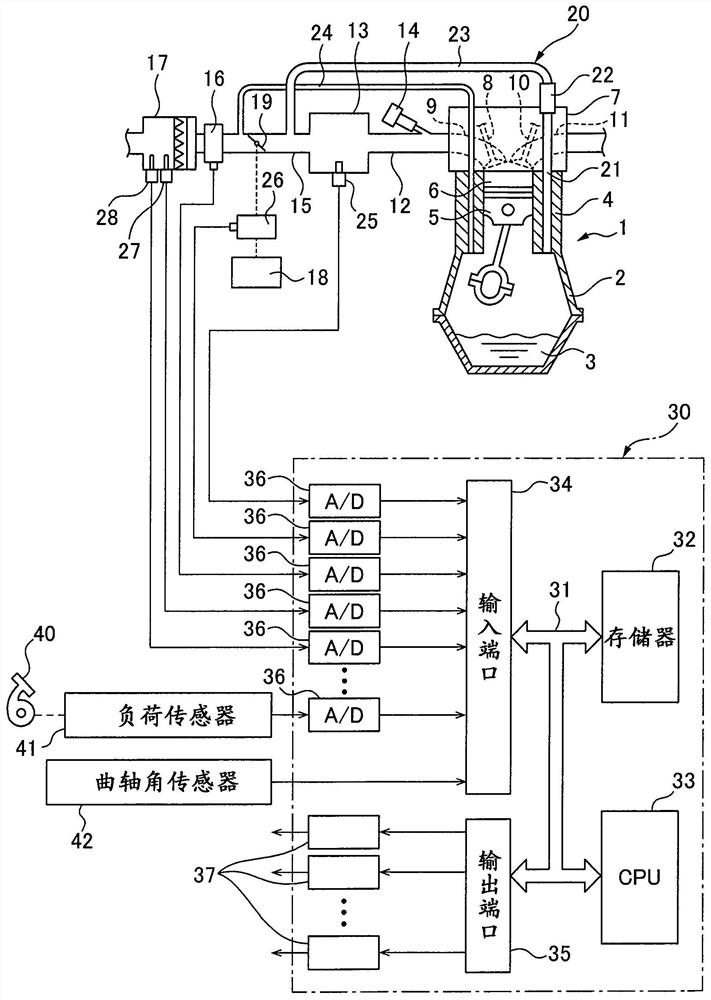

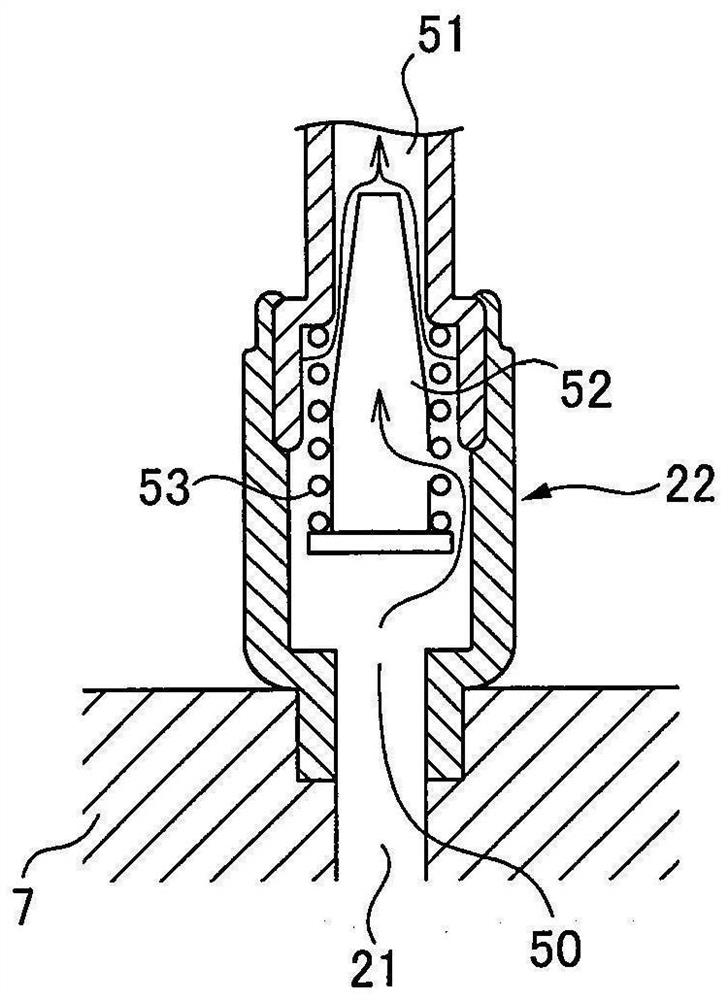

Cooling device for engine

ActiveUS20130139768A1Fine cooling controlEasy to operateLiquid coolingCoolant flow controlPistonPetroleum engineering

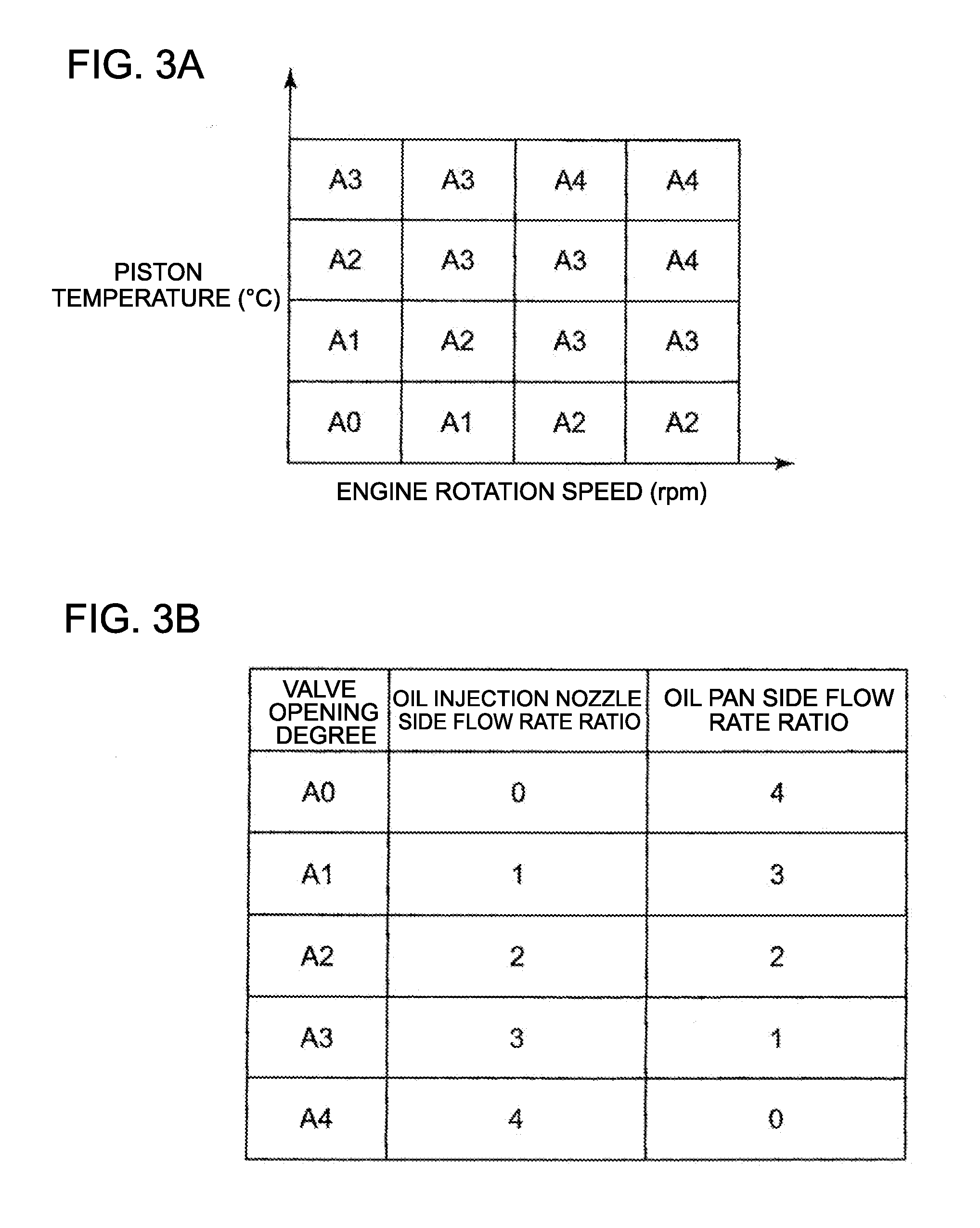

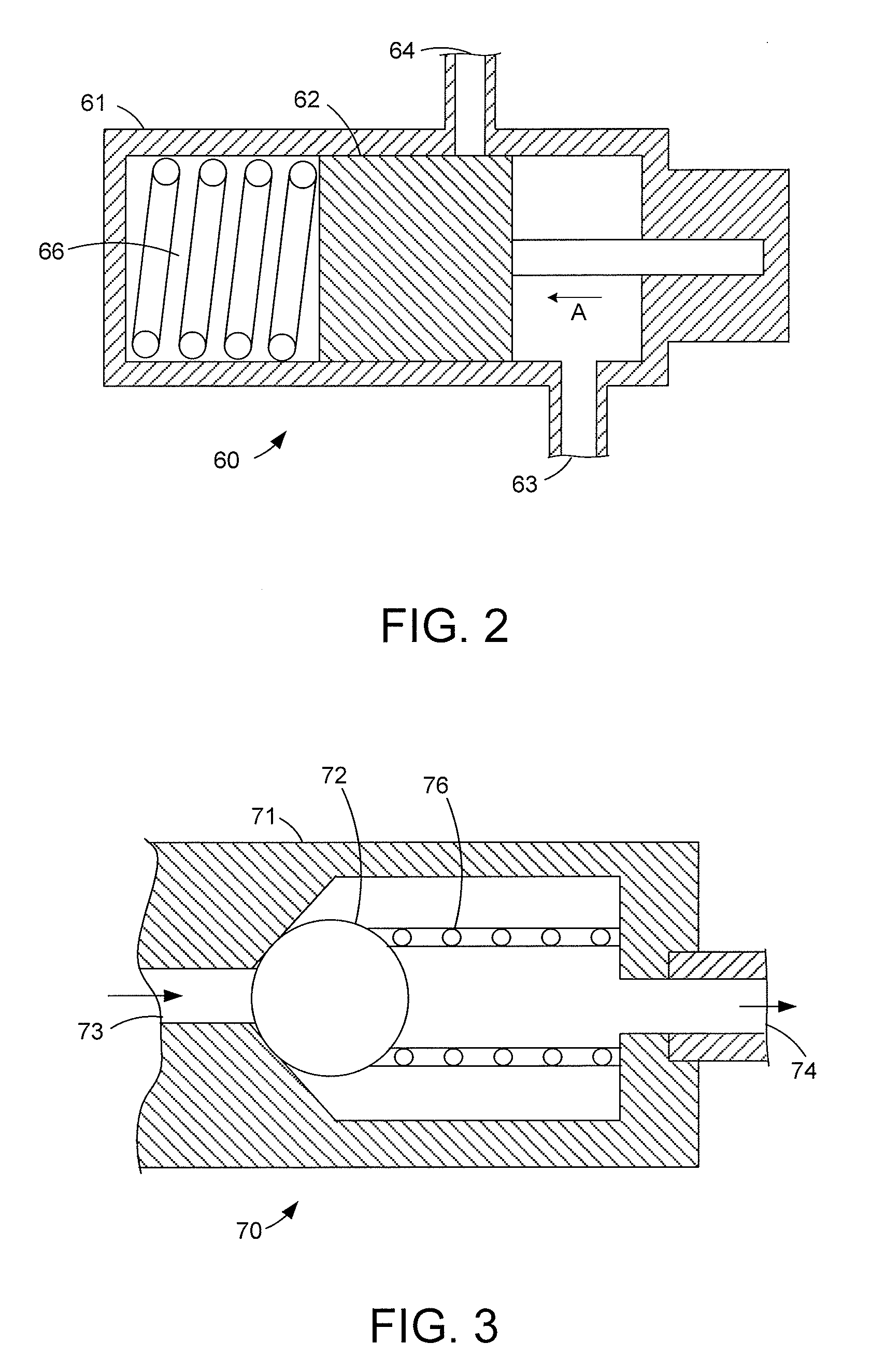

Disclosed is an oil jet device for cooling a piston, including: an oil cooler 4 that is disposed upstream of an oil injection nozzle 8; an oil pump 5 that is disposed upstream of the oil cooler 4; a first switching adjustment valve 6 that is disposed between the oil injection nozzle 8 and the oil cooler 4 and adjusts a flow dividing ratio at which the cooling oil from the oil cooler 4 is distributed to the oil injection nozzle 8 side and to an oil pan side; and a control unit that has an oil quantity adjustment map 4 for switching the first switching adjustment valve 6 based on a piston temperature calculation map 20 for calculating the temperature of the piston 1 using detection values acquired respectively by a cooling water temperature sensor 35, a rotation speed sensor 36 and a load sensor 37.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

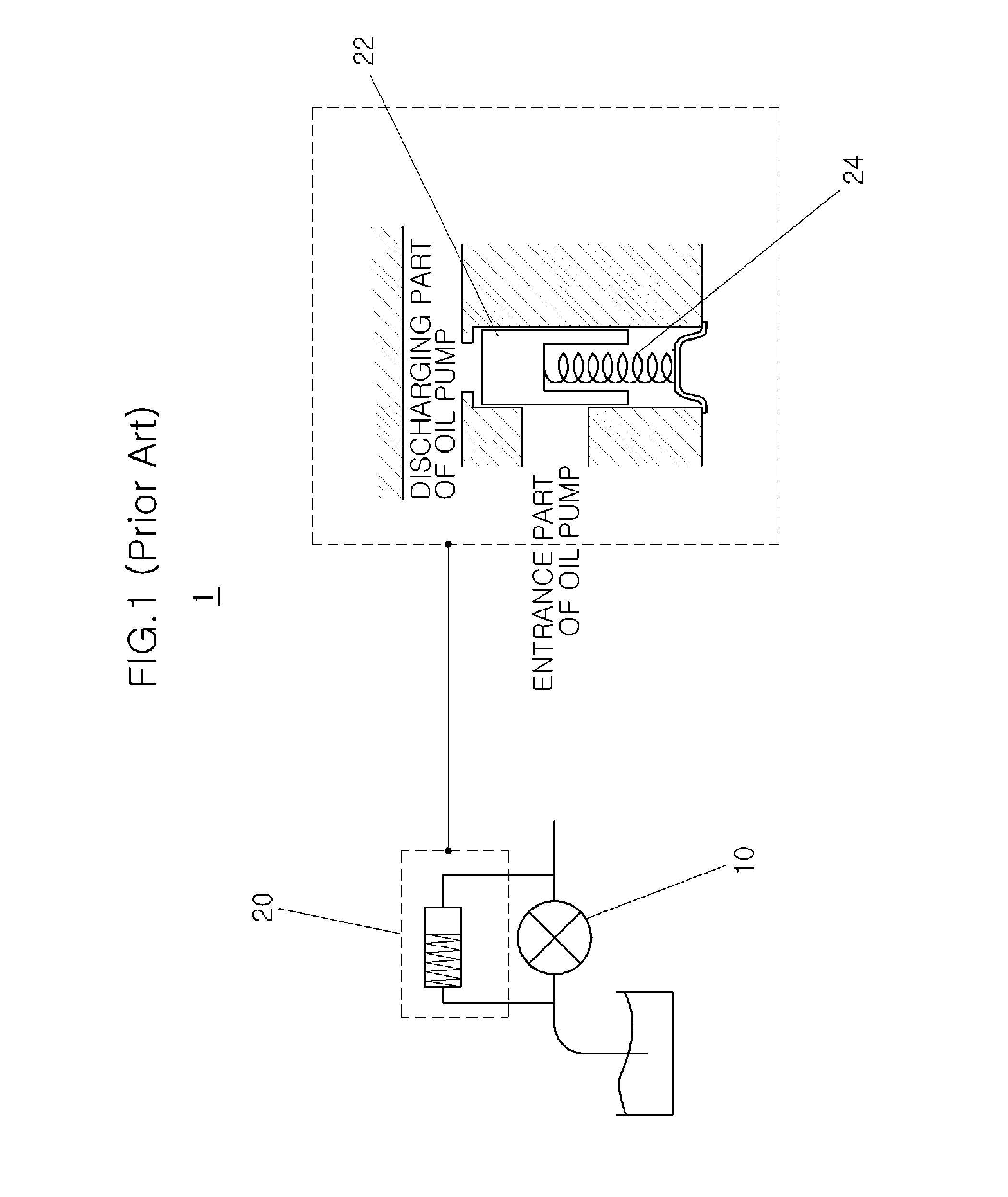

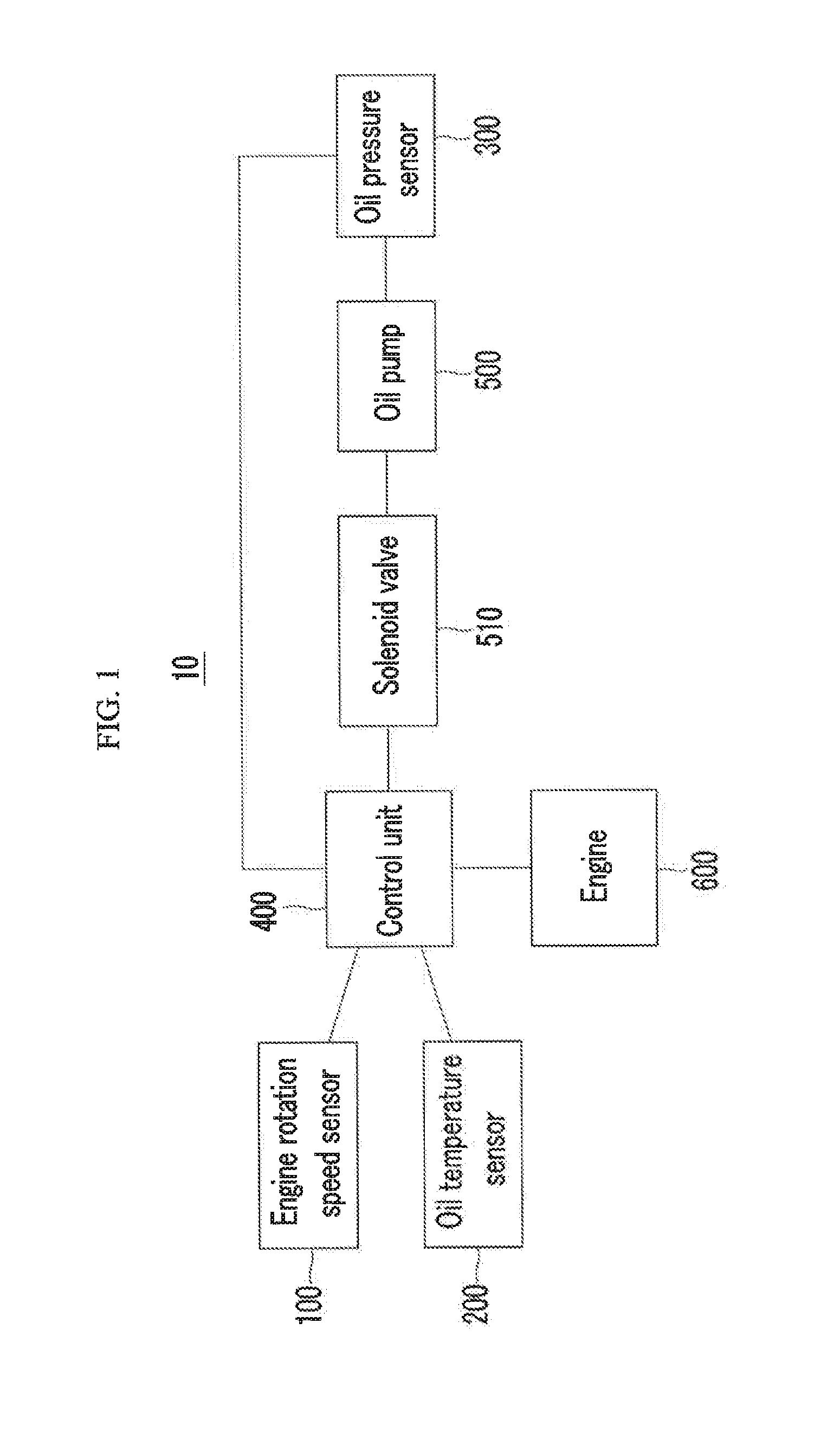

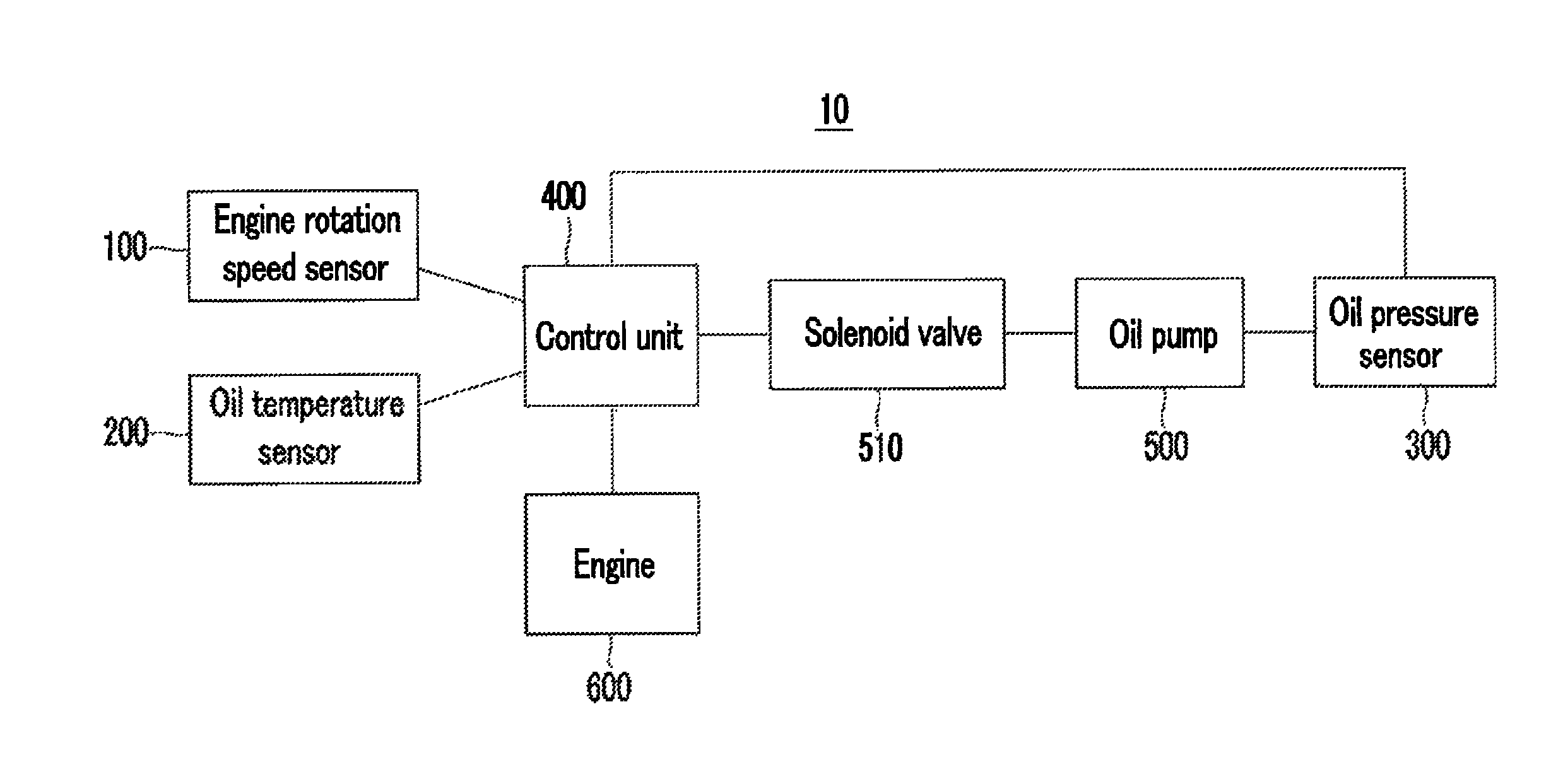

Oil pump control system for vehicle

InactiveUS20130151113A1Low efficiencyMaximize efficiencyAnalogue computers for vehiclesClutchesControl systemControl valves

An oil pump control system for a vehicle, may include an oil pump configured to supply oil to an engine, an oil pressure control valve regulating oil pressure value of a discharging part in the oil pump, an oil pressure sensor sensing and outputting the oil pressure value of the discharging part in the oil pump, and a controller receiving a signal of the oil pressure value, determining a target oil pressure value of the discharging part in the oil pump in response to information relating to an oil pressure and operation state of the engine among vehicle information inputted from outside, comparing the sensed oil pressure value inputted from the oil pressure sensor with the target oil pressure value, and performing feedback control to drive the oil pressure control valve.

Owner:HYUNDAI MOTOR CO LTD +1

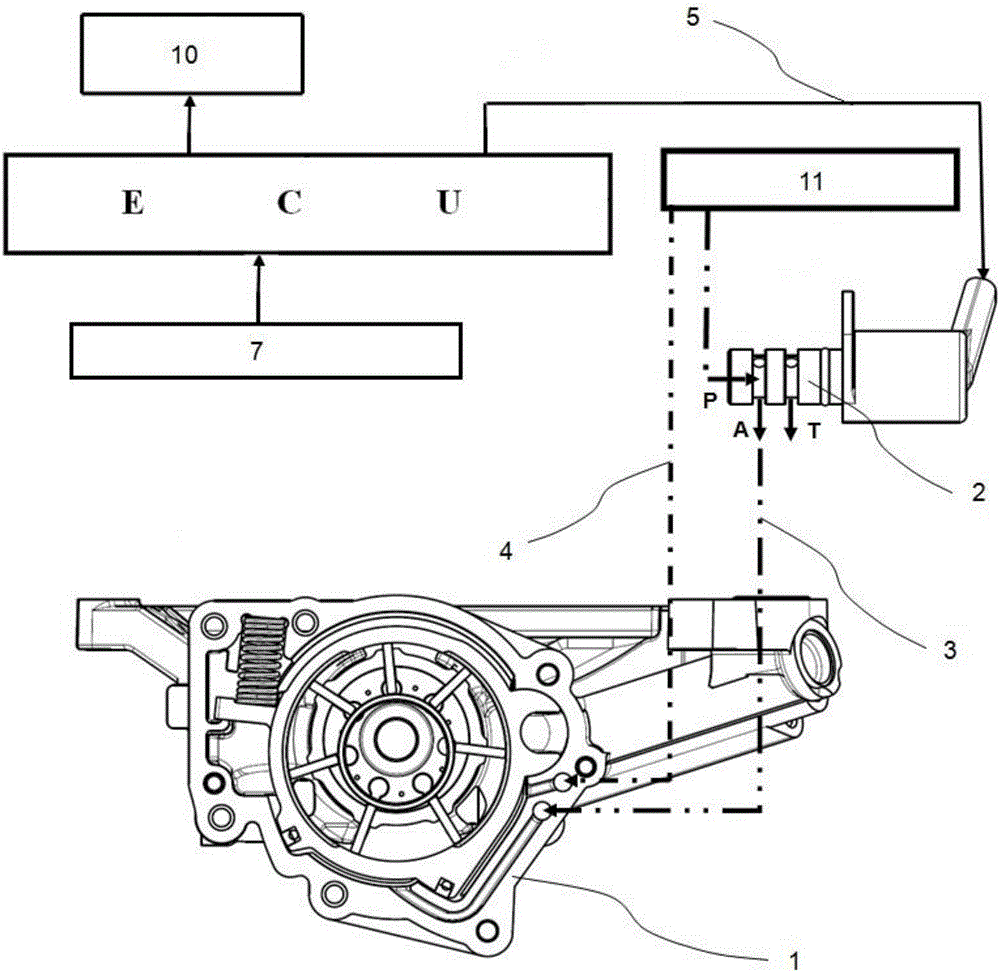

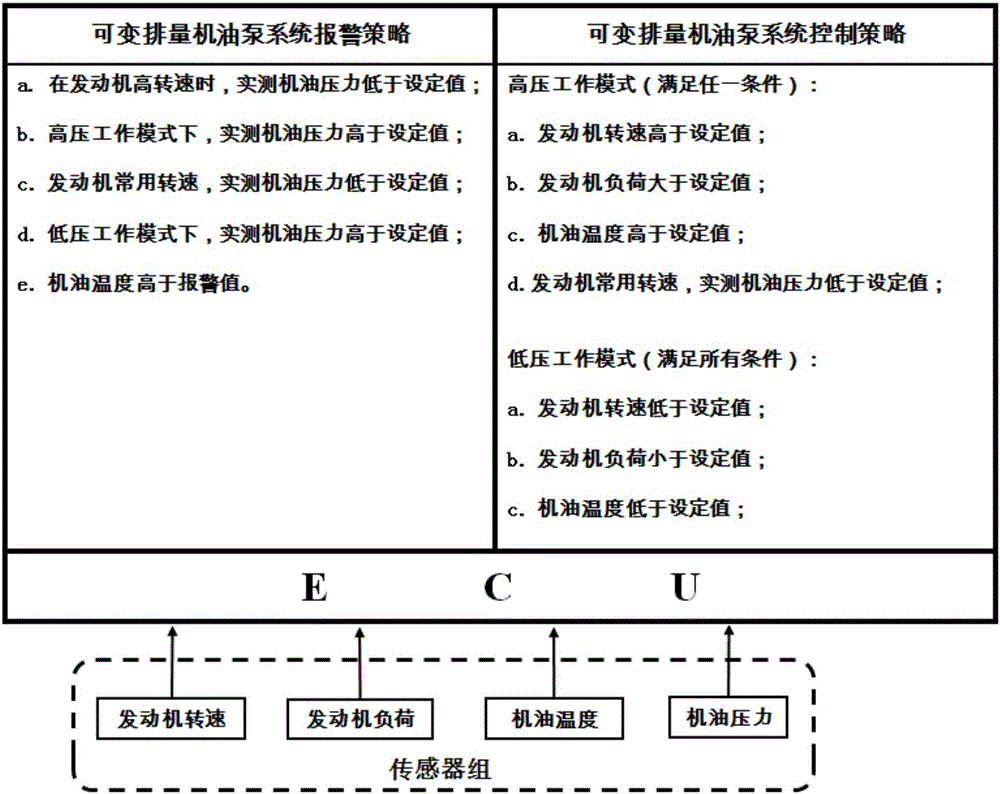

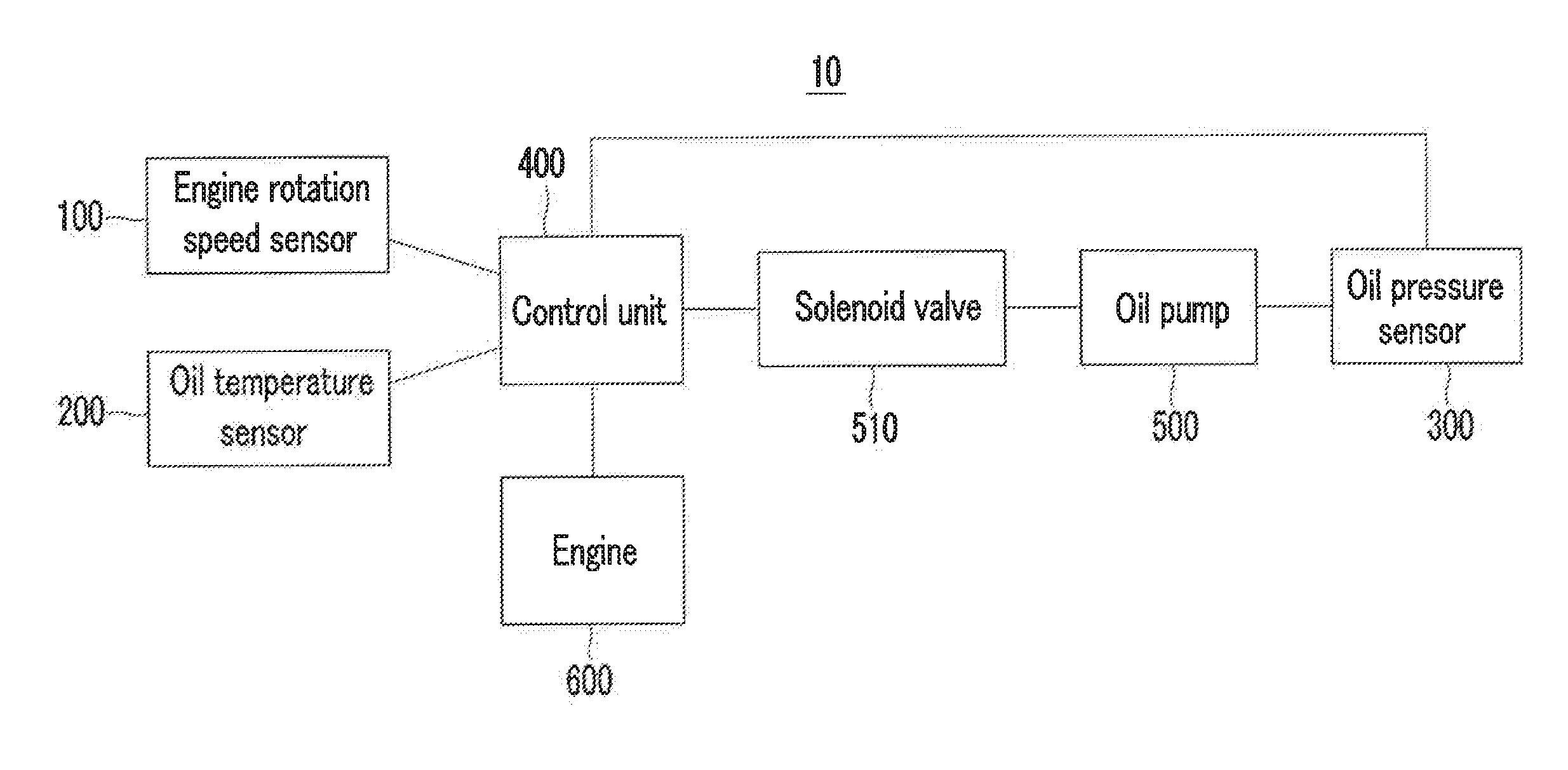

Variable displacement oil pump control system and control method thereof

InactiveCN106567755ADisplacement intelligent adjustmentSolve the problem of high fuel consumption due to excess oil pump capacityEngine loadEngine revolutionsControl signalControl system

The invention provides a variable displacement oil pump control system and a control method thereof. A first feedback oil duct and a second feedback oil duct of the control system are both connected between a main oil duct and a variable displacement oil pump. An electromagnetic valve is installed on the first feedback oil duct and is connected with an ECU through a wiring harness. A sensor set is in signal connection with the ECU. The ECU receives detection signals of the sensor set, control signals are sent to the electromagnetic valve after the detection signals are analyzed and judged by a control strategy module inside the ECU, and the electromagnetic valve executes corresponding movements according to the control signals. By the adoption of the control method, the ECU is used for receiving the engine rotating speed, engine loads, oil temperature signals and oil pressure signals sent by the sensor set, and the working mode of the variable displacement oil pump can be intelligently selected through the internal control strategy module inside according to the actual using conditions of an engine. By means of the variable displacement oil pump control system and the control method thereof, the displacement of the oil pump can be intelligently adjusted, the problem that the capacity of a commonly-used working condition oil pump of the engine is excessive and thus oil consumption is made high is solved, and the oil economy of an entire vehicle is improved.

Owner:CHINA FIRST AUTOMOBILE

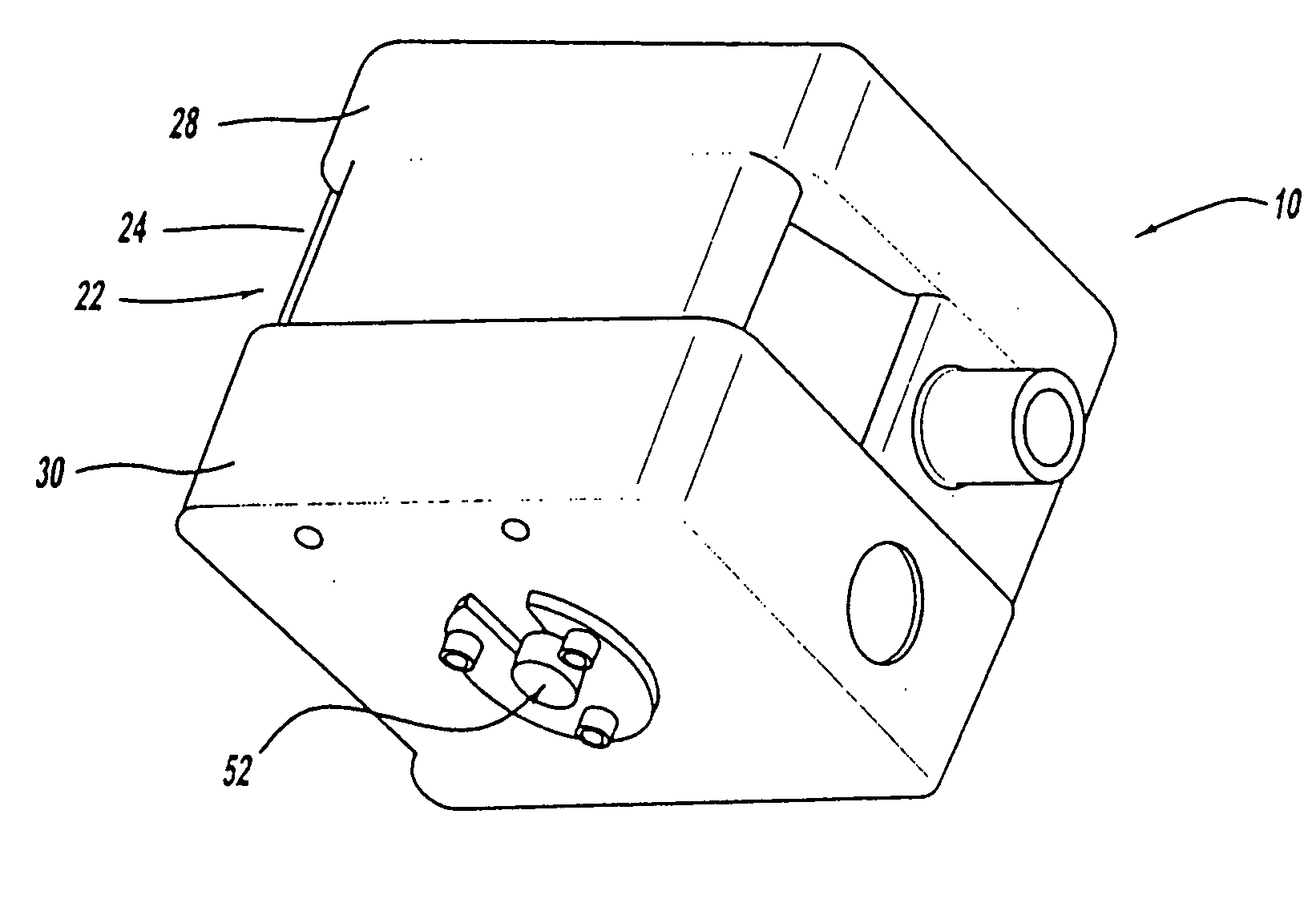

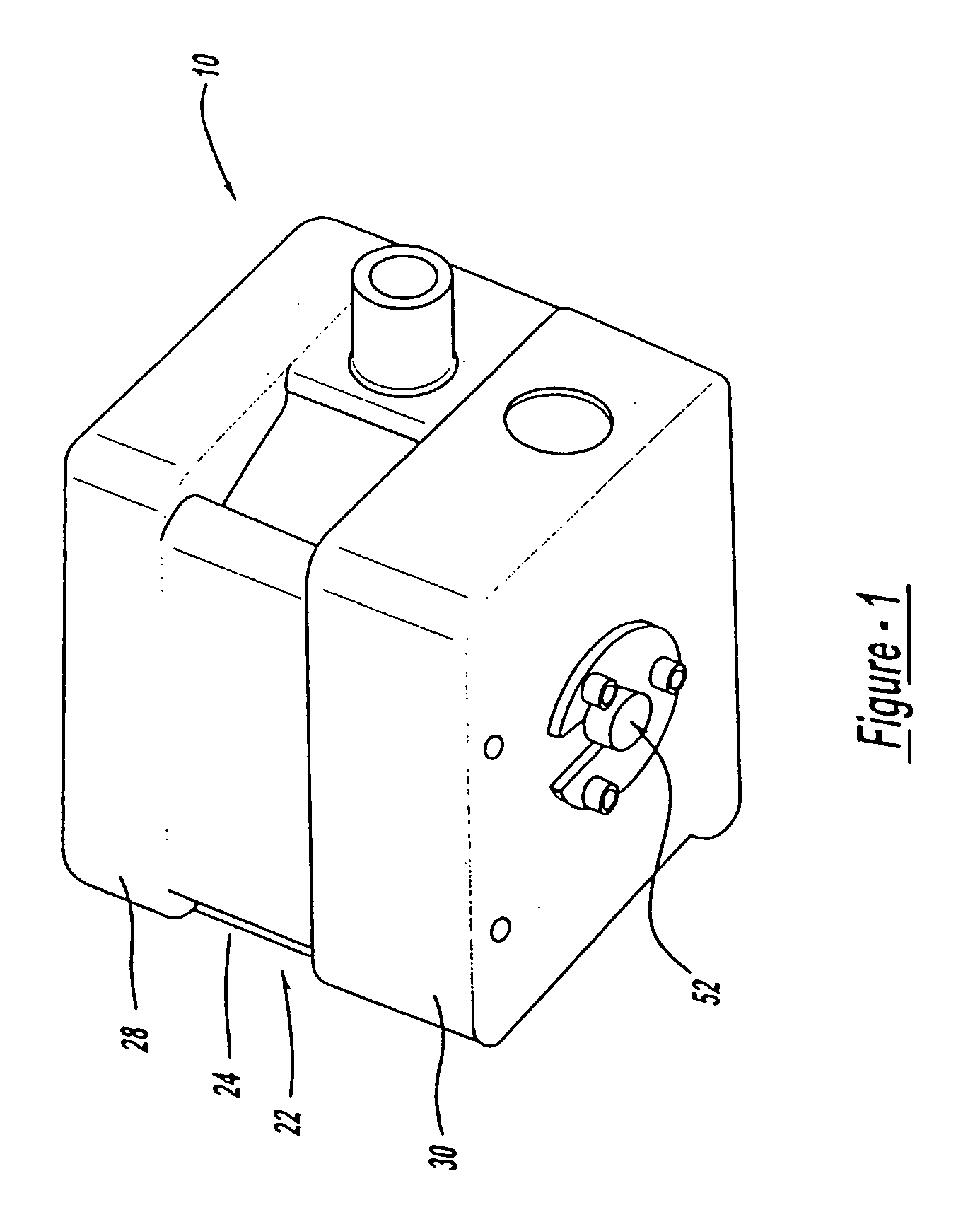

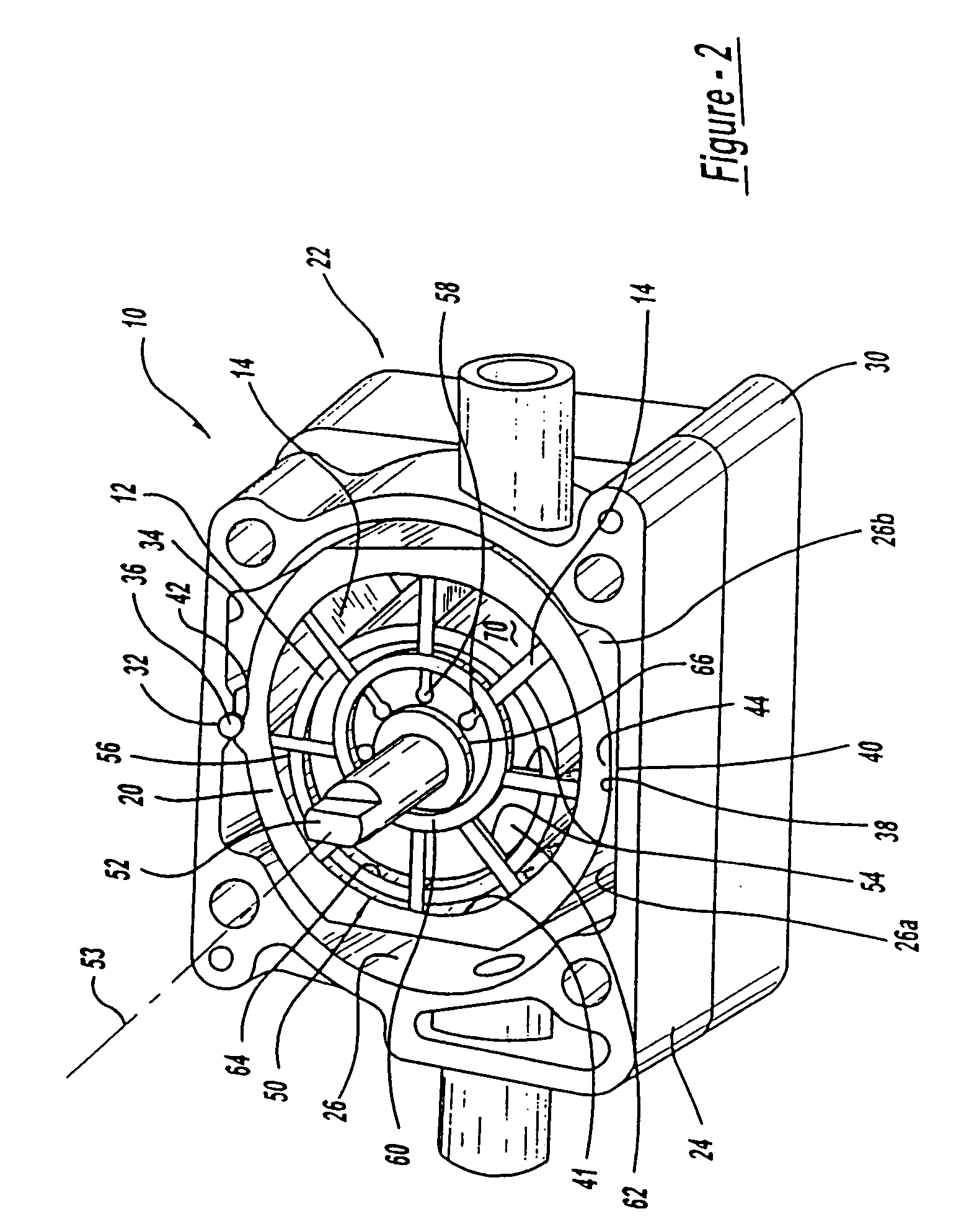

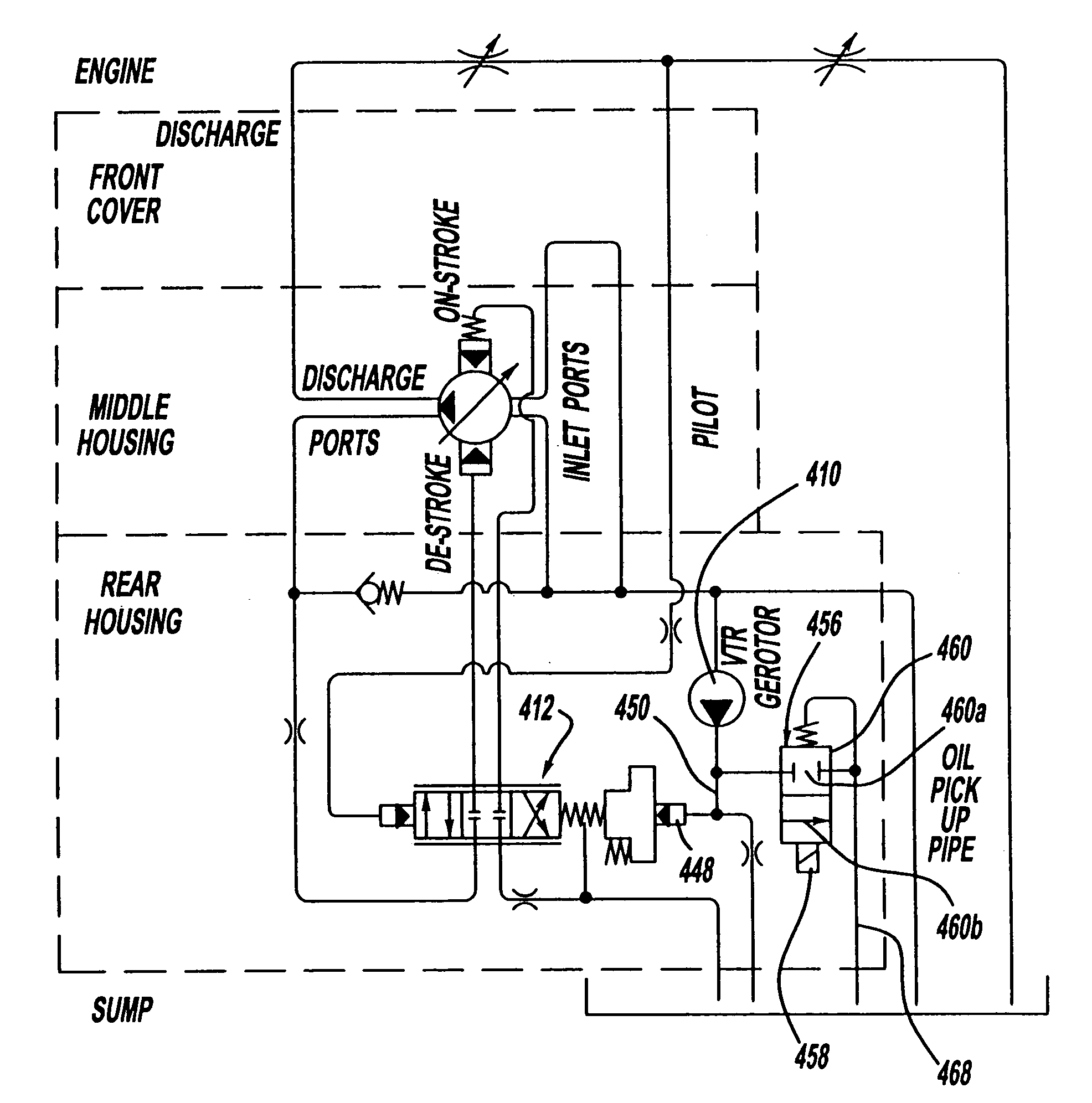

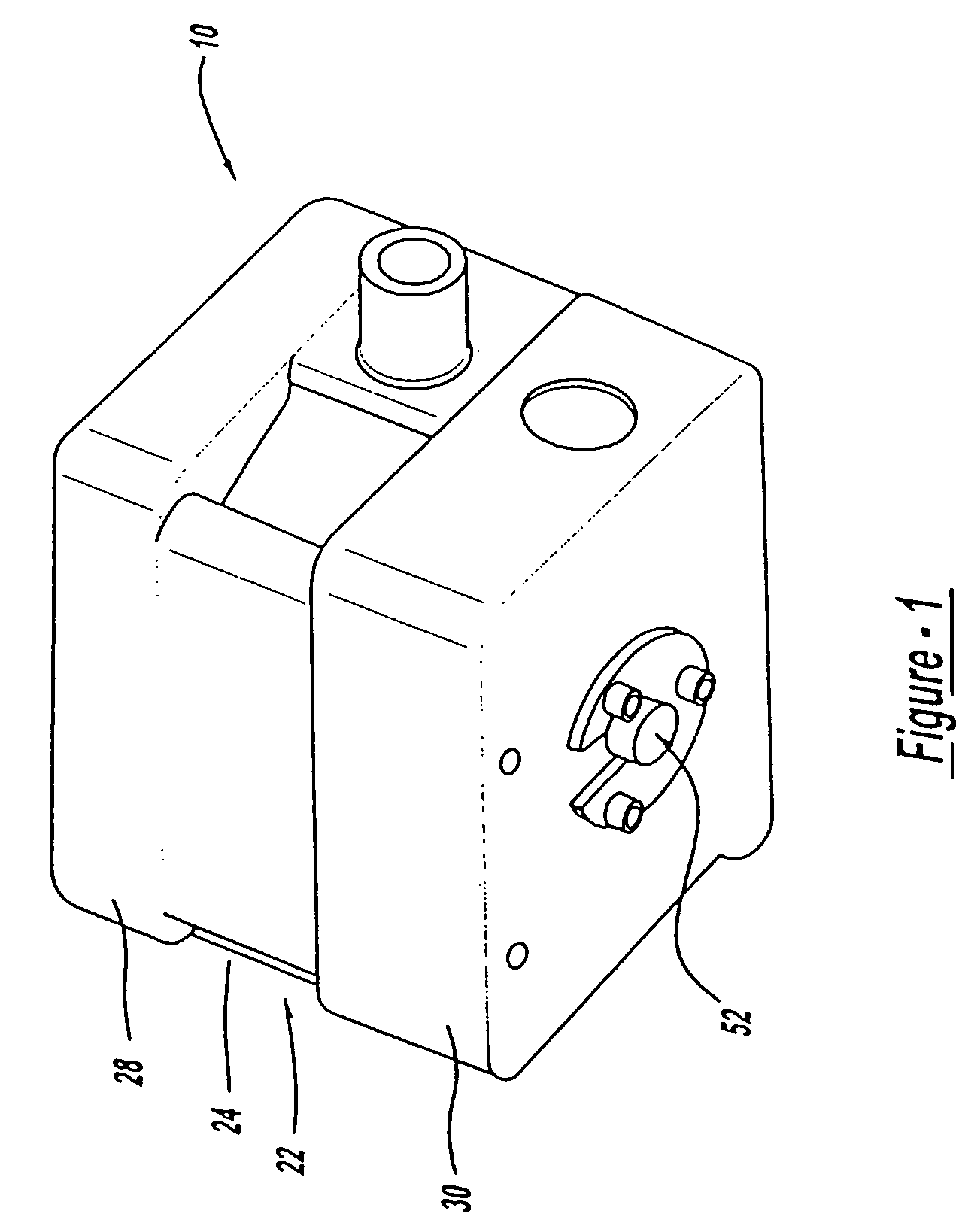

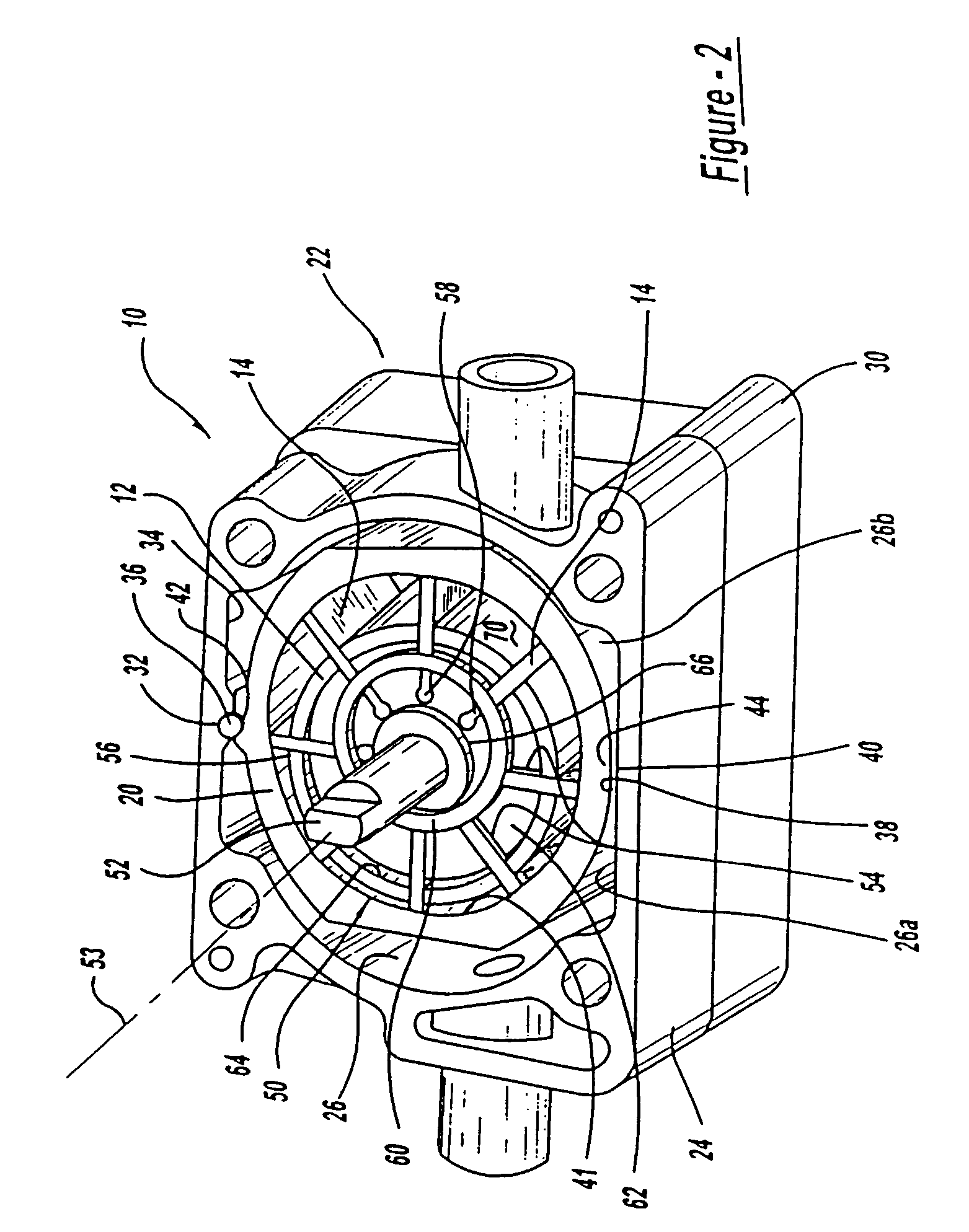

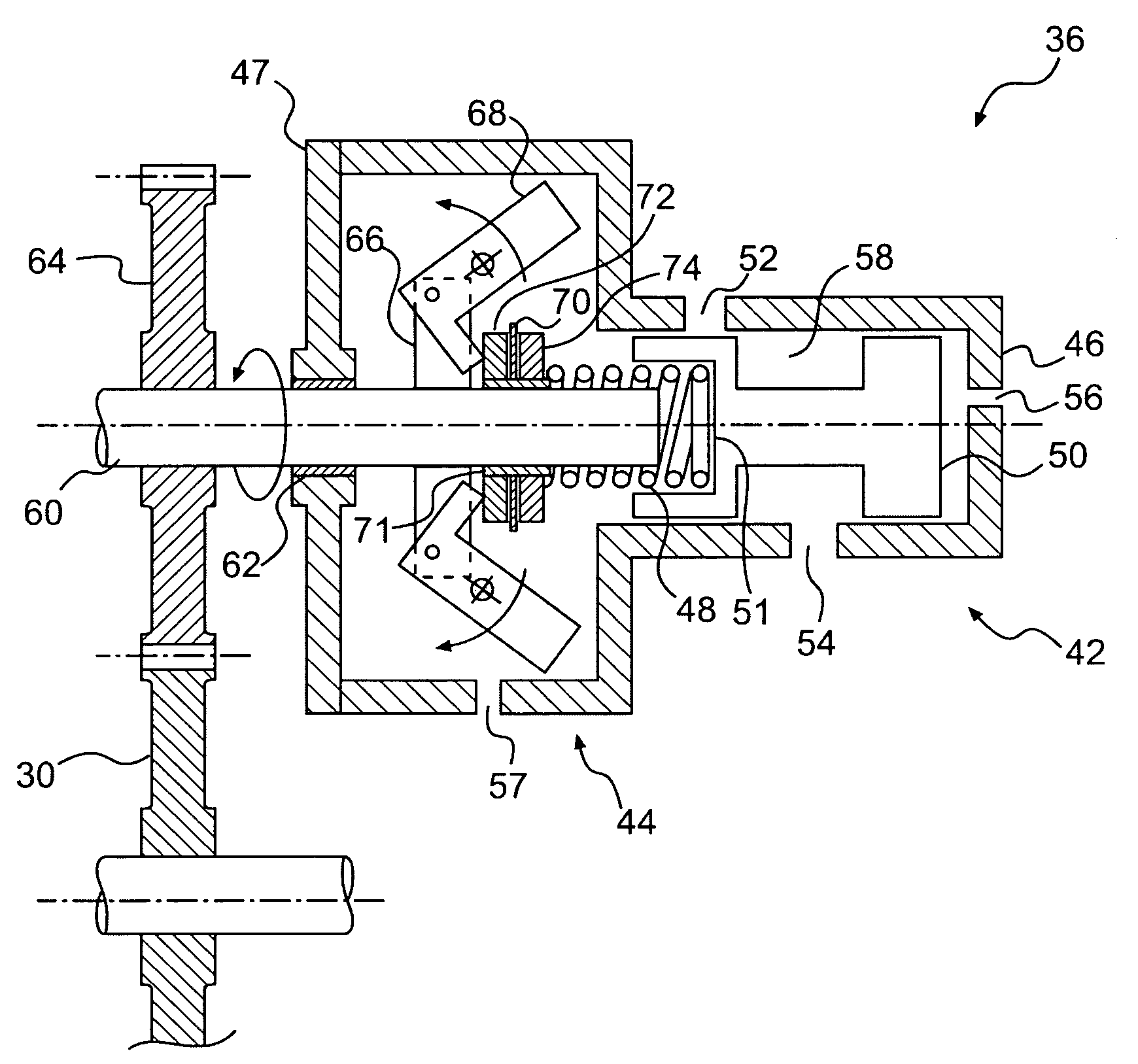

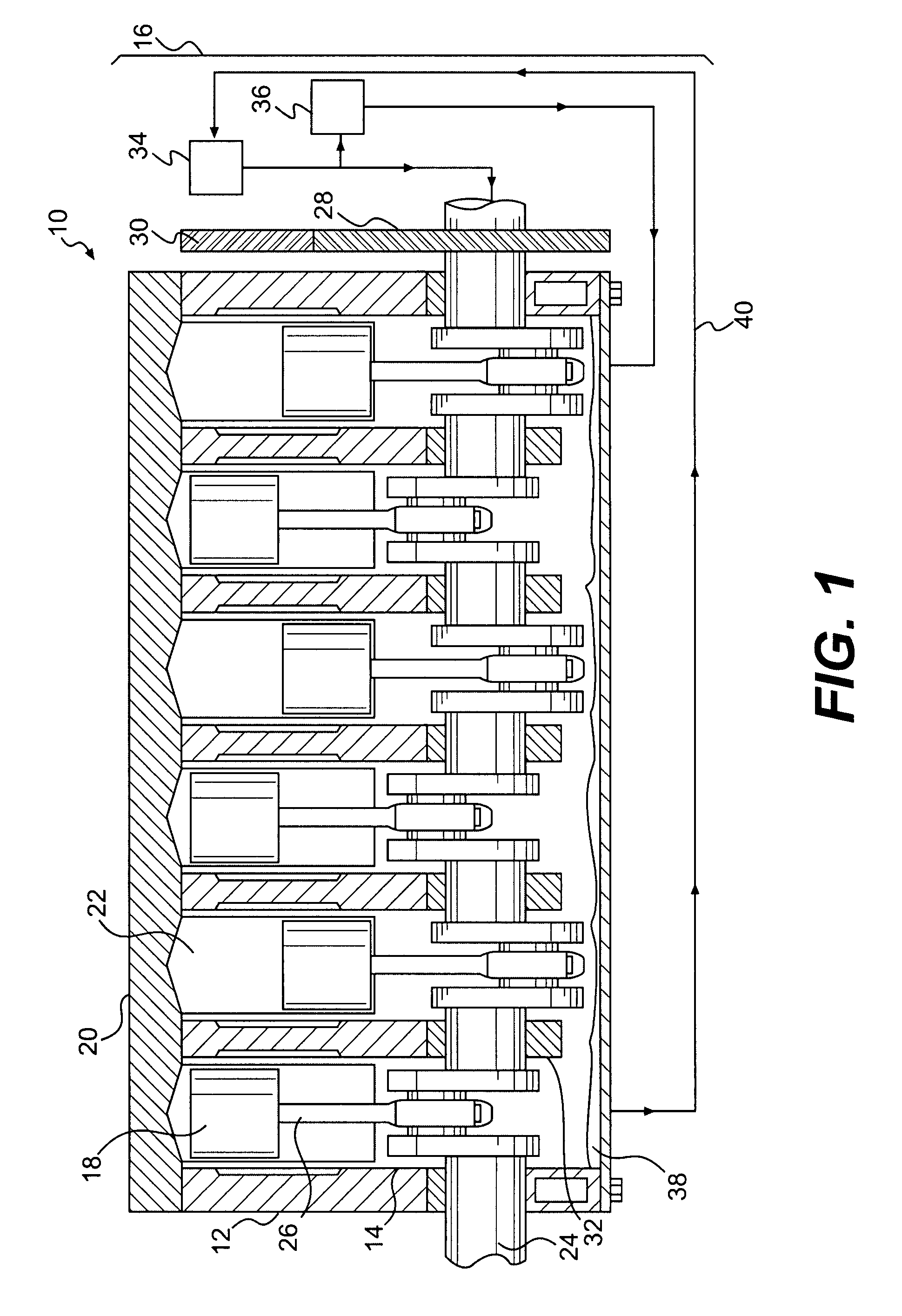

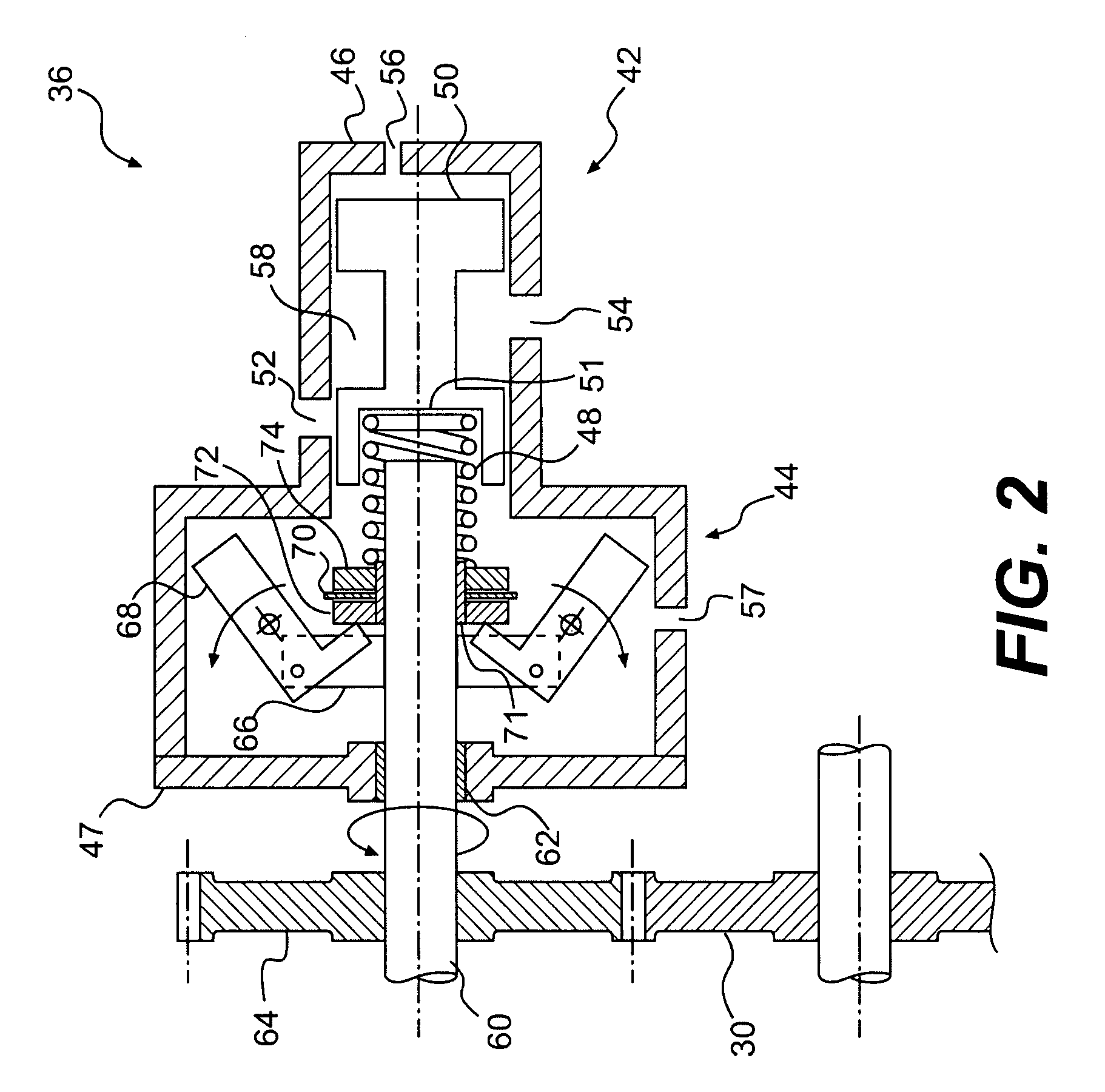

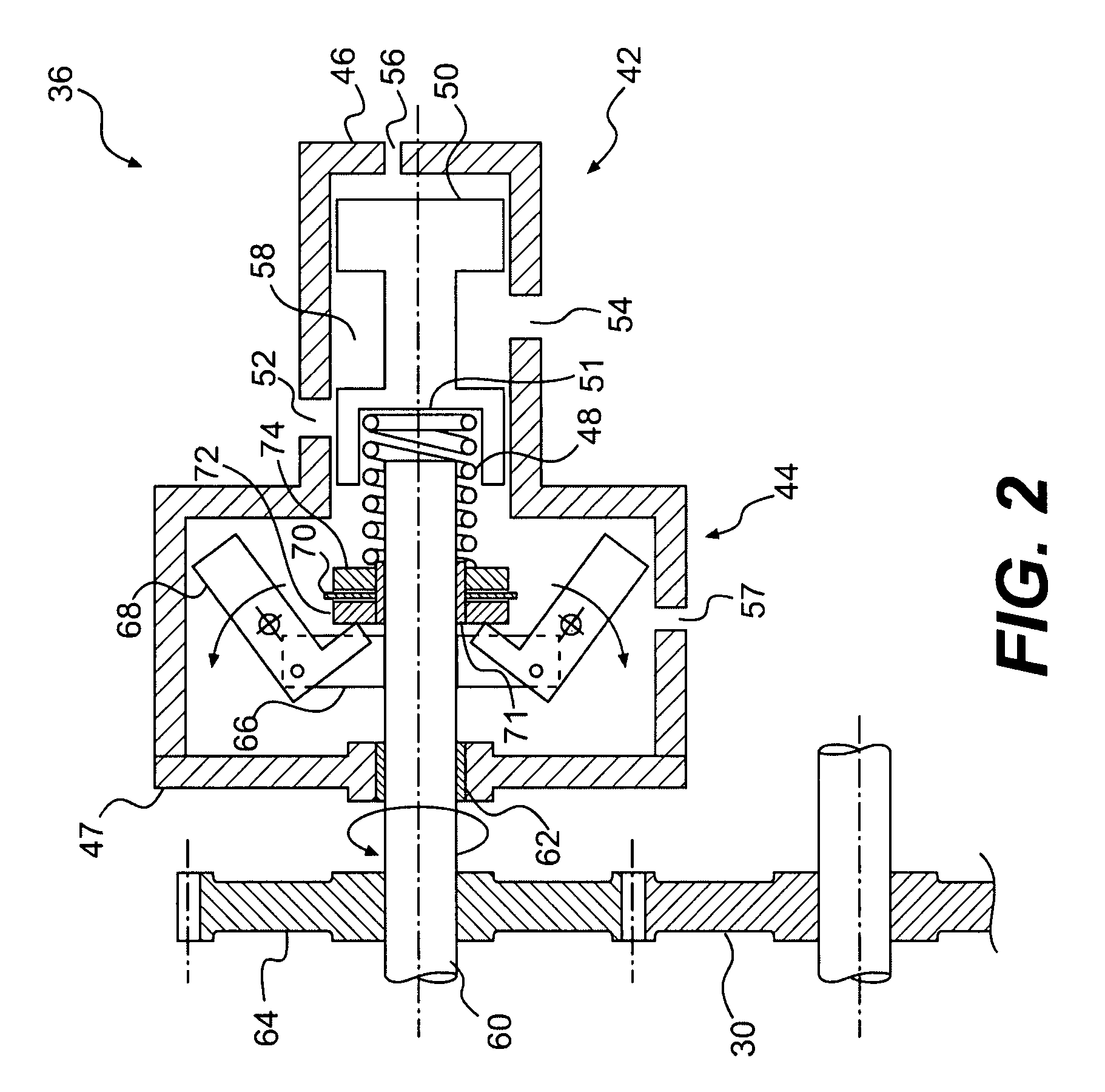

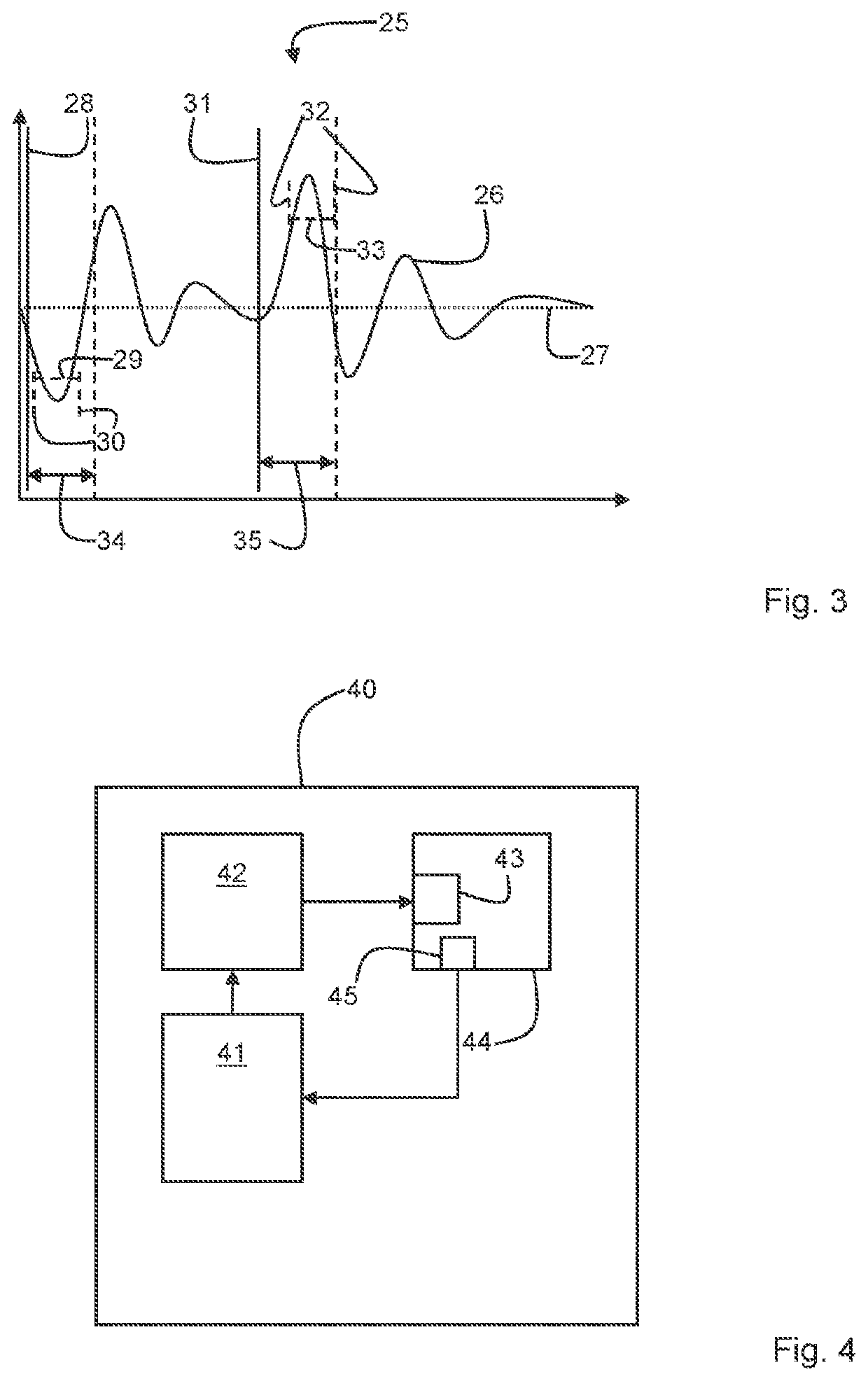

Variable displacement vane pump with variable target reguator

A variable displacement vane-type fluid pump is provided which permits improved regulation of the pump discharge such that the pump can meet the various requirements of lubrication for internal combustion engines at all speeds with minimized use of power. Of course, the vane pump may also be utilized in a wide range of power transmission and other fluid distribution applications. The vane pump of the invention may also use both hydrostatic and mechanical actuators to control the position of its containment ring or eccentric ring and hence, regulate the output of the pump. According to yet another aspect of the present invention, to prevent inlet flow restriction or cavitation, a valve may be provided to permit some of the pump outlet or discharge flow to bleed into the pump inlet to provide needed velocity energy to the fluid flow into the pump inlet. A system for lubrication of an engine using a fixed displacement pump for providing an engine speed input for controlling a second main variable displacement type oil pump and maintaining a target oil pressure in the oil pressure circuit. A solenoid valve is used for venting output of the fixed displacement pump to create a second target oil pressure characteristic or curve when desired.

Owner:SLW AUTOMOTIVE

Variable displacement vane pump with variable target regulator

A variable displacement vane-type fluid pump is provided which permits improved regulation of the pump discharge such that the pump can meet the various requirements of lubrication for internal combustion engines at all speeds with minimized use of power. Of course, the vane pump may also be utilized in a wide range of power transmission and other fluid distribution applications. The vane pump of the invention may also use both hydrostatic and mechanical actuators to control the position of its containment ring or eccentric ring and hence, regulate the output of the pump. According to yet another aspect of the present invention, to prevent inlet flow restriction or cavitation, a valve may be provided to permit some of the pump outlet or discharge flow to bleed into the pump inlet to provide needed velocity energy to the fluid flow into the pump inlet. A system for lubrication of an engine using a fixed displacement pump for providing an engine speed input for controlling a second main variable displacement type oil pump and maintaining a target oil pressure in the oil pressure circuit. A solenoid valve is used for venting output of the fixed displacement pump to create a second target oil pressure characteristic or curve when desired.

Owner:SLW AUTOMOTIVE

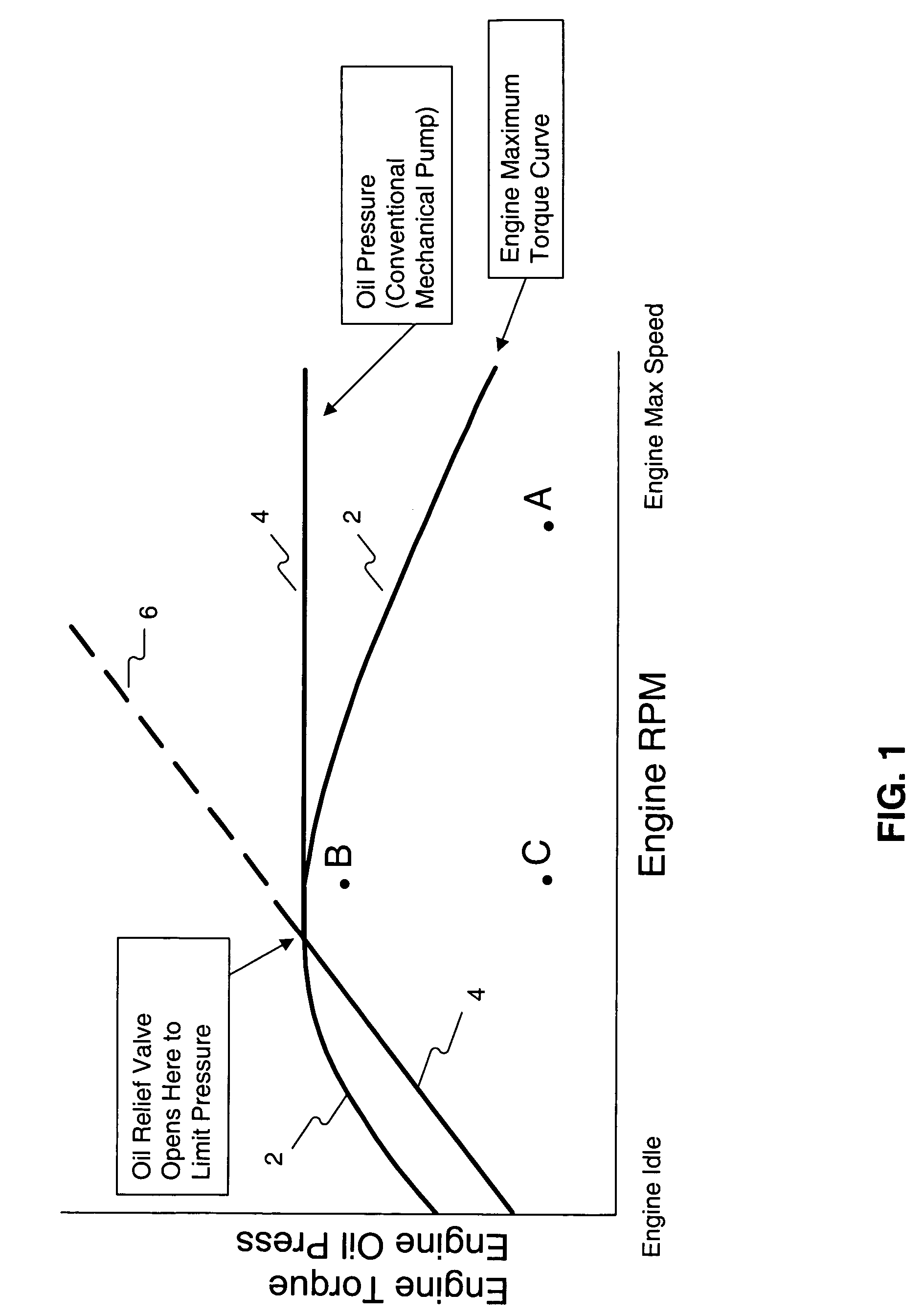

Engine speed sensitive oil pressure regulator

ActiveUS20090107451A1Reduce pressureLubrication of auxillariesLubricant conduit arrangementsLine tubingEngineering

A pressure regulator for a power source may include a housing in fluid communication with a pressurized fluid line and a reservoir, and a pressure relief valve having an open position that creates a flow path between the pressurized fluid line and the reservoir, and a closed position. The pressure relief valve may open when an opening force exerted by pressurized fluid entering the housing overcomes a closing force acting on the pressure relief valve, allowing pressurized fluid to flow from the pressurized fluid line to the reservoir. The pressure regulator may also include a governor coupled to the pressure relief valve, wherein the governor is configured to regulate the pressure in the pressurized fluid line by selectively adjusting the closing force exerted on the pressure relief valve based on engine speed.

Owner:CATERPILLAR INC

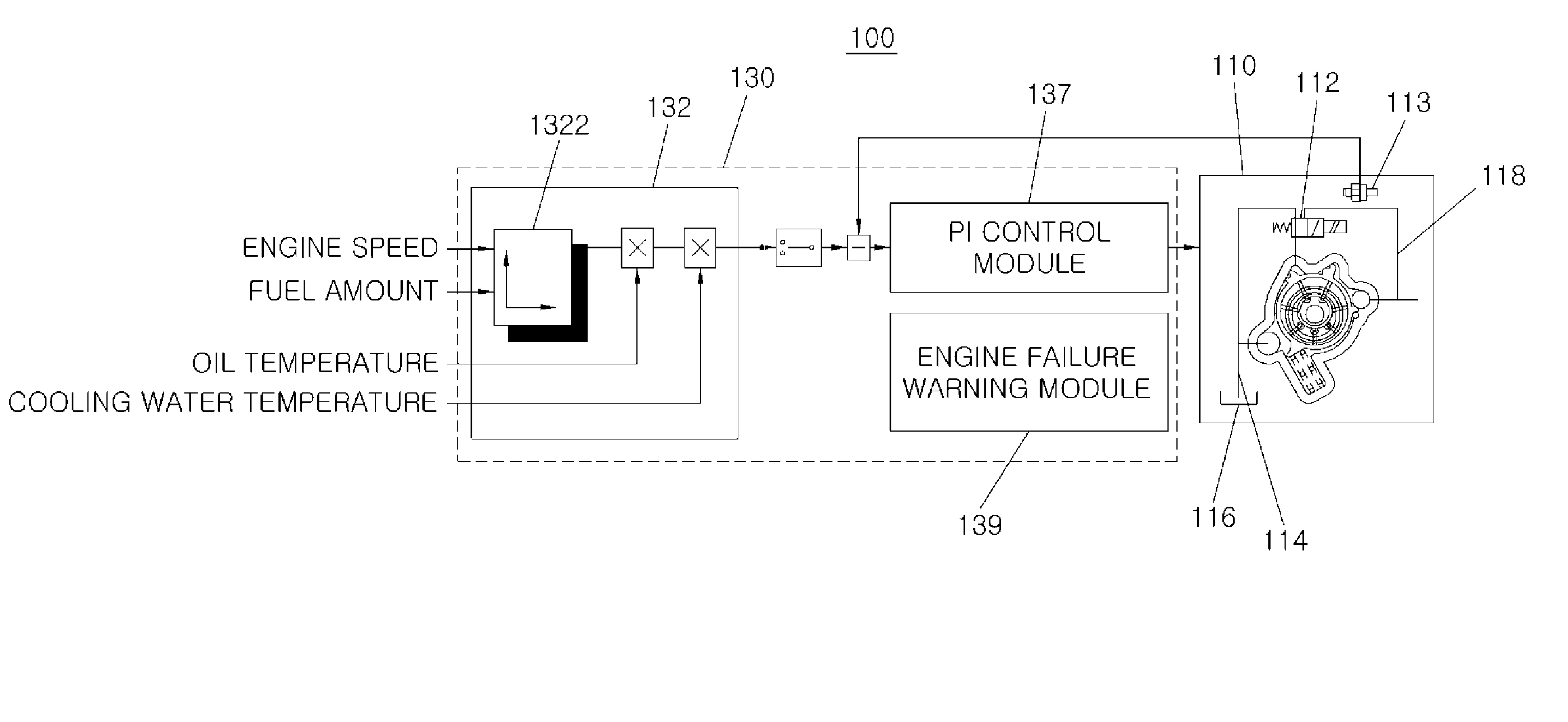

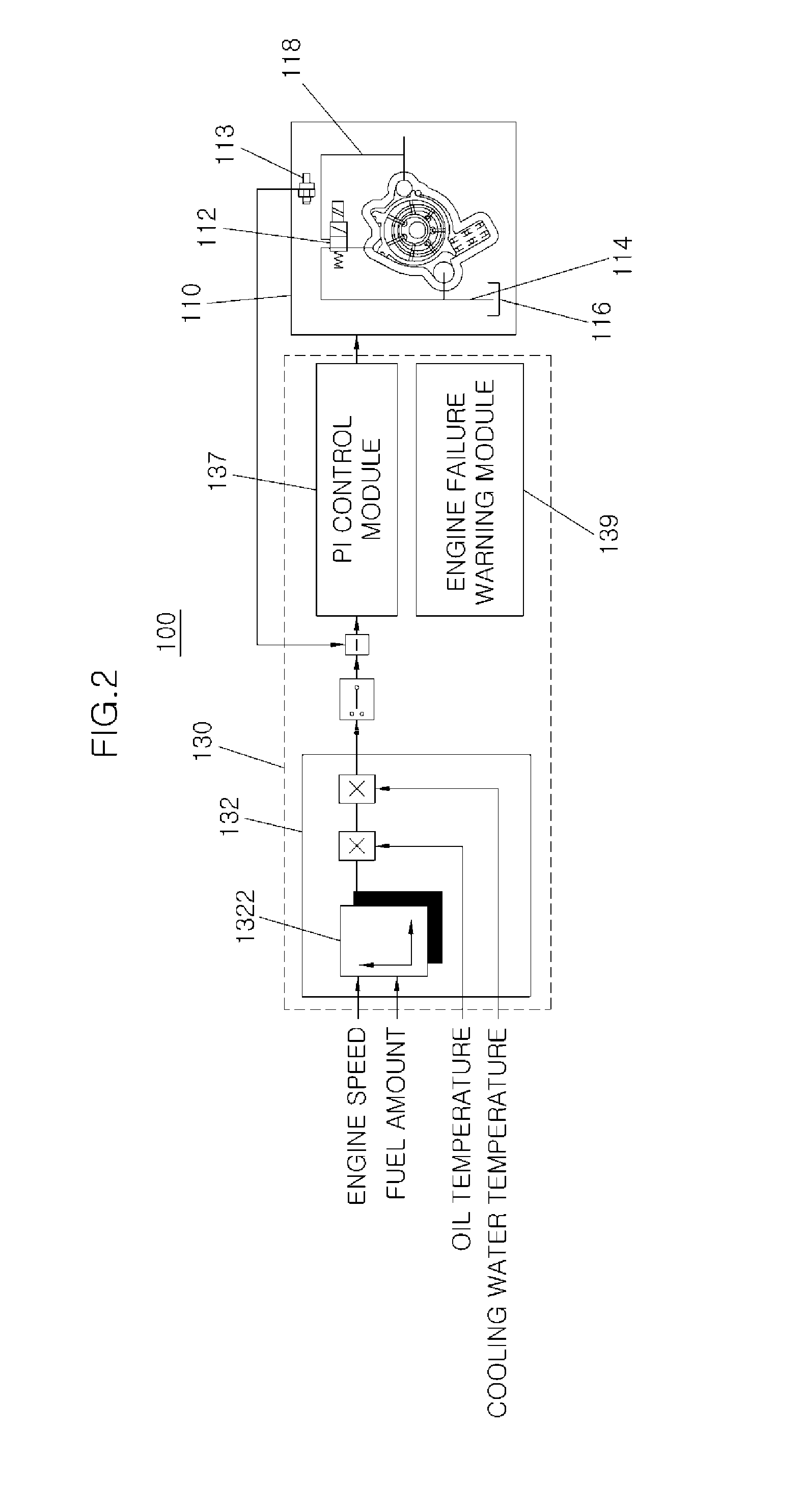

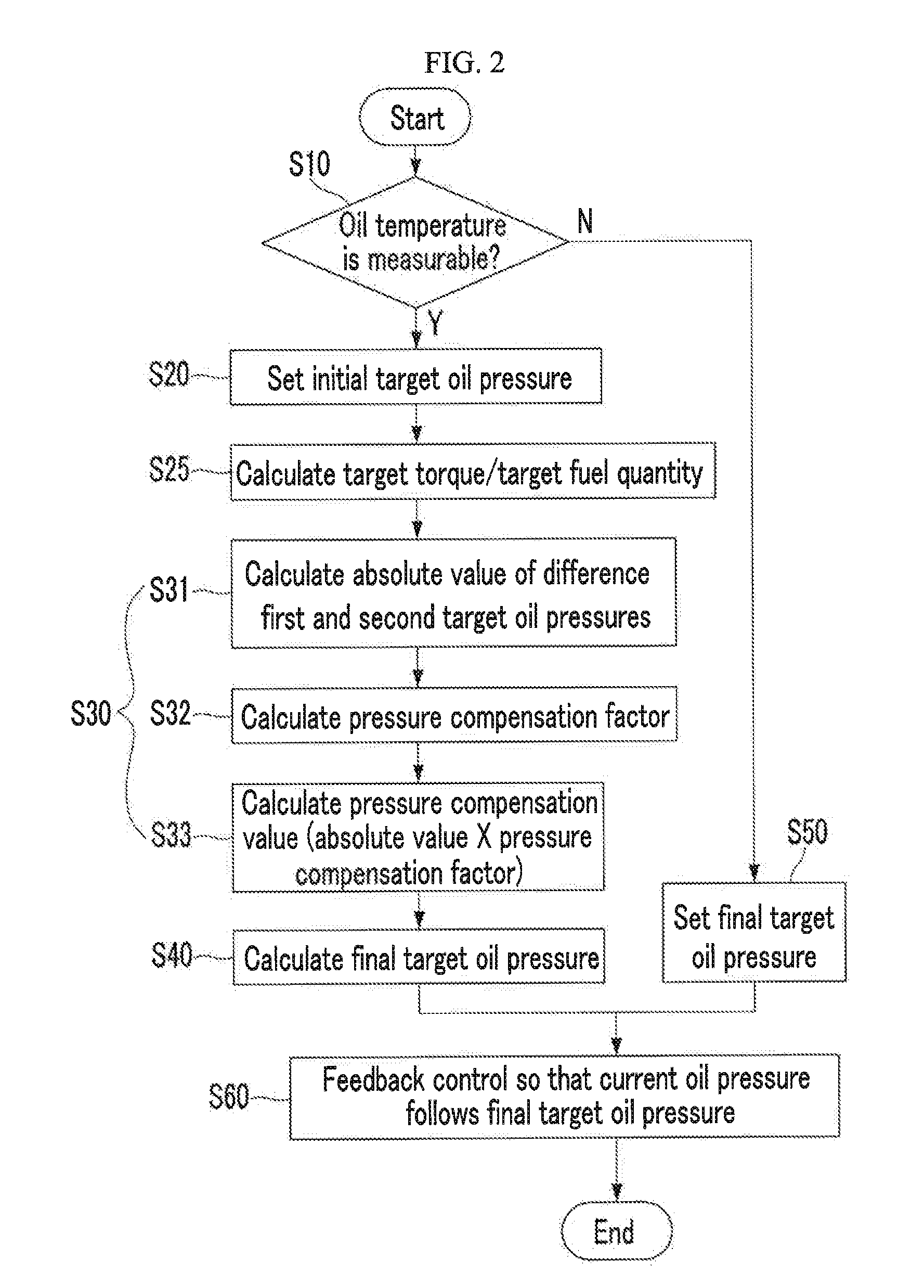

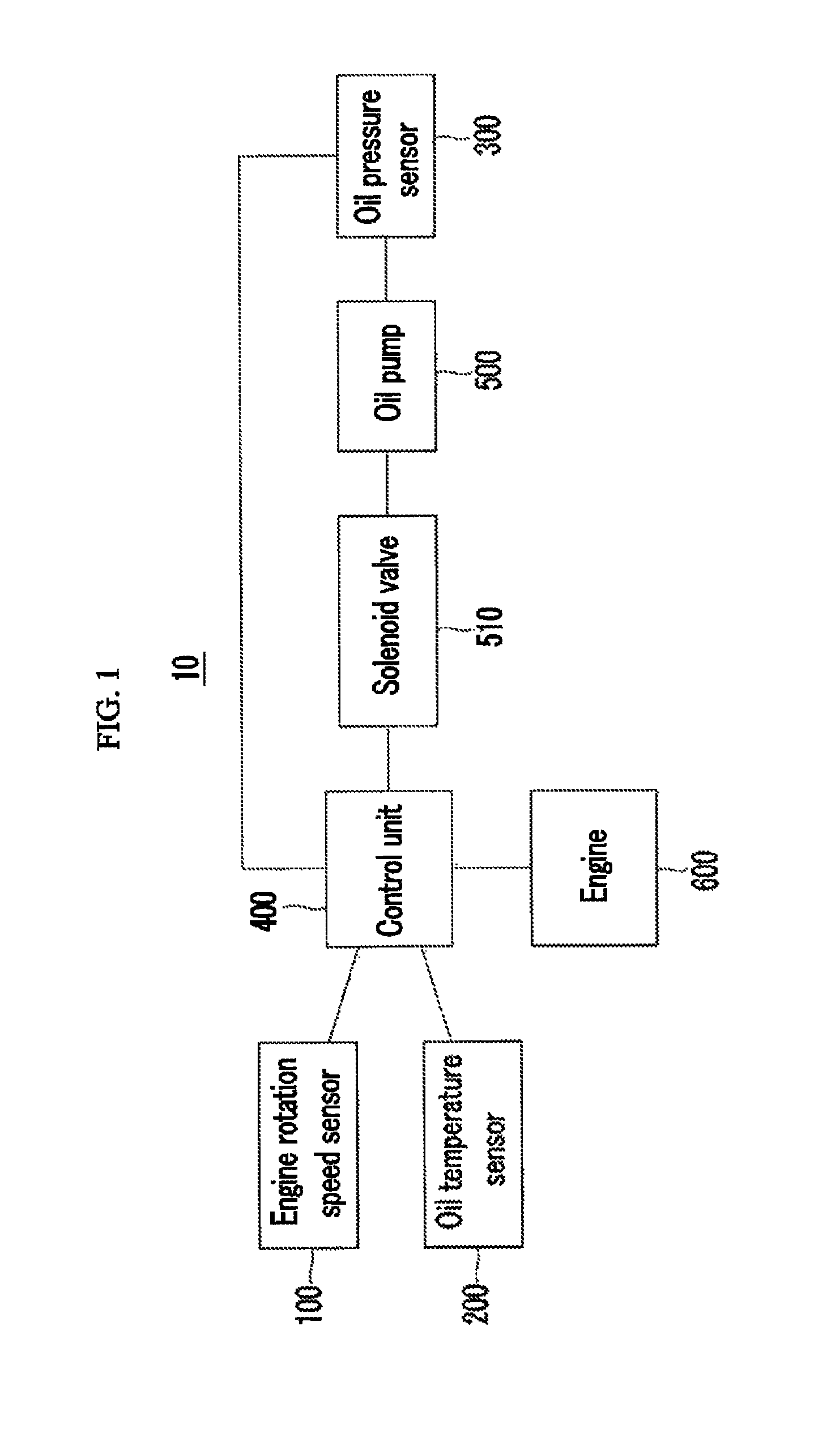

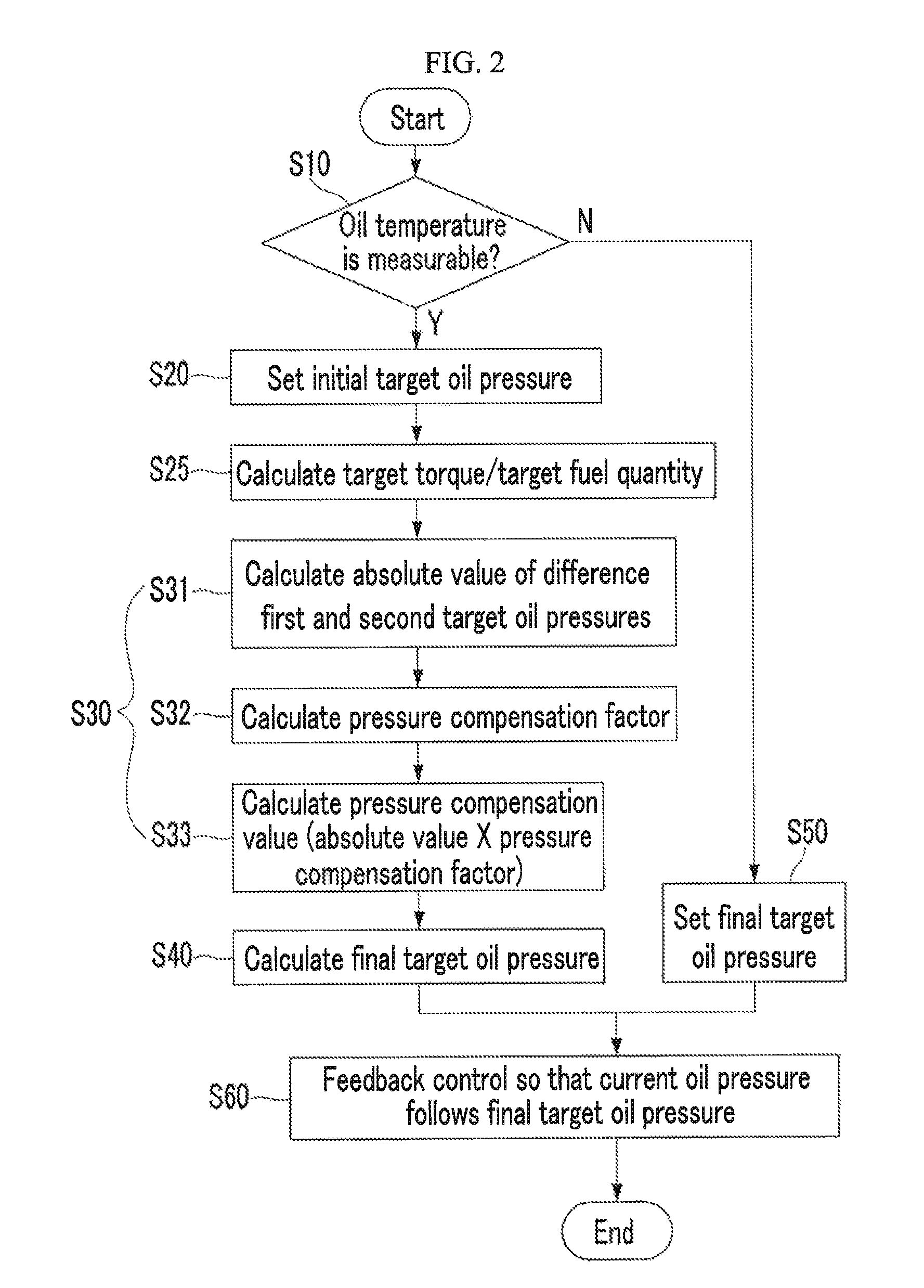

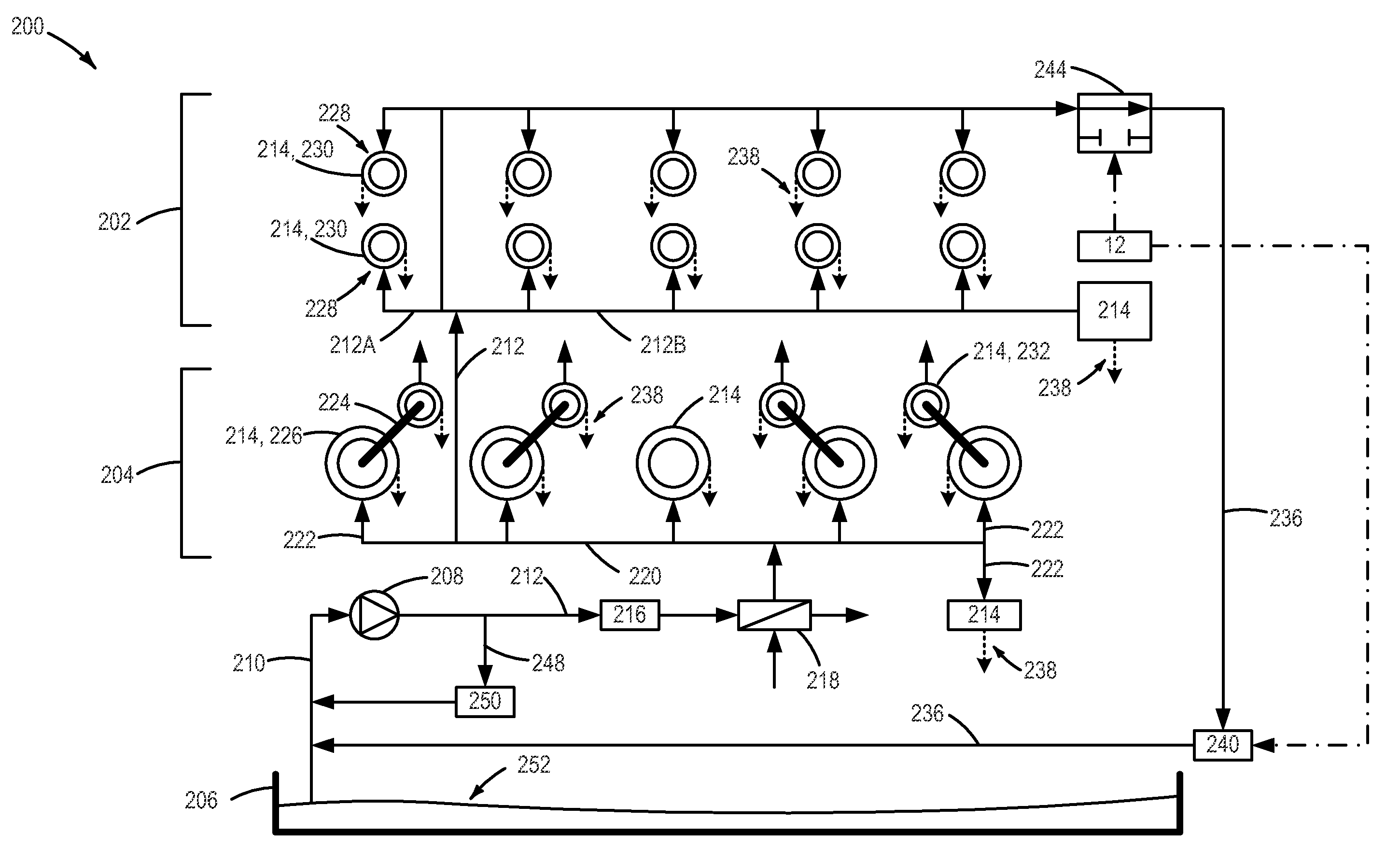

System and method for controlling oil pump

ActiveUS20140100739A1Improve fuel efficiencyReduce oil pressureDigital data processing detailsEngine revolutionsControl systemOil temperature

Disclosed are an oil pump control system and method, the oil pump control method including setting an initial target oil pressure of the oil pump based on a rotation speed of an engine or an oil temperature, determining a pressure compensation value by considering the target torque or target fuel quantity of the engine based on the initial target oil pressure, determining a final target oil pressure by adding the pressure compensation value to the initial target oil pressure, and feedback-controlling the oil pump so that current oil pressure measured in real time follows the final target oil pressure.

Owner:HYUNDAI MOTOR CO LTD +1

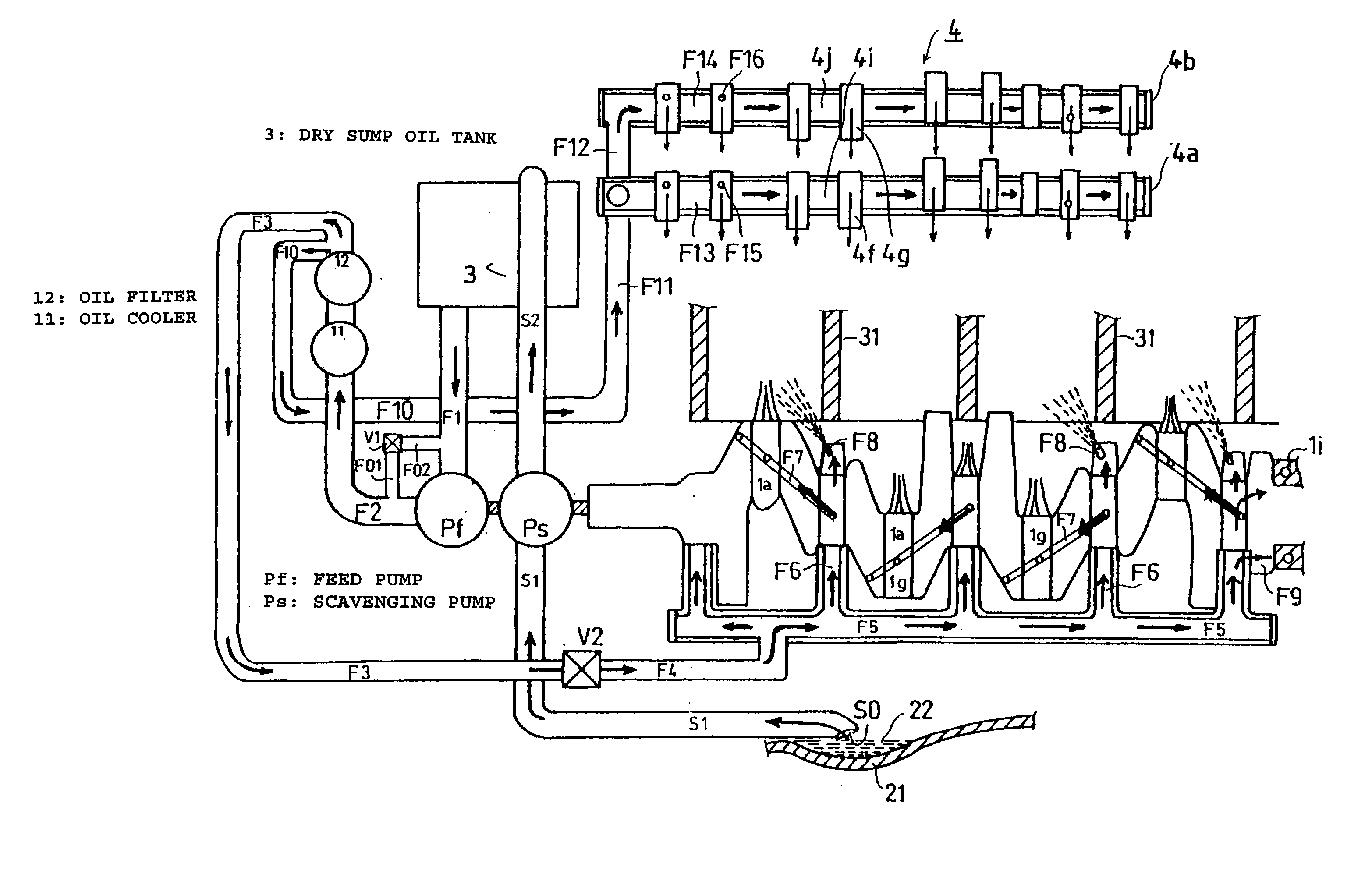

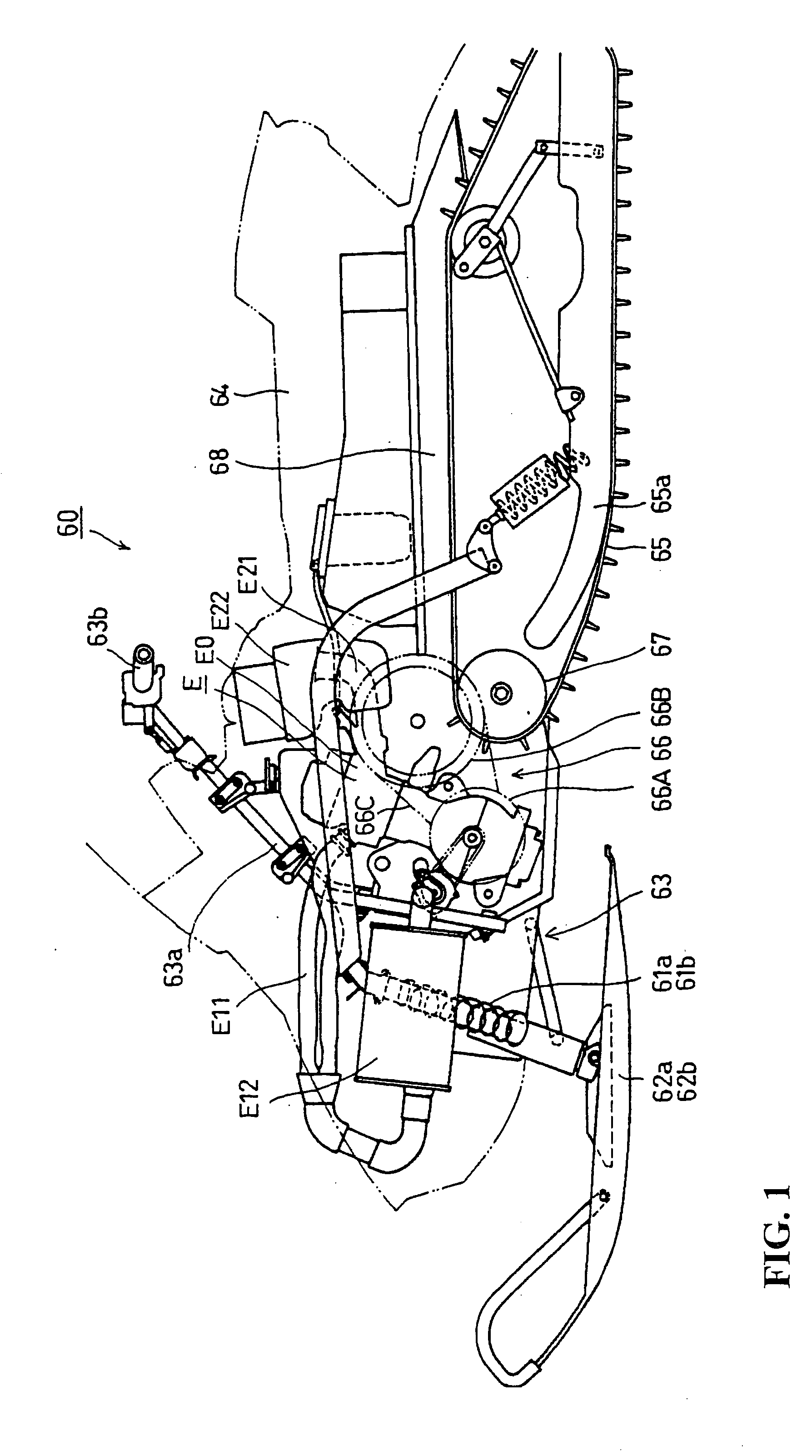

Valve train lubricating structure in internal combustion engine

InactiveUS20050199202A1Improved lubricating structure prevents a drop in pressure of the supply oilPositive and effective lubricationLubrication of auxillariesLubricant conduit arrangementsCrankpinValvetrain

To prevent a drop in a lubricating oil supply pressure in a valve train from occurring by disposing a lubricating oil supply path for the exclusive use of the valve train without allowing the lubricating oil to flow through an oil gallery, thereby securing a sufficient amount of supply of the lubricating oil in the valve train to enhance lubrication efficiency. A feed pump rotating with a crankshaft is disposed at a leftward end of the crankshaft. Lubricating oil supplied from the feed pump flows through an oil cooler and an oil filter. Part of the lubricating oil is supplied through a lubricating oil supply path to an oil gallery and to journals, crankpins, and the like of the crankshaft. The other part of the lubricating oil is supplied through lubricating oil supply paths for the exclusive use of the valve train.

Owner:HONDA MOTOR CO LTD

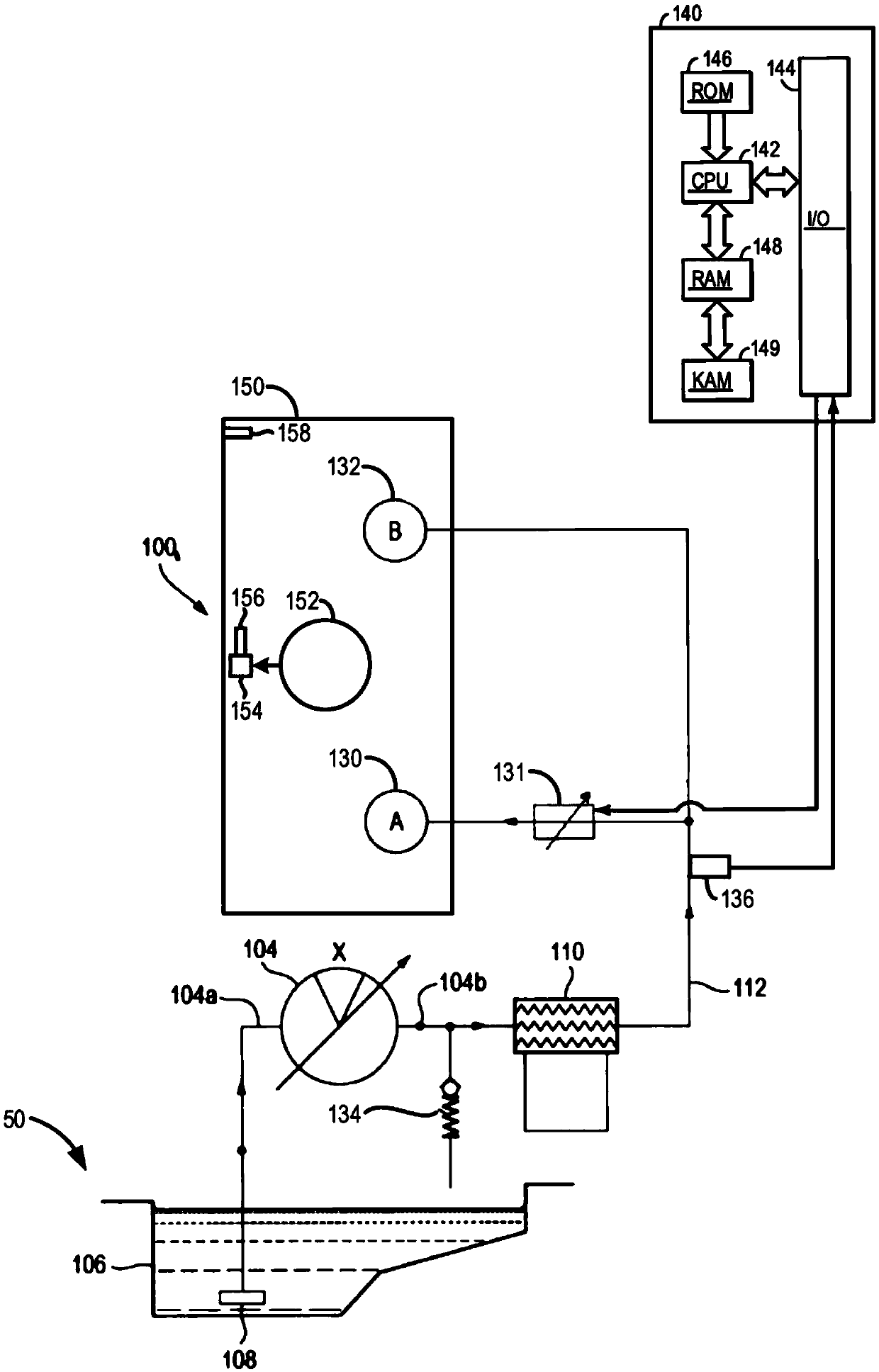

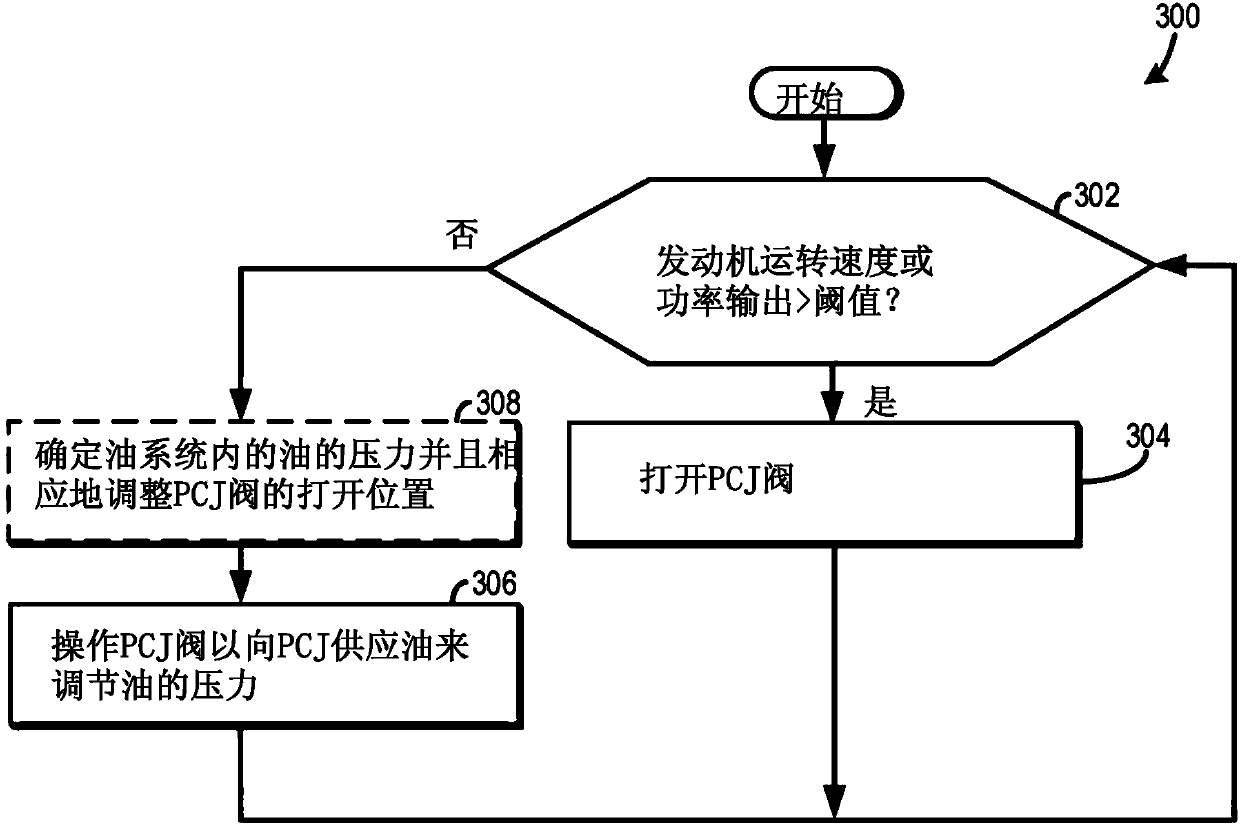

Method and apparatus to regulate oil pressure via controllable piston cooling jets

InactiveCN107781022AImprove efficiencyLow costLiquid coolingEngine pressureSpray nozzleControl valves

The invention relates to a method and apparatus to regulate oil pressure via controllable piston cooling jets. A method of regulating oil pressure within an engine assembly is provided. The engine assembly includes an oil pump configured to provide oil to an oil system of the engine assembly; a piston cooling jet configured to direct a jet of oil from the oil system towards a piston of an engine;and an electronic control valve configured to control the flow of oil to the piston cooling jet. The method includes operating the electronic control valve to provide a flow rate of oil above a threshold flow rate to the piston cooling jet when the engine assembly is operating above a threshold power output or engine running speed; and regulating the pressure of oil within the oil system when theengine assembly is operating below the threshold power output or engine running speed, by operating the electronic control valve.

Owner:FORD GLOBAL TECH LLC

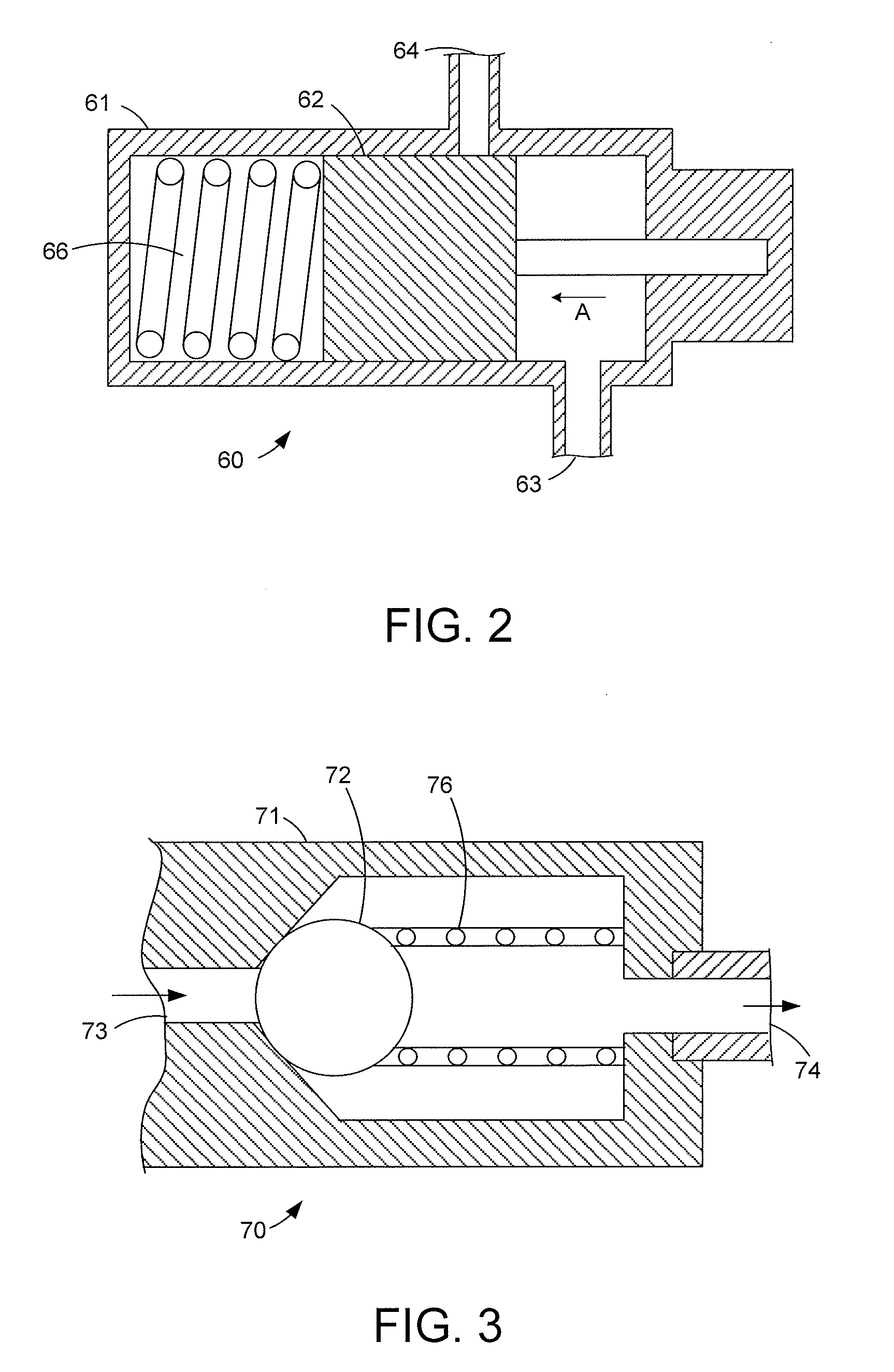

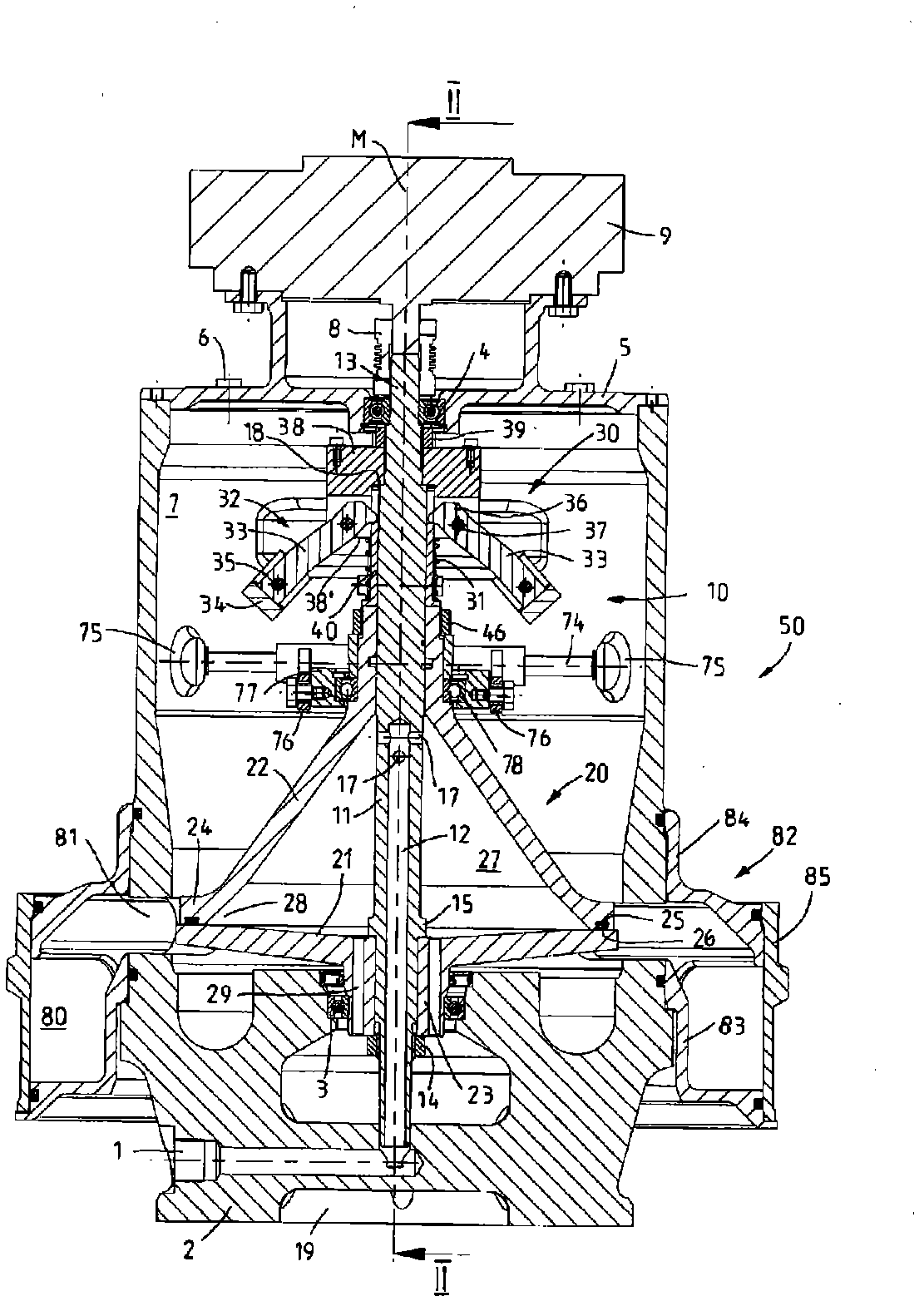

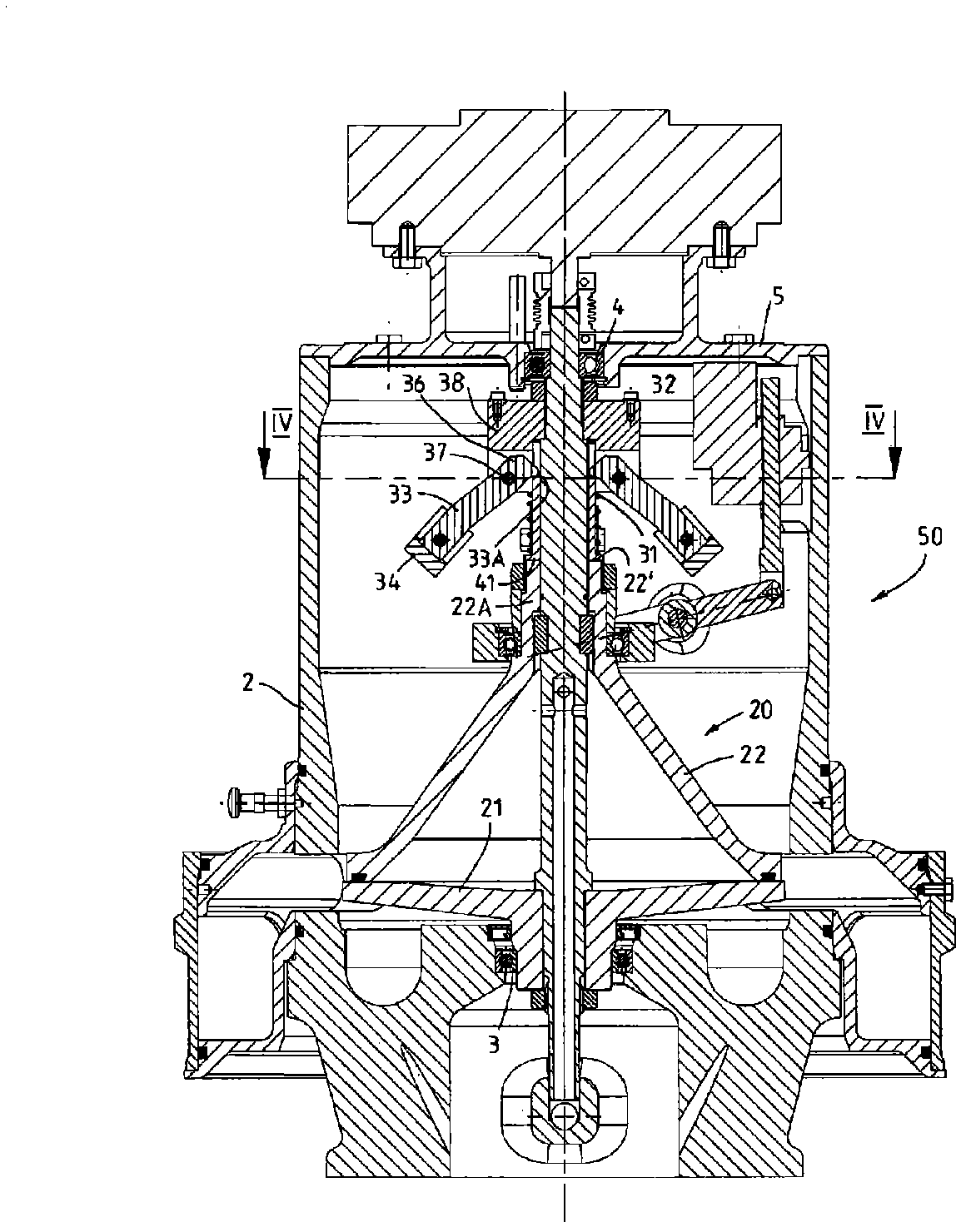

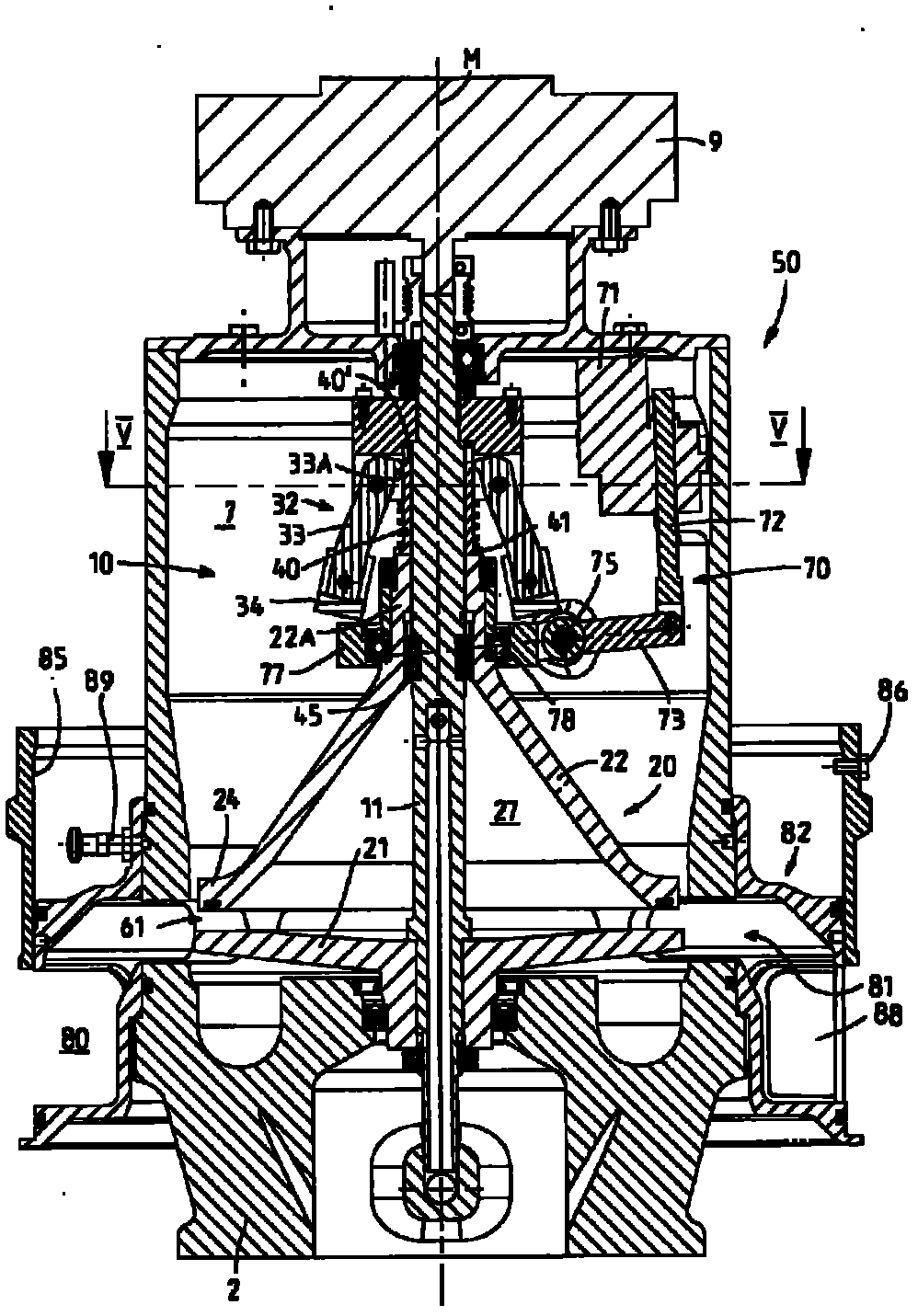

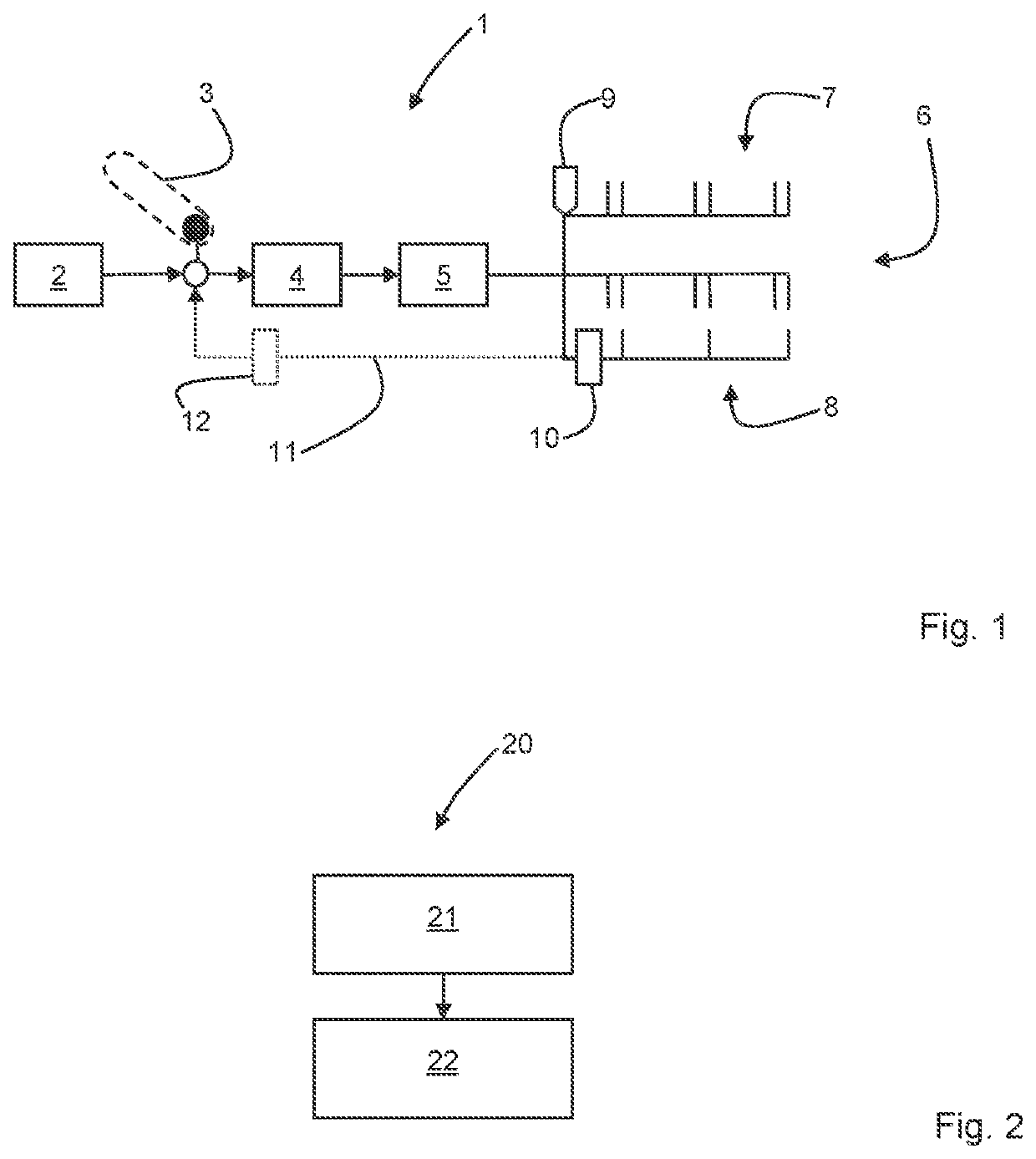

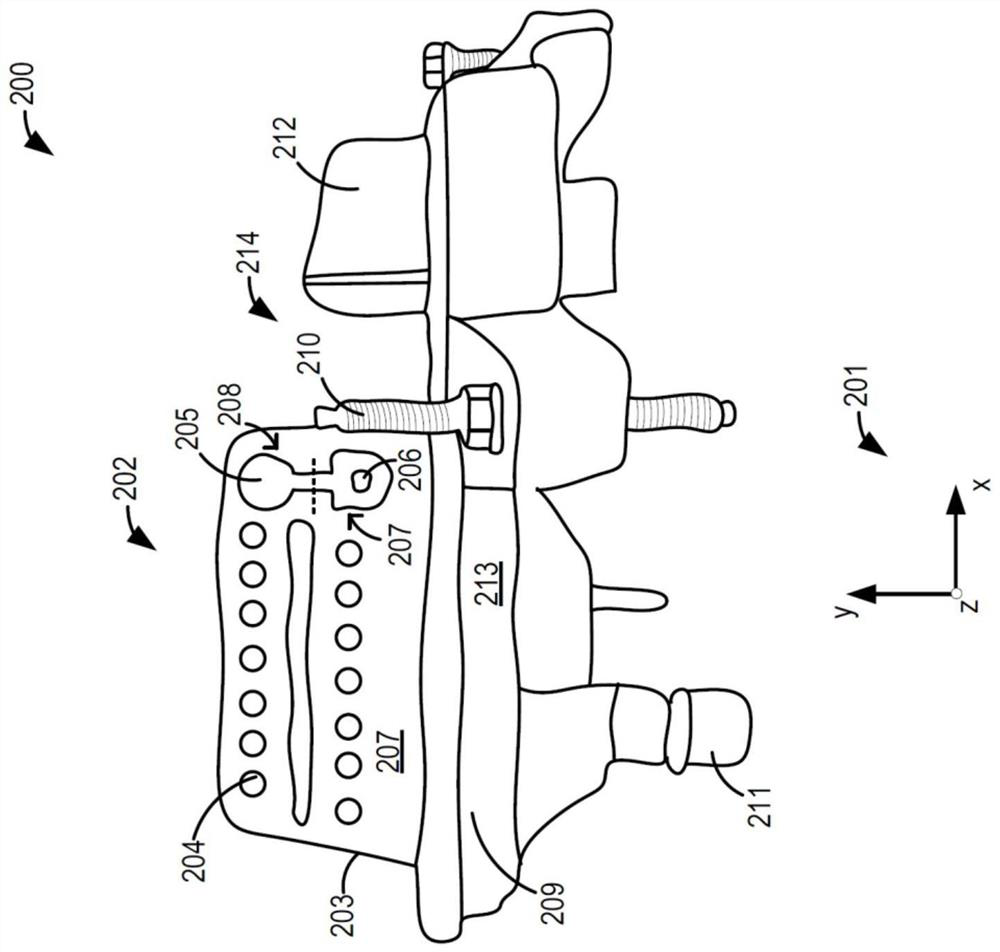

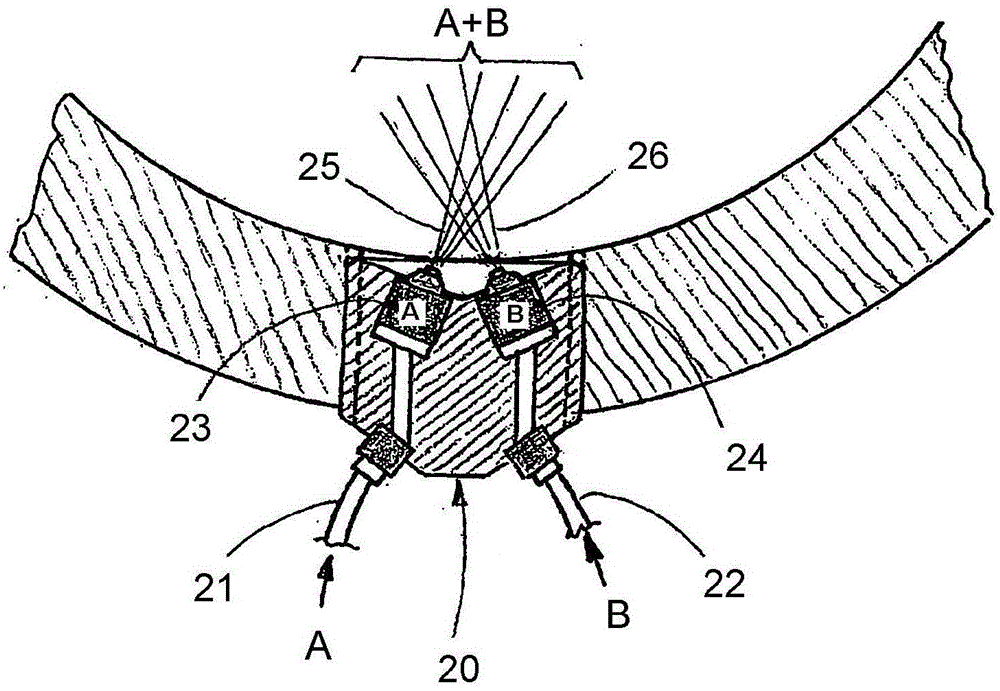

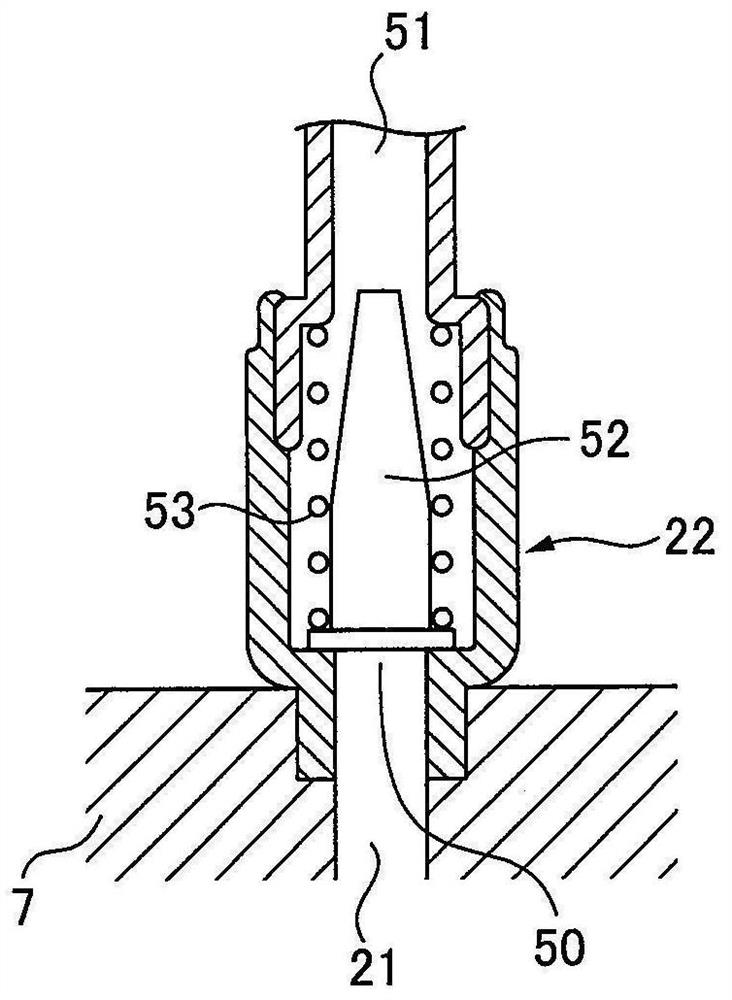

Centrifuge and centrifuge rotor for the same

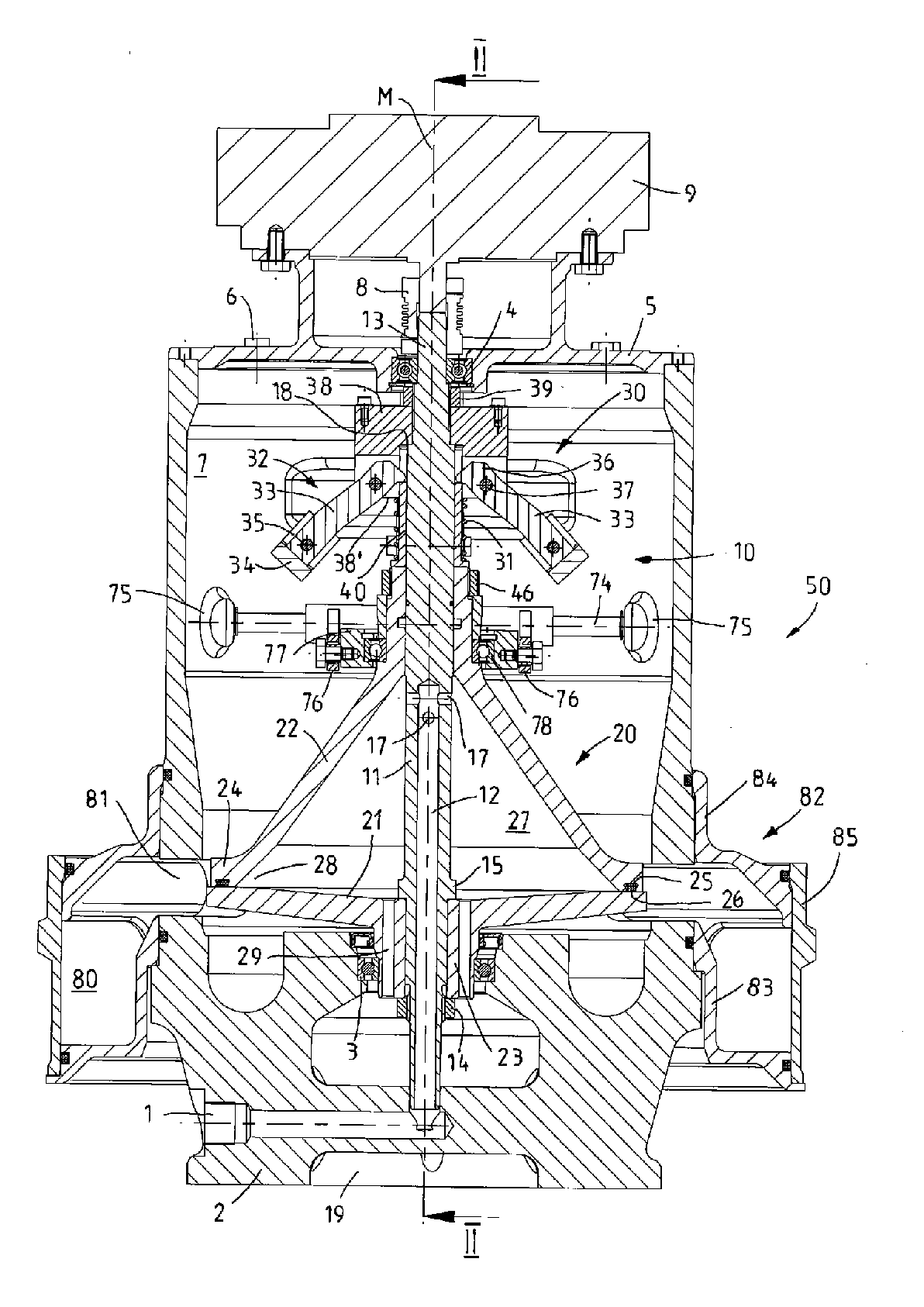

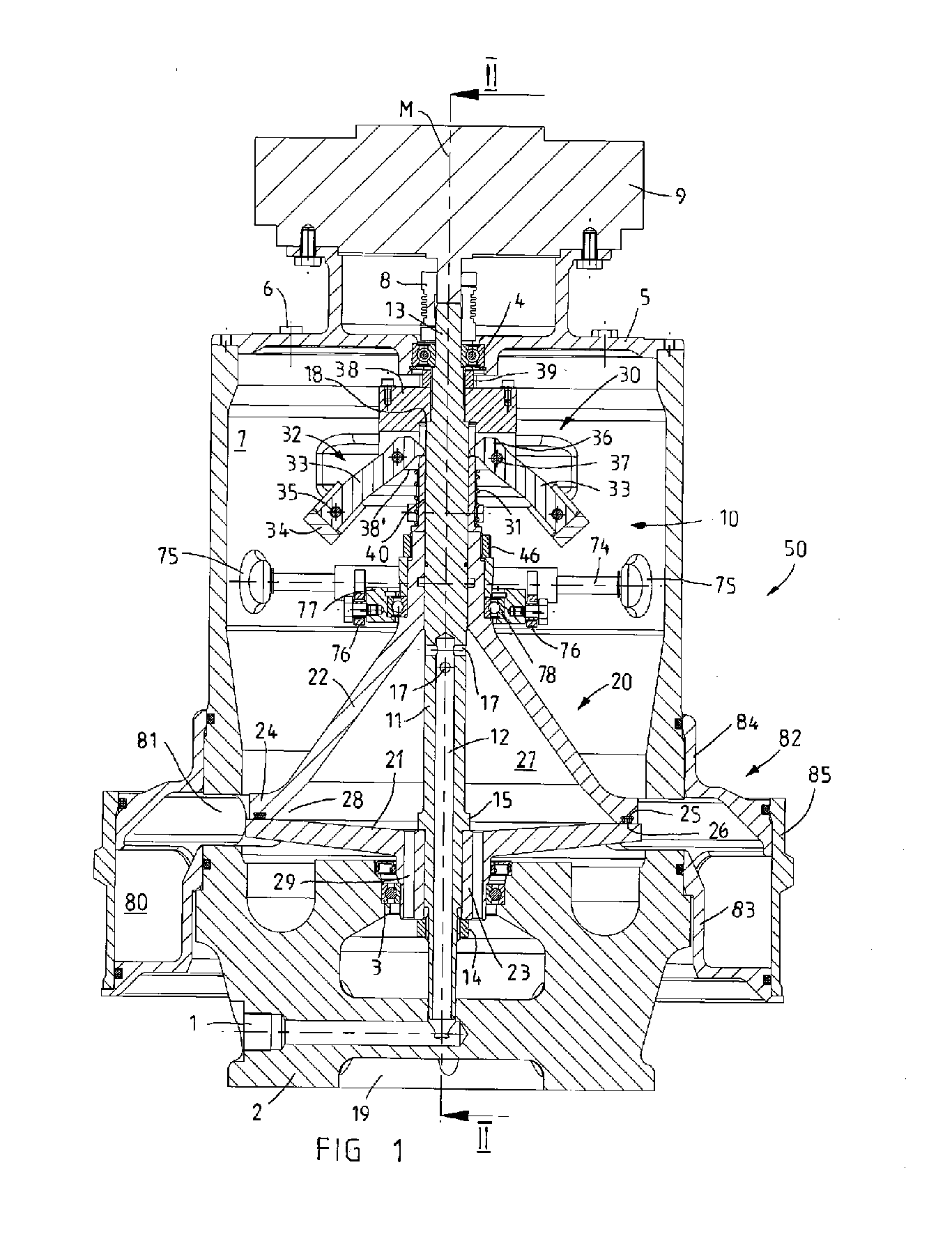

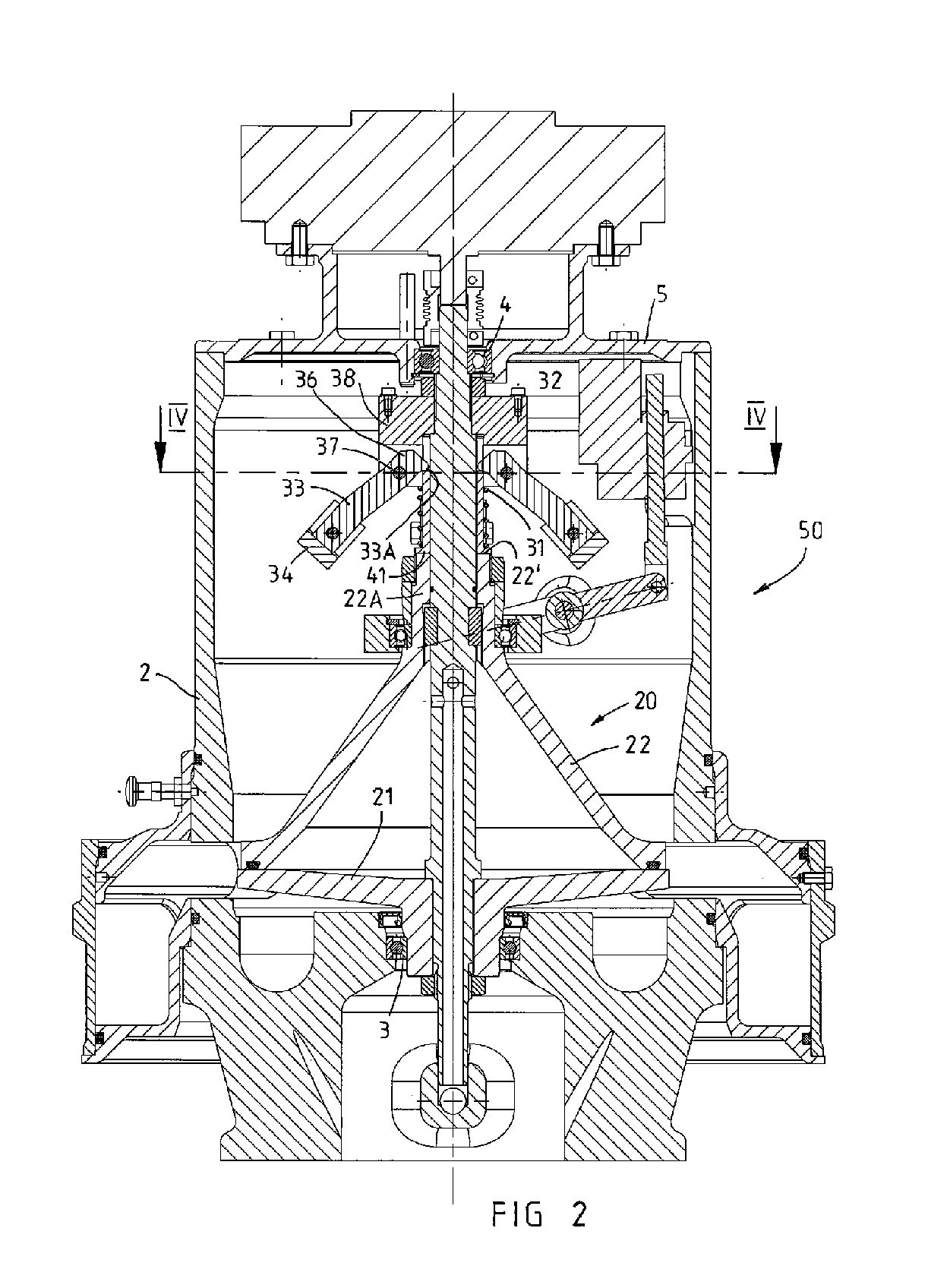

The invention relates to a centrifuge for separating solids from a liquid, comprising a centrifuge rotor 10 with a rotor shaft 11, partially formed as a hollow shaft, and a centrifuging drum 20, being rotatable with the rotor shaft, wherein the liquid to be separated can be supplied via the cavity of the hollow shaft. To ease emptying of the drum, the centrifuging drum 20 comprises a drum lower part 21 and a drum upper part 22, which bears loosely against said drum lower part 21. The upper part 22 is guided in an axially movable manner on the shaft 11 and is movable by means of a disengagement mechanism 70 parallel to the rotor axis into an open position in which, for self-emptying of the interior space 27, the drum parts 21, 22 are spaced apart from one another while they still rotate with the rotor shaft 11.

Owner:BOLL & KIRCH FILTERBAU GMBH

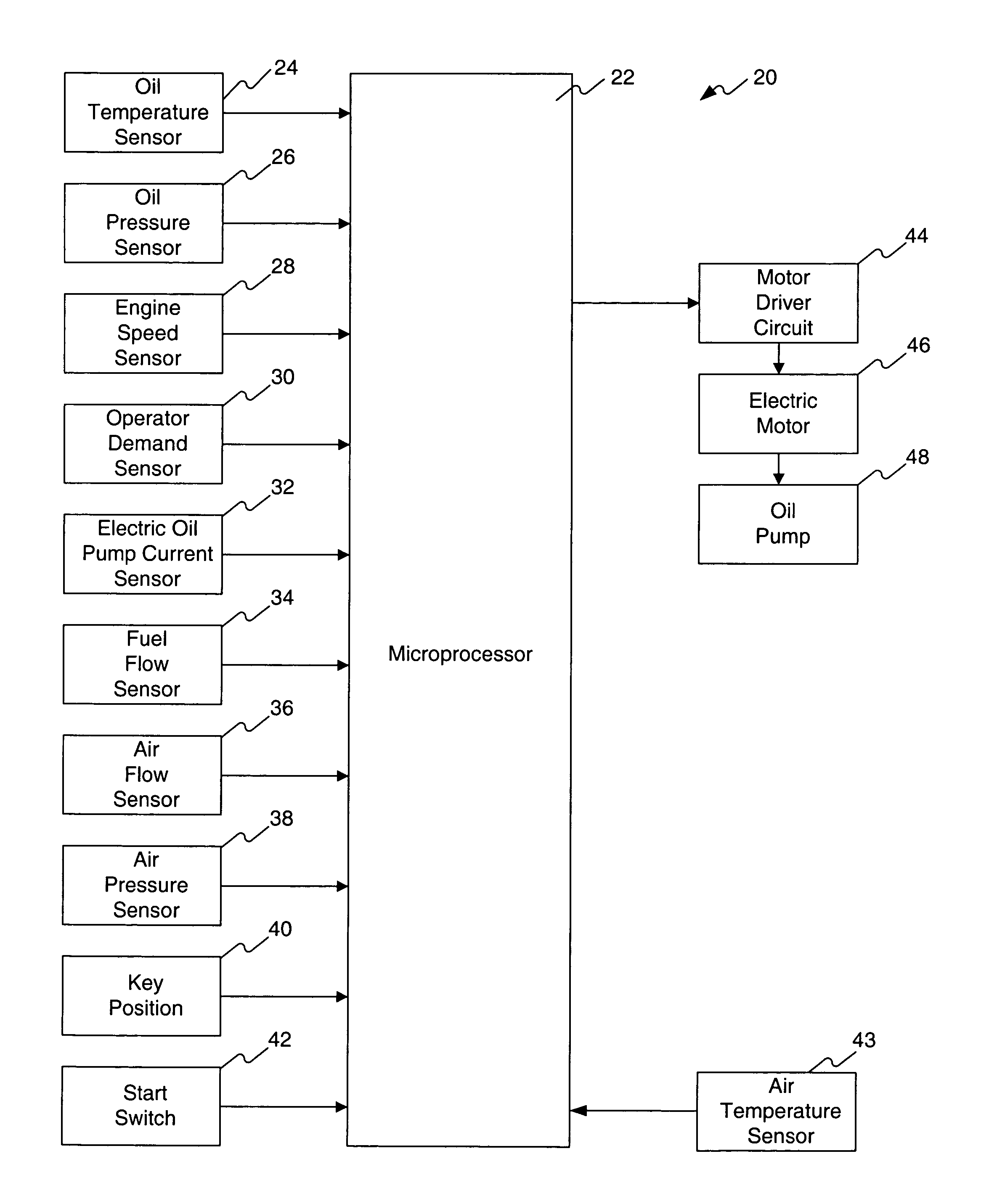

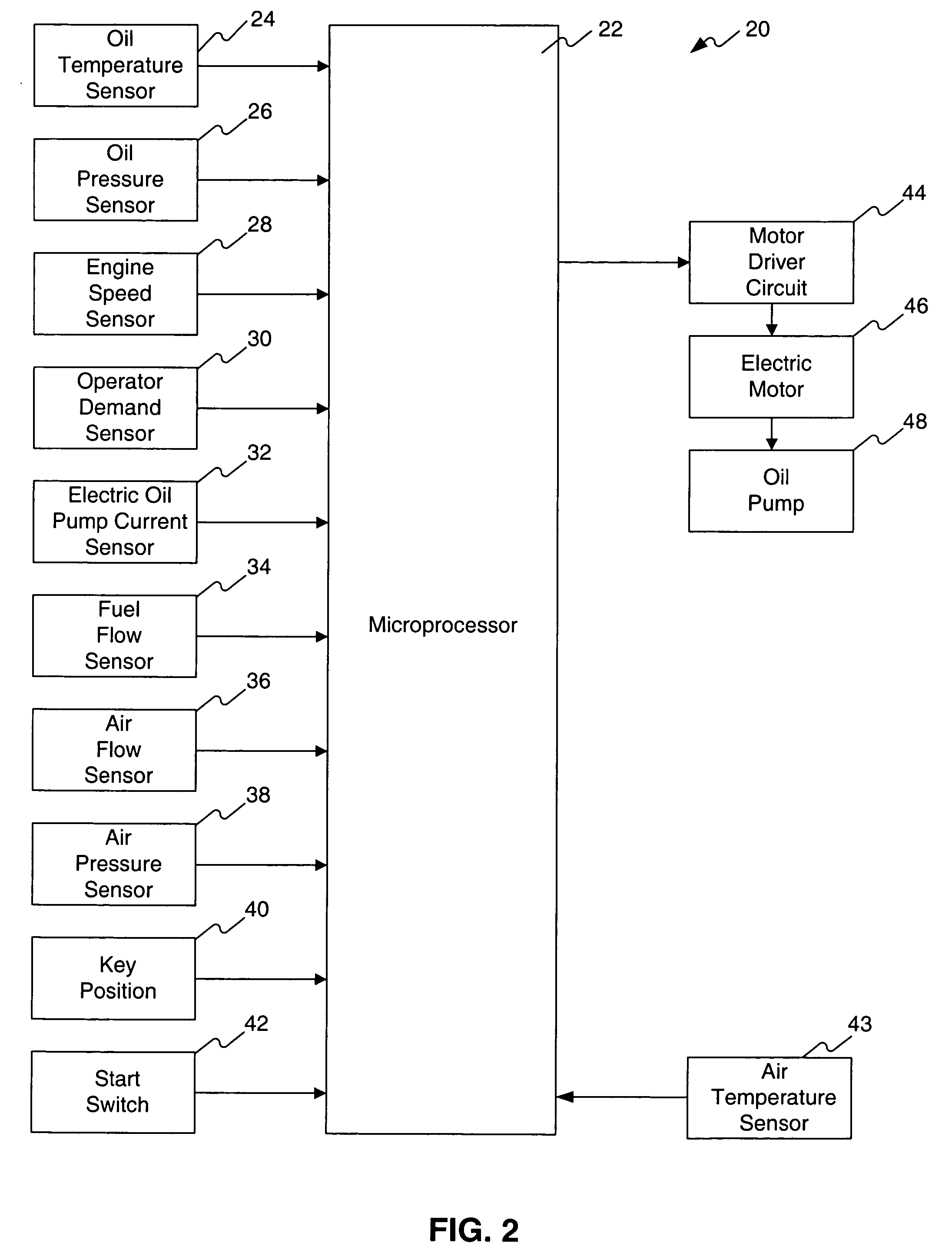

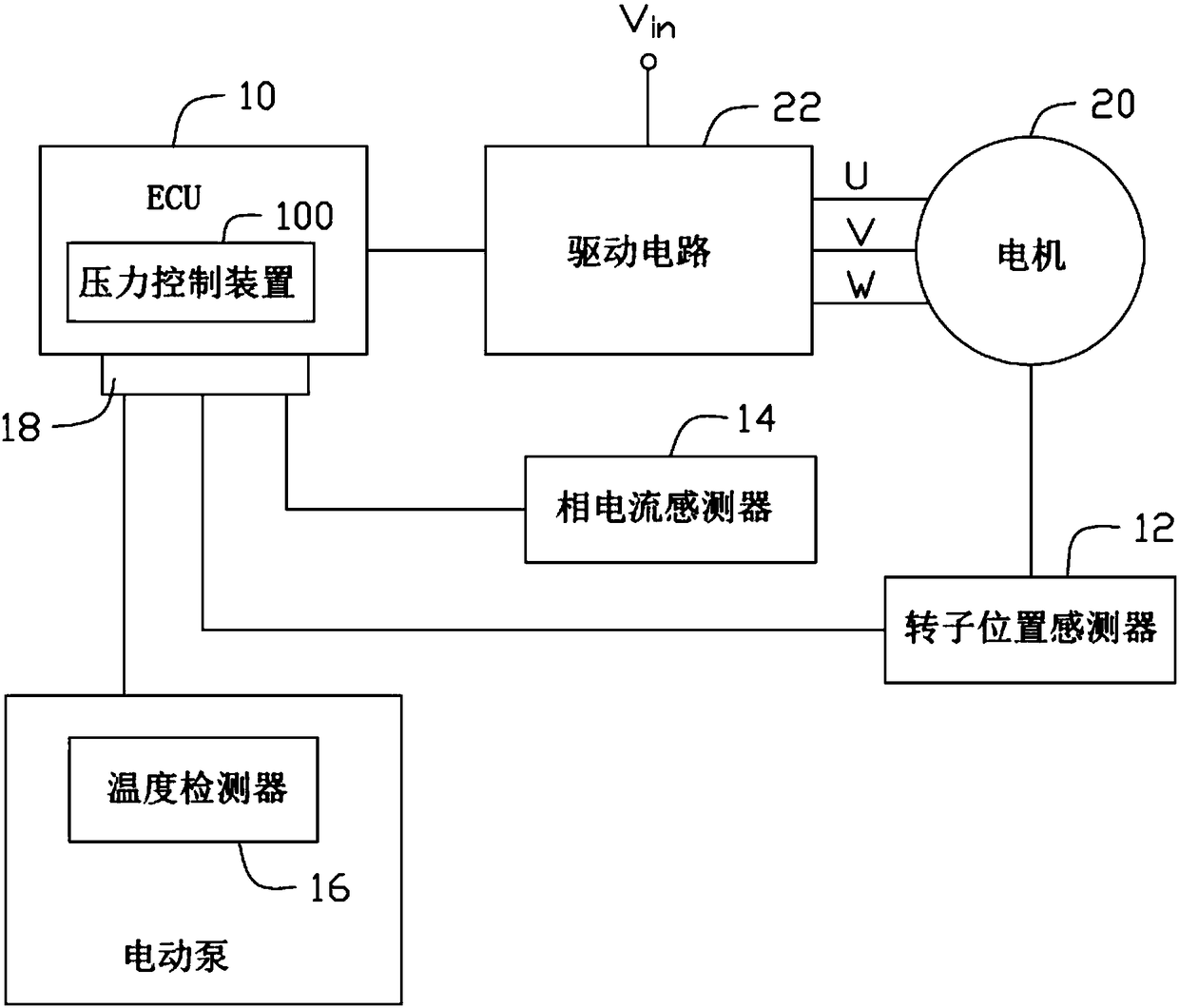

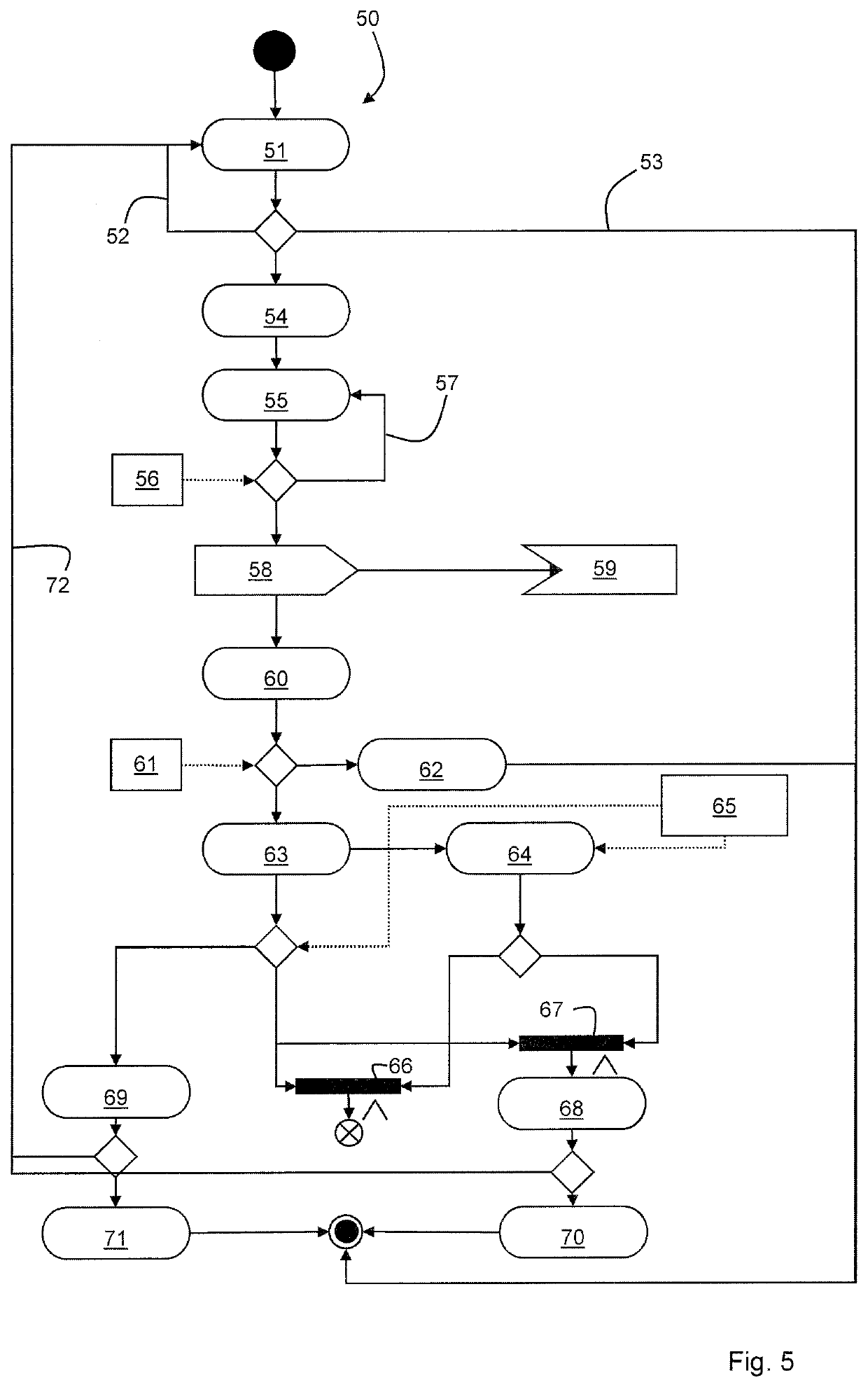

Pressure control device, system and method

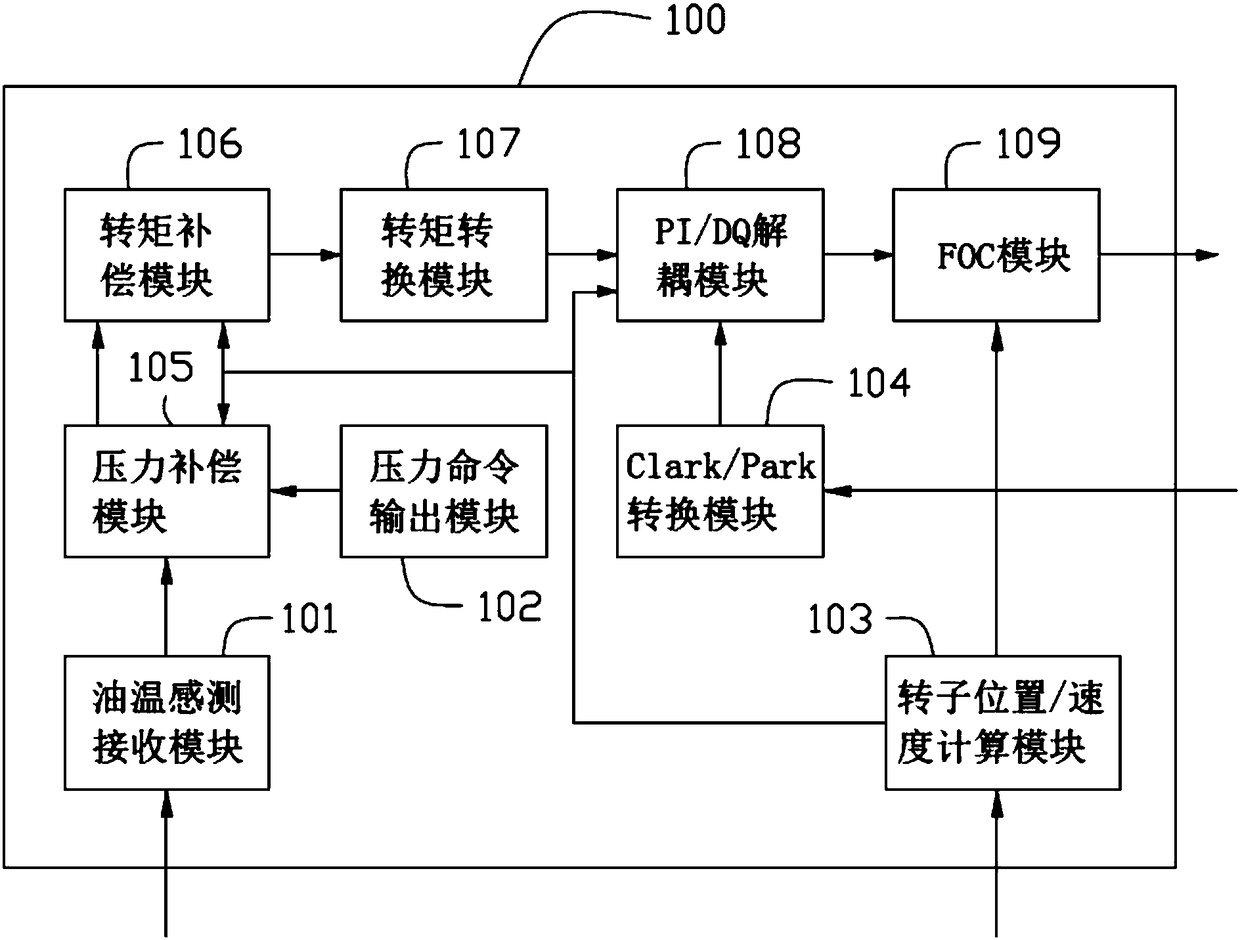

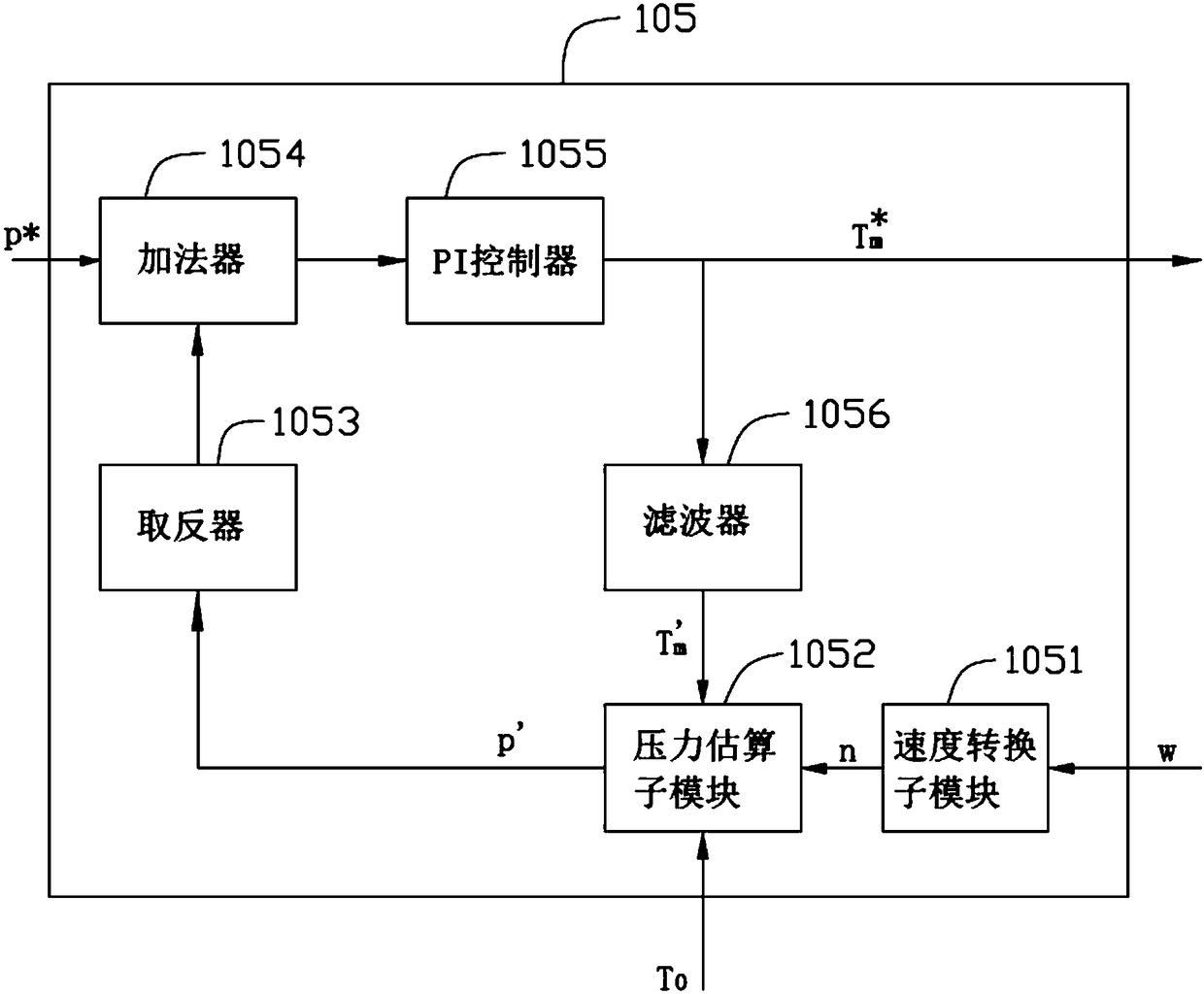

ActiveCN108336938AHigh precisionShort response timeHybrid vehiclesVector control systemsDriver circuitControl theory

The application provides a pressure control device, system and method for controlling an output oil pressure of an electric pump. The system is composed a motor, an oil pump driven by the motor, a motor driver circuit connected with the motor, and a pressure control device. The pressure control device is configured to output a target value of the oil pressure based on the oil pump, an obtained estimated motor electromagnetic torque corresponding to the target value, and an actual detection current flowing through the motor and determine an electrification voltage of the motor; and power is provided for the motor based on the electrification voltage by the motor driver circuit.

Owner:JOHNSON ELECTRIC SHENZHEN

Cooling device for engine

Disclosed is an oil jet device for cooling a piston, including: an oil cooler 4 that is disposed upstream of an oil injection nozzle 8; an oil pump 5 that is disposed upstream of the oil cooler 4; a first switching adjustment valve 6 that is disposed between the oil injection nozzle 8 and the oil cooler 4 and adjusts a flow dividing ratio at which the cooling oil from the oil cooler 4 is distributed to the oil injection nozzle 8 side and to an oil pan side; and a control unit that has an oil quantity adjustment map 4 for switching the first switching adjustment valve 6 based on a piston temperature calculation map 20 for calculating the temperature of the piston 1 using detection values acquired respectively by a cooling water temperature sensor 35, a rotation speed sensor 36 and a load sensor 37.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

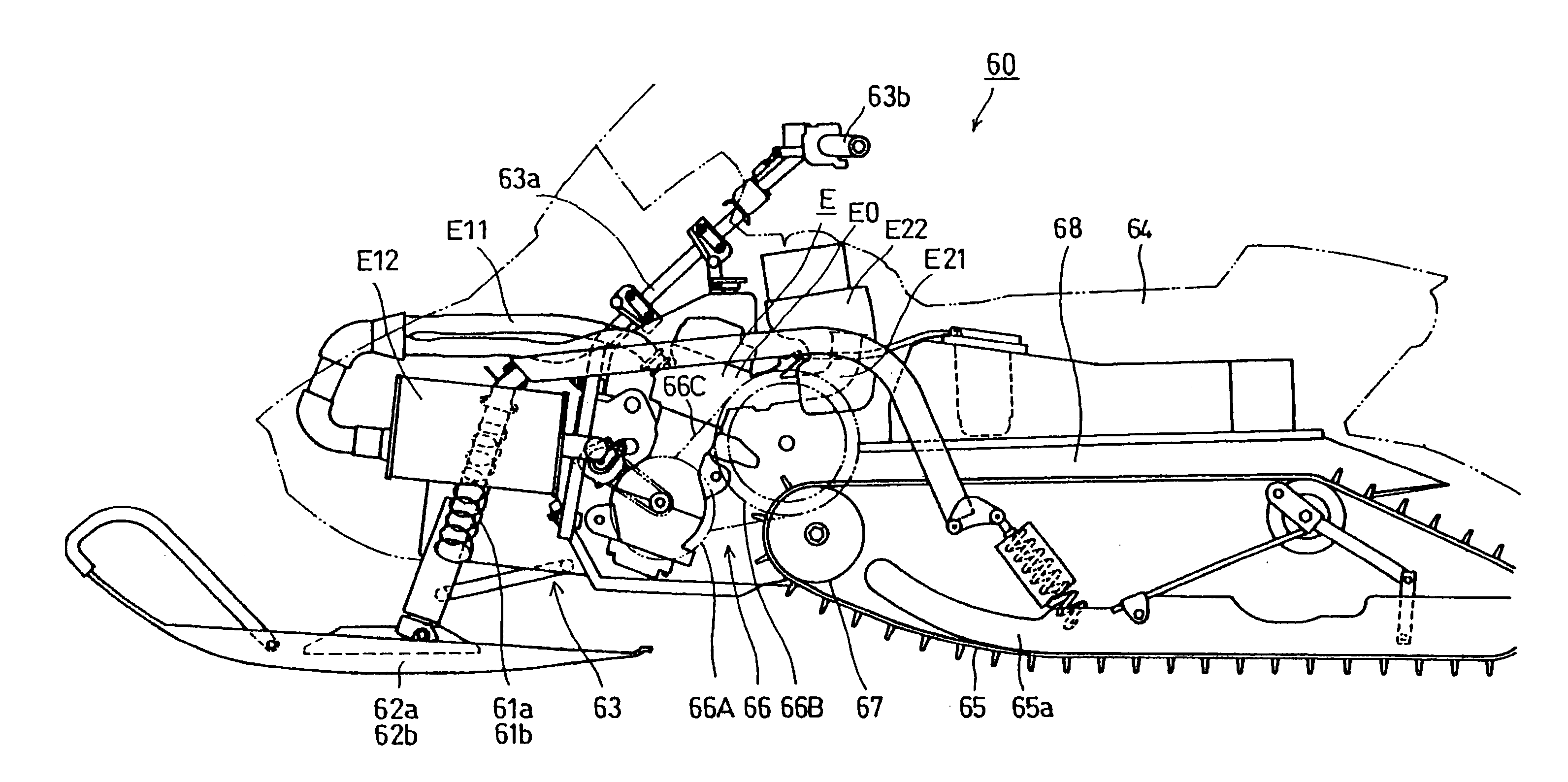

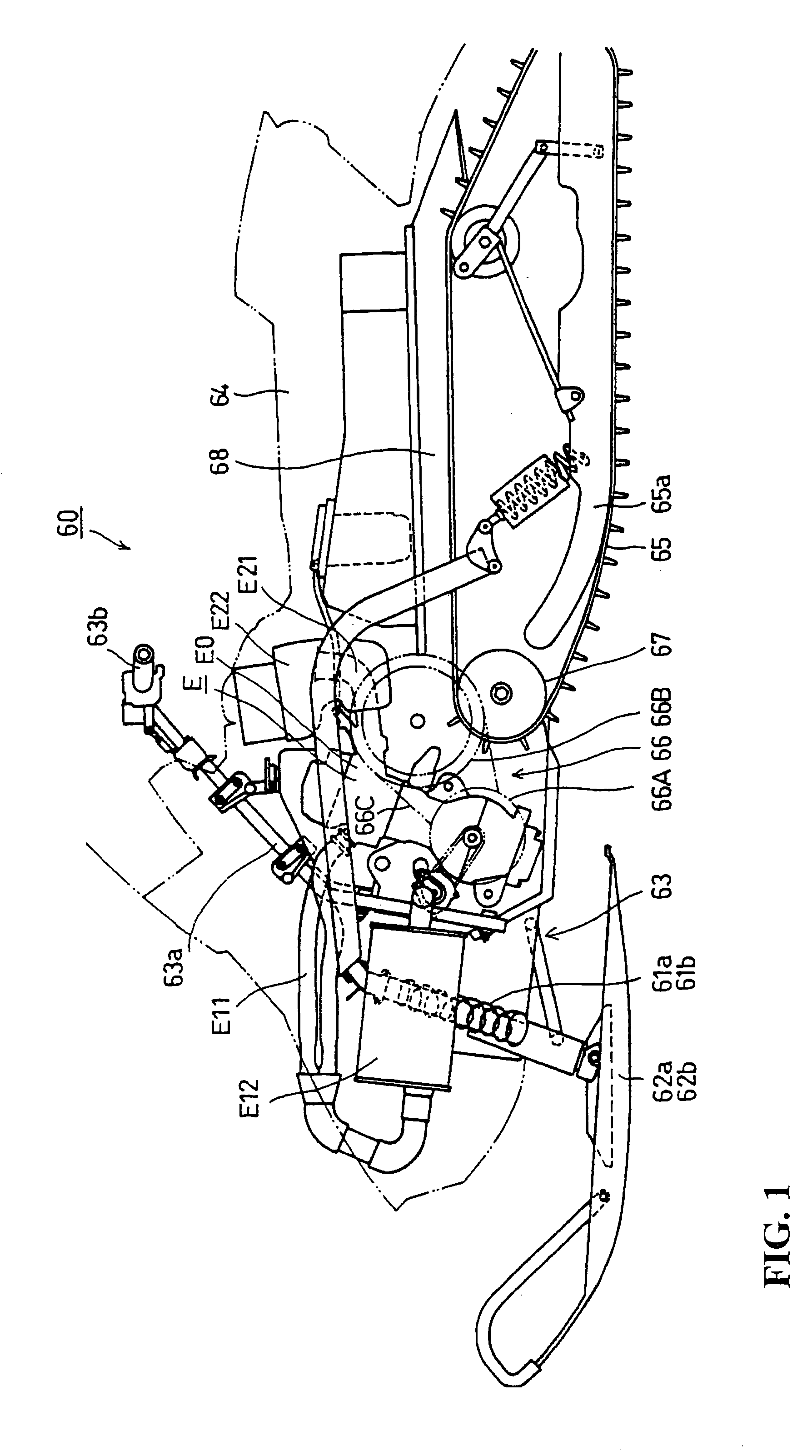

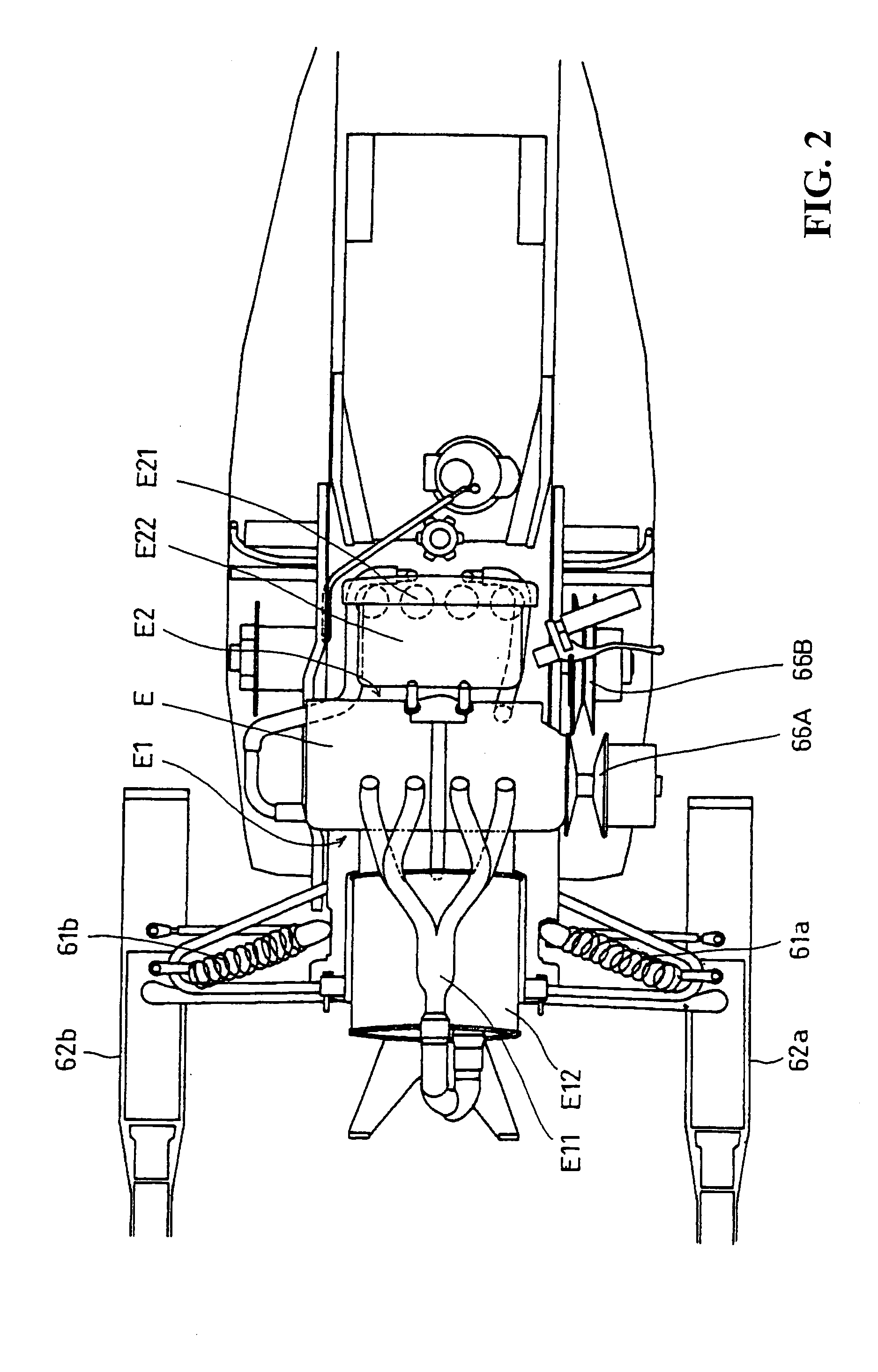

Valve train lubricating structure in internal combustion engine

InactiveUS7290514B2Improved lubricating structure prevents a drop in pressure of the supply oilPositive and effective lubricationLubrication of auxillariesPropulsion power plantsExternal combustion engineCrankpin

To prevent a drop in a lubricating oil supply pressure in a valve train from occurring by disposing a lubricating oil supply path for the exclusive use of the valve train without allowing the lubricating oil to flow through an oil gallery, thereby securing a sufficient amount of supply of the lubricating oil in the valve train to enhance lubrication efficiency. A feed pump rotating with a crankshaft is disposed at a leftward end of the crankshaft. Lubricating oil supplied from the feed pump flows through an oil cooler and an oil filter. Part of the lubricating oil is supplied through a lubricating oil supply path to an oil gallery and to journals, crankpins, and the like of the crankshaft. The other part of the lubricating oil is supplied through lubricating oil supply paths for the exclusive use of the valve train.

Owner:HONDA MOTOR CO LTD

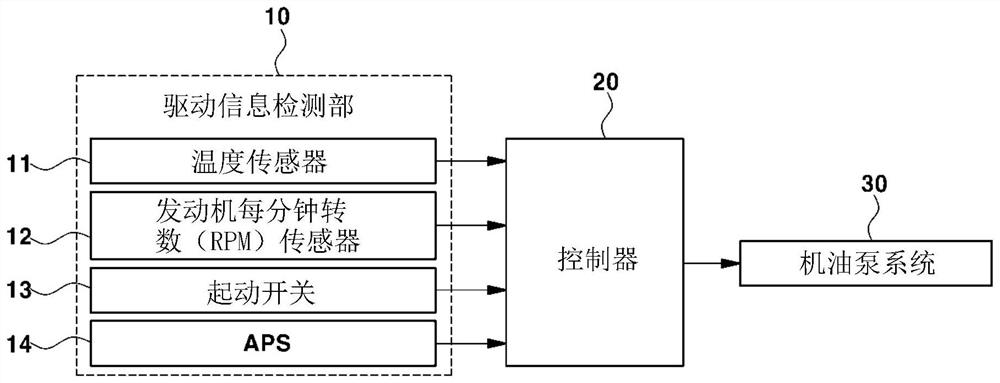

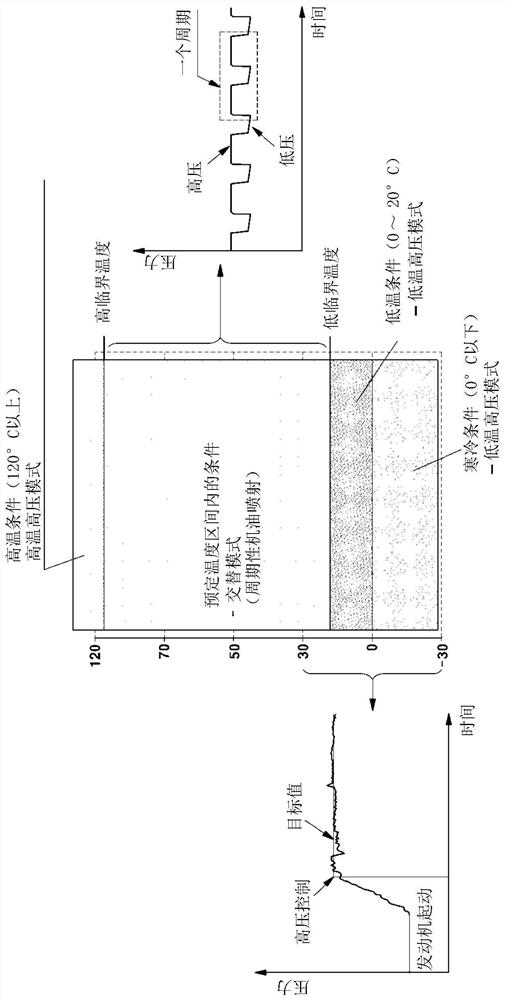

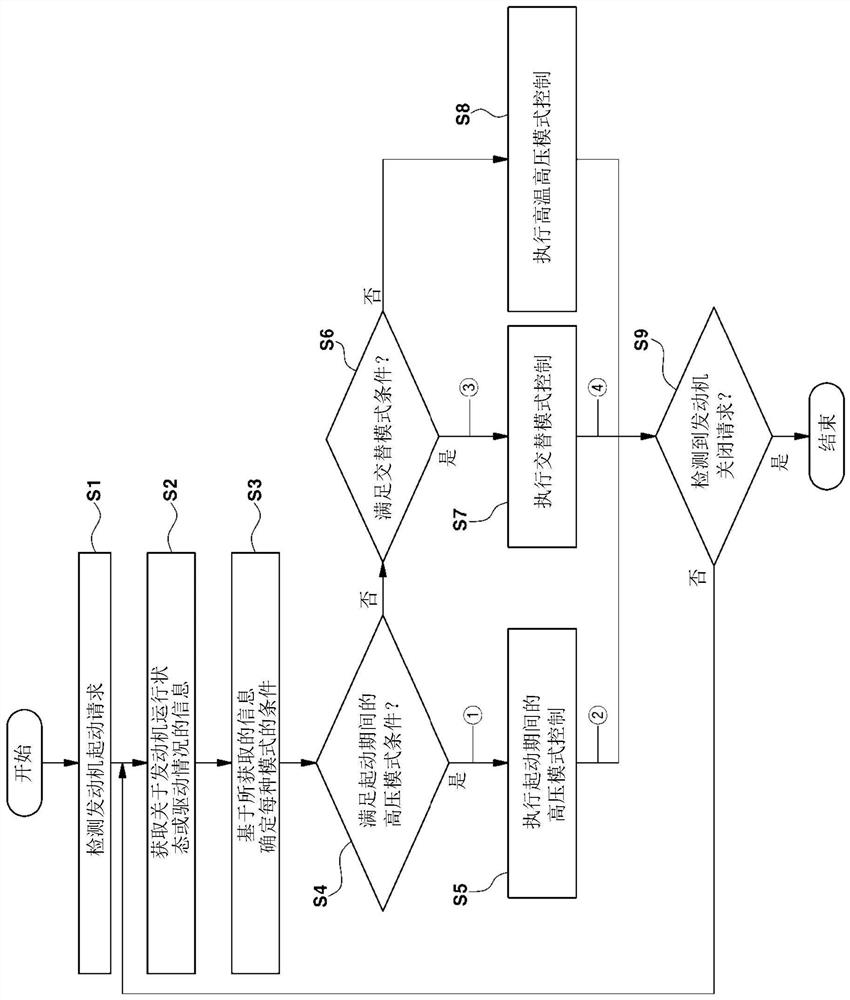

Method of controlling oil pump of vehicle

PendingCN112502808ASolve the problem of poor lubricationLiquid coolingElectrical controlControl engineeringControl theory

The invention relates to a method of controlling an oil pump of a vehicle. The method includes: acquiring, by a controller, information on an engine operating state or a driving condition detected bya driving information detection part; determining, by the controller, whether a predetermined condition of an alternate mode is satisfied on the basis of the acquired information on the engine operating state or the driving condition; and, when the condition of the alternate mode is satisfied, sequentially performing, by the controller, a high-pressure operation control that controls an operationof an oil pump system so as to an oil pressure of an engine to converge on a predetermined target high-pressure value and a low-pressure operation control that controls the oil pressure of the engineto converge on a predetermined target low-pressure value.

Owner:HYUNDAI MOTOR CO LTD +1

Oil supply system for an engine

An oil supply system for a reciprocating piston internal combustion engine is disclosed in which the supply of oil to piston cooling jets is controlled by pressure operated valves designed to open at a pre-defined valve opening pressure. The pressure of oil supplied by a pump is controlled to be below this pre-defined valve opening pressure during operation of the engine in which piston cooling is not required, and the pressure of oil is controlled to above the pre-defined valve opening pressure when piston cooling is required. The control of the pump is by an electronic control unit based upon a combination of engine speed and engine load.

Owner:FORD GLOBAL TECH LLC

Centrifuge and centrifuge rotor for the same

ActiveUS20110183830A1Simple wayReduce loadRotary centrifugesEngine revolutionsCentrifuge rotorInterior space

A centrifuge for separating solids from a liquid including a centrifuge rotor with a rotor shaft, partially formed as a hollow shaft, and a centrifuging drum, being rotatable with the rotor shaft, wherein the liquid to be separated can be supplied via the cavity of the hollow shaft. To ease emptying of the drum, the centrifuging drum includes a drum lower part and a drum upper part, which bears loosely against the drum lower part. The upper part is guided in an axially movable manner on the shaft and is movable by means of a disengagement mechanism parallel to the rotor axis into an open position in which, for self-emptying of the interior space, the drum parts are spaced apart from one another while they still rotate with the rotor shaft.

Owner:BOLL & KIRCH FILTERBAU

Engine speed sensitive oil pressure regulator

A pressure regulator for a power source may include a housing in fluid communication with a pressurized fluid line and a reservoir, and a pressure relief valve having an open position that creates a flow path between the pressurized fluid line and the reservoir, and a closed position. The pressure relief valve may open when an opening force exerted by pressurized fluid entering the housing overcomes a closing force acting on the pressure relief valve, allowing pressurized fluid to flow from the pressurized fluid line to the reservoir. The pressure regulator may also include a governor coupled to the pressure relief valve, wherein the governor is configured to regulate the pressure in the pressurized fluid line by selectively adjusting the closing force exerted on the pressure relief valve based on engine speed.

Owner:CATERPILLAR INC

System and method for controlling oil pump

ActiveUS9031741B2Improve fuel efficiencyReduce oil pressureAnalogue computers for vehiclesDigital data processing detailsControl systemFeedback control

Disclosed are an oil pump control system and method, the oil pump control method including setting an initial target oil pressure of the oil pump based on a rotation speed of an engine or an oil temperature, determining a pressure compensation value by considering the target torque or target fuel quantity of the engine based on the initial target oil pressure, determining a final target oil pressure by adding the pressure compensation value to the initial target oil pressure, and feedback-controlling the oil pump so that current oil pressure measured in real time follows the final target oil pressure.

Owner:HYUNDAI MOTOR CO LTD +1

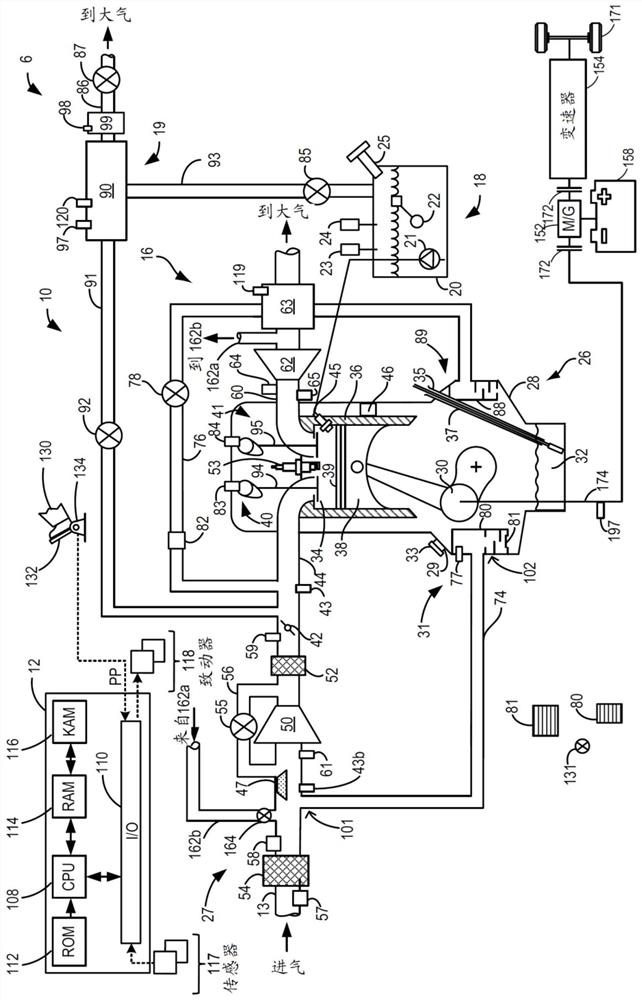

Diagnostic method for an oil piston cooling jet valve, diagnostic device, control unit, motor vehicle

ActiveUS20220018269A1Lower oil temperatureEasy to assembleLiquid coolingEngine pressureDiagnostic dataControl engineering

A diagnostic method for an oil piston cooling jet valve of an oil pressure system of an internal combustion engine of a motor vehicle, including: Driving the OPCJ valve for detecting oil pressure diagnostic data if multiple enabling conditions have been met, the multiple enabling conditions including: Presence of a stationary operation of the internal combustion engine; presence of a predetermined operating range; presence of an oil temperature within a predetermined oil temperature range; prevention of a scheduled driving of the OPCJ valve for regular piston cooling; and prevention of an error of the oil pressure system. The diagnostic method further including: Determining whether an oil pressure measuring point is within a predefined oil pressure measuring point range. The invention further relates to a diagnostic device, a control unit and a motor vehicle, which are each suitable or configured for carrying out the method.

Owner:VOLKSWAGEN AG

Systems and methods for crankcase system diagnostics

PendingCN113389614AImprove overall lifespanReduce releaseNon-fuel substance addition to fuelInternal combustion piston enginesCrankcaseMechanical engineering

Provided are systems and methods for crankcase system diagnostics. Methods and systems are provided for assessing a state of a vent hose that fluidically couples a crankcase of an engine to an engine air intake system. In one example, a method may include sealing the crankcase from the vent hose, initiating cranking of the engine, monitoring a series of pressure pulsations during a monitoring window duration via a pressure sensor positioned between a crankcase oil separator and the vent hose, and indicating a presence of degradation associated with the vent hose based on the series of pressure pulsations and the monitoring window duration. In this way, diagnosis of a state of the vent hose may be reliably assessed without crankcase pressures confounding pressure measurements as recorded via the pressure sensor.

Owner:FORD GLOBAL TECH LLC

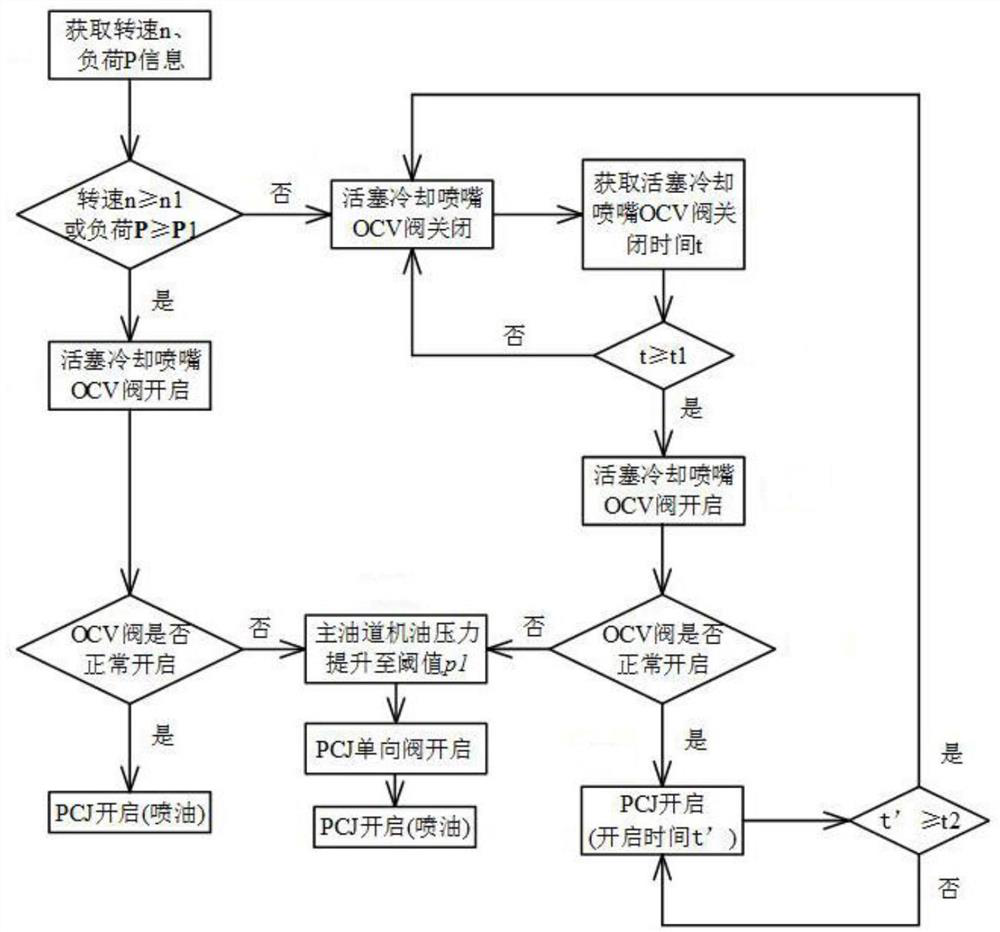

Engine lubricating system and control method thereof

ActiveCN113187579AGuaranteed fuel injection processGuaranteed lubrication effectEngine loadEngine revolutionsEngineeringOil filter

The invention discloses an engine lubricating system. The system comprises a variable displacement oil pump, an oil filter and a cylinder body main oil duct which are sequentially connected in series, one end of the cylinder body main oil duct is connected to an oil return opening of the variable displacement oil pump through an oil pump feedback oil duct and an oil pump OCV in sequence, the other end of the cylinder body main oil duct is connected to a piston cooling nozzle through a piston cooling nozzle oil duct and a piston cooling nozzle OCV in sequence, the oil pump OCV is connected with an oil pump one-way valve in parallel, and the piston cooling nozzle OCV is connected with a piston cooling nozzle one-way valve in parallel. The signal input end of a control unit is connected with an oil pressure sensor and an engine, and the signal output end of the control unit is connected with the oil pump OCV and the piston cooling nozzle one-way valve. The invention further discloses a control method of the engine lubricating system. The control method comprises the steps that judgment is conducted according to four obtained parameters and signals, and four control modes are executed. The situation that a piston cannot be lubricated due to failure of a lubricating system control valve is avoided, and the situation that the piston cannot be lubricated under long-term low-load low-rotating-speed conditions is avoided.

Owner:DONGFENG MOTOR GRP

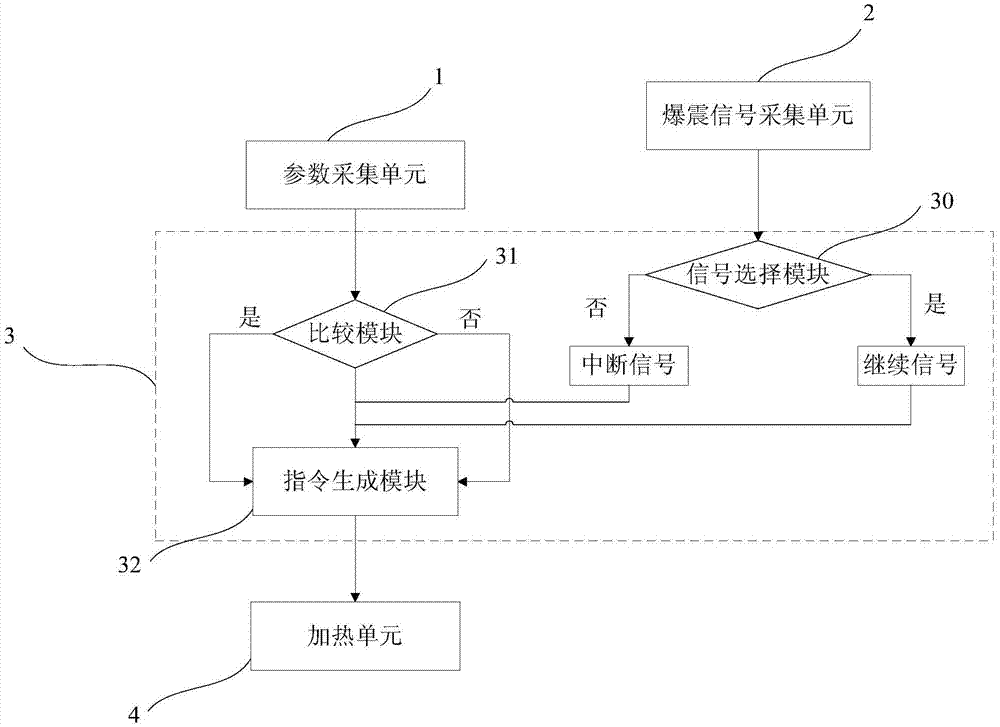

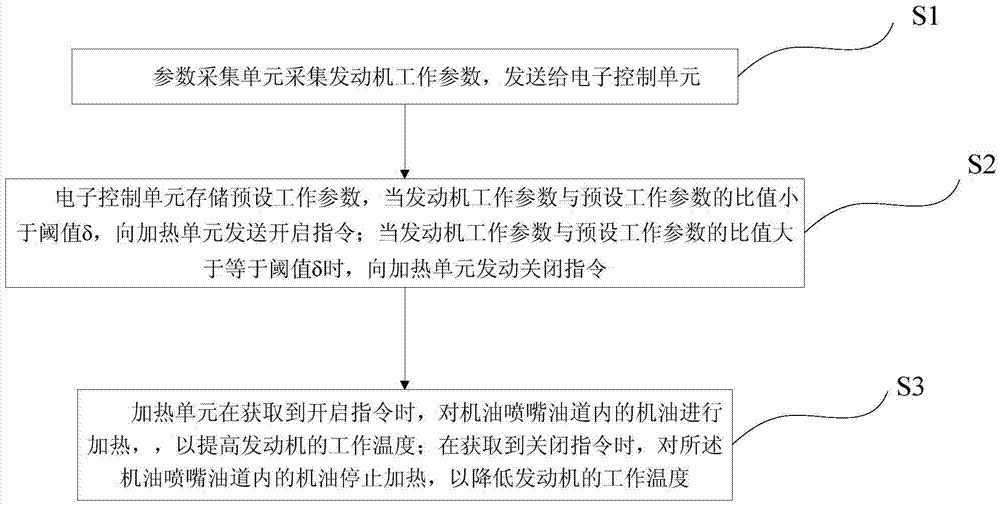

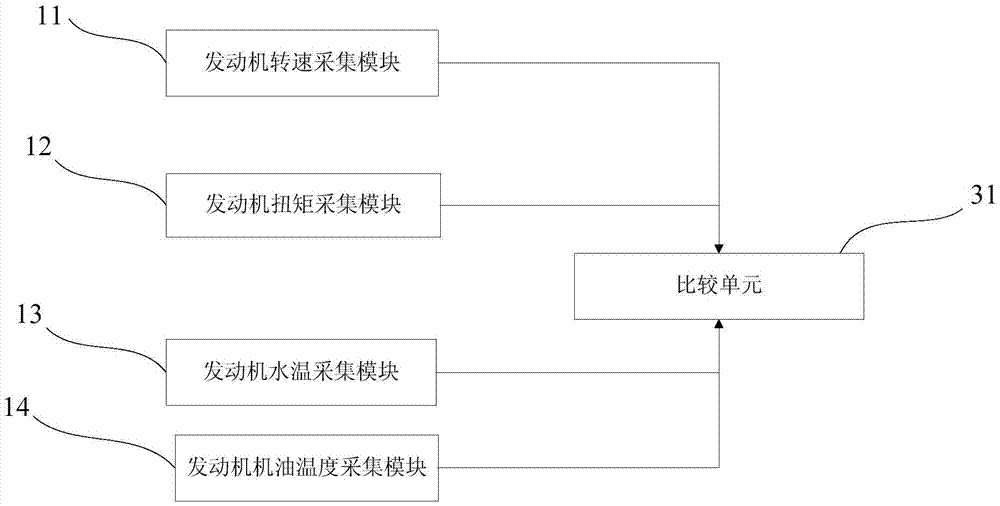

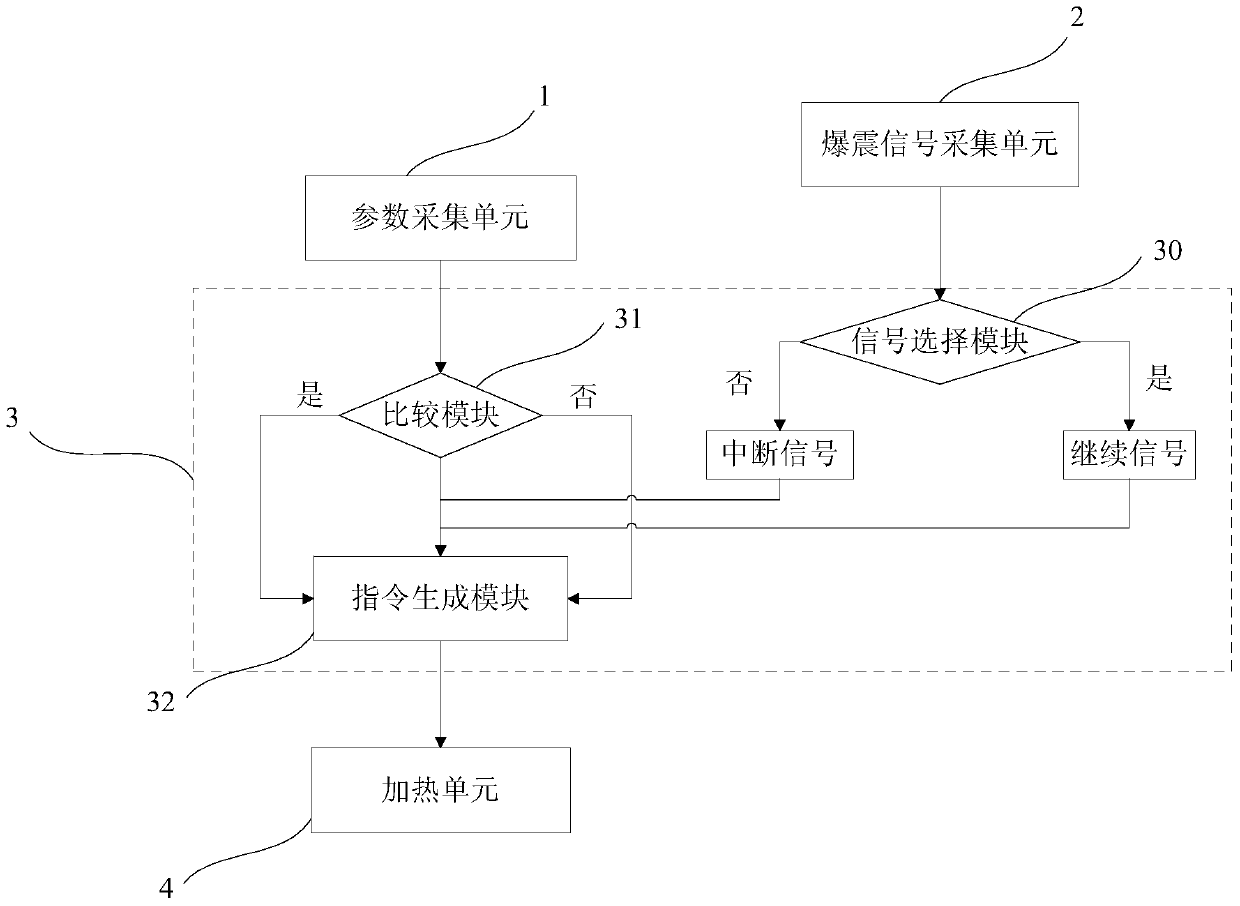

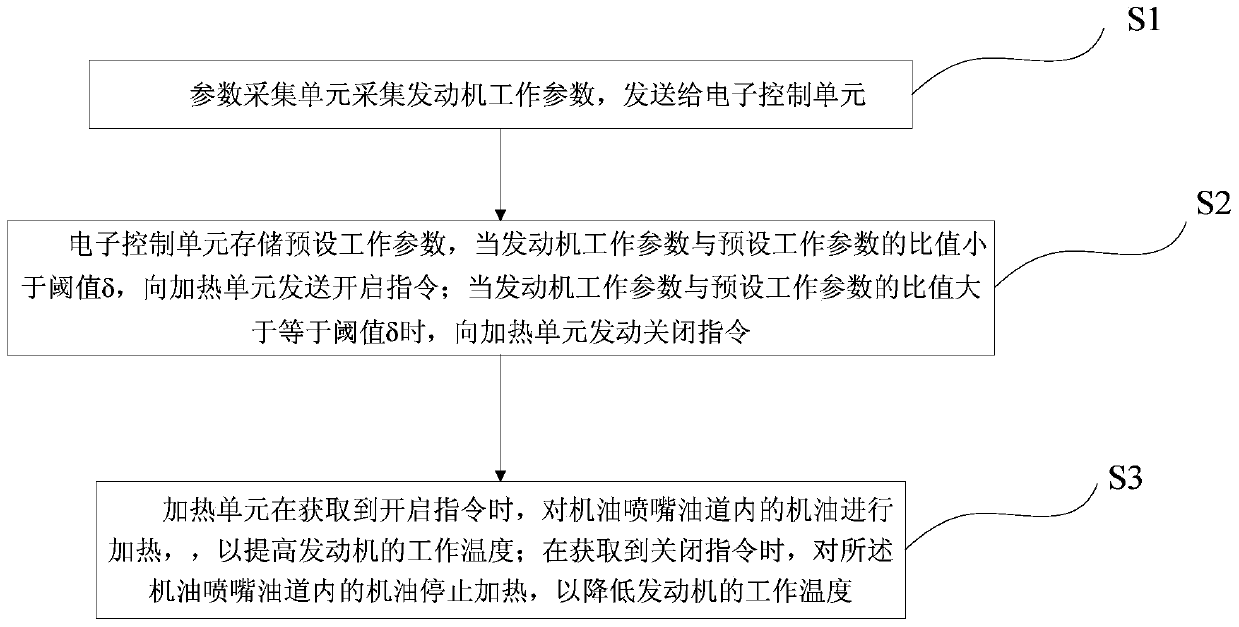

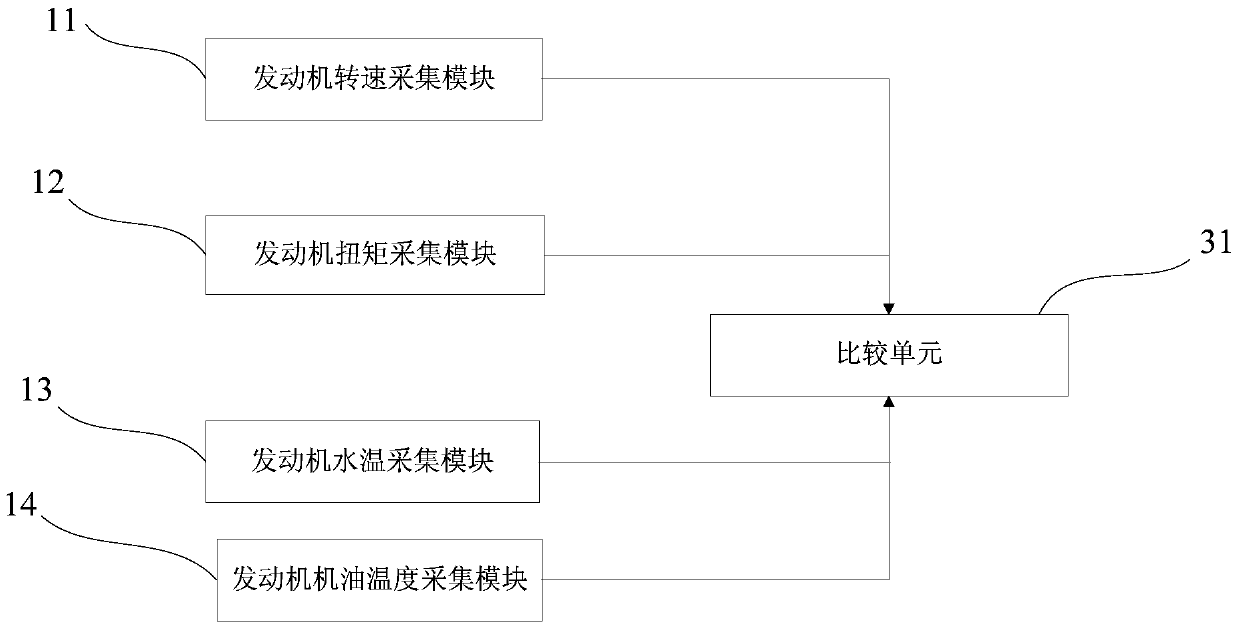

Temperature control system for engine, and control method thereof

ActiveCN106930801AReal-time understanding of work statusIncrease working temperatureEngine loadEngine revolutionsTemperature controlWork performance

The invention provides a temperature control system for an engine, and a control method thereof, relates to the technical field of engine control, and aims at automatically adjusting the working temperature of the engine in the case of cold start-up or low-temperature running of the engine, thereby improving the working performance of the engine. The temperature control system for the engine comprises a parameter acquisition unit, an electronic control unit and a heating unit, wherein the working parameters of the engine are acquired through the parameter acquisition unit, the ratios of the working parameters of the engine to preset working parameters, are compared with a threshold value delta through the electronic control unit to obtain corresponding instructions, the turn-off and turn-on of the heating unit are controlled to automatically control the temperature of engine oil located in an oil channel of an engine oil nozzle, and the piston is heated by virtue of the heated engine oil to raise the working temperature of the engine. The temperature control system for the engine is used in the technical field of engine control.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

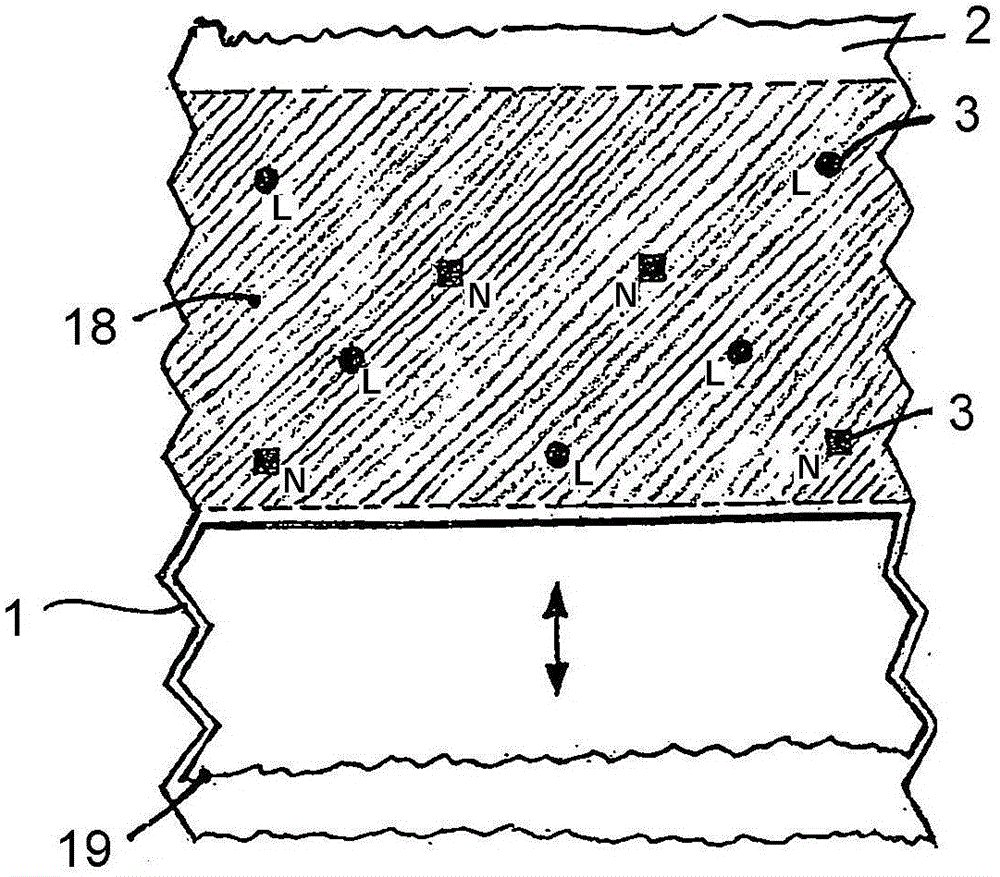

System for influencing the sliding properties of a sliding pair

ActiveCN105008681AReliable mode of actionReduce wearWaterborne vesselsEngine loadClassical mechanicsEngineering

The invention relates to a system for influencing the sliding properties of the sliding surfaces of a sliding pair by supplying the sliding surfaces with a conditioning agent, a plurality of different components being used to produce the conditioning agent. A good functioning of the sliding pair can be obtained in the long term by dynamically conditioning the sliding properties of the sliding surfaces, the sliding situation of the sliding surfaces being continuously monitored and the conditioning agent supplied to the sliding surfaces being optimized depending on the current sliding situation.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

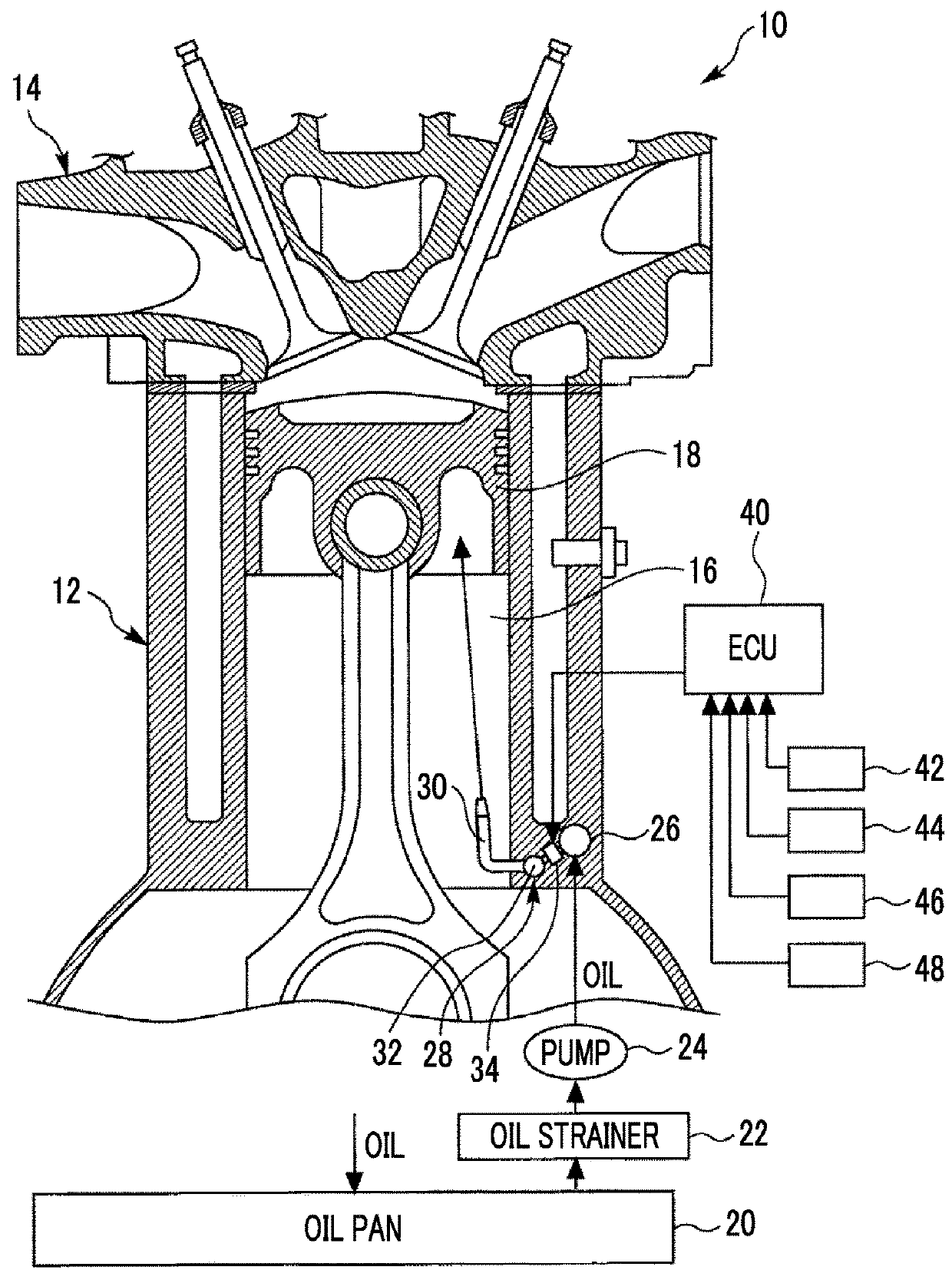

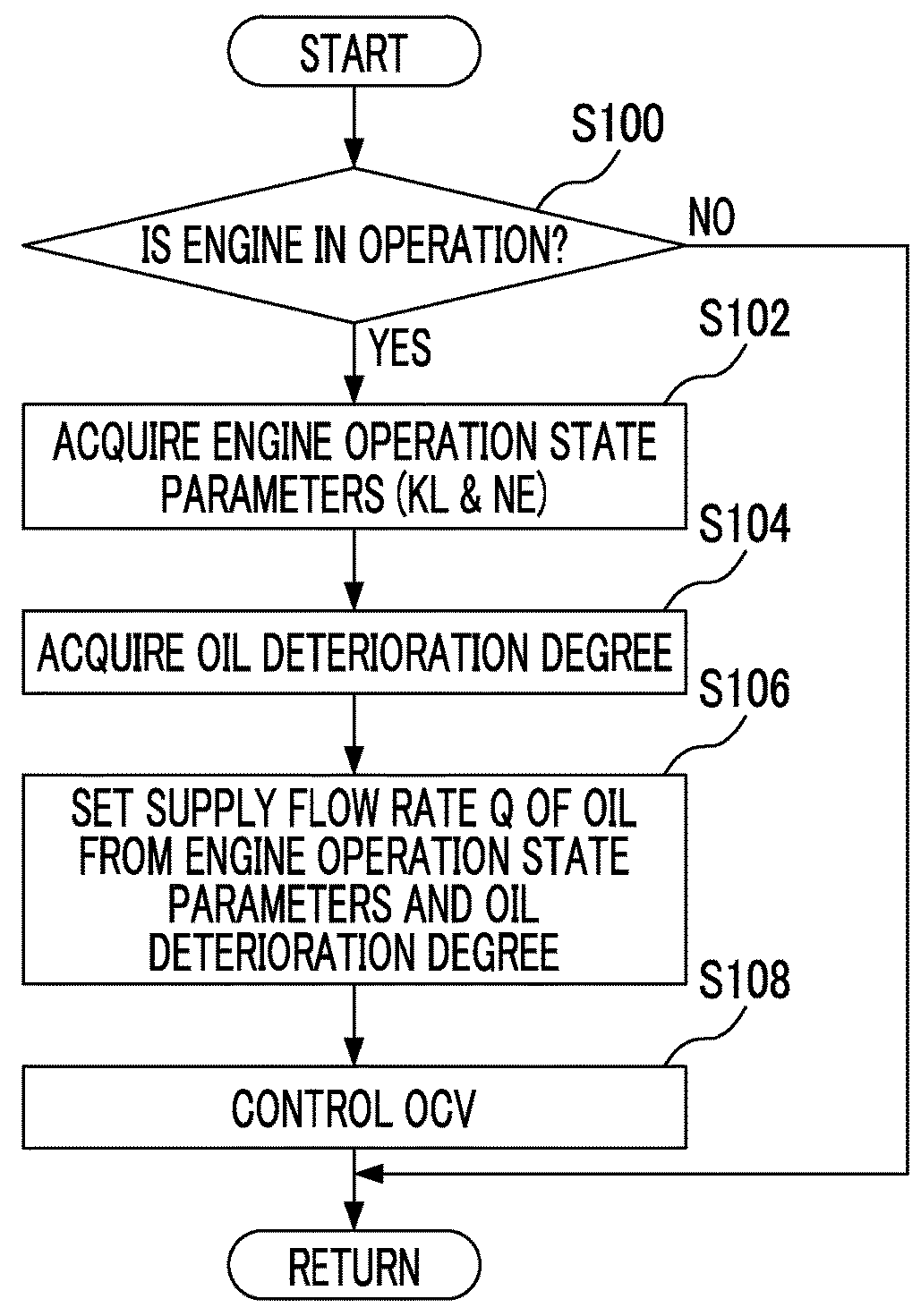

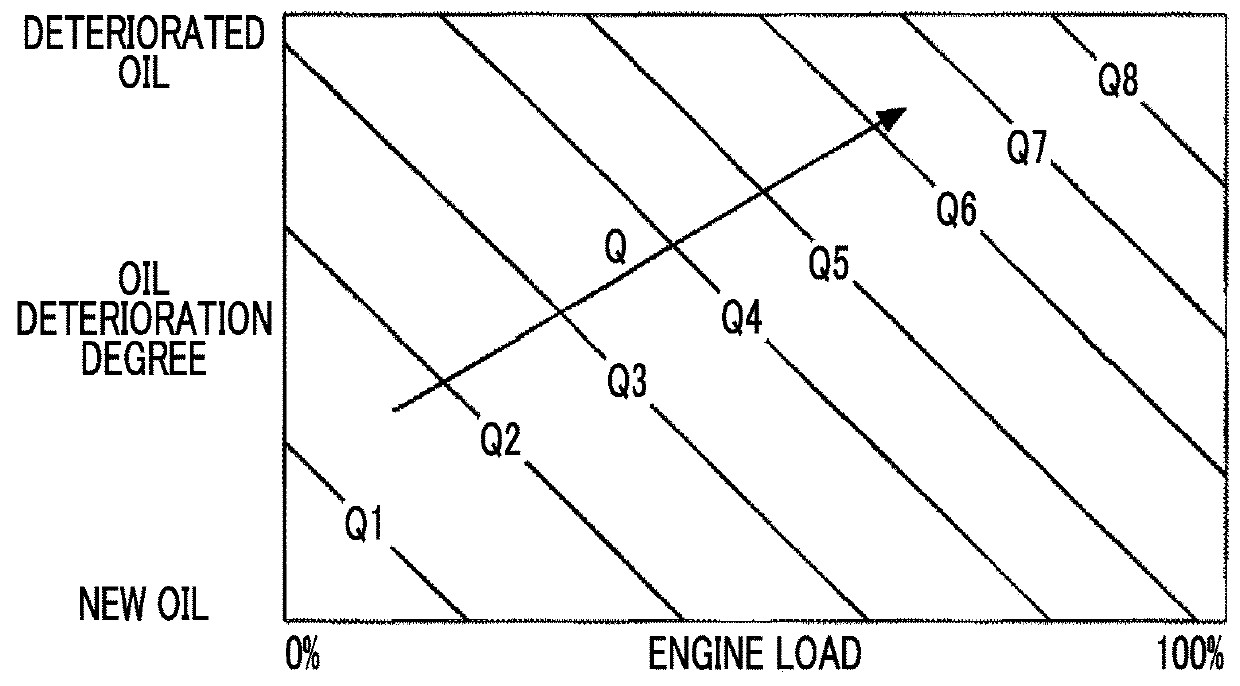

Control device and control method for internal combustion engine

InactiveUS20180274405A1Deposit generation can be more effectively suppressedLiquid coolingElectrical controlExternal combustion engineActuator

A control device for an internal combustion engine including a piston, an oil jet configured to inject oil toward the piston, and an actuator configured to adjust a supply flow rate of the oil to the oil jet. The control device includes an electronic control unit configured to control the actuator such that the supply flow rate under the same engine load and the same engine rotation speed increases as a degree of deterioration of the oil increases.

Owner:TOYOTA JIDOSHA KK

A kind of engine temperature control system and its control method

ActiveCN106930801BReal-time understanding of work statusIncrease working temperatureEngine loadEngine revolutionsAuto regulationTemperature control

The invention provides a temperature control system for an engine, and a control method thereof, relates to the technical field of engine control, and aims at automatically adjusting the working temperature of the engine in the case of cold start-up or low-temperature running of the engine, thereby improving the working performance of the engine. The temperature control system for the engine comprises a parameter acquisition unit, an electronic control unit and a heating unit, wherein the working parameters of the engine are acquired through the parameter acquisition unit, the ratios of the working parameters of the engine to preset working parameters, are compared with a threshold value delta through the electronic control unit to obtain corresponding instructions, the turn-off and turn-on of the heating unit are controlled to automatically control the temperature of engine oil located in an oil channel of an engine oil nozzle, and the piston is heated by virtue of the heated engine oil to raise the working temperature of the engine. The temperature control system for the engine is used in the technical field of engine control.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

Blow-by gas delivery path abnormality detection device for internal combustion engine

ActiveCN112012809AAccurate detectionElectrical controlInternal combustion piston enginesInternal combustion engineNeural network nn

The invention provides a blow-by gas delivery path abnormality detection device for an internal combustion engine, which can accurately detect blow-by gas leakage abnormality. A learning completion neural network in which an engine load, an engine rotational speed, and an intake air pressure in an engine intake passage downstream of a throttle valve (19) are stored as input parameters of the neural network, and weight learning is performed as a truth value tag when blow-by gas leaks from a blow-by gas delivery passage (20). When the vehicle is running, the learned neural network is used to detect a leak abnormality of blow-by gas from the blow-by gas delivery path (20) on the basis of the input parameter.

Owner:TOYOTA JIDOSHA KK

Oil drain system bypass

A system and method are provided for increasing heating of engine oil during a cold start. In one example, engine oil is returned directly to the oil pump inlet, thus bypassing the sump. In this way, a smaller volume of oil receives more heat and is used for lubricating engine components during a cold start, thus providing reduced friction earlier than otherwise possible.

Owner:FORD GLOBAL TECH LLC

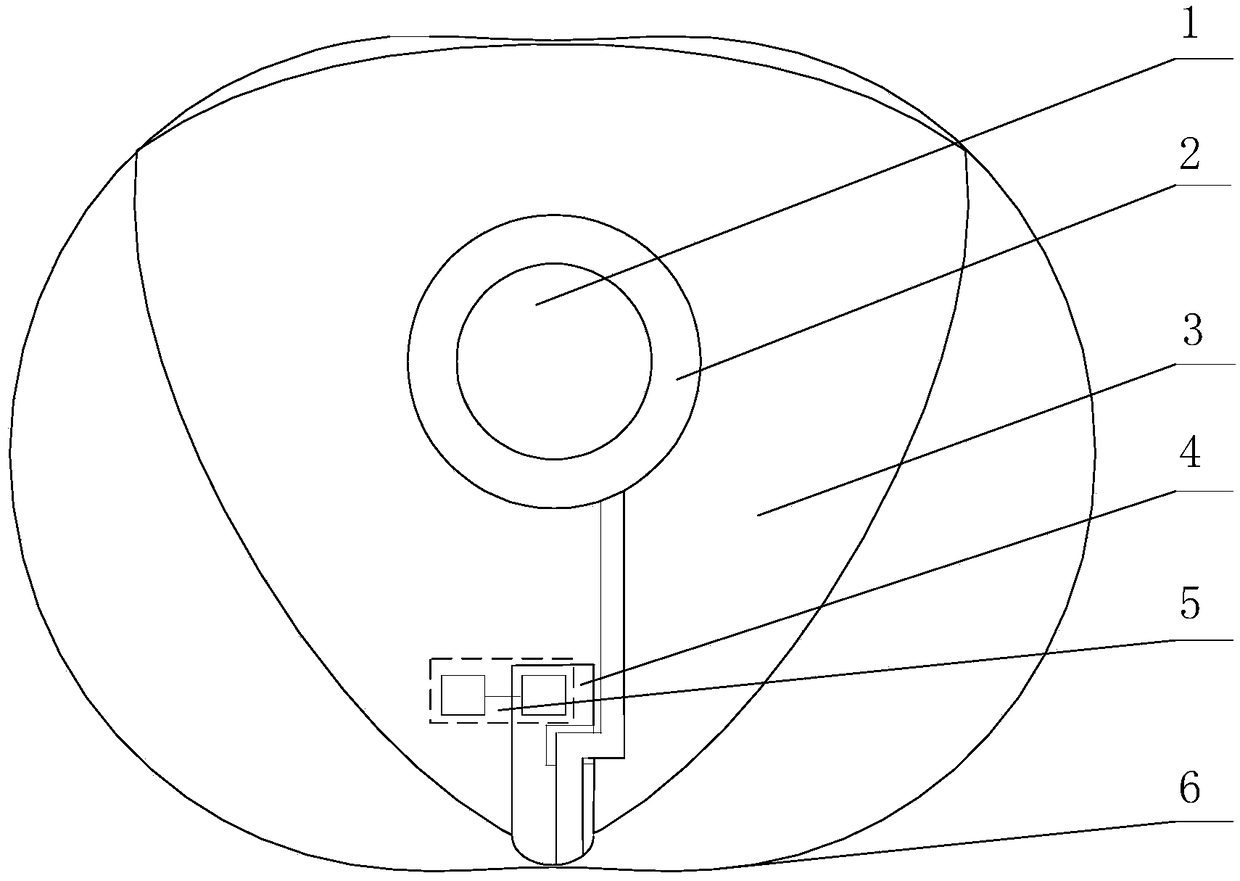

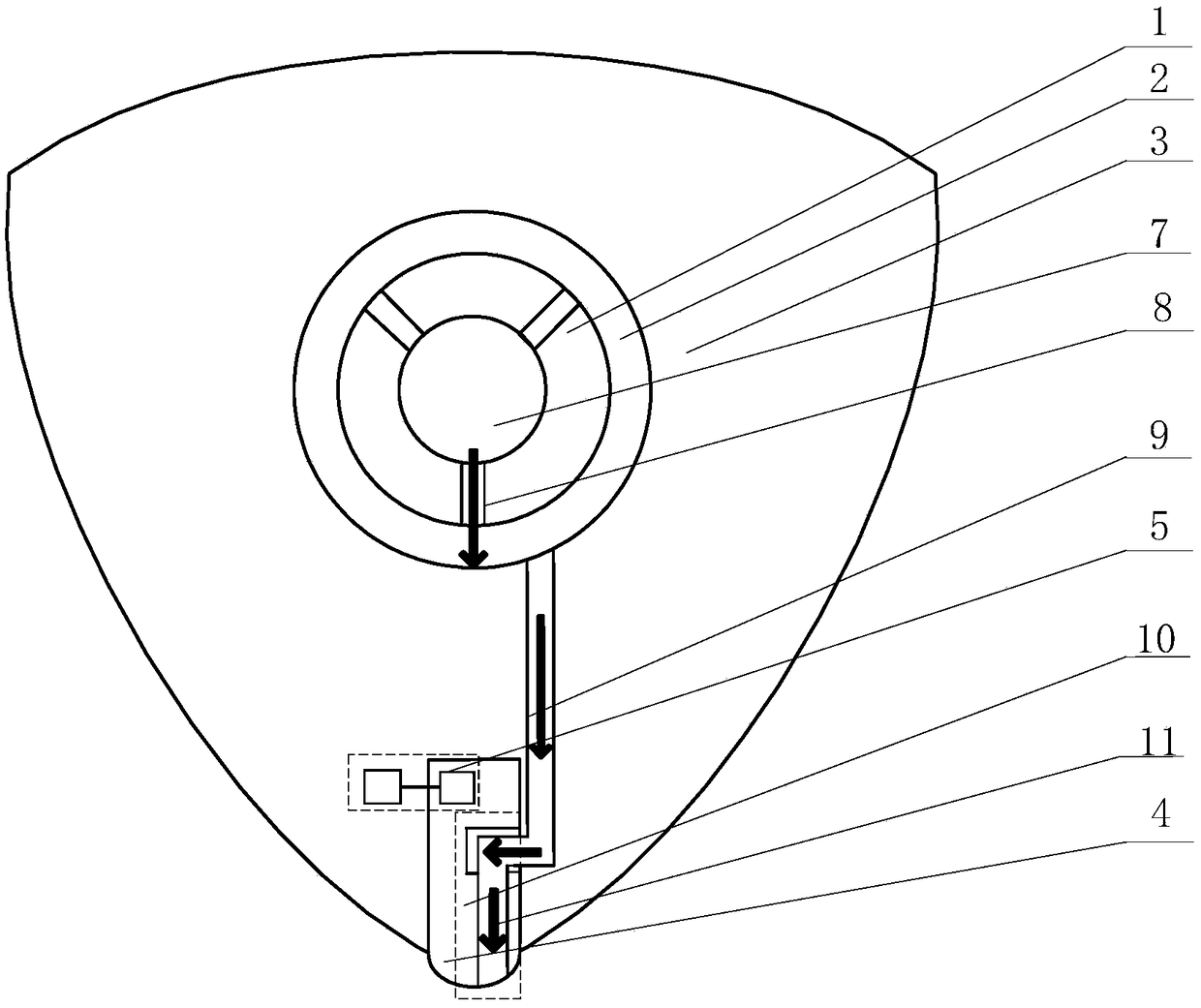

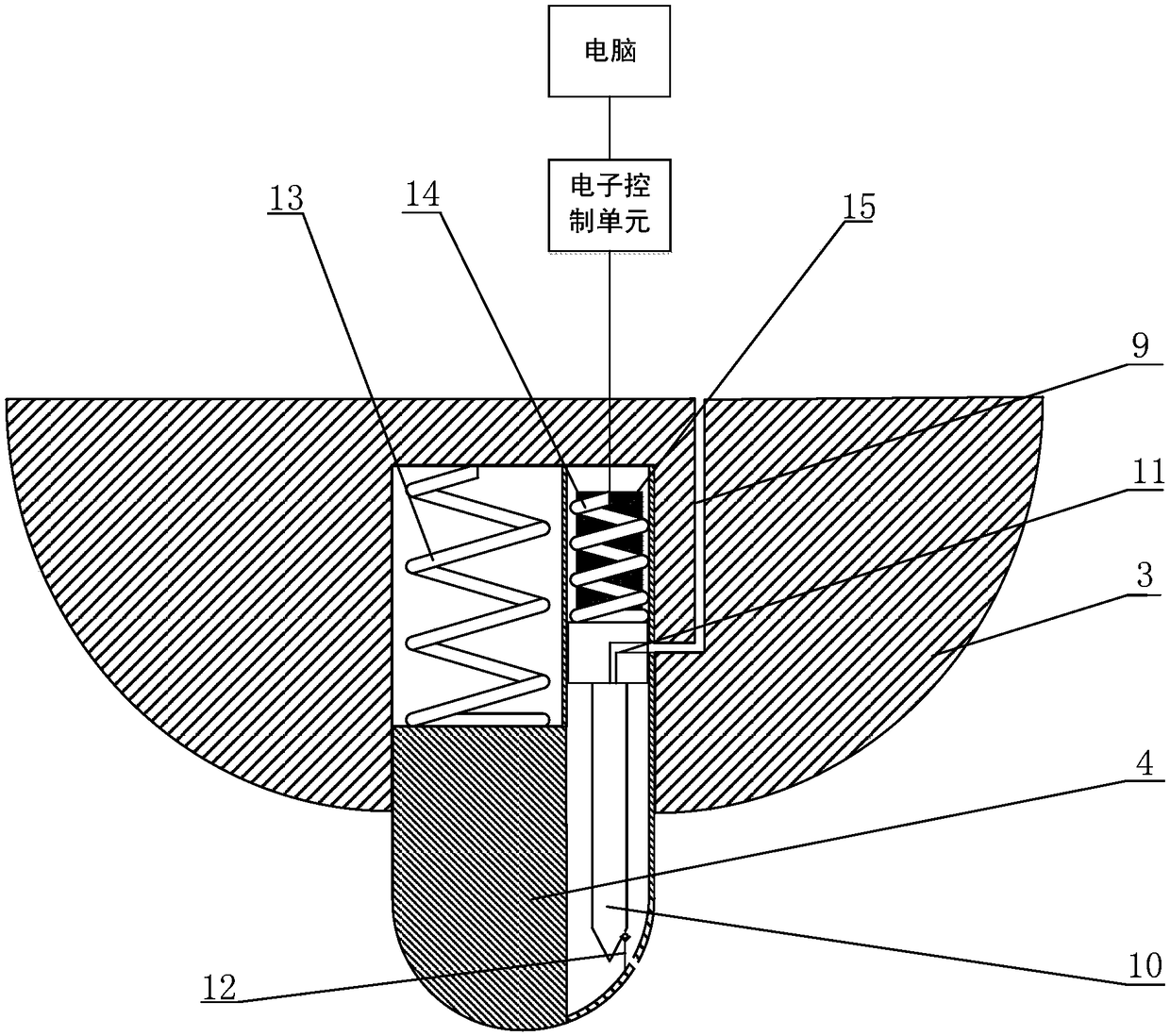

Lubricating system for a rotary engine

ActiveCN106762015BPrecise time controlImprove running performanceEngine revolutionsMachines/enginesLubricationCrankshaft

The invention relates to a lubricating system for a rotor engine and belongs to the field of engines. The lubricating system comprises a crankshaft, a bearing, a rotor, a sealing piece and an electronic control unit component, the crankshaft is processed with an eccentric shaft central oil way and an eccentric shaft radial oil way, and an oil way communicated with the crankshaft is radially processed on the inner side of the rotor; the sealing piece comprises a sealing piece substrate, a slider and oil needle integrated member, a one-way valve, a second sealing elastic device, a second sealing elastic device and an electromagnetic valve; a communicating oil way for supplying lubricating oil is processed from an eccentric shaft to the radial sealing piece, and the electromagnetic valve is controlled by the electronic control unit component to realize reliable supply of the lubricating oil. By the lubricating system, reliable and effective oil supply can be realized when the rotor engine rotates, and lubricating of between the eccentric shaft and a bearing and between the sealing piece and a cylinder can be ensured respectively, so that friction wear is reduced, reliable sealing is guaranteed, service life of each of the eccentric shaft, the bearing, the sealing piece and the cylinder is prolonged, and running performance of the rotor engine is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com