Centrifuge and centrifuge rotor for the same

By adopting the design of the loose support and disengagement mechanism of the upper and lower drum parts in the centrifuge, the self-emptying of the centrifugal drum and the sealing performance at high speeds are realized, which solves the problems of solid material clogging and load increase in the existing technology, and improves the efficiency of the centrifuge. improve the efficiency and service life of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

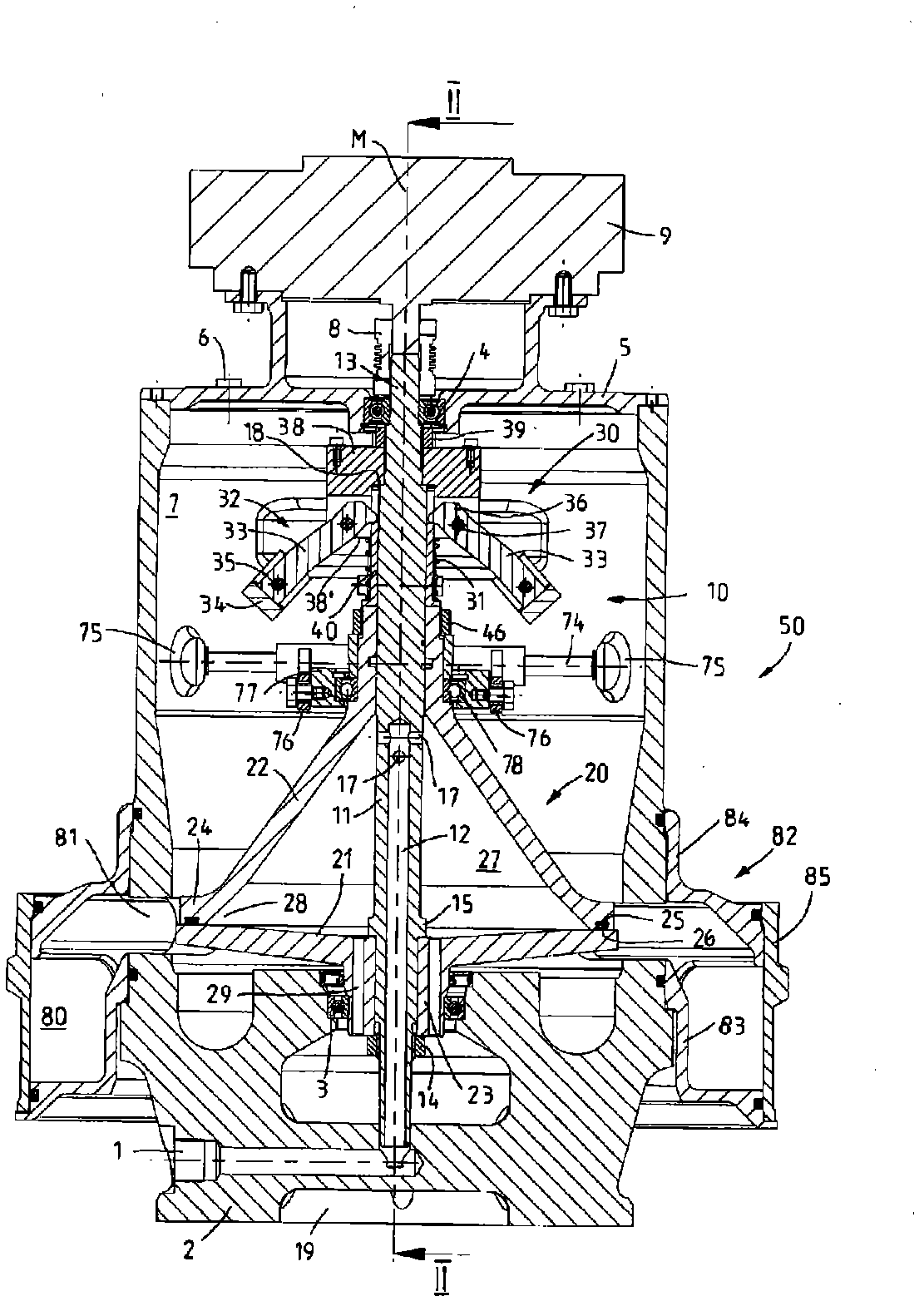

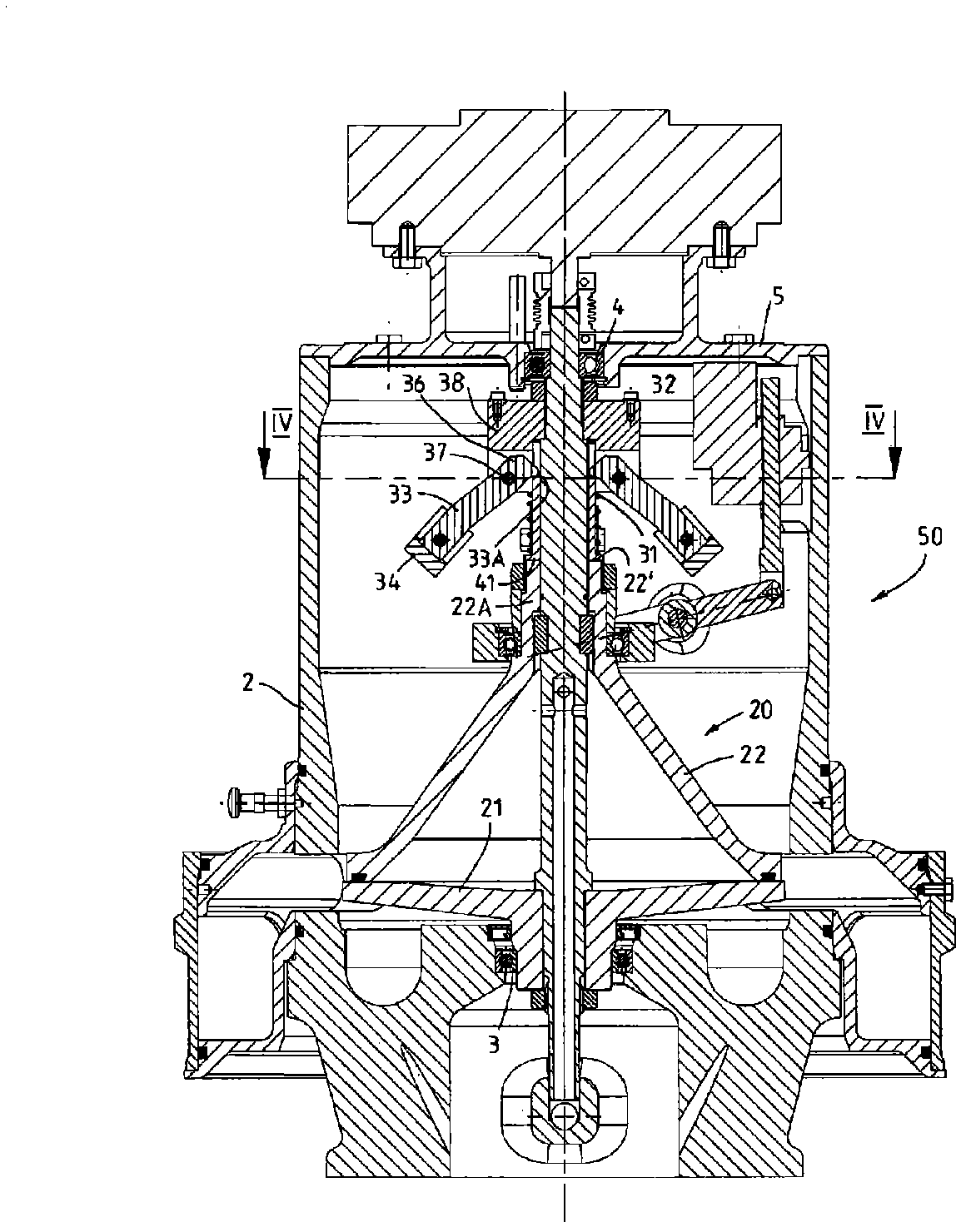

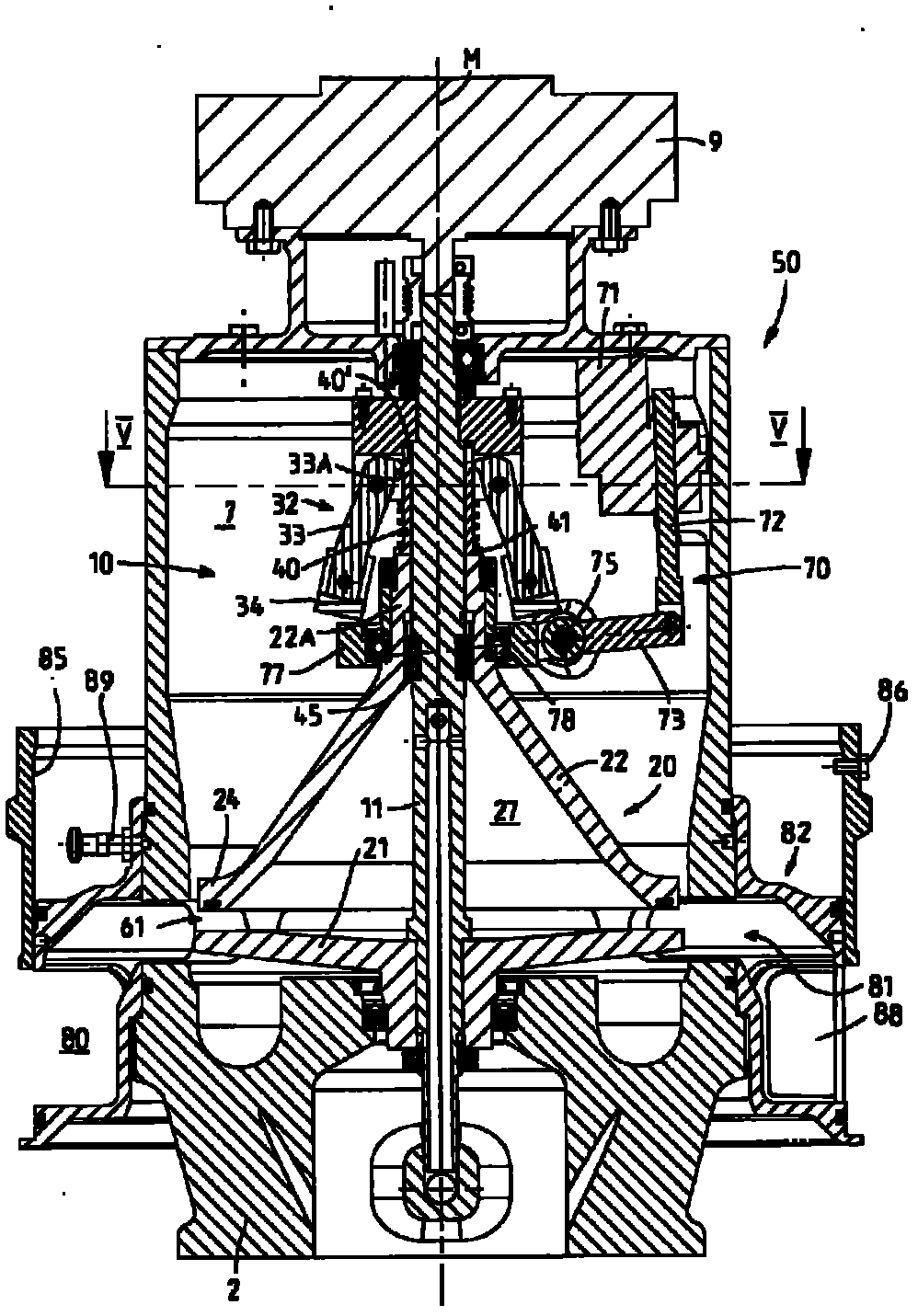

[0018] specific implementation plan

[0019] In these figures, reference numeral 50 generally designates a centrifuge according to the invention for separating solid matter or particles of solid matter from a liquid (for example, in particular a lubricating oil liquid) which can be passed through the centrifuge An inlet opening 1 in the seat part of the housing 2 is fed to the centrifuge 50 . From the inlet opening 1, the liquid to be separated flows into a duct 12, which is formed by the cavity of the rotor shaft 11, which is formed as a hollow shaft in the lower region of the centrifuge rotor, which is shown as a whole in the figure with Reference number 10 marks. The rotor shaft 11 extends approximately over the entire height of the centrifuge housing 2 and is arranged here substantially on the central axis M of the centrifuge housing 2 , which has an overall cylindrical design, the central axis M At the same time, the axis of rotation of the centrifuge rotor 10 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com