Patents

Literature

53results about How to "Engine startability can be improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel injection valve

ActiveUS6854670B2Promote atomizationHigh particle densityBurnersSpray nozzlesInjectorMembrane configuration

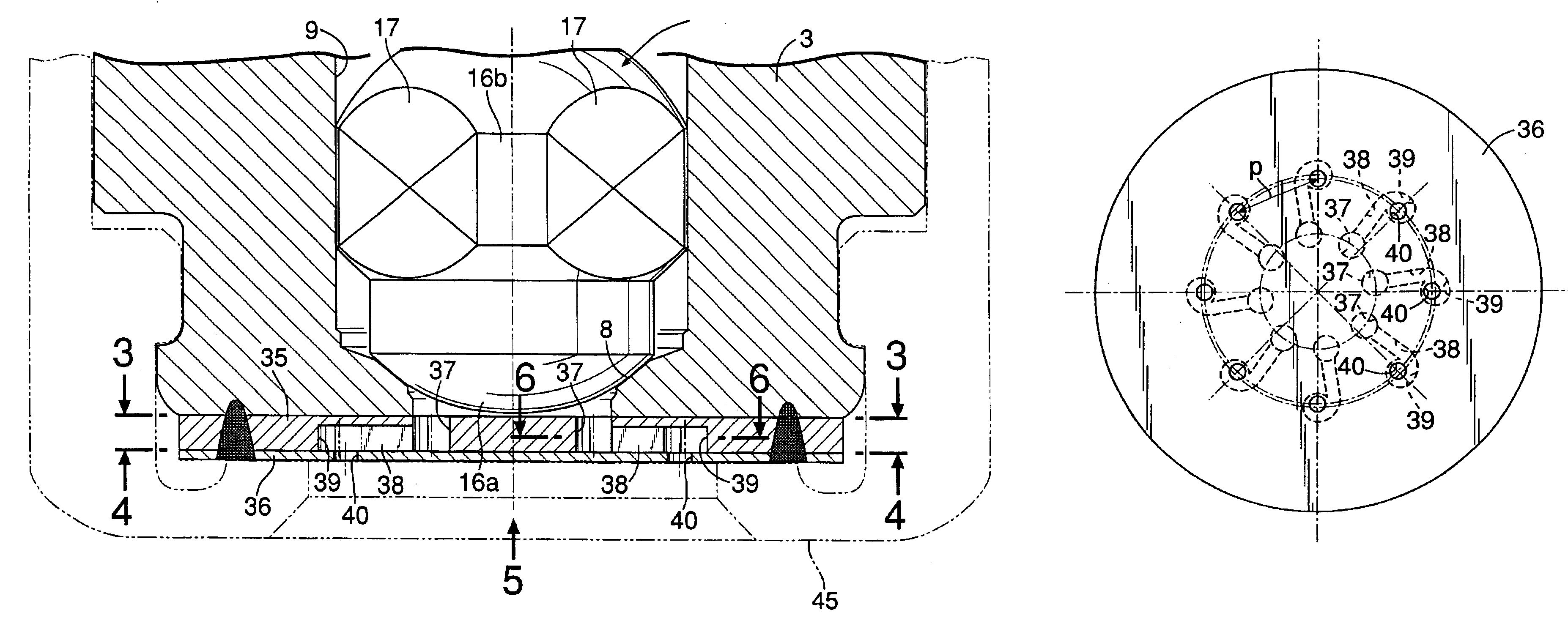

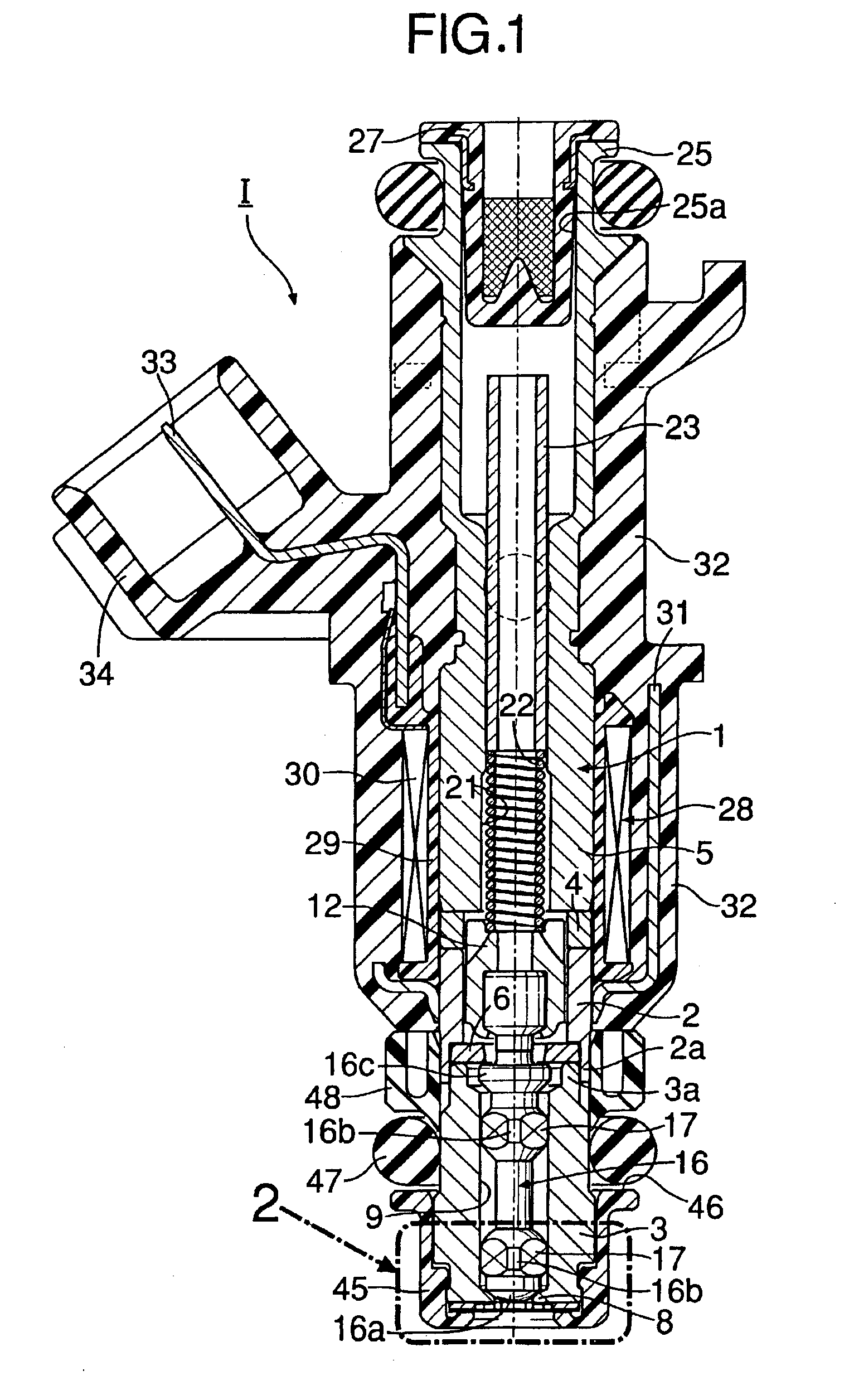

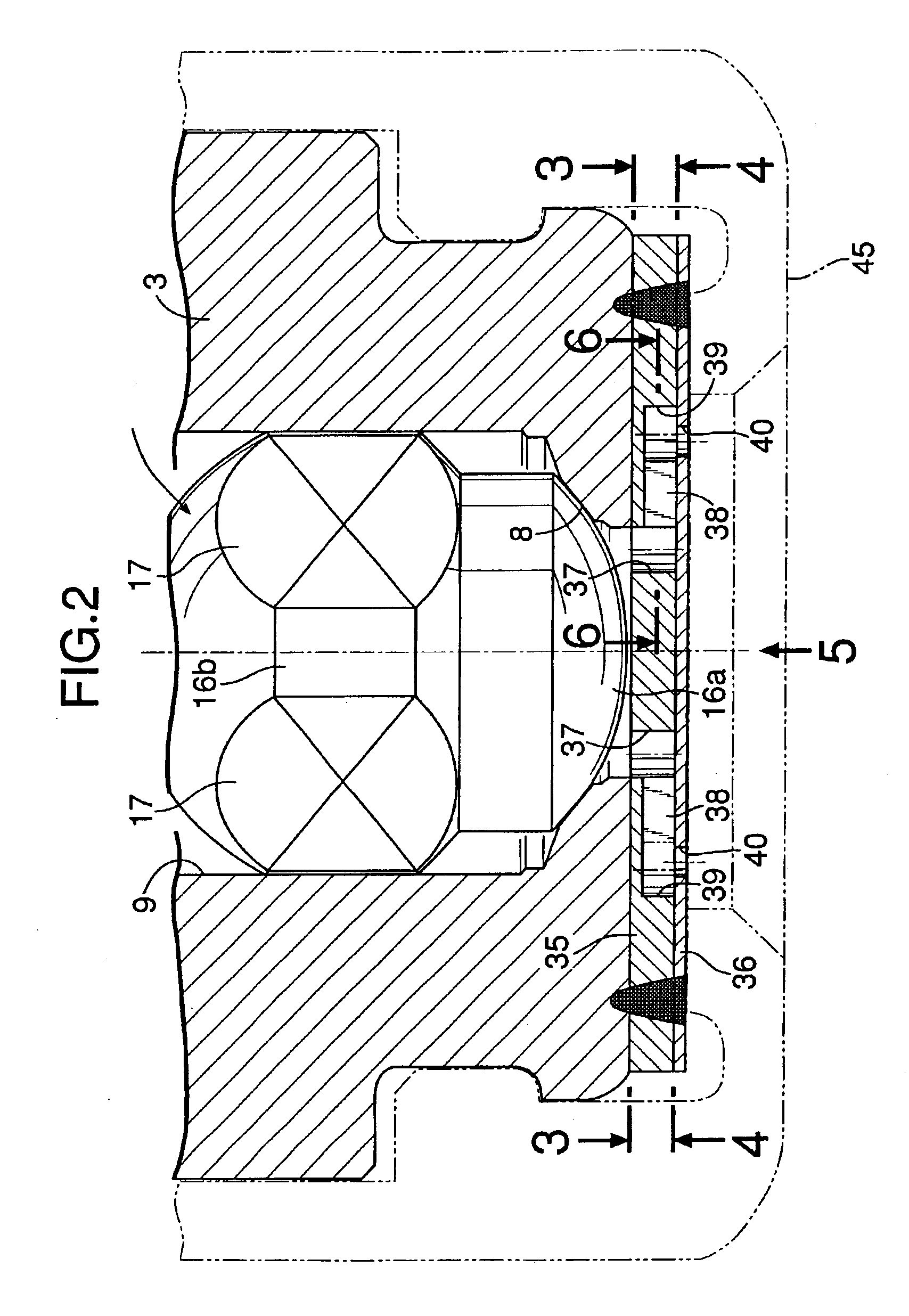

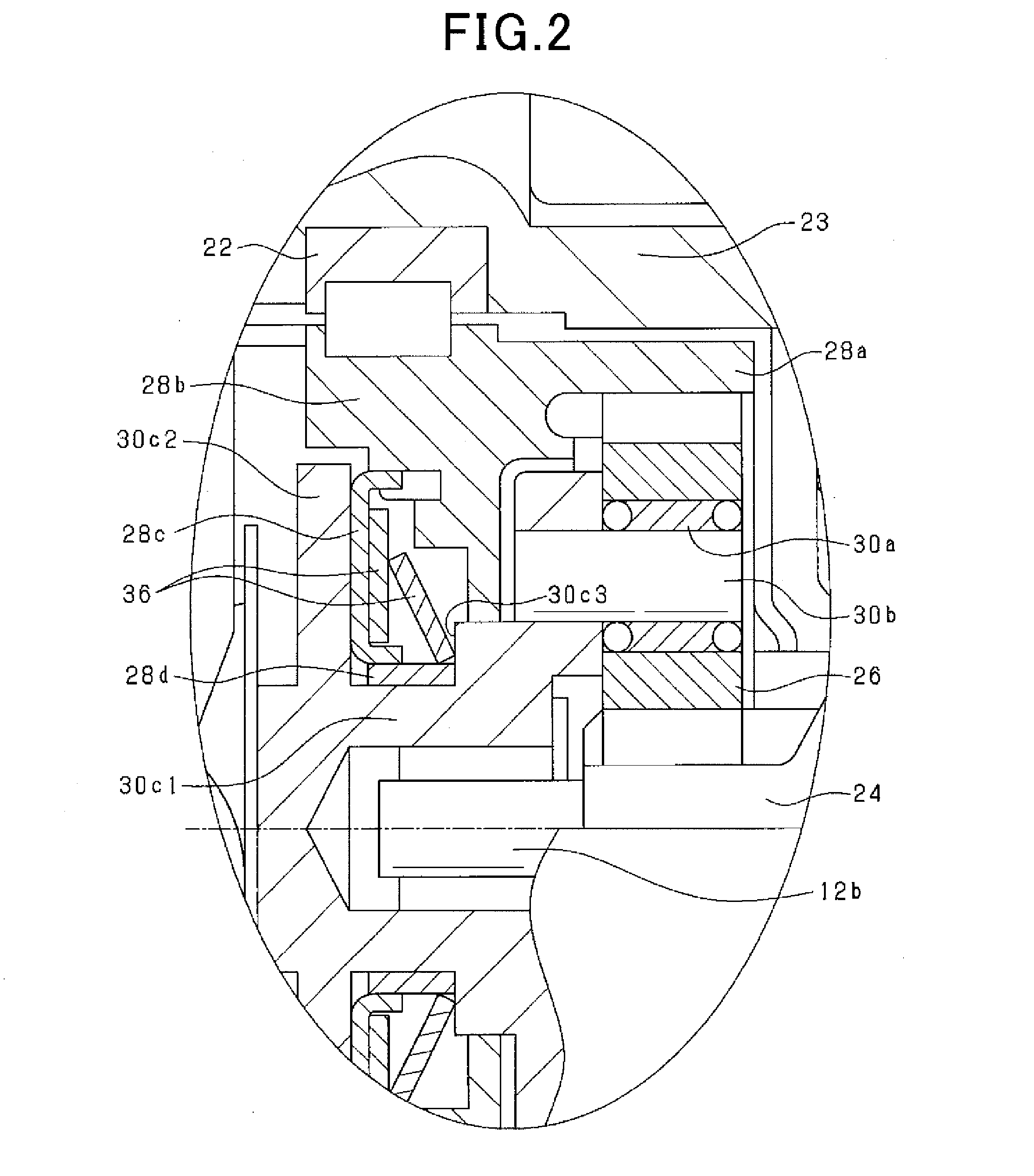

A fuel injection valve includes a valve seat member, and an injector plate which is coupled to a front end face of the valve seat member and has a plurality of fuel injection orifices disposed about an axis of the valve seat member to communicate with a valve seat. Swirling means for swirling a fuel injected from each of the fuel injection orifices is provided in at least one of the valve seat member and the injector plate. The plurality of fuel injection orifices are disposed so that liquid membrane portions of adjoining hollow conical fuel spray forms formed by the fuel injected from the fuel injection orifices collide with one another. Thus, the atomization of the injected fuel can be further promoted, and a coalesced fuel spray form having a fuel particle density higher in a central zone and lower in an outer peripheral zone can be formed.

Owner:HITACHI ASTEMO LTD

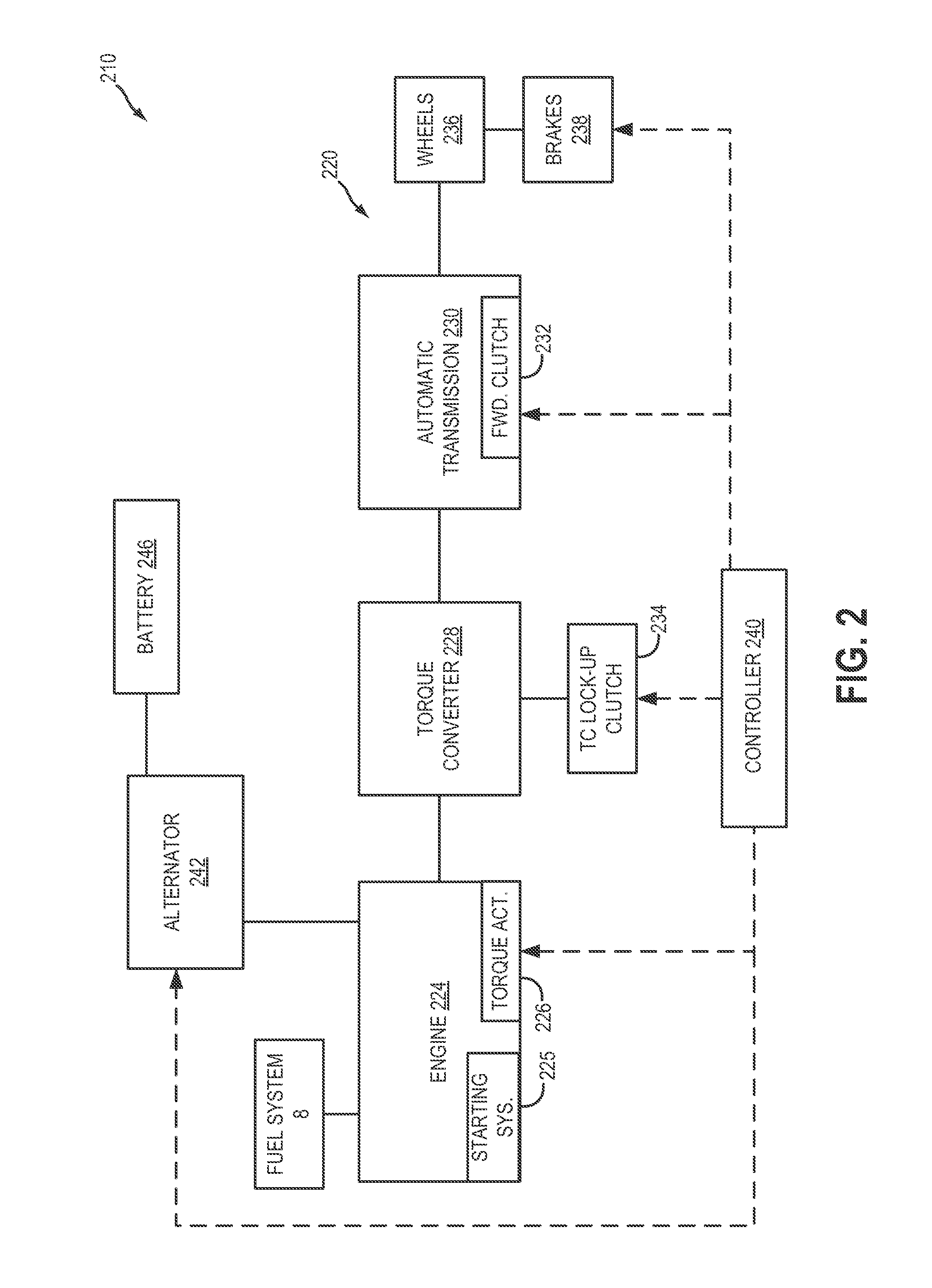

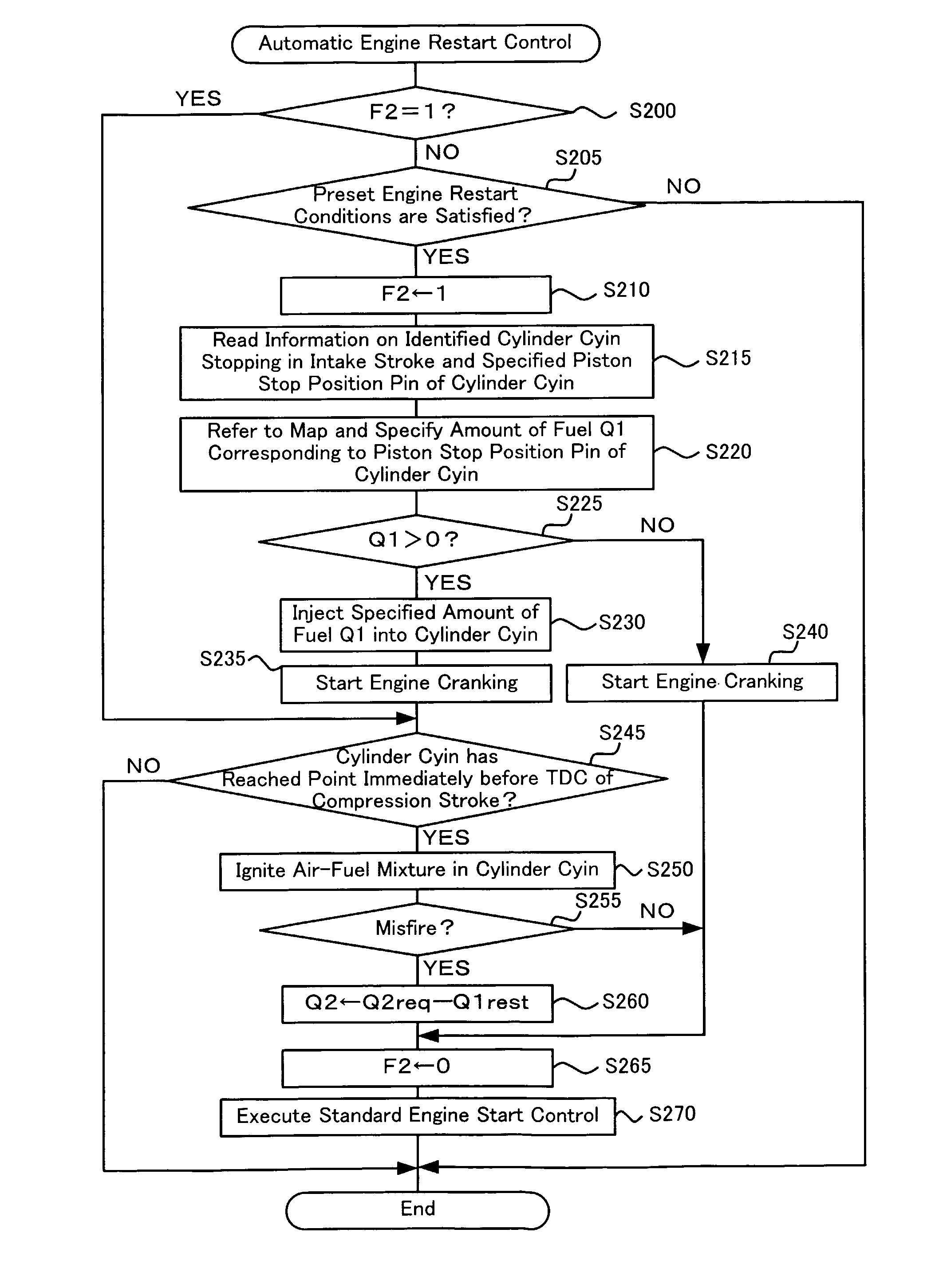

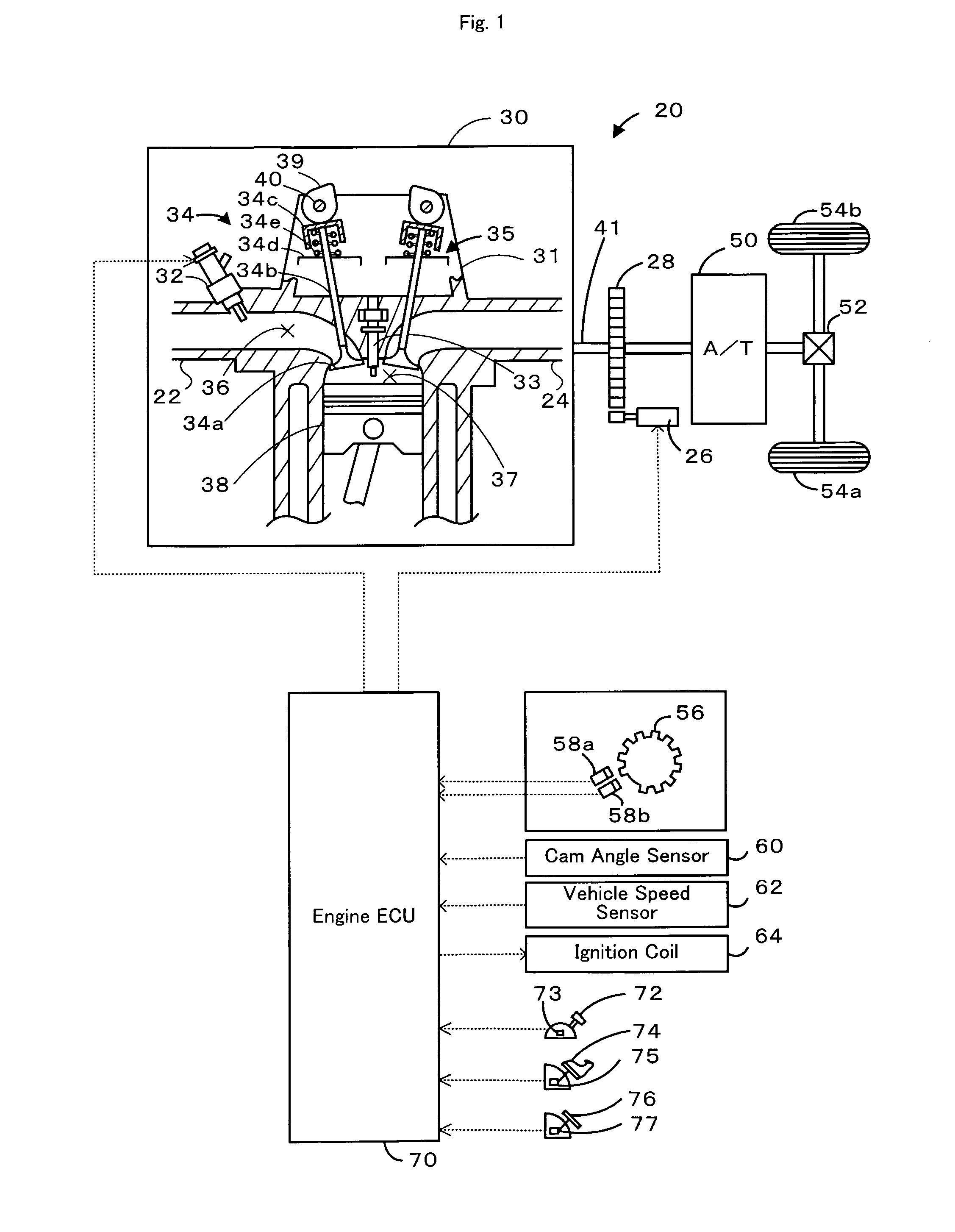

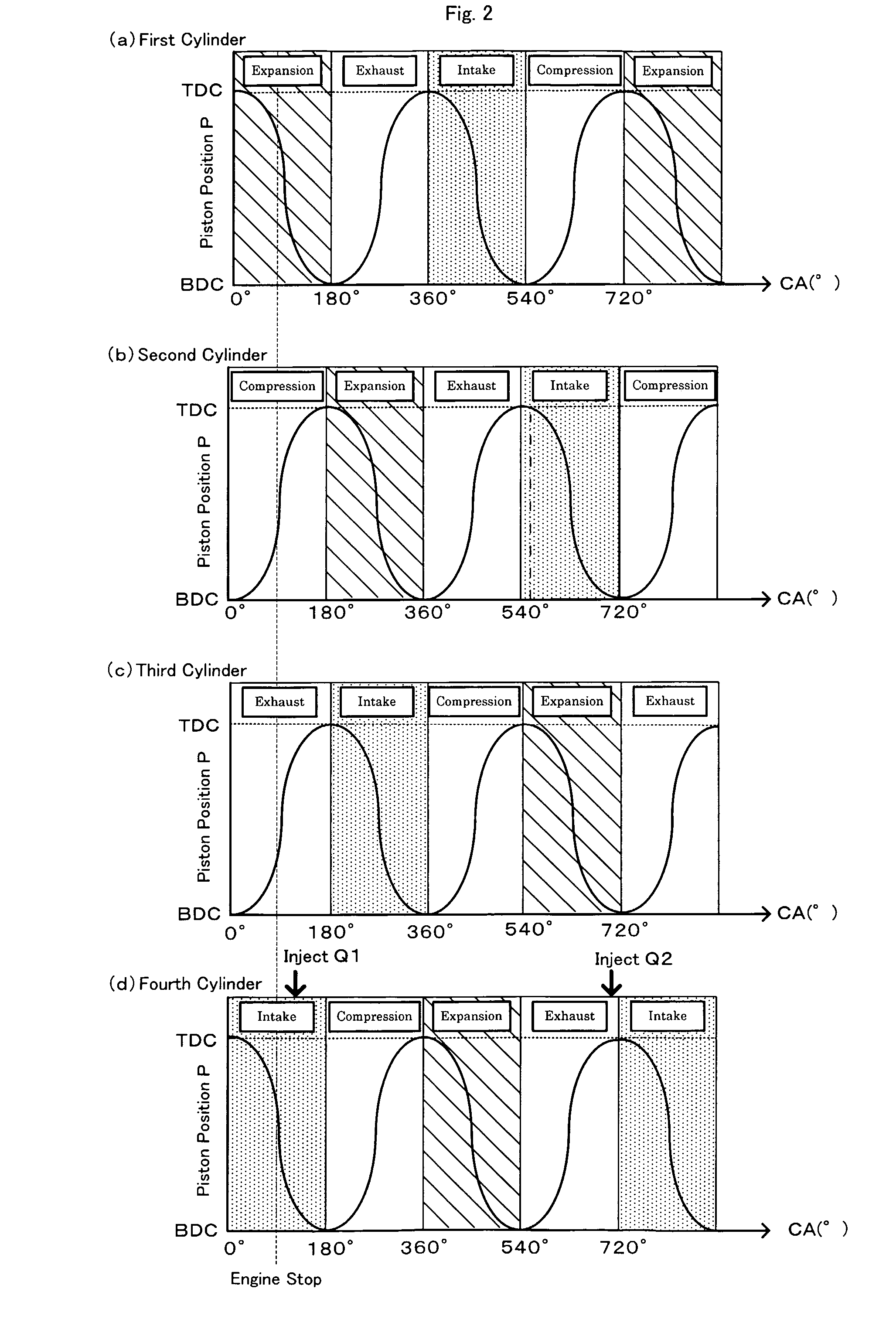

Engine Start Control Apparatus, Engine Start Control Method, and Motor Vehicle Equipped with Engine Start Control Apparatus

ActiveUS20080092841A1Stable levelImprove drivabilityAnalogue computers for vehiclesPower operated startersCombustionIdle speed

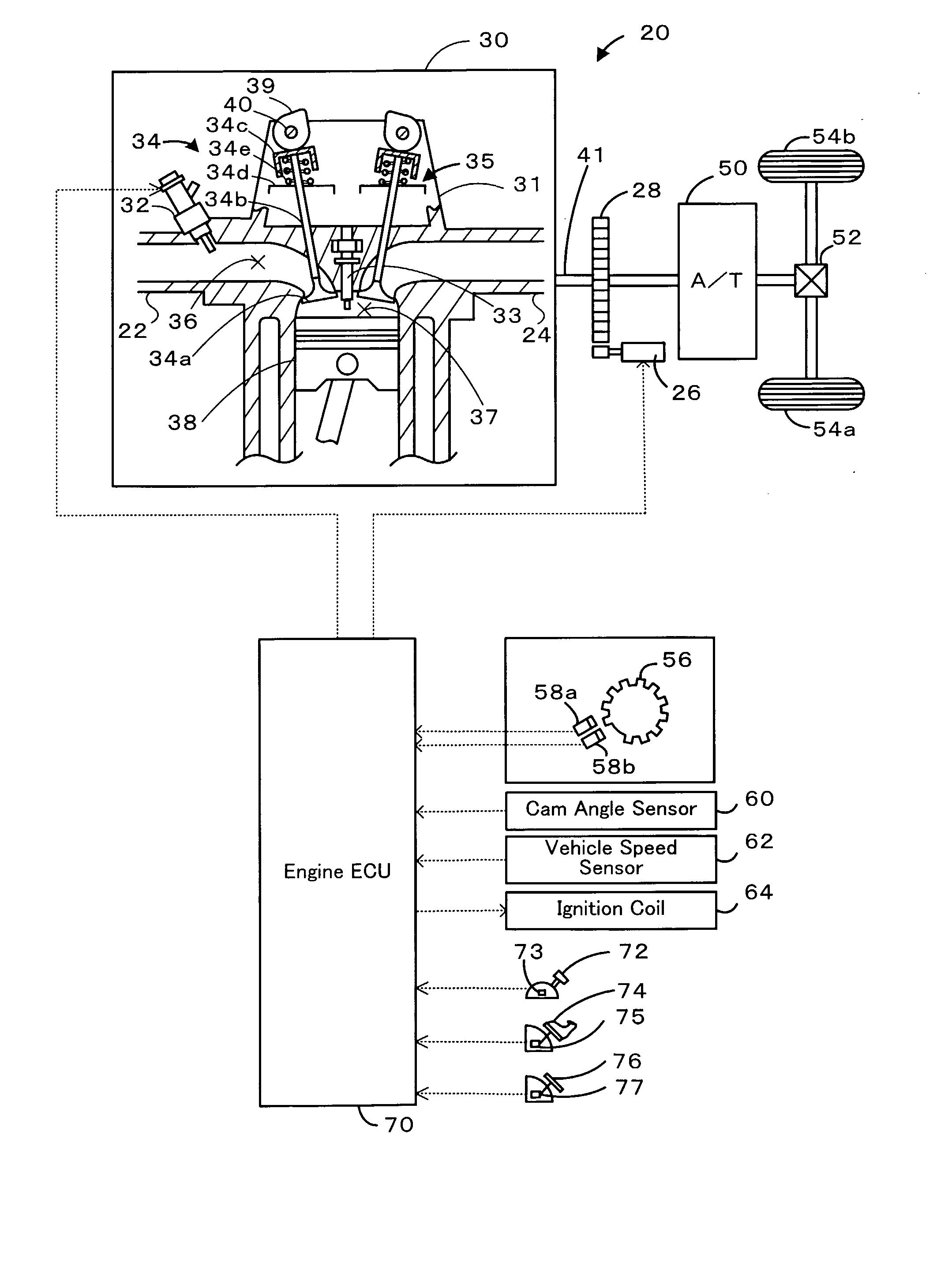

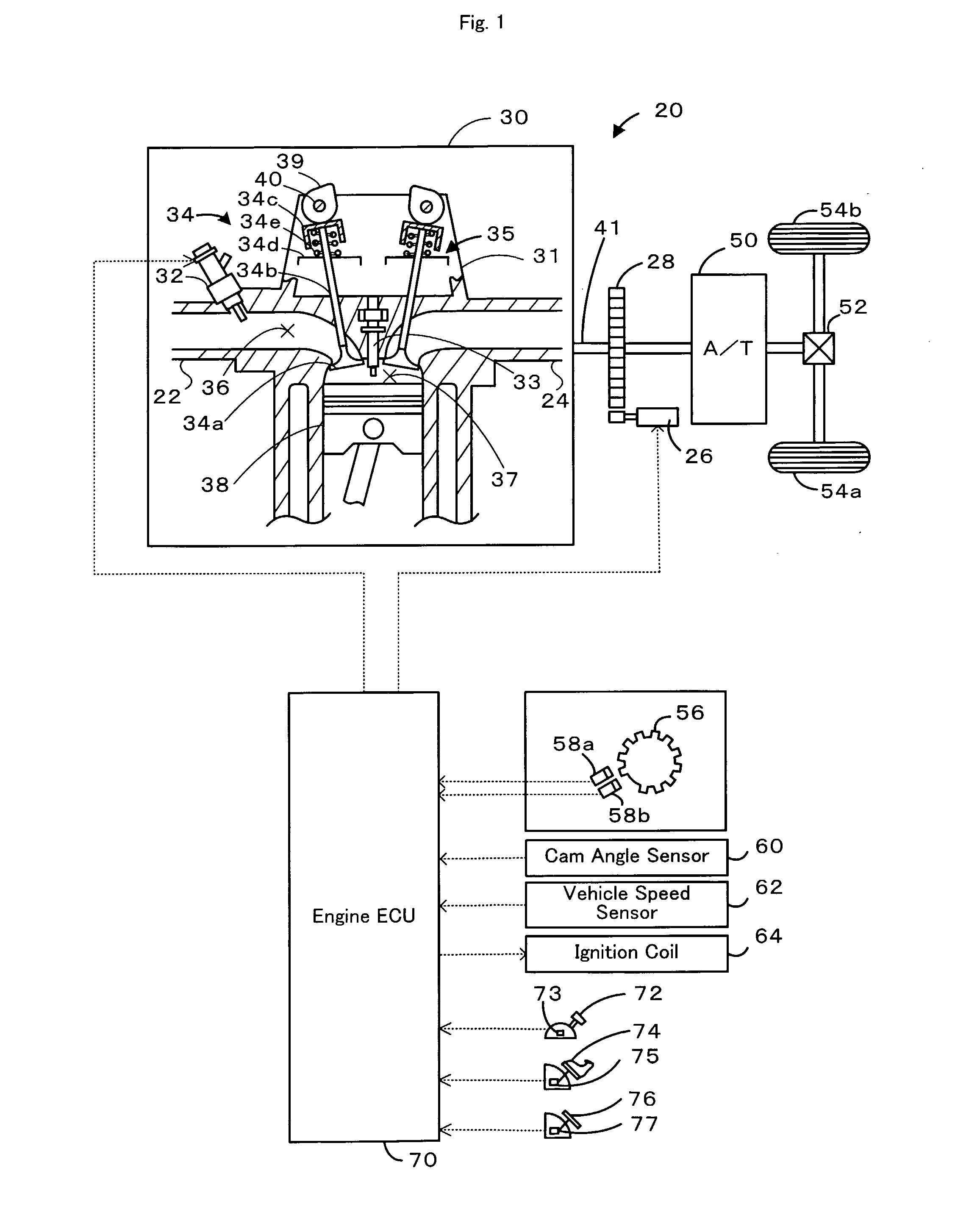

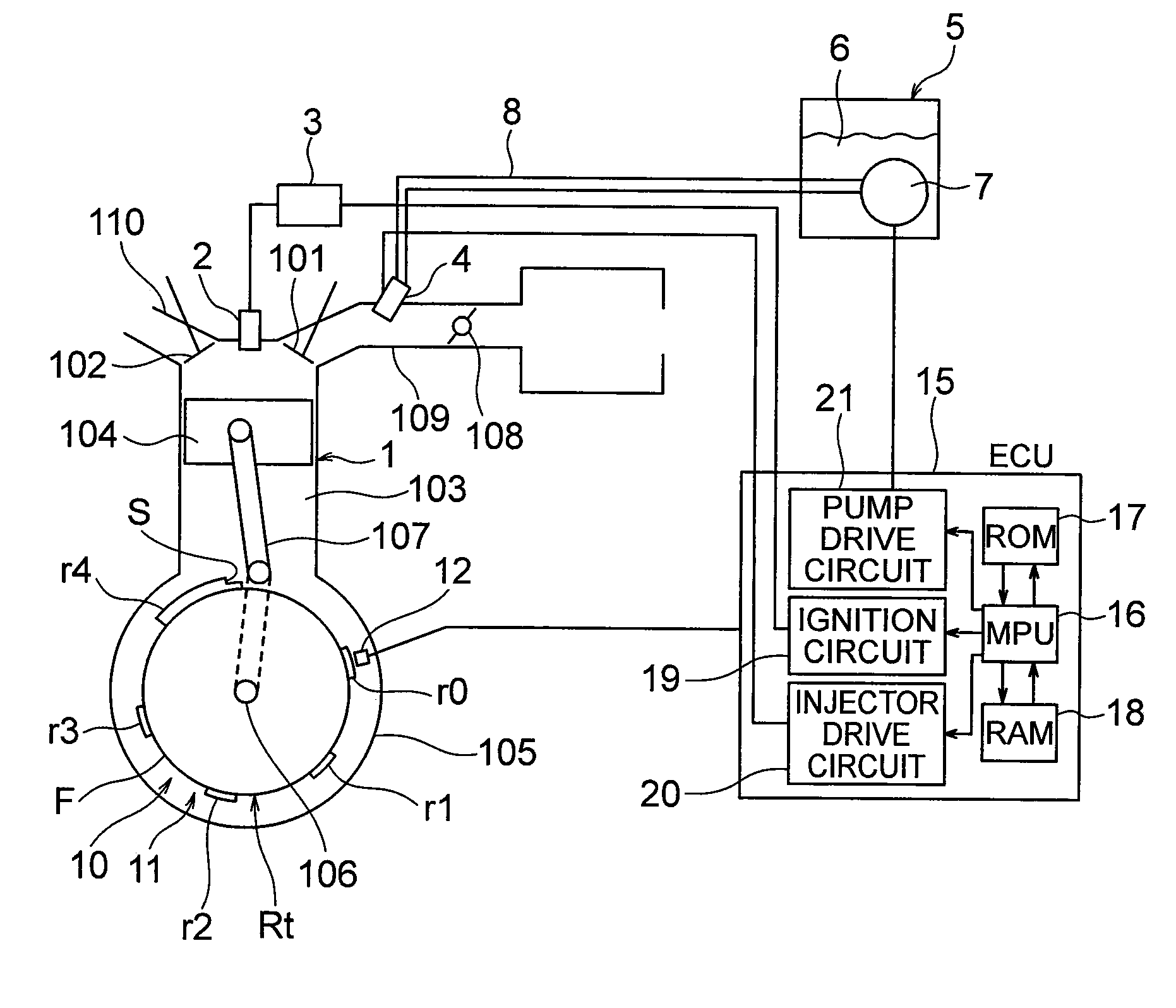

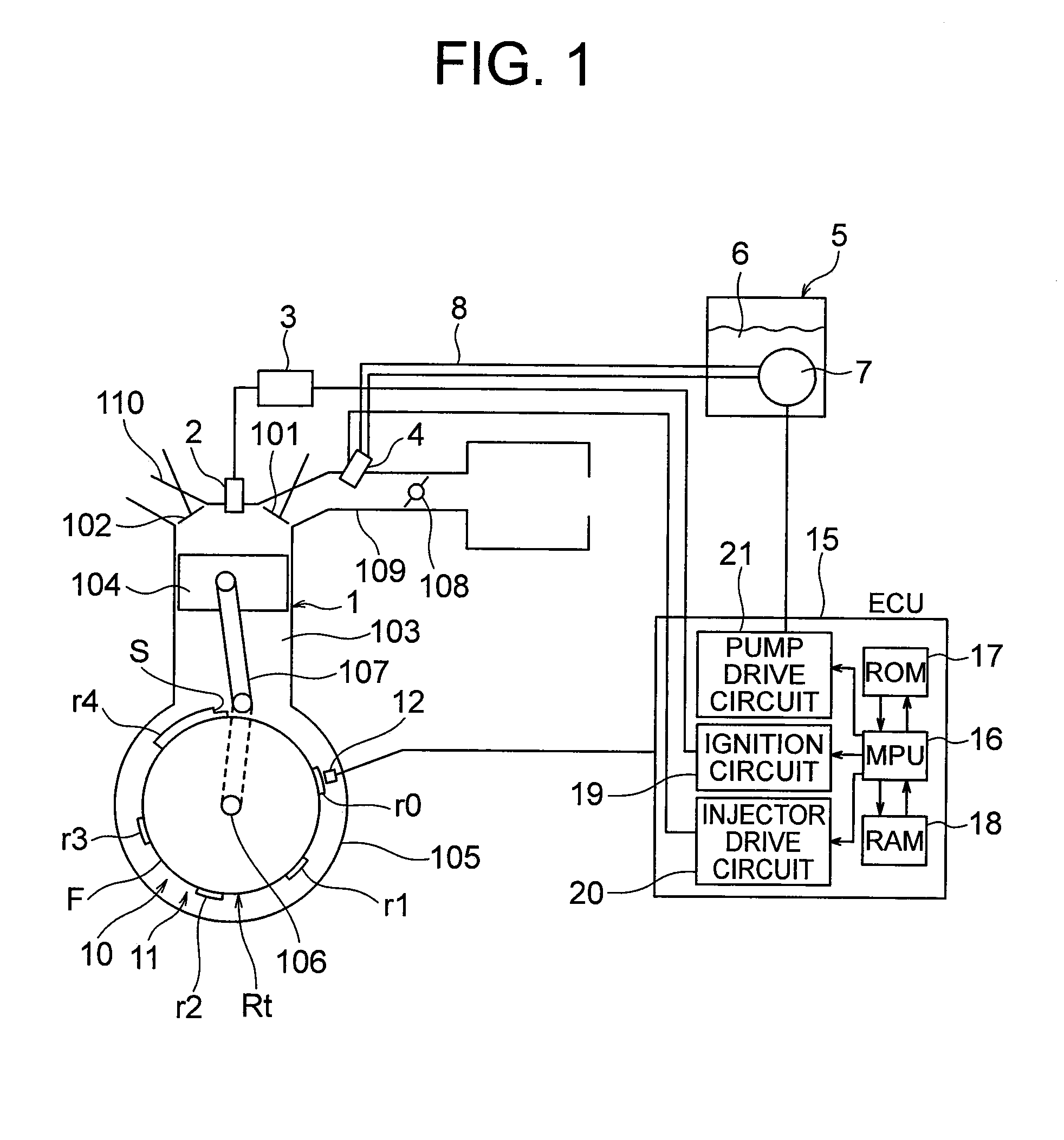

In a motor vehicle with idle stop function, upon satisfaction of preset engine restart conditions (step S205), automatic engine restart control refers to a preset map representing a variation in amount of fuel Q1, which is to be initially injected into a cylinder Cyin stopping in an intake stroke, against the piston stop position Pin of the cylinder Cyin, and specifies the amount of fuel Q1 corresponding to the detected piston stop position Pin of the cylinder Cyin (step S220). The automatic engine restart control then controls an injector to inject the specified amount of fuel Q1 into an intake port of the cylinder Cyin (step S230). Under the condition that the piston stop position Pin of the cylinder Cyin suggests low gas intake performance, the increased amount of fuel Q1 is injected into the intake port of the cylinder Cyin. This arrangement desirably reduces a misfire rate at the timing of first combustion and thereby improves the startability of an engine. When the amount of fuel Q1 specified at step S220 is equal to zero, the cylinder Cyin is not subject to the first combustion. Such control desirably prevents poor emission.

Owner:TOYOTA JIDOSHA KK +1

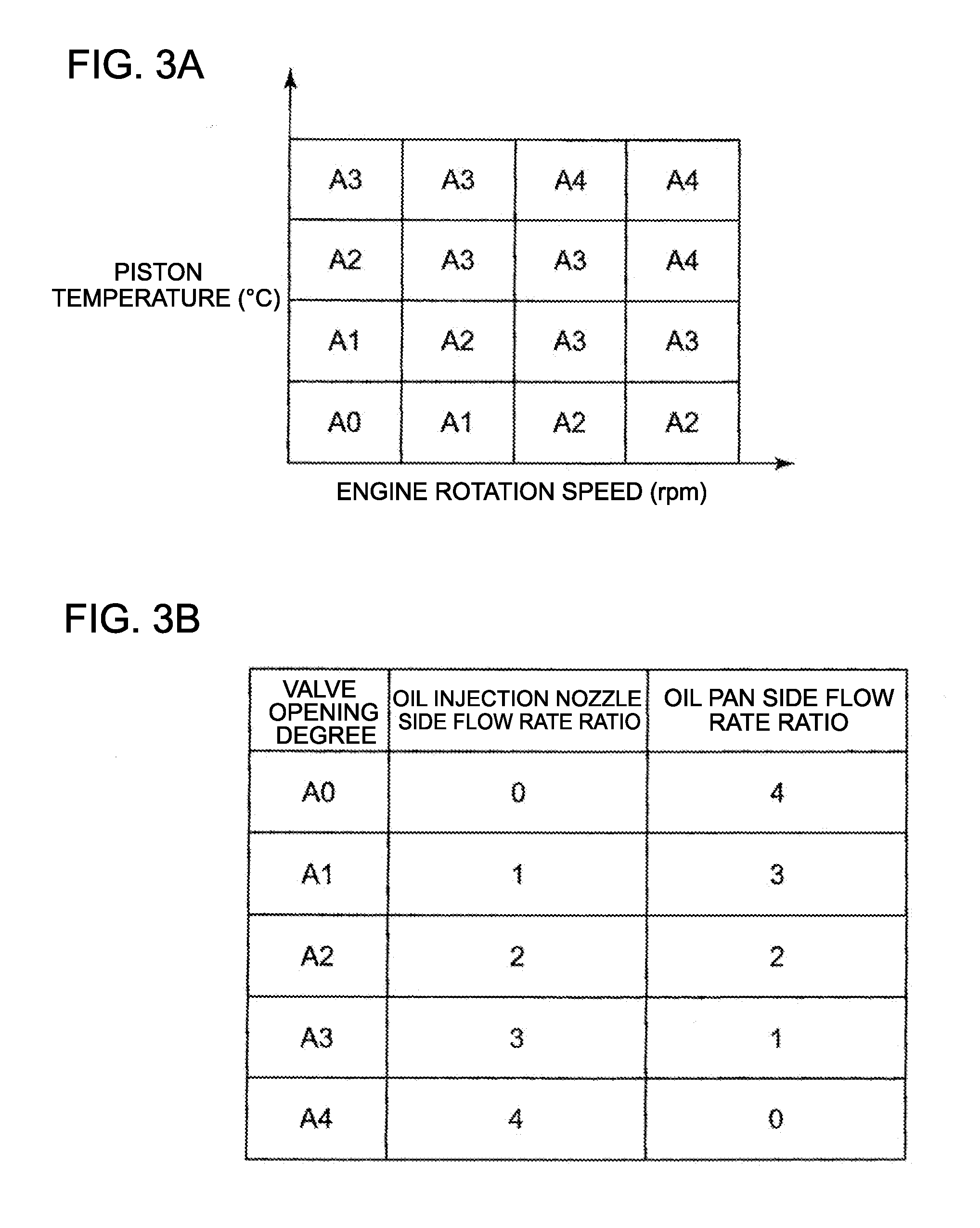

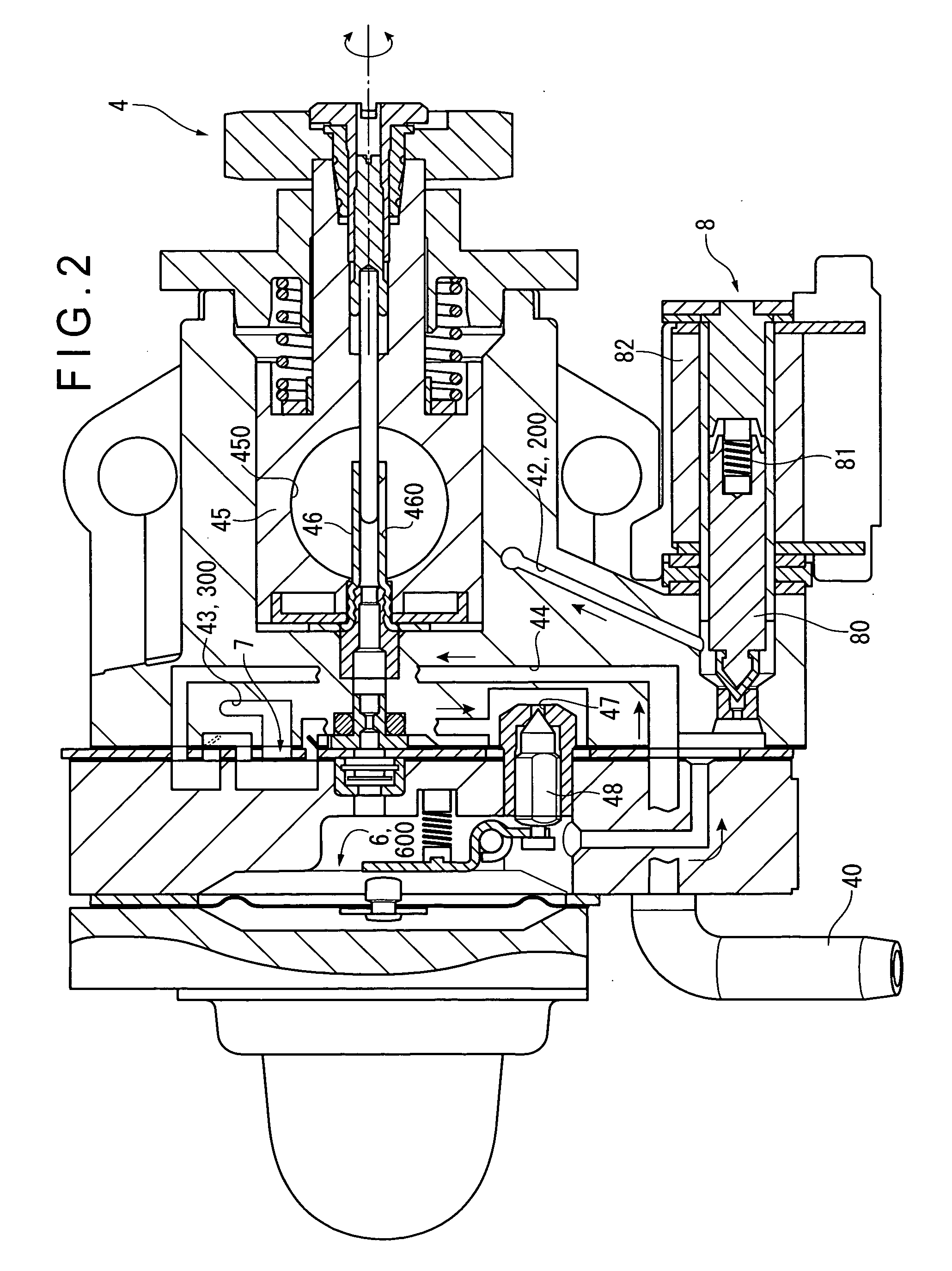

Cooling device for engine

ActiveUS20130139768A1Fine cooling controlEasy to operateLiquid coolingCoolant flow controlPistonPetroleum engineering

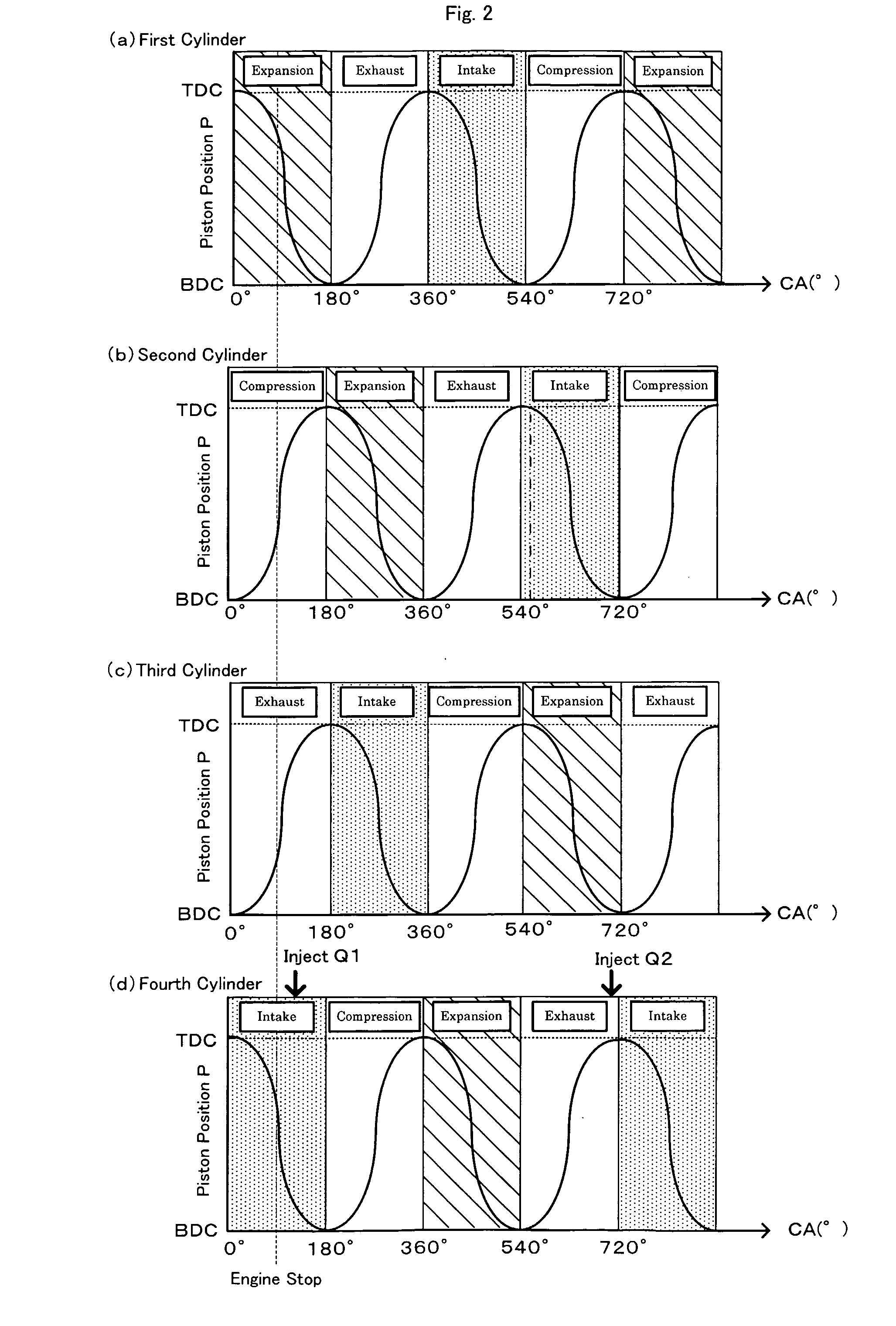

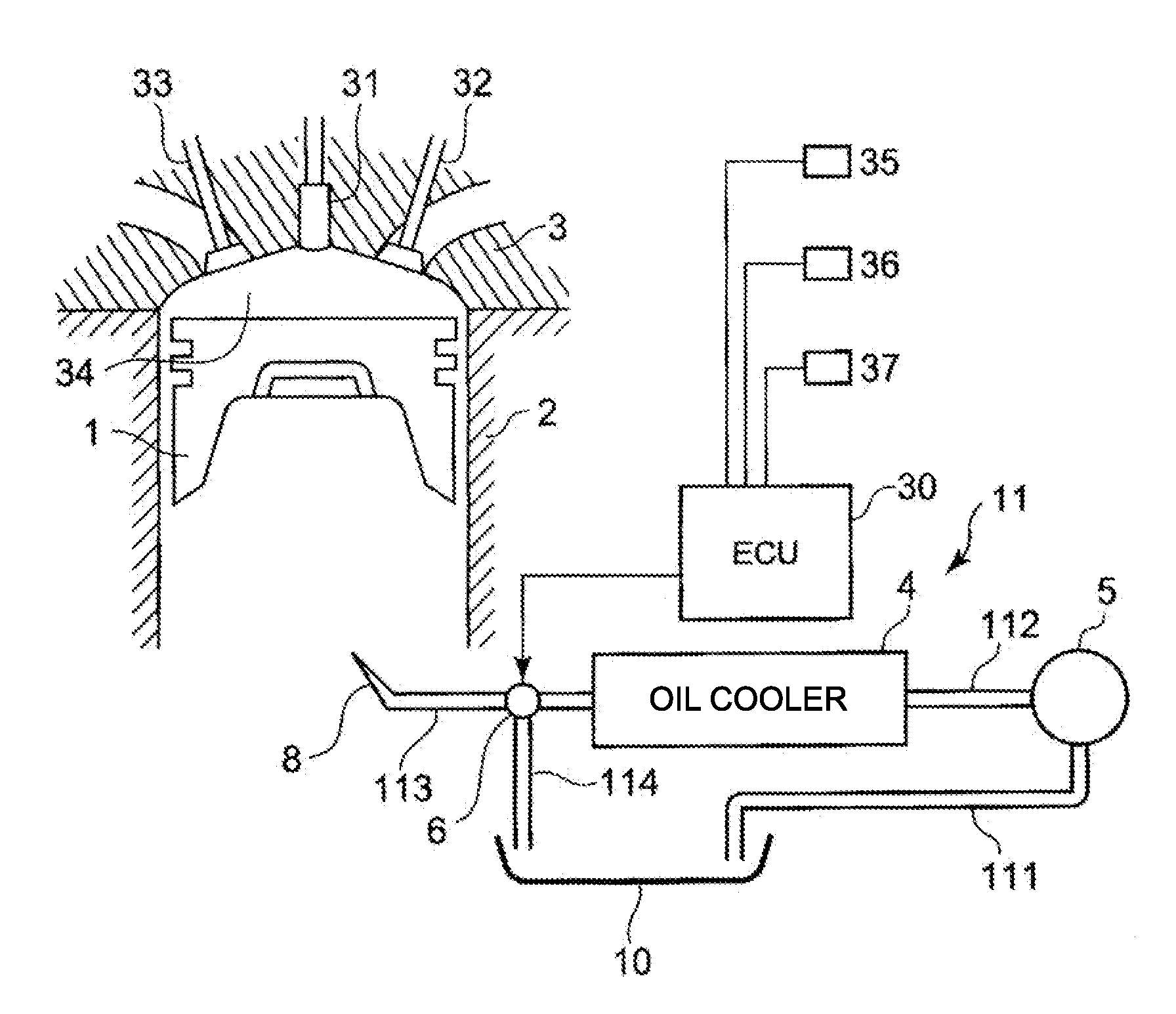

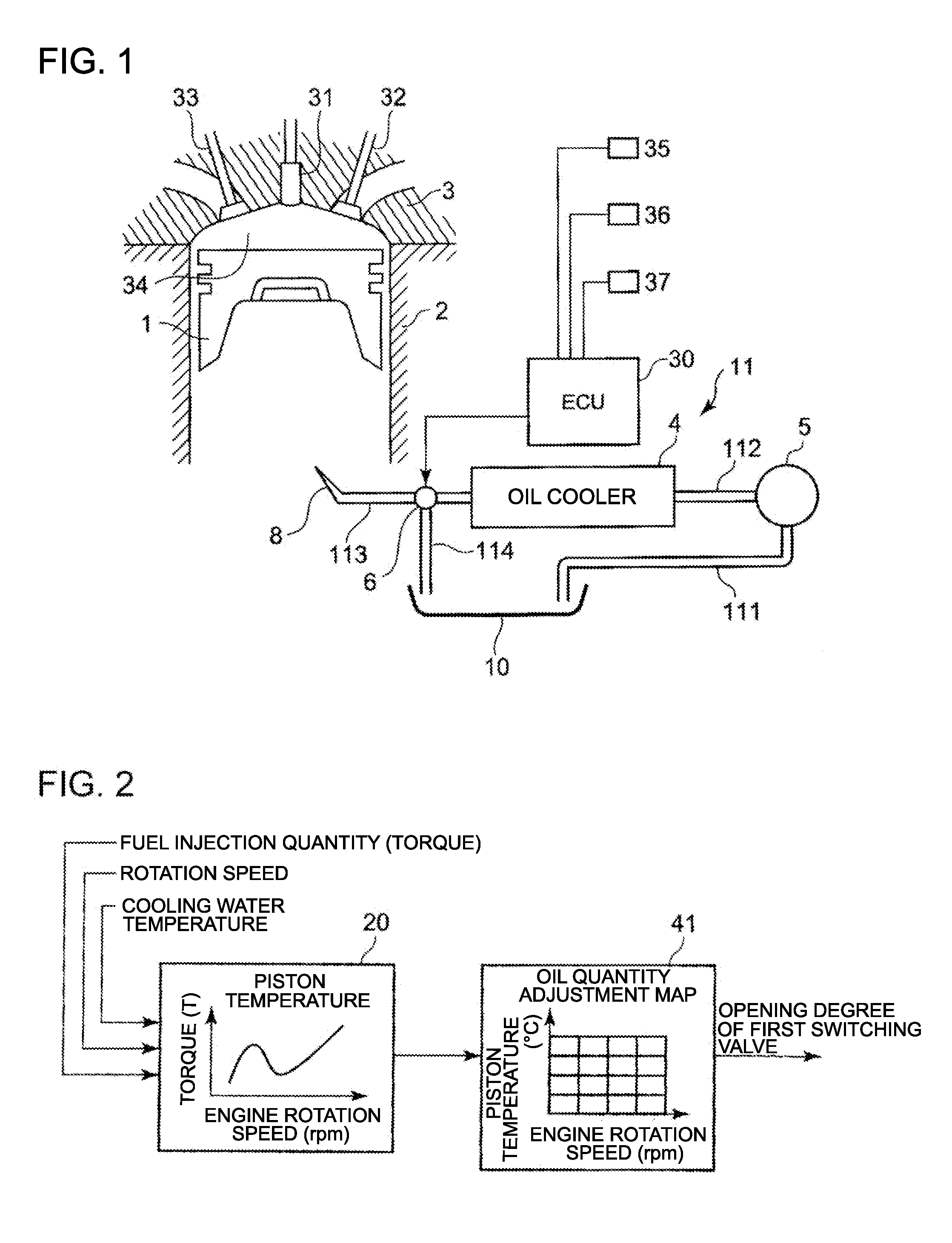

Disclosed is an oil jet device for cooling a piston, including: an oil cooler 4 that is disposed upstream of an oil injection nozzle 8; an oil pump 5 that is disposed upstream of the oil cooler 4; a first switching adjustment valve 6 that is disposed between the oil injection nozzle 8 and the oil cooler 4 and adjusts a flow dividing ratio at which the cooling oil from the oil cooler 4 is distributed to the oil injection nozzle 8 side and to an oil pan side; and a control unit that has an oil quantity adjustment map 4 for switching the first switching adjustment valve 6 based on a piston temperature calculation map 20 for calculating the temperature of the piston 1 using detection values acquired respectively by a cooling water temperature sensor 35, a rotation speed sensor 36 and a load sensor 37.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

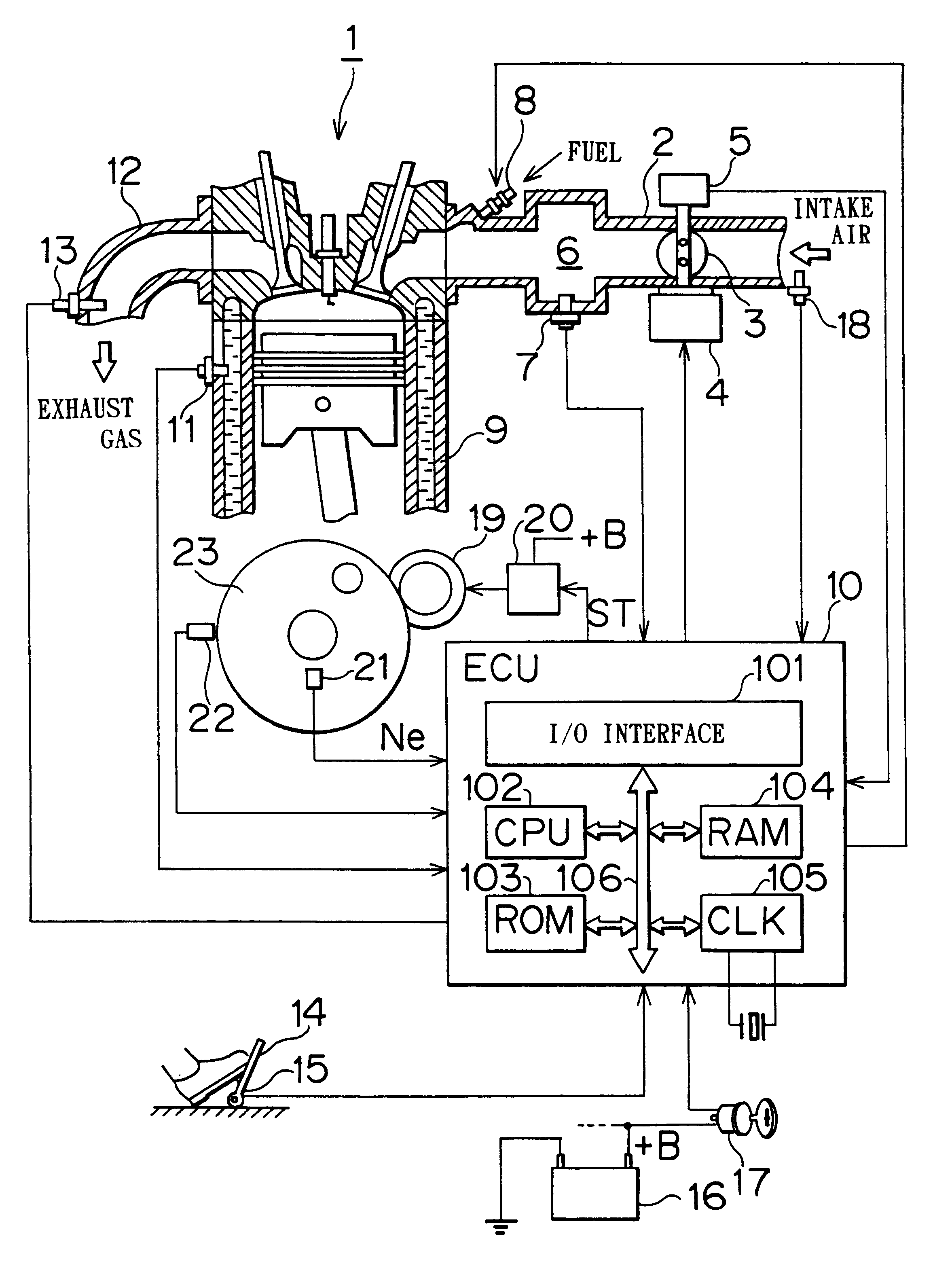

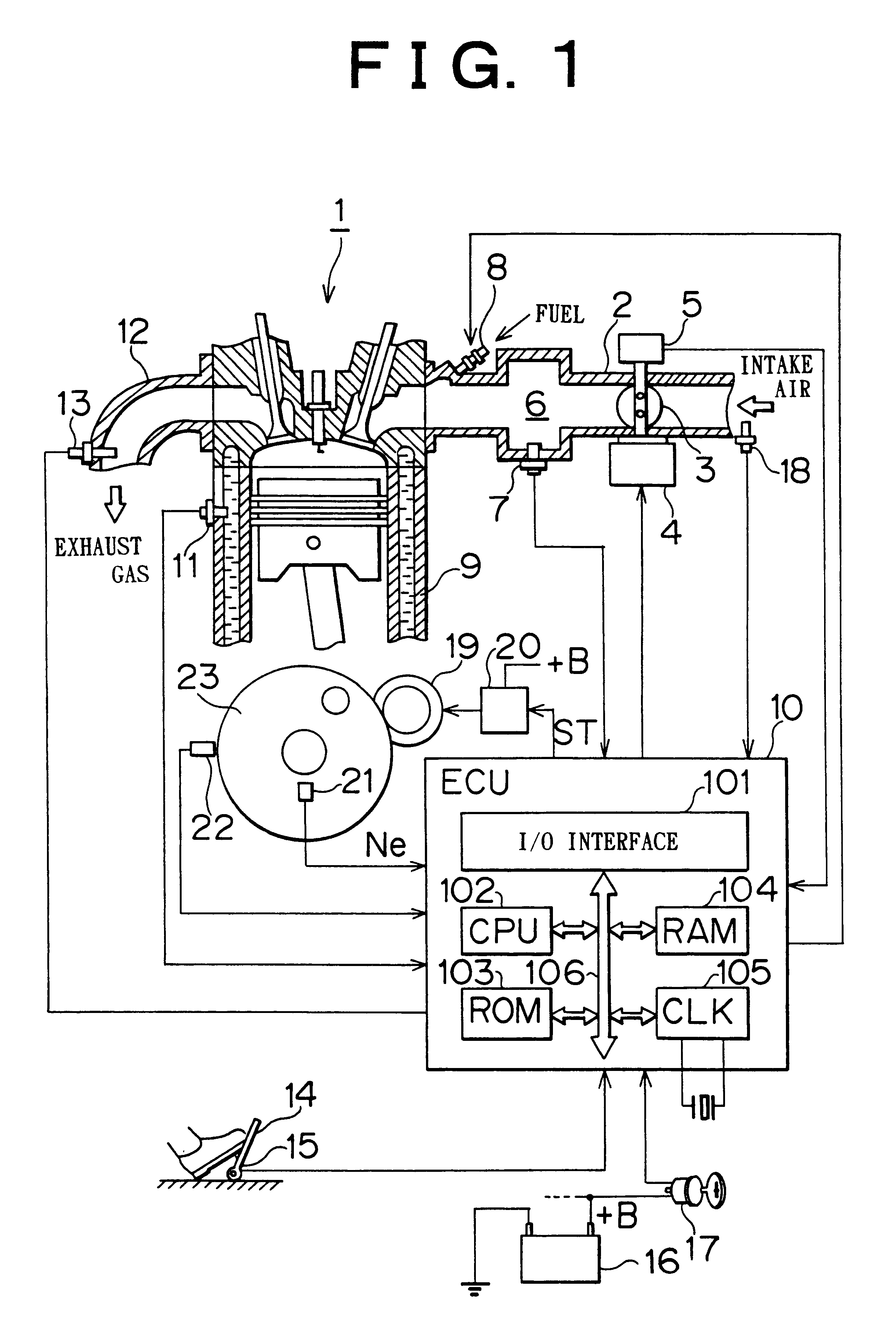

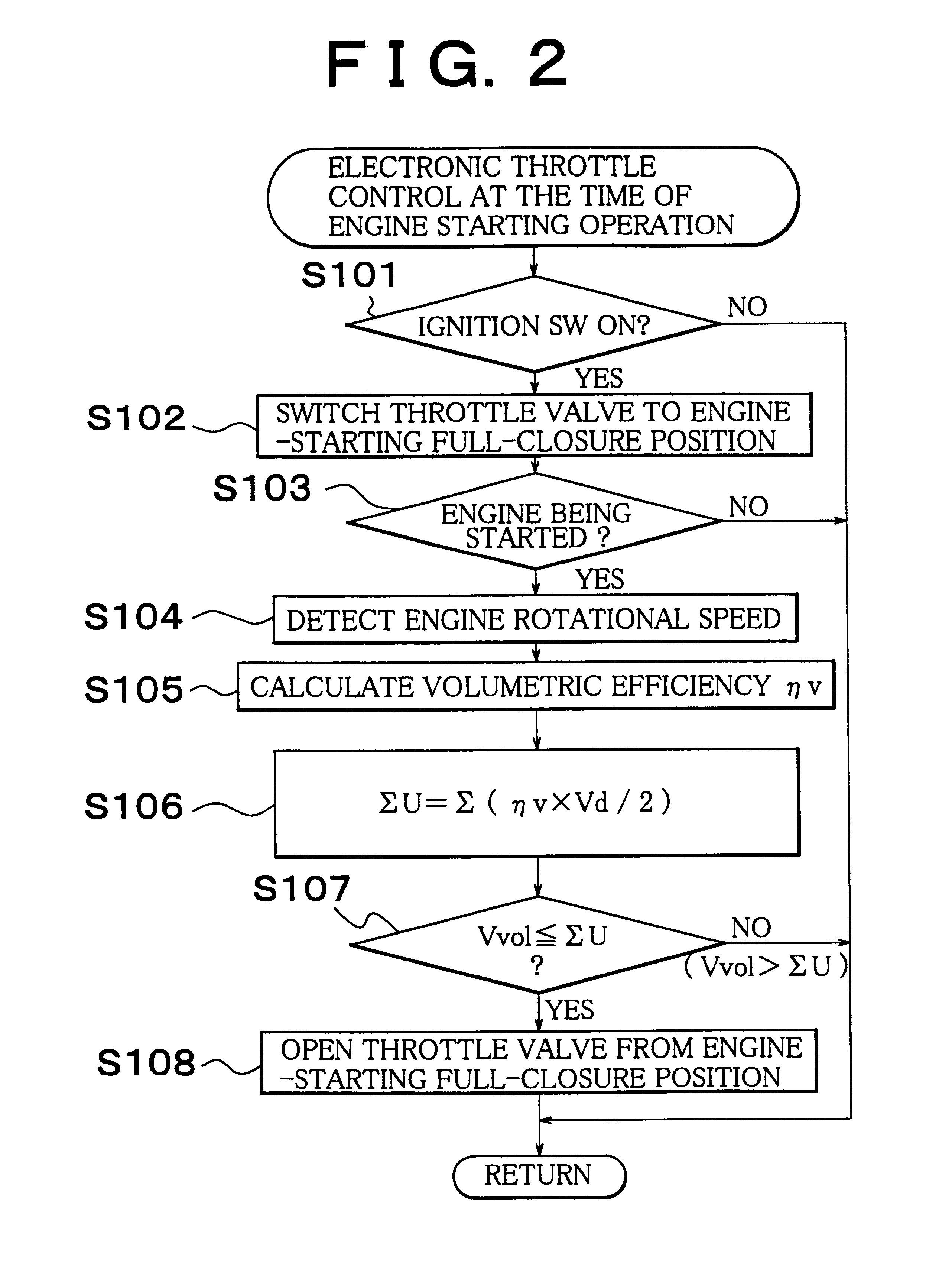

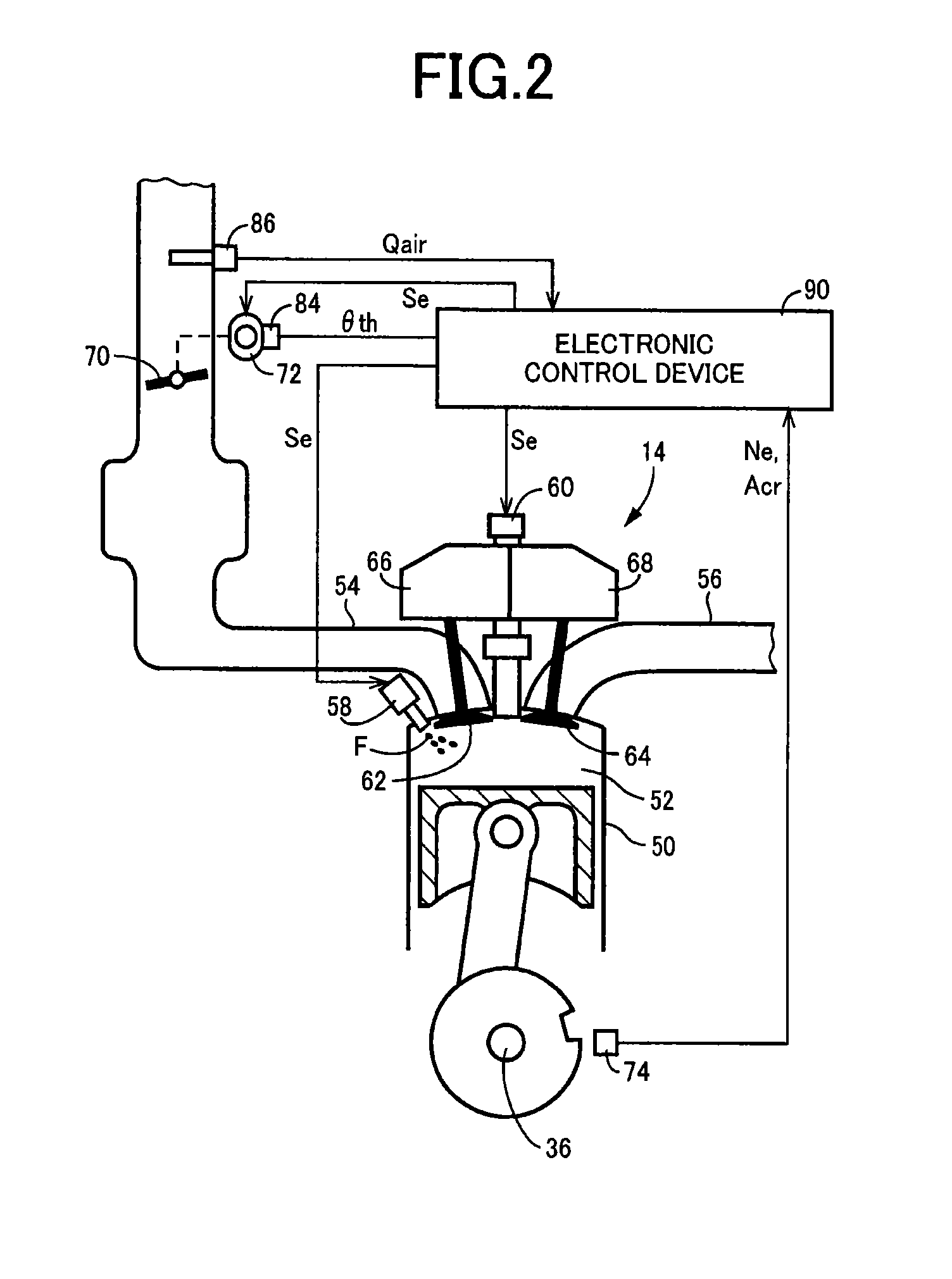

Intake air control system for internal combustion engine

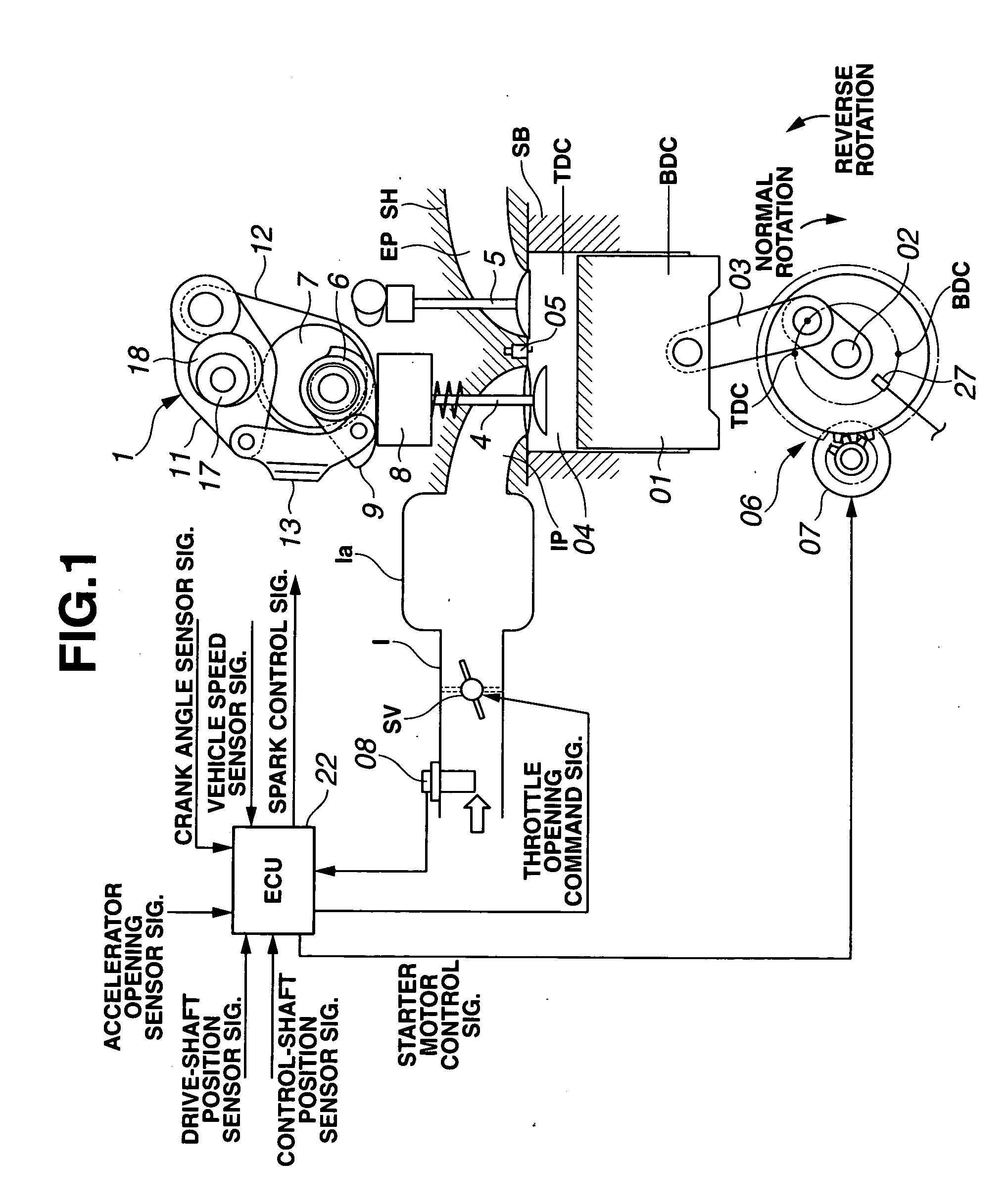

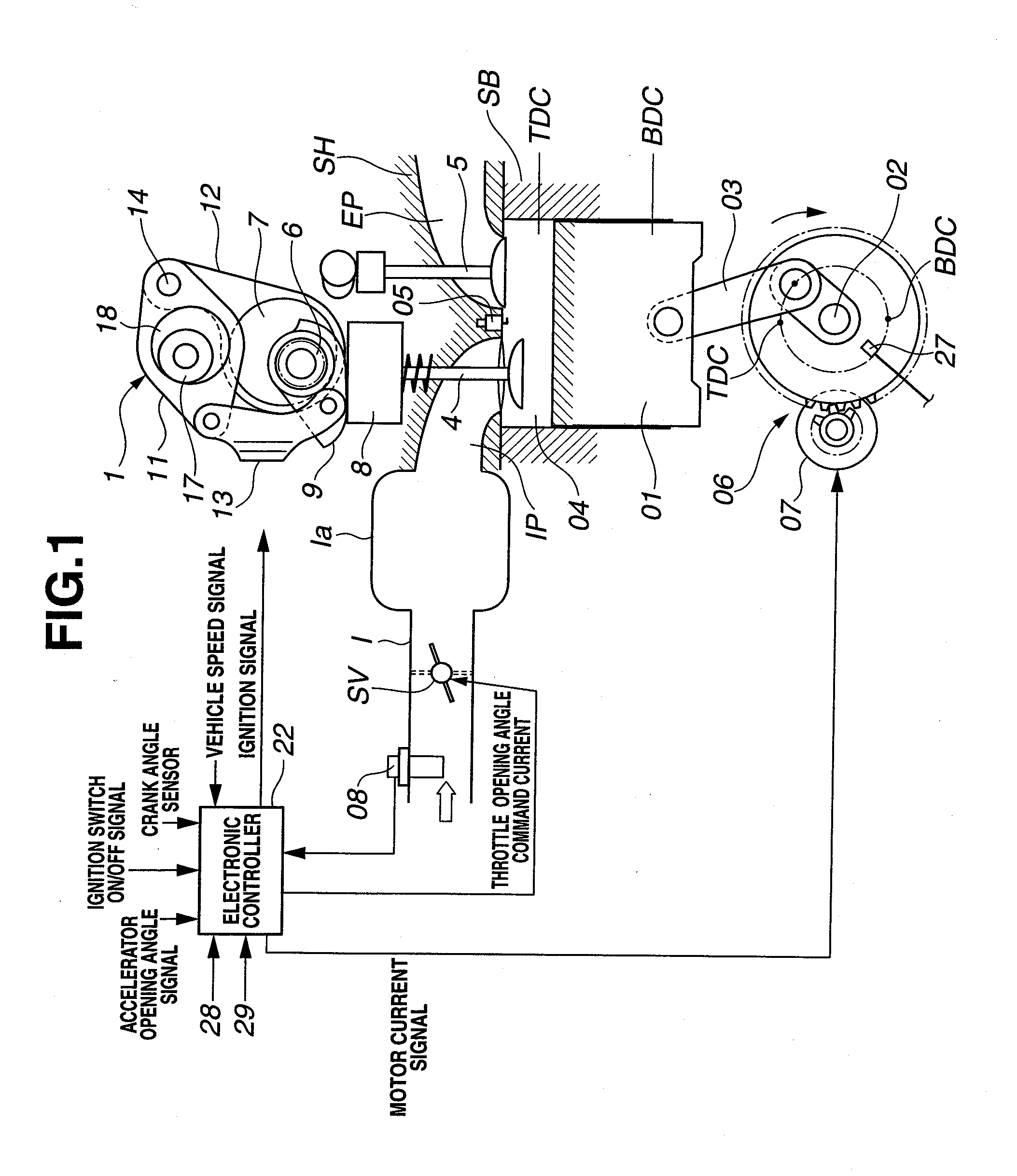

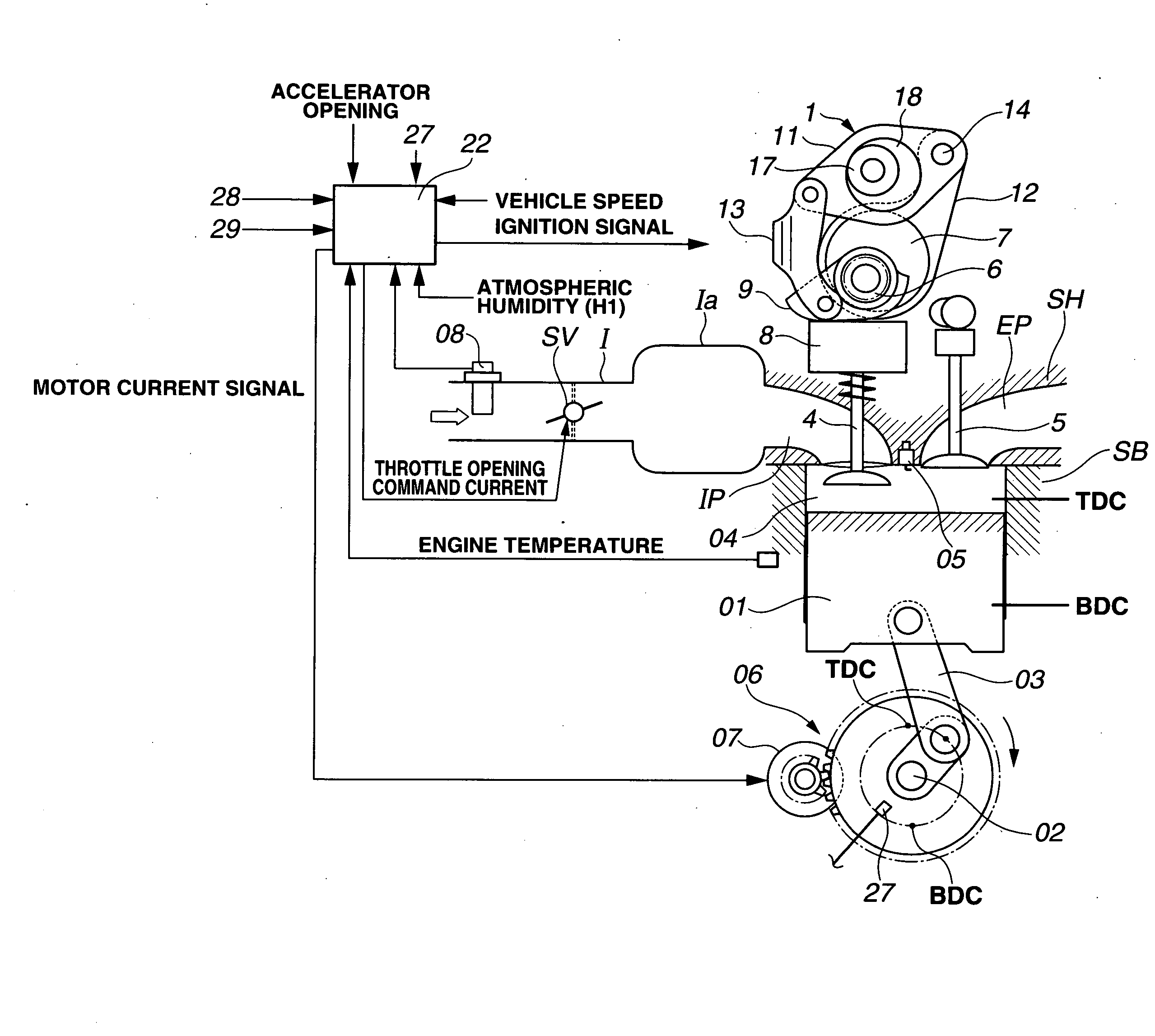

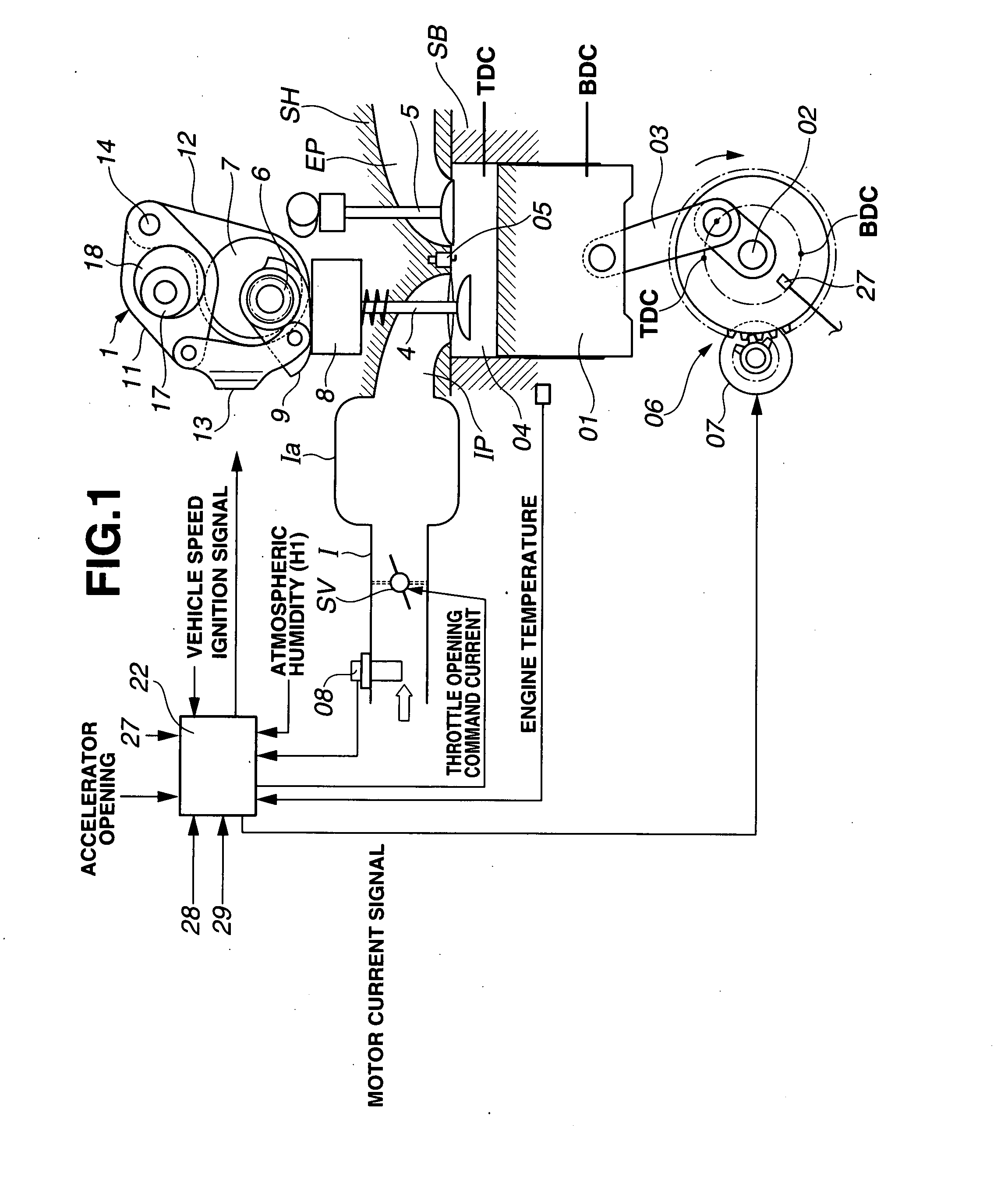

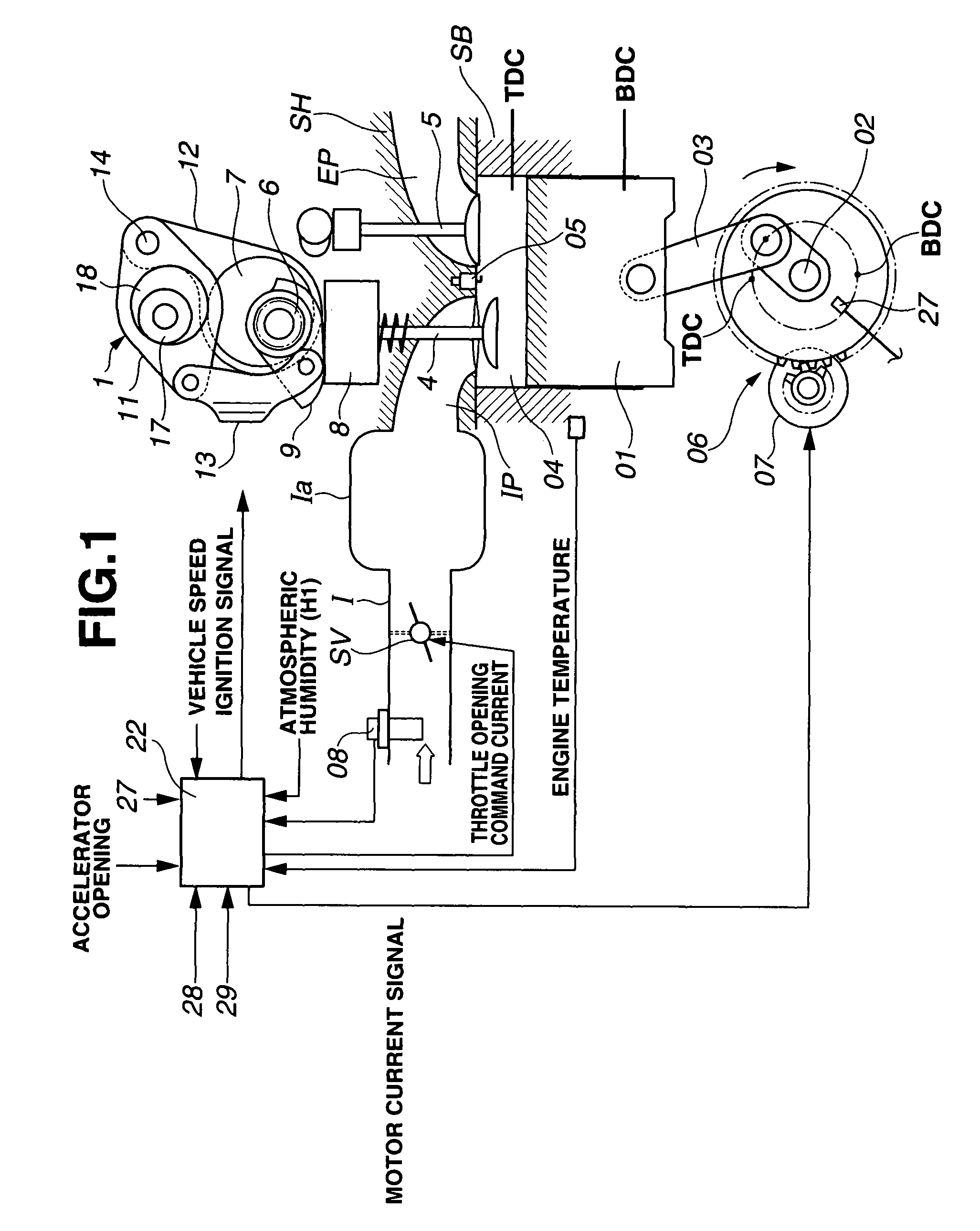

InactiveUS6338331B1Reduce concentrationEngine startability can be improvedElectrical controlInternal combustion piston enginesControl systemInternal combustion engine

An internal combustion engine having an intake passage that is closed at the time of engine starting operation wherein a holding time for completely closing a throttle valve is made as long as possible within such a range that the engine does not fail to be started. The throttle valve is held at its full-closure position when an ignition switch is turned on. Then, at the time of engine starting operation, an amount of air consumed by the engine is calculated based on a cumulative rotational speed of the engine, a cylinder volume of the engine, and a parameter of volumetric efficiency corresponding to an engine rotational speed, and, if so, the throttle valve is opened to a predetermined opening degree.

Owner:TOYOTA JIDOSHA KK

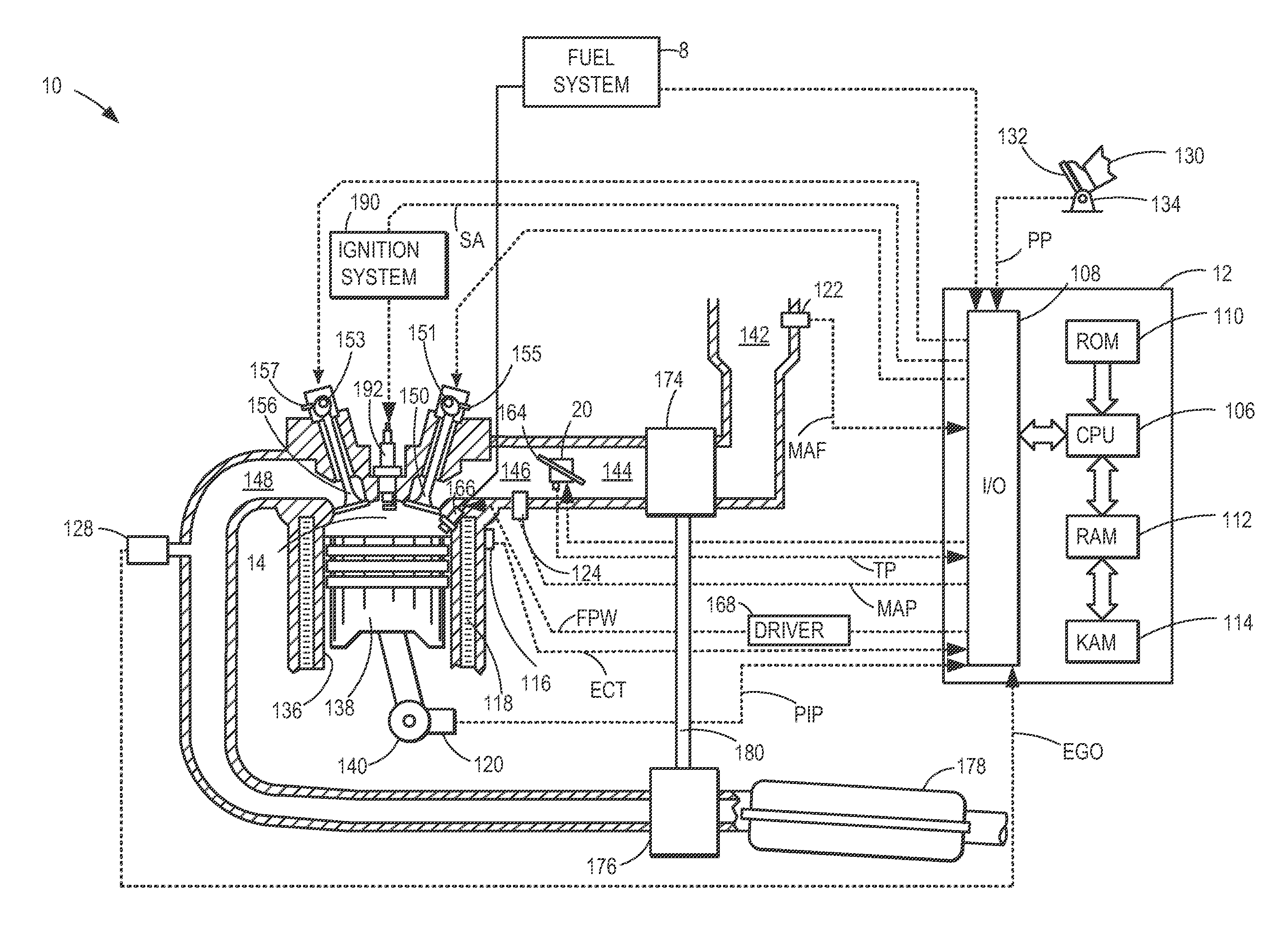

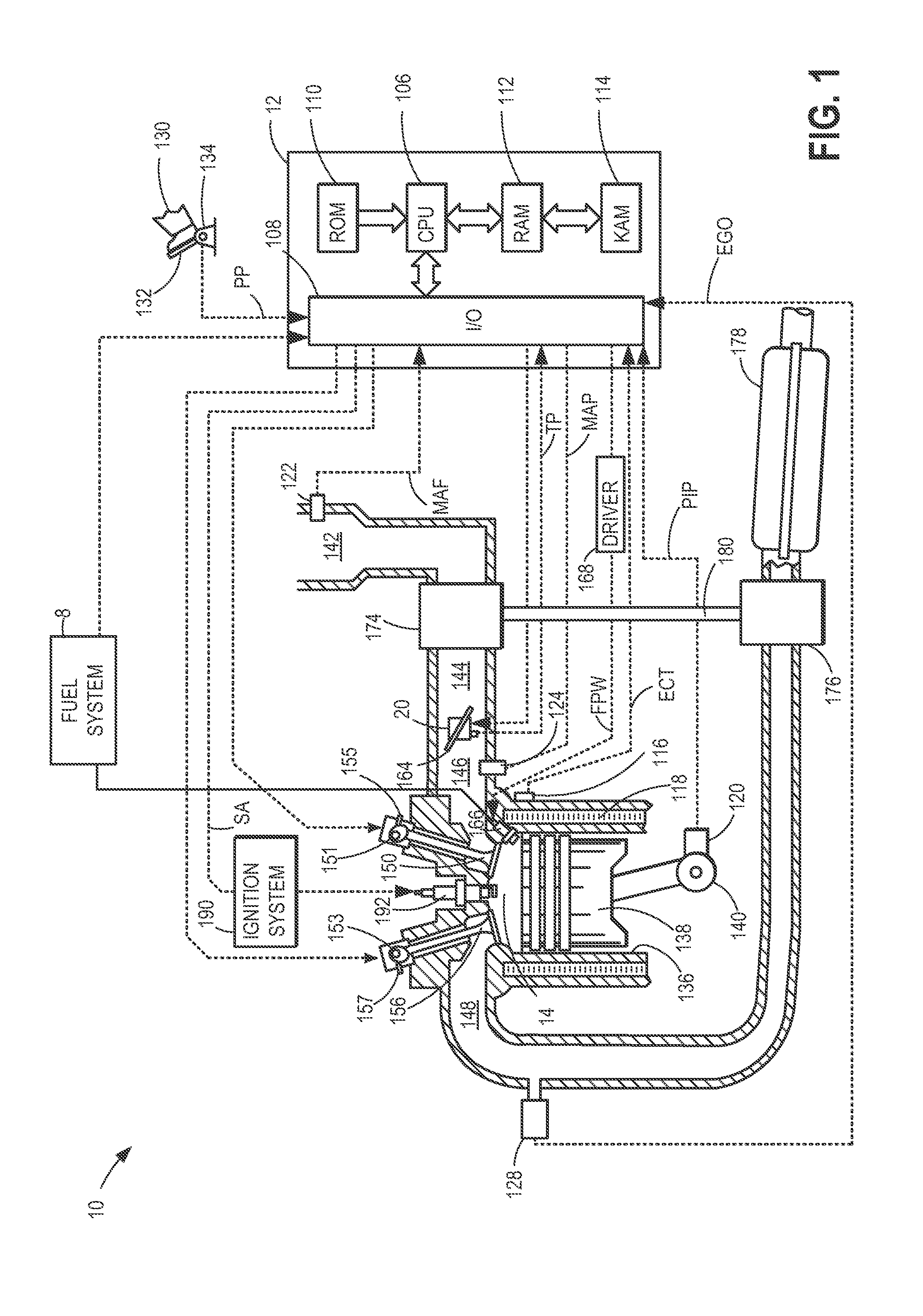

Method and system for engine control

ActiveUS20130218441A1Reducing engine restart timeSufficient pressureValve arrangementsElectrical controlCombustionRail pressure

Methods and systems are provided for restarting an engine when a high pressure fuel pump is degraded. In response to an indication of high pressure fuel pump degradation, fuel may be injected during an intake stroke, rather than a compression stroke, for a selected number of combustion events since the engine restart. By shifting to an intake stroke injection, the engine may be started even when sufficient fuel rail pressures are not available.

Owner:FORD GLOBAL TECH LLC

Engine start control apparatus, engine start control method, and motor vehicle equipped with engine start control apparatus

ActiveUS7949461B2Startability is improvedPrevent poor emissionAnalogue computers for vehiclesPower operated startersAutomatic Generation ControlCombustion

In a motor vehicle with idle stop function, upon satisfaction of preset engine restart conditions (step S205), automatic engine restart control refers to a preset map representing a variation in amount of fuel Q1, which is to be initially injected into a cylinder Cyin stopping in an intake stroke, against the piston stop position Pin of the cylinder Cyin, and specifies the amount of fuel Q1 corresponding to the detected piston stop position Pin of the cylinder Cyin (step S220). The automatic engine restart control then controls an injector to inject the specified amount of fuel Q1 into an intake port of the cylinder Cyin (step S230). Under the condition that the piston stop position Pin of the cylinder Cyin suggests low gas intake performance, the increased amount of fuel Q1 is injected into the intake port of the cylinder Cyin. This arrangement desirably reduces a misfire rate at the timing of first combustion and thereby improves the startability of an engine. When the amount of fuel Q1 specified at step S220 is equal to zero, the cylinder Cyin is not subject to the first combustion. Such control desirably prevents poor emission.

Owner:TOYOTA JIDOSHA KK +1

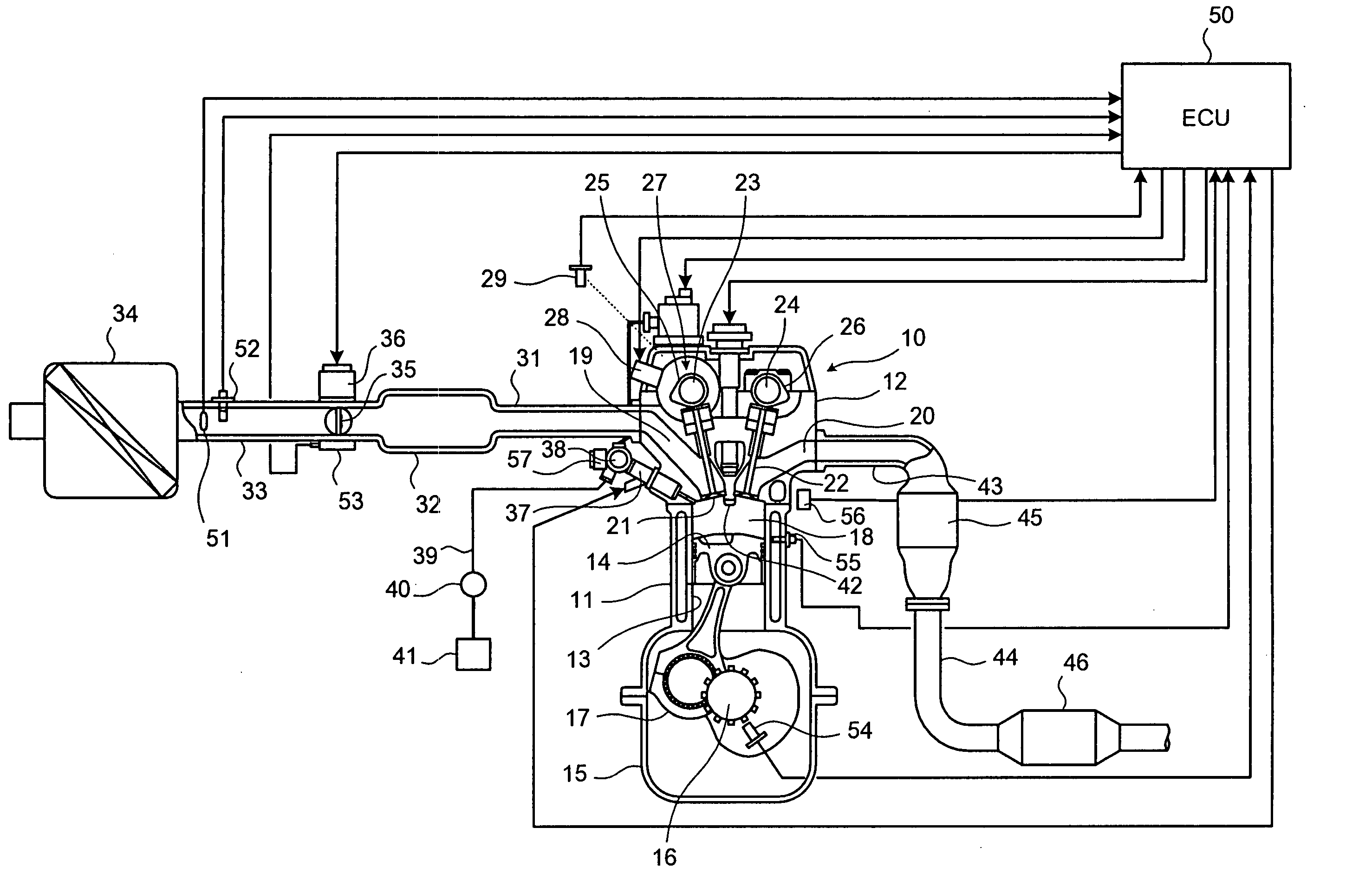

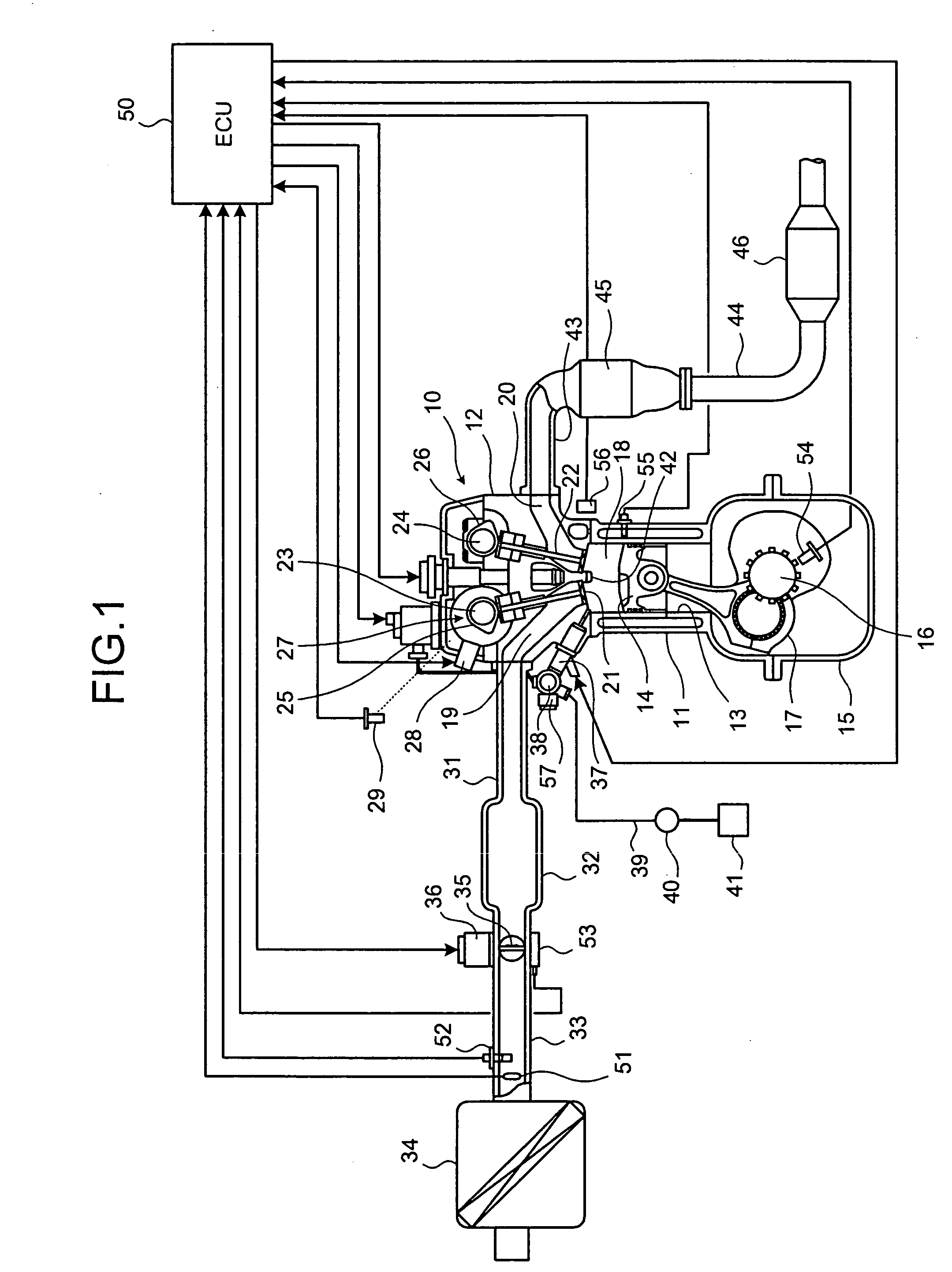

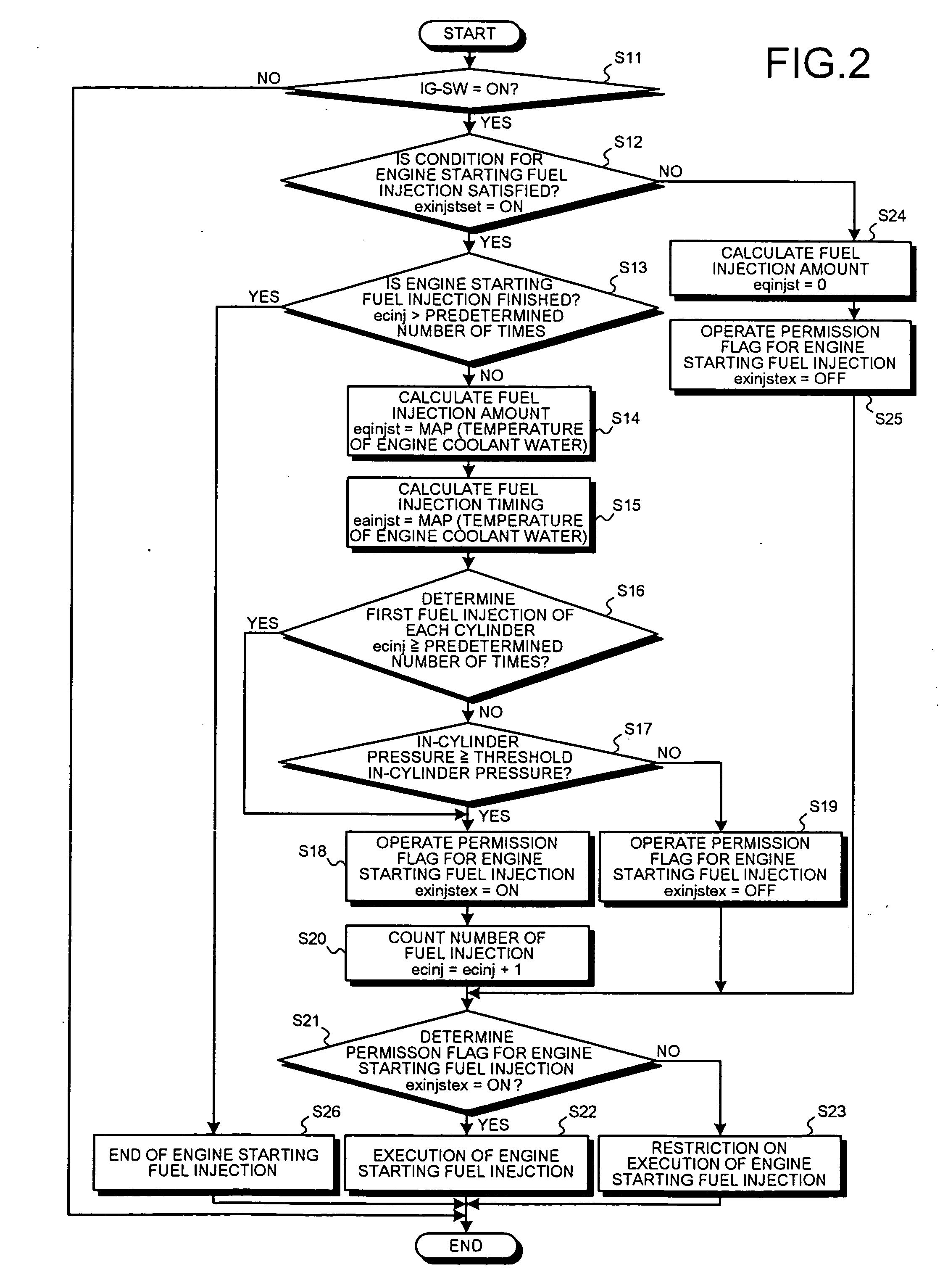

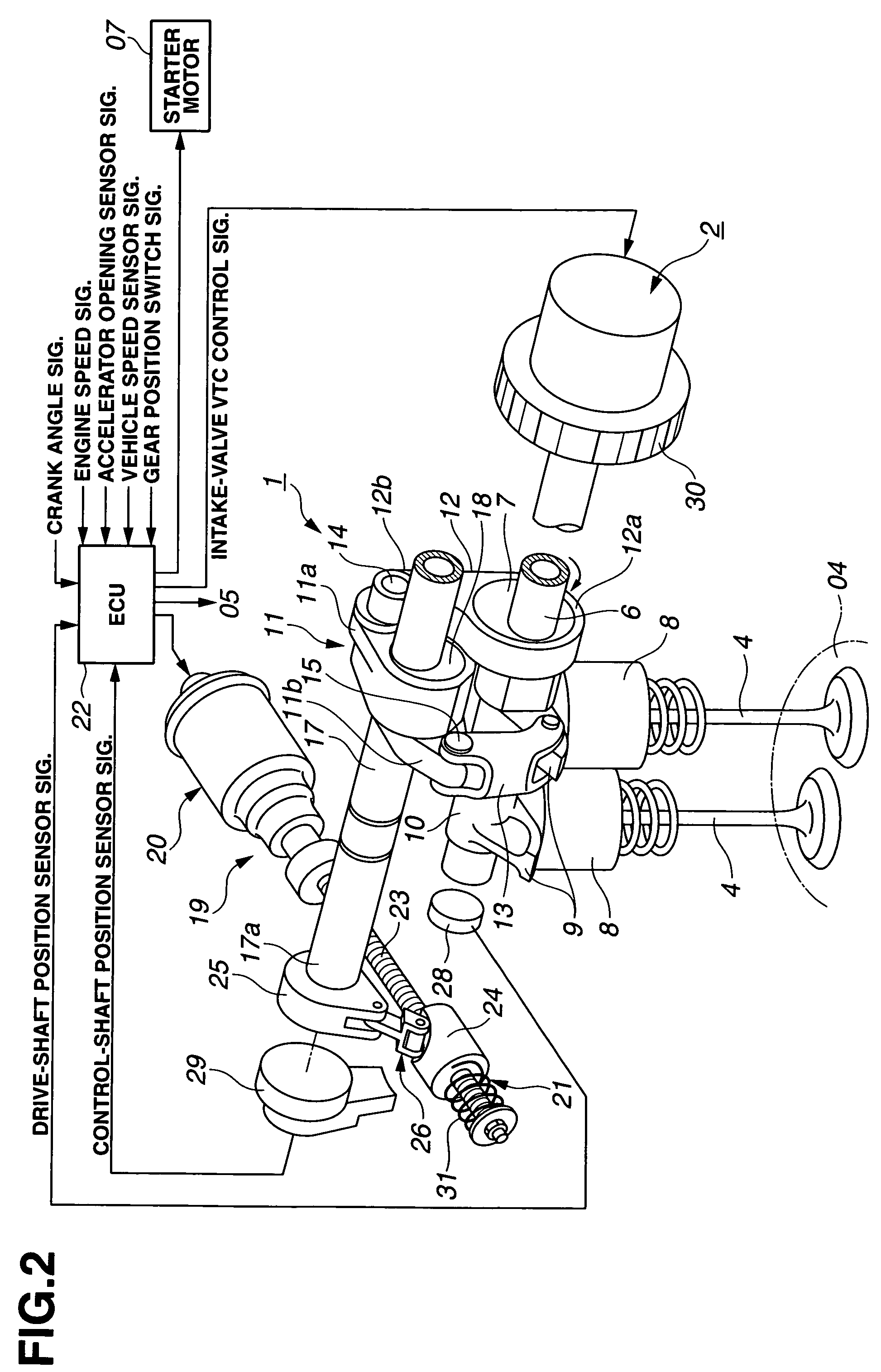

Control apparatus of internal combustion engine

InactiveUS20060231066A1Engine startability can be improvedUniform atomizationElectrical controlCombustion enginesCombustion chamberInternal combustion engine

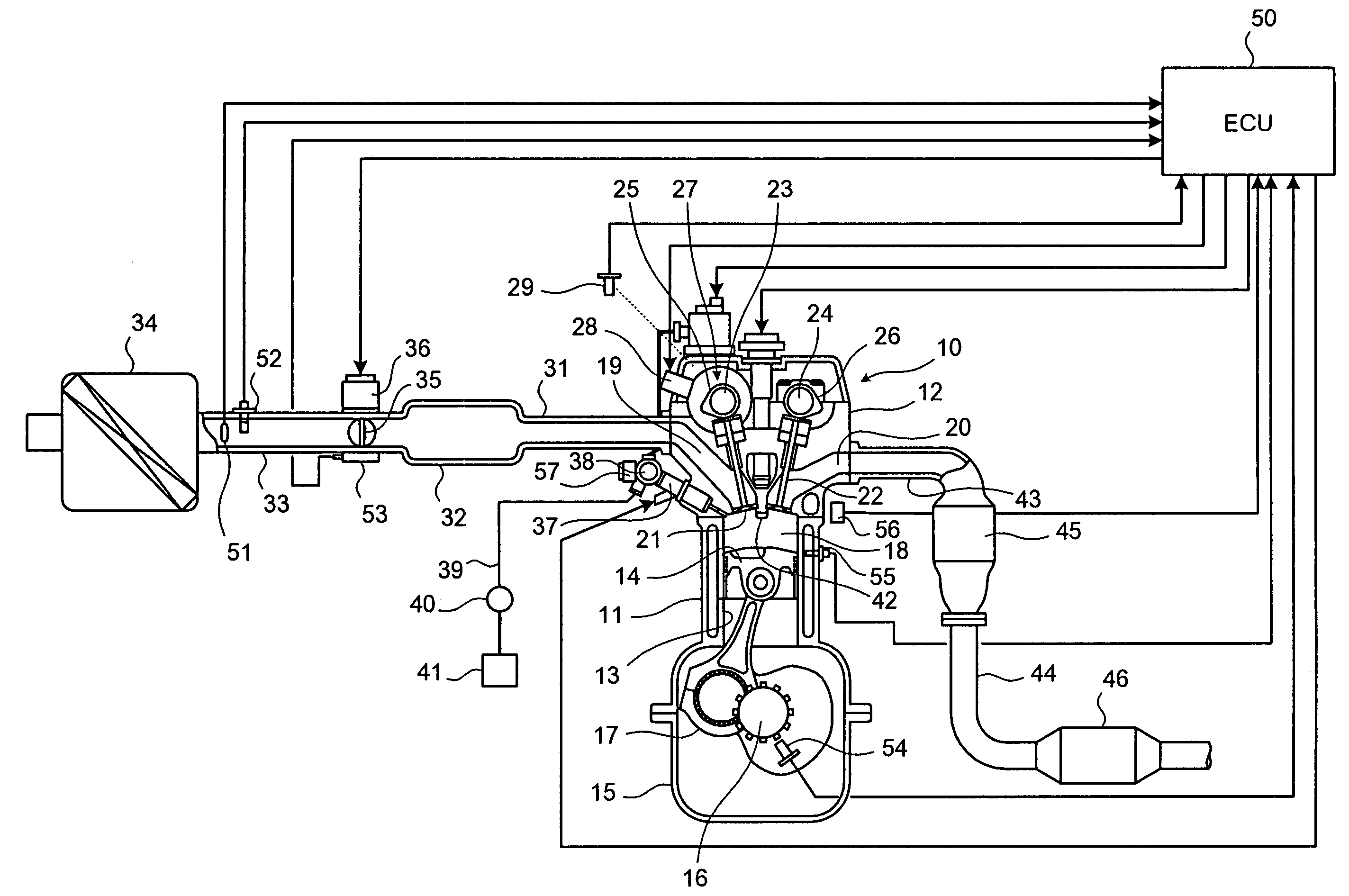

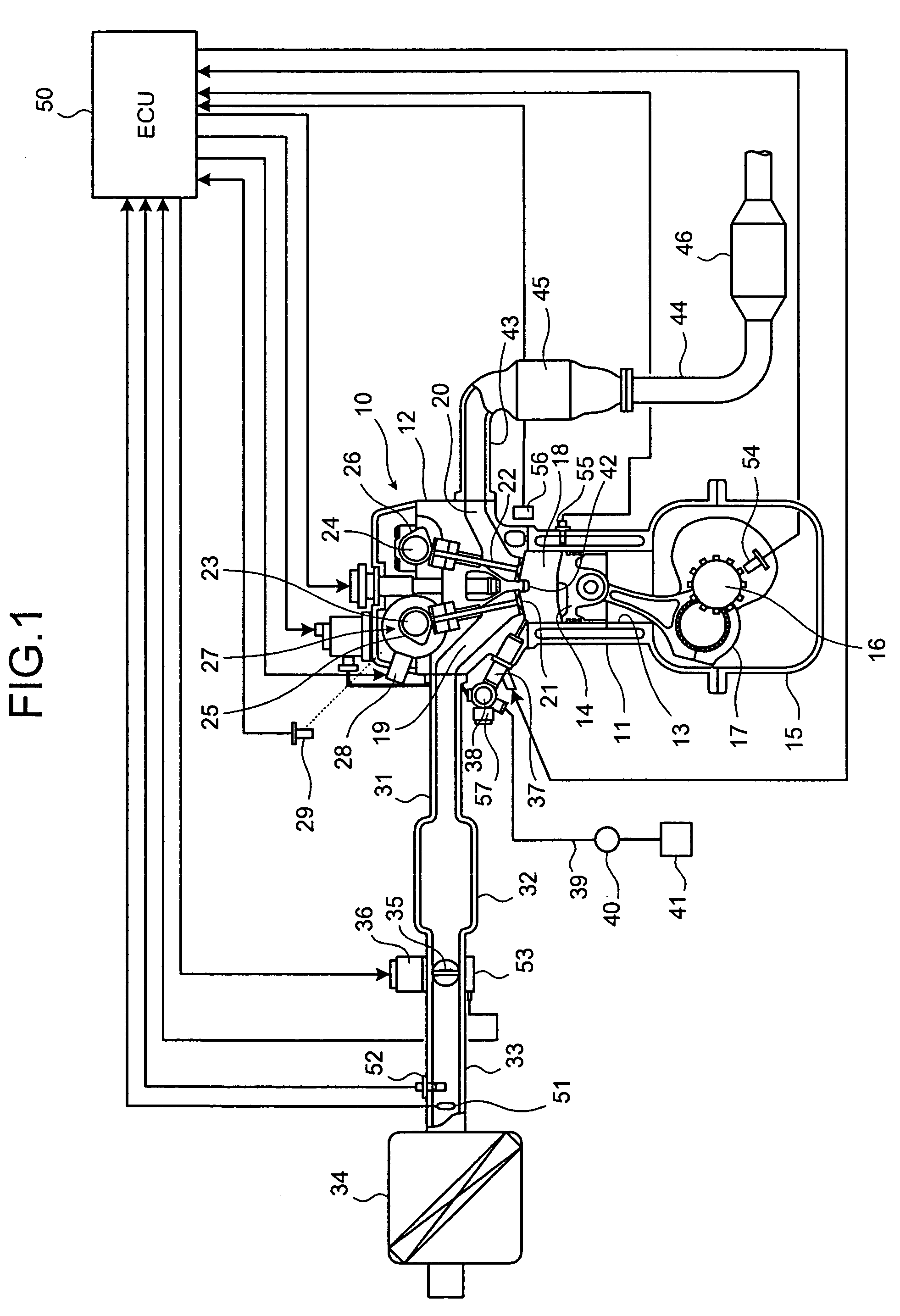

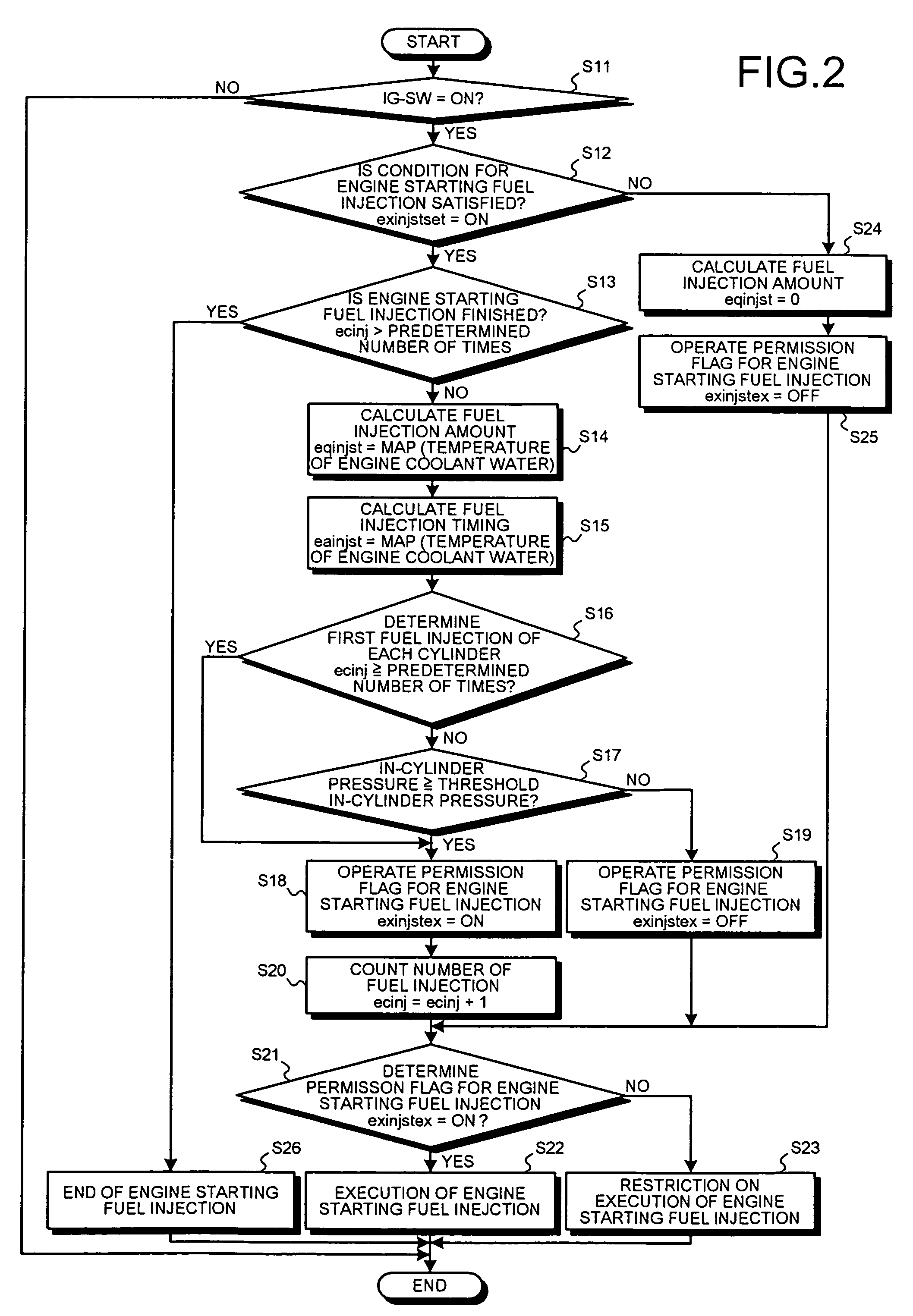

A control apparatus of an internal combustion engine includes a fuel pressure sensor to detect the pressure of the fuel supplied from a fuel pump to an injector; an in-cylinder pressure sensor, which serves as a combustion chamber temperature detecting unit that detects the temperature in the combustion chamber or the parameter depending on the temperature, to detect in-cylinder pressure (combustion chamber pressure); and an ECU that controls to execute the first fuel injection of each cylinder by the injector when the fuel pressure detected by the fuel pressure sensor is not less than a predetermined threshold fuel pressure and when the in-cylinder pressure detected by the in-cylinder pressure sensor is not less than a threshold in-cylinder pressure.

Owner:TOYOTA JIDOSHA KK +1

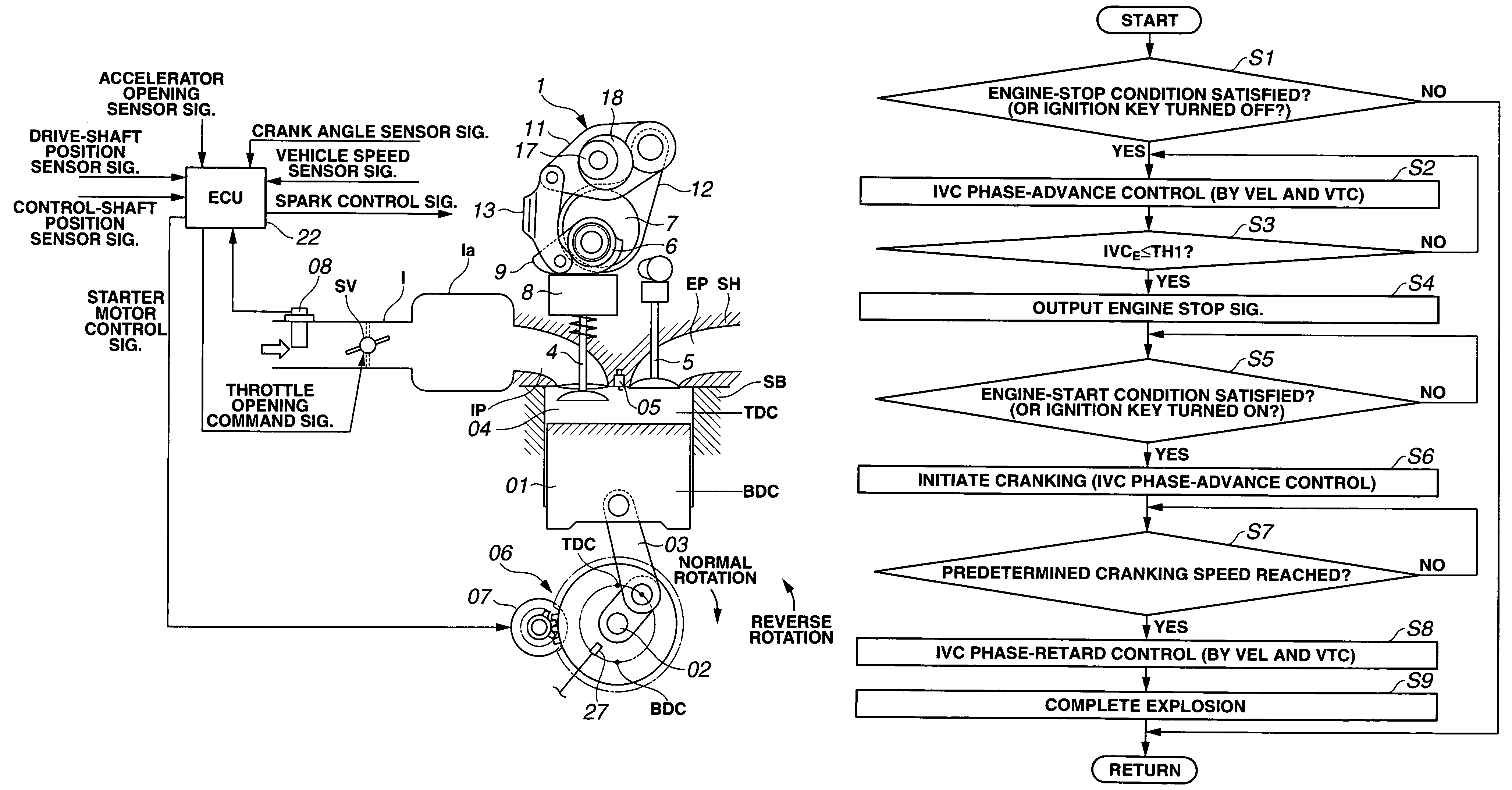

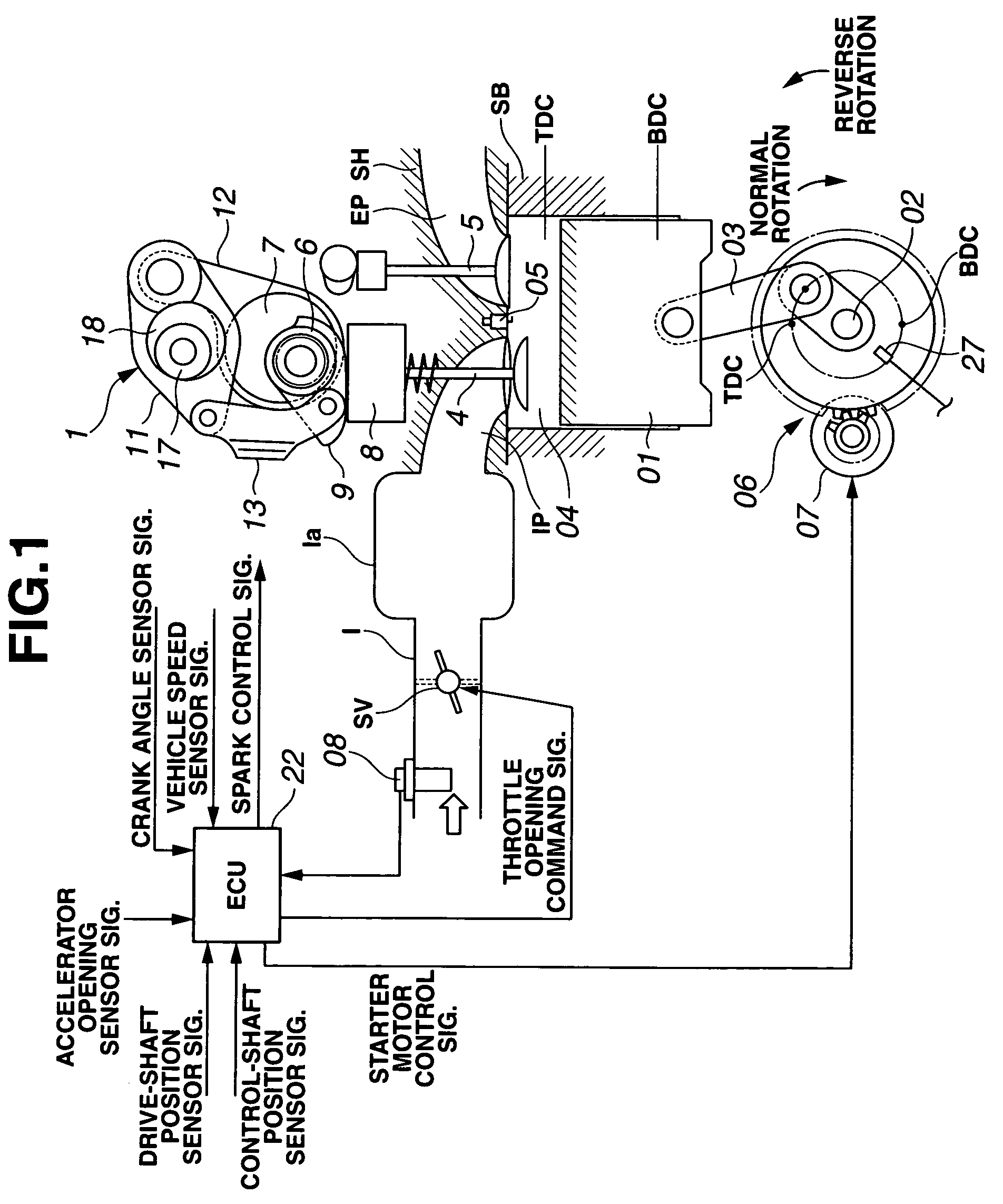

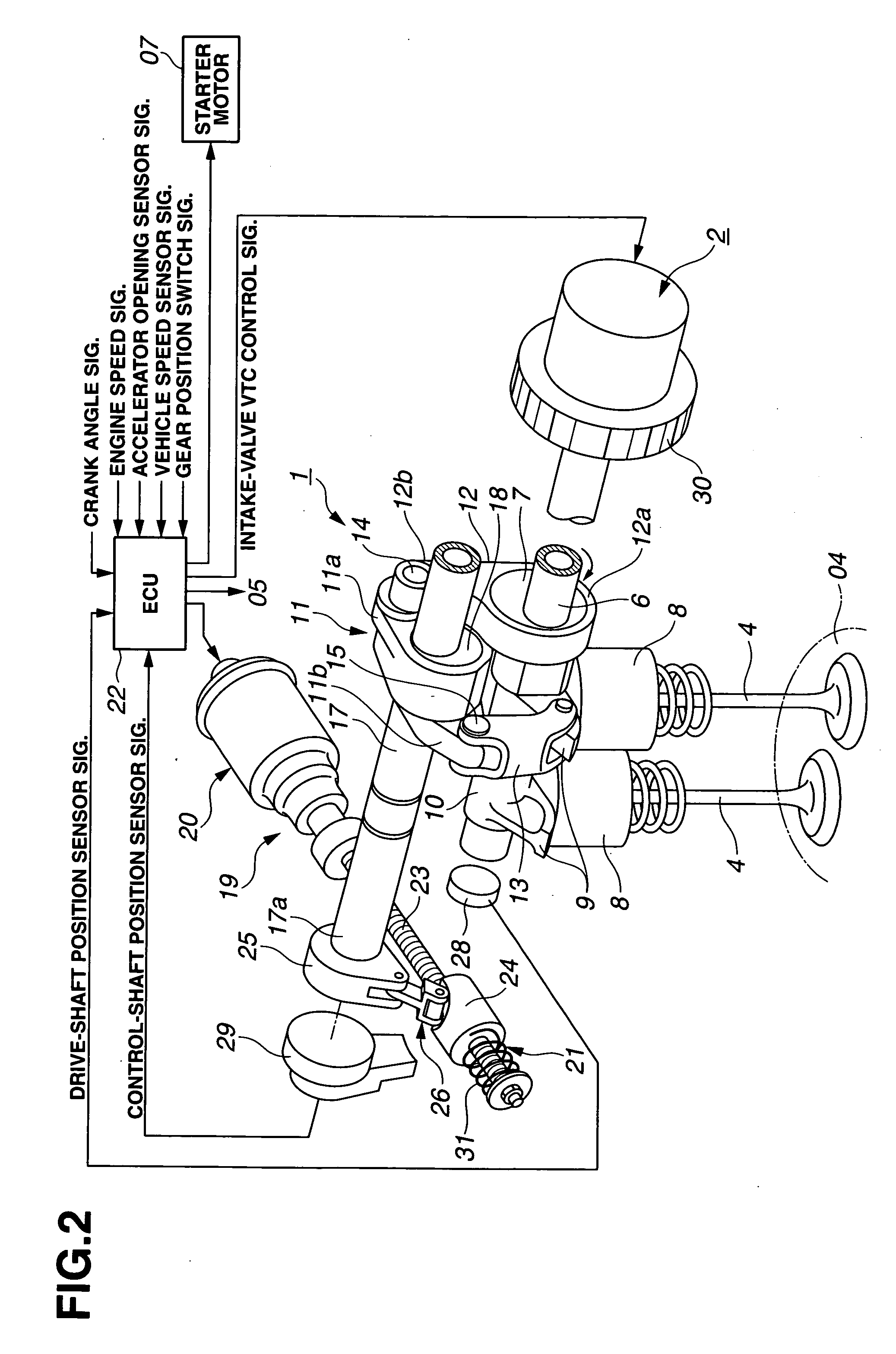

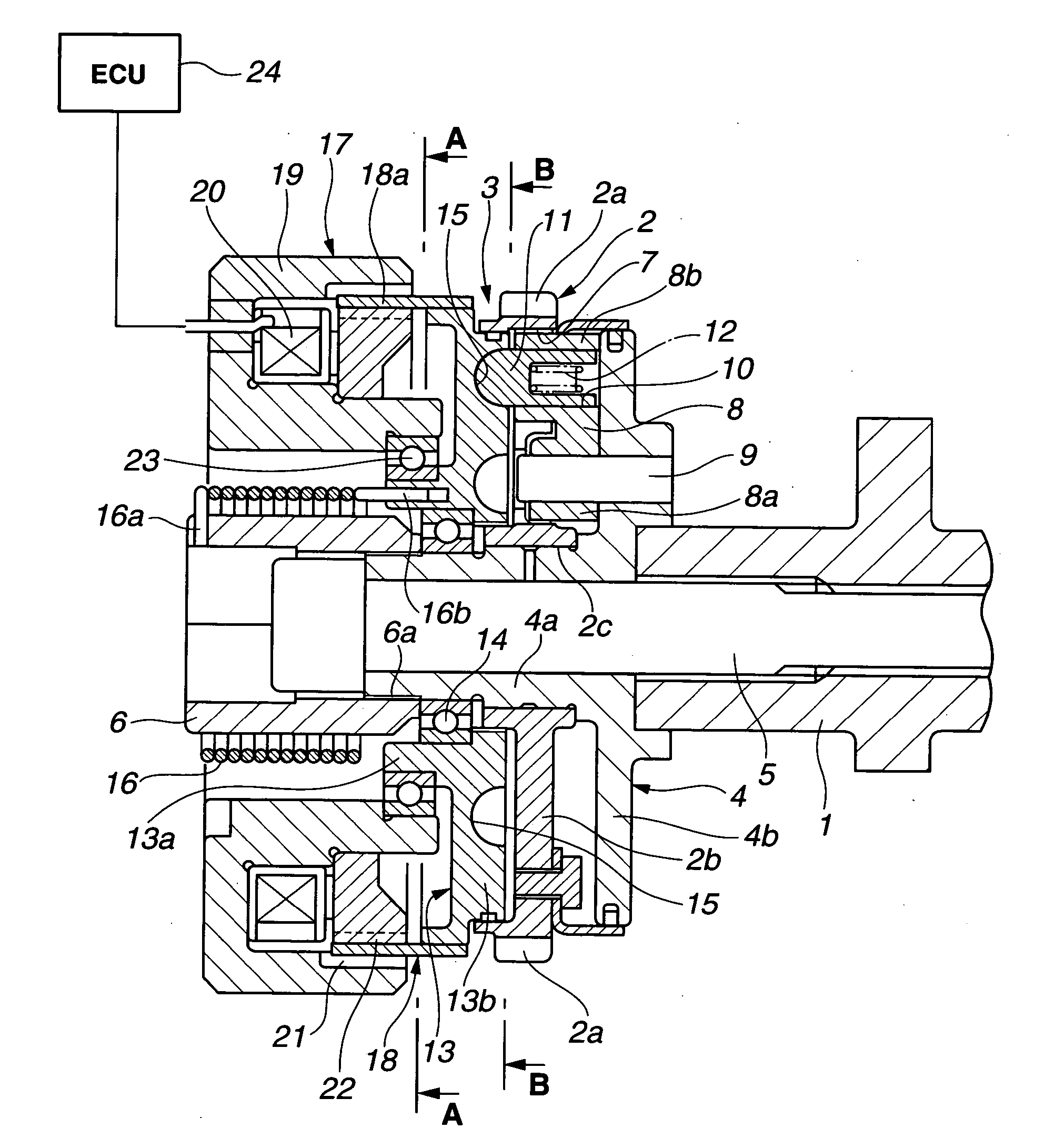

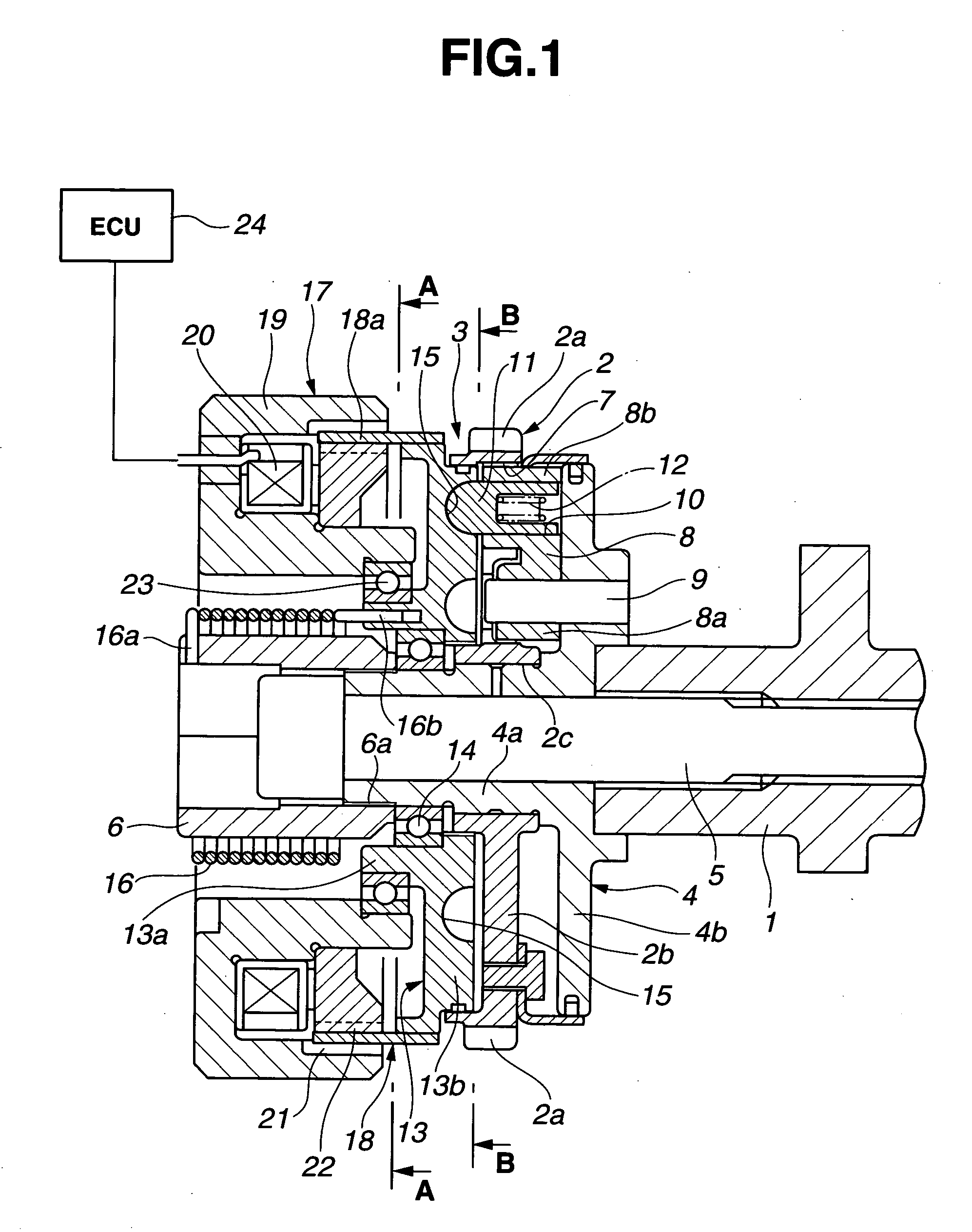

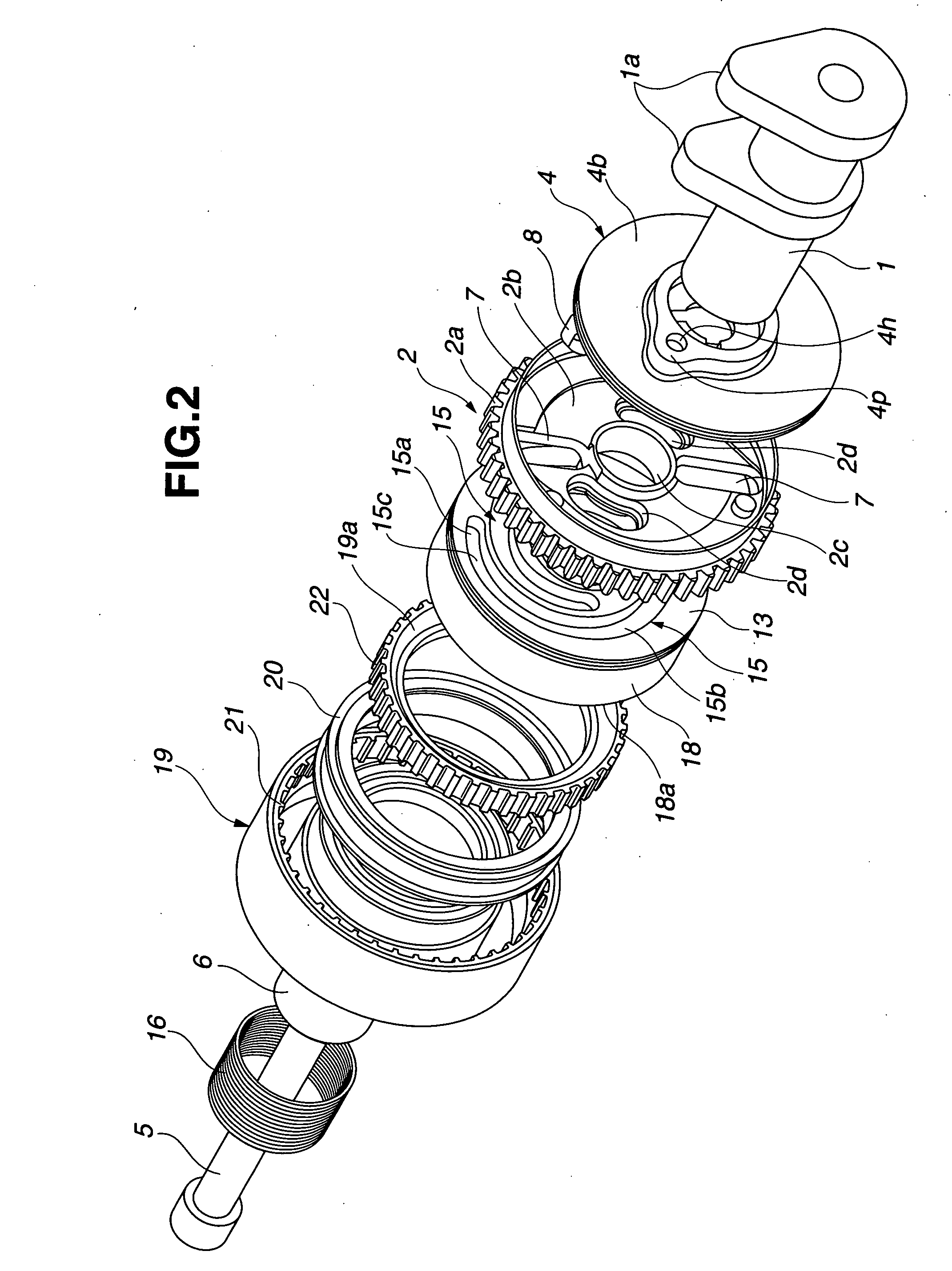

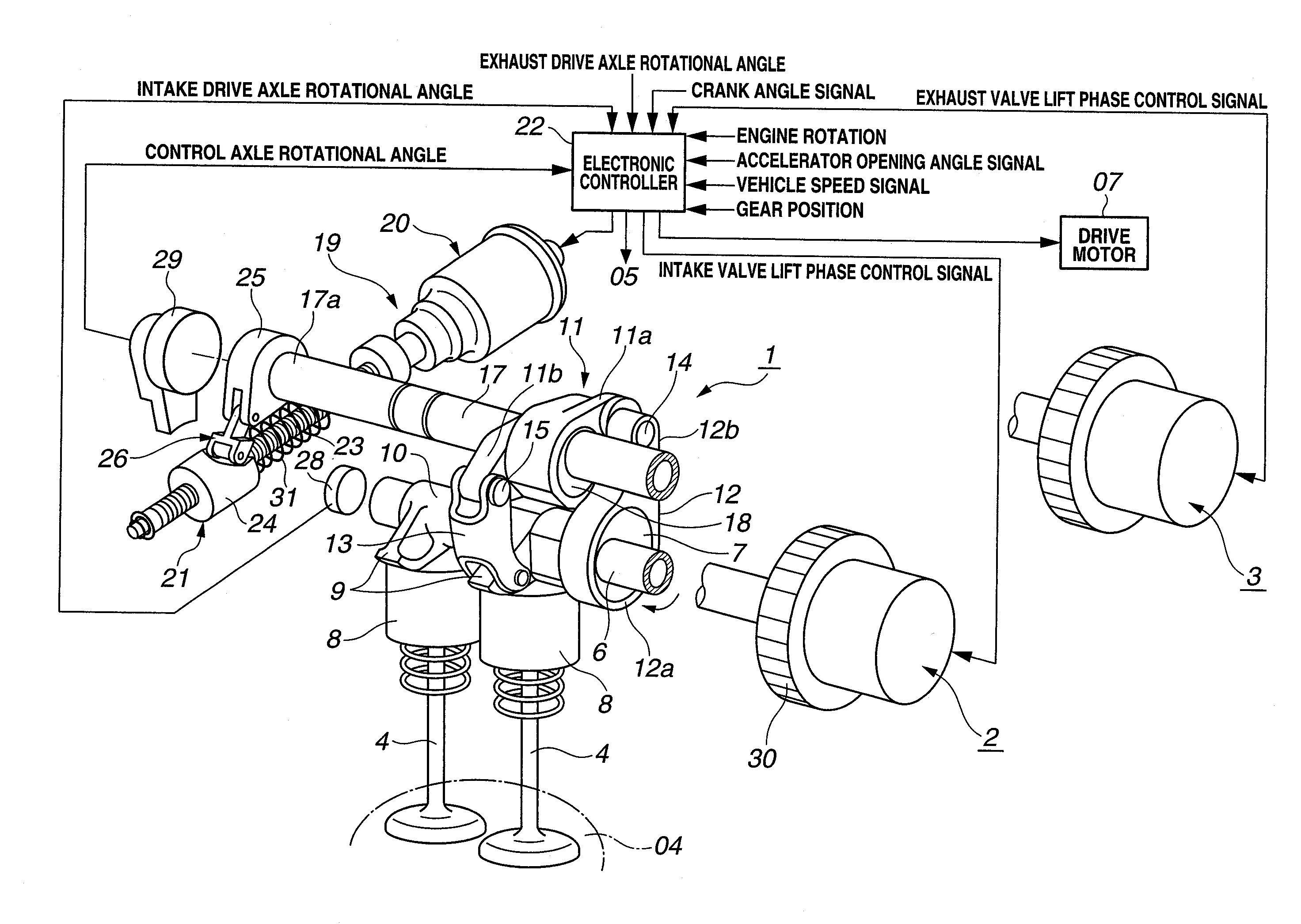

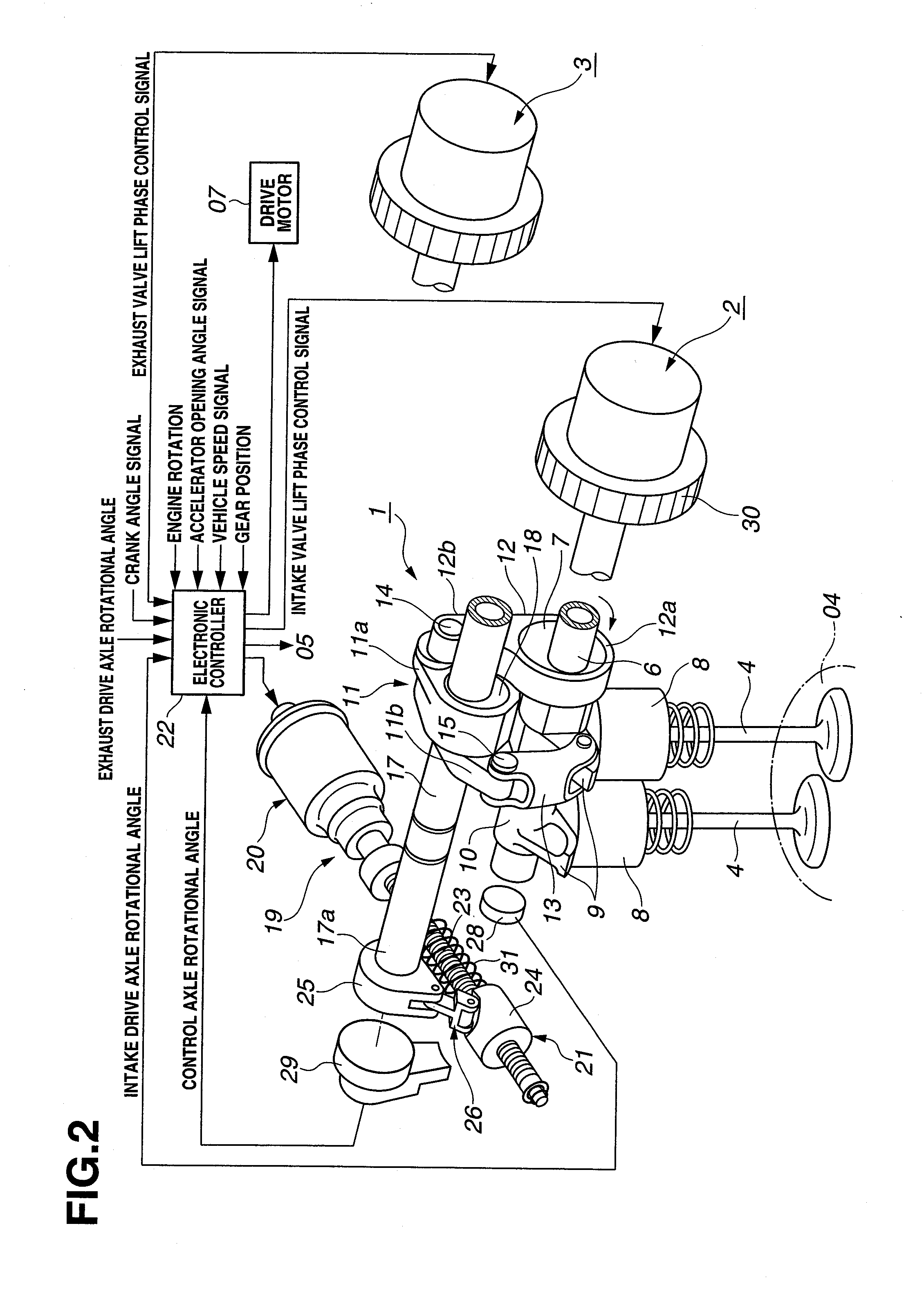

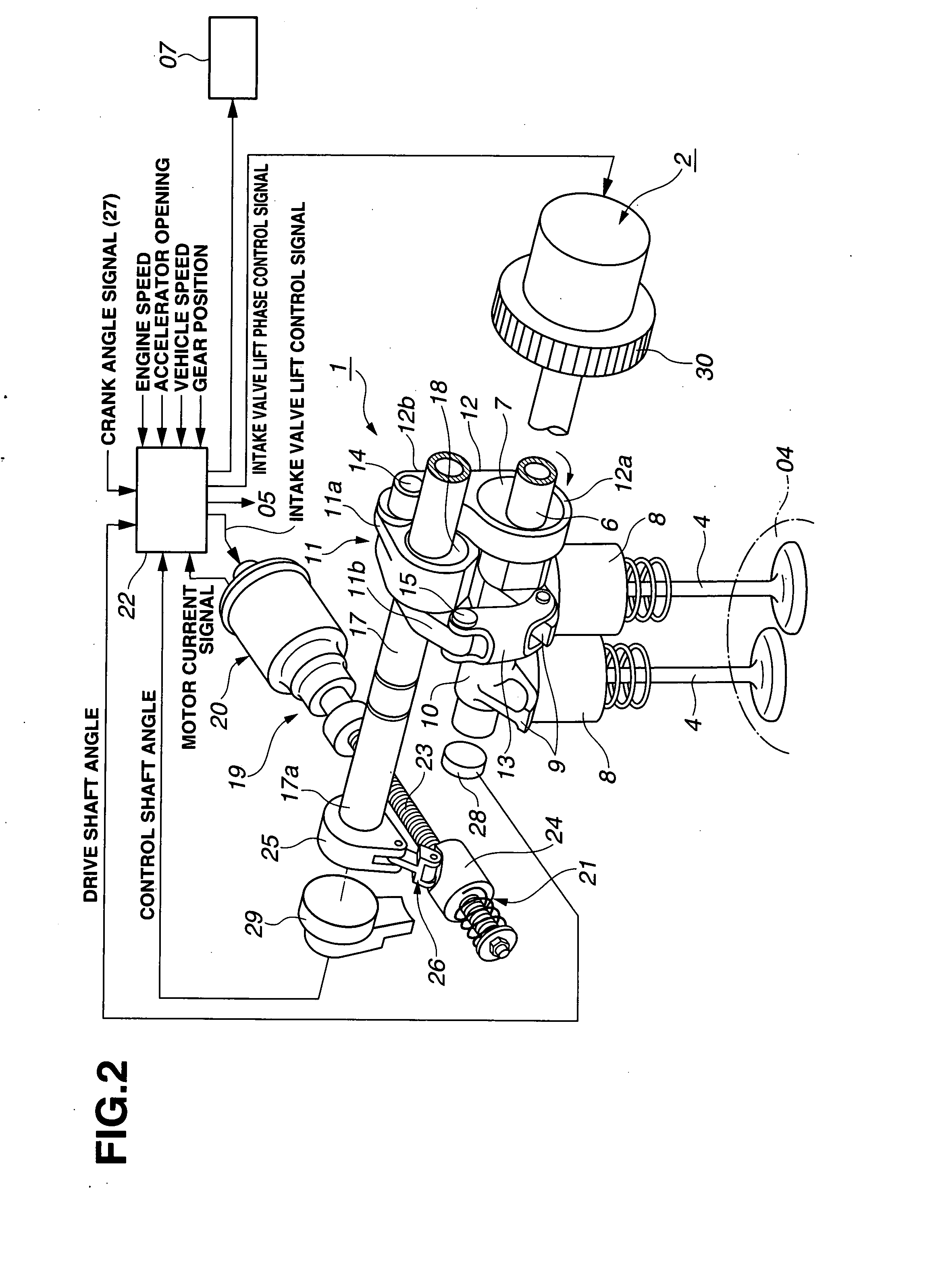

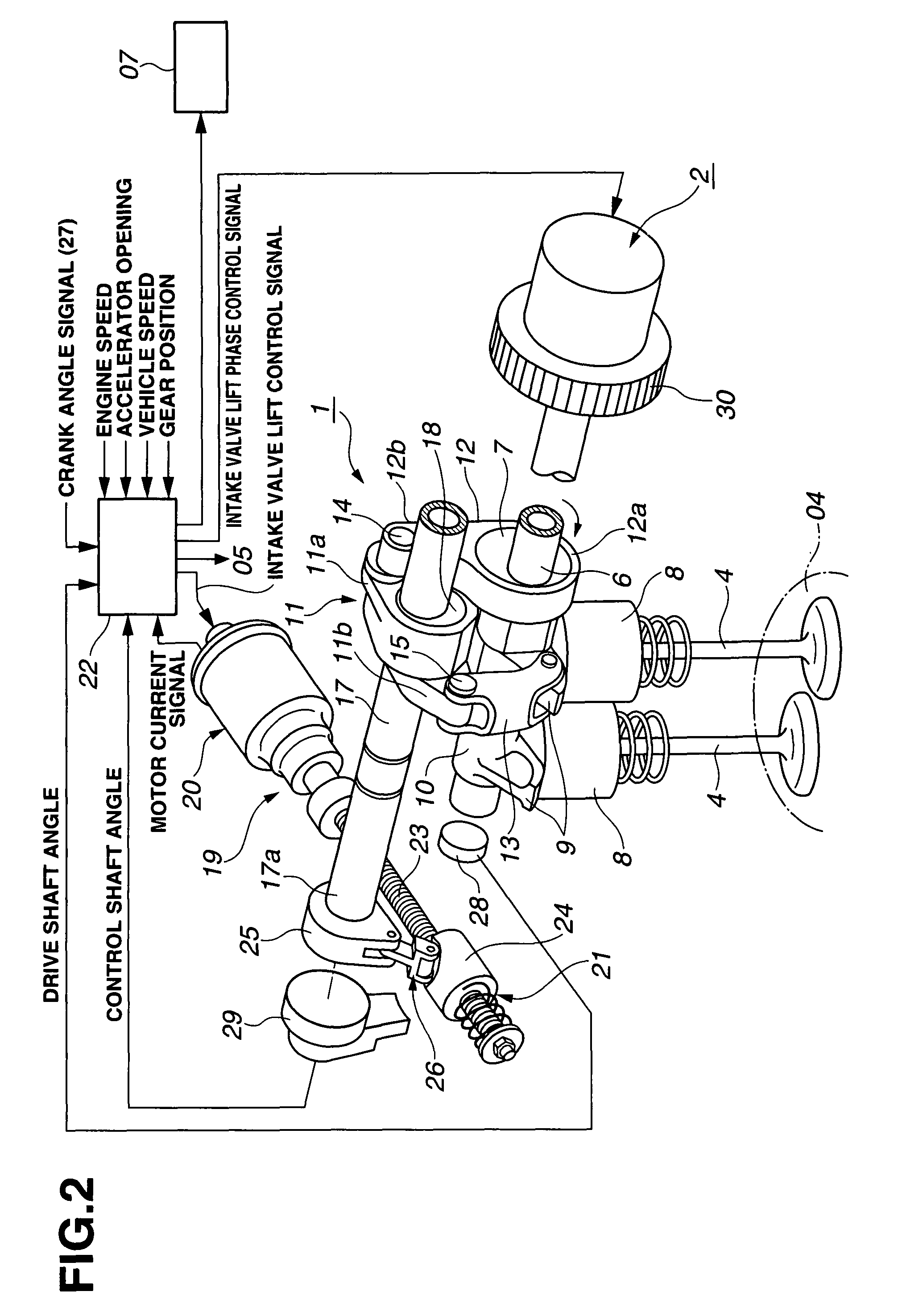

Variable valve actuation system of internal combustion engine

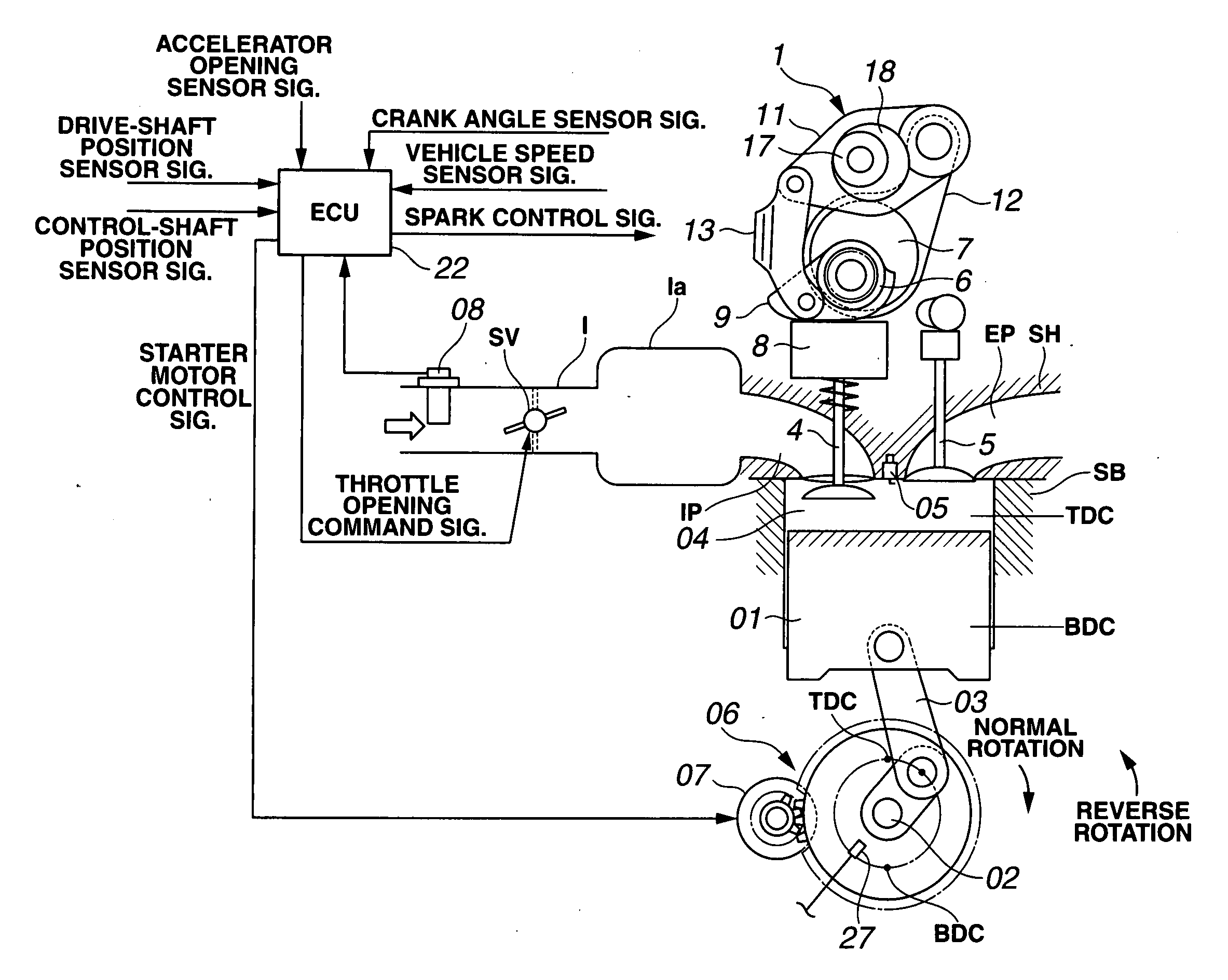

InactiveUS7703424B2Increase friction lossReduce noiseValve arrangementsOutput powerTop dead centerValve actuator

In a variable valve actuation system of an internal combustion engine employing a variable valve actuator capable of variably adjusting at least intake valve closure timing depending on engine operating conditions, a processor of a control unit is programmed to phase-advance the intake valve closure timing to a predetermined timing value after a piston top dead center position and before a piston bottom dead center position on intake stroke during at least one of an engine starting period and an engine stopping period. The variable valve actuator includes a biasing device by which the intake valve closure timing is permanently biased toward the predetermined timing value.

Owner:HITACHI LTD

Control apparatus of internal combustion engine

InactiveUS7150262B2Engine startability can be improvedUniform atomizationElectrical controlCombustion enginesExternal combustion engineInternal combustion engine

Owner:TOYOTA JIDOSHA KK +1

Variable valve actuation system of internal combustion engine

InactiveUS20070144473A1Reduce noiseReduce vibrationValve arrangementsOutput powerTop dead centerEngineering

In a variable valve actuation system of an internal combustion engine employing a variable valve actuator capable of variably adjusting at least intake valve closure timing depending on engine operating conditions, a processor of a control unit is programmed to phase-advance the intake valve closure timing to a predetermined timing value after a piston top dead center position and before a piston bottom dead center position on intake stroke during at least one of an engine starting period and an engine stopping period. The variable valve actuator includes a biasing device by which the intake valve closure timing is permanently biased toward the predetermined timing value.

Owner:HITACHI LTD

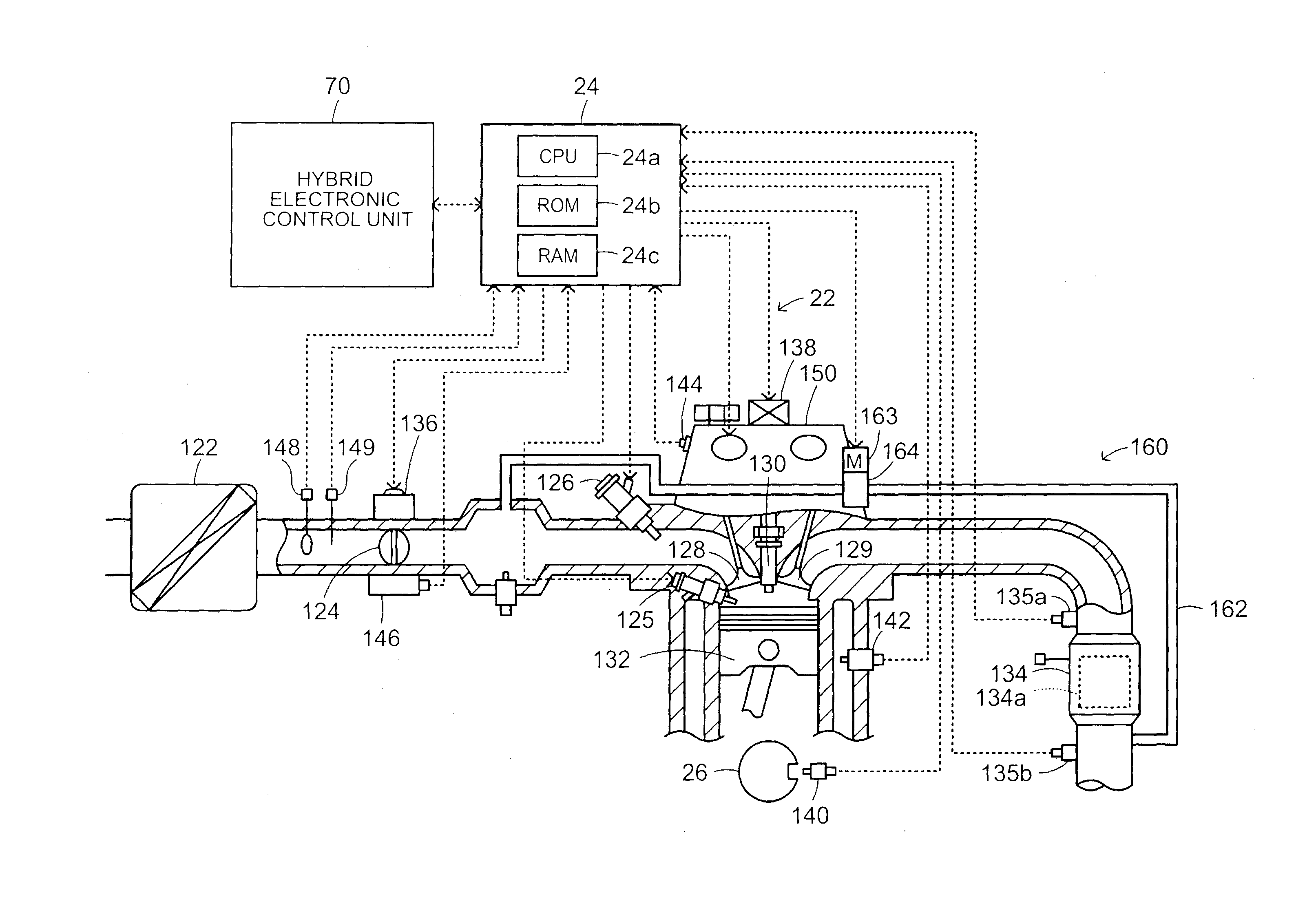

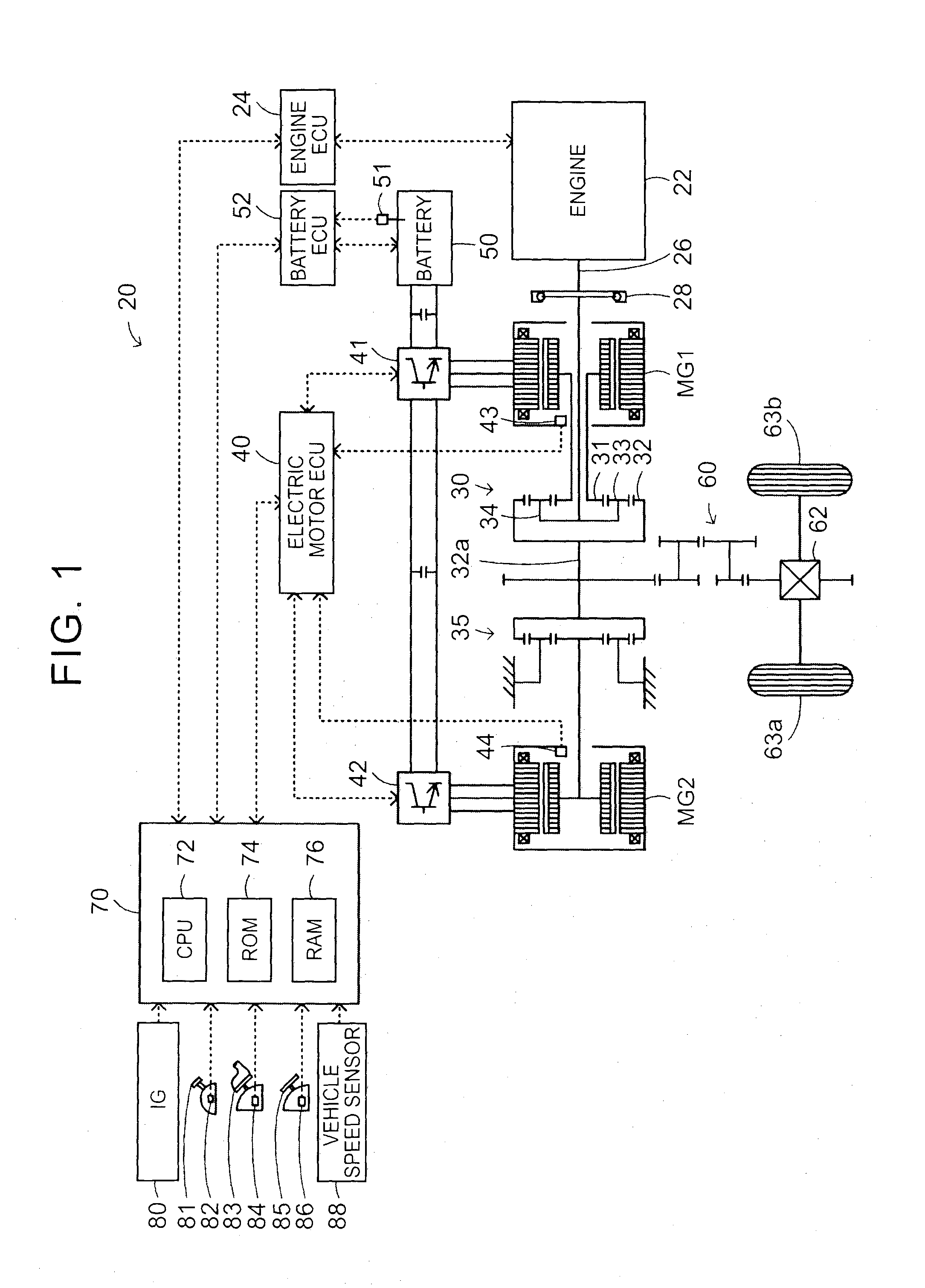

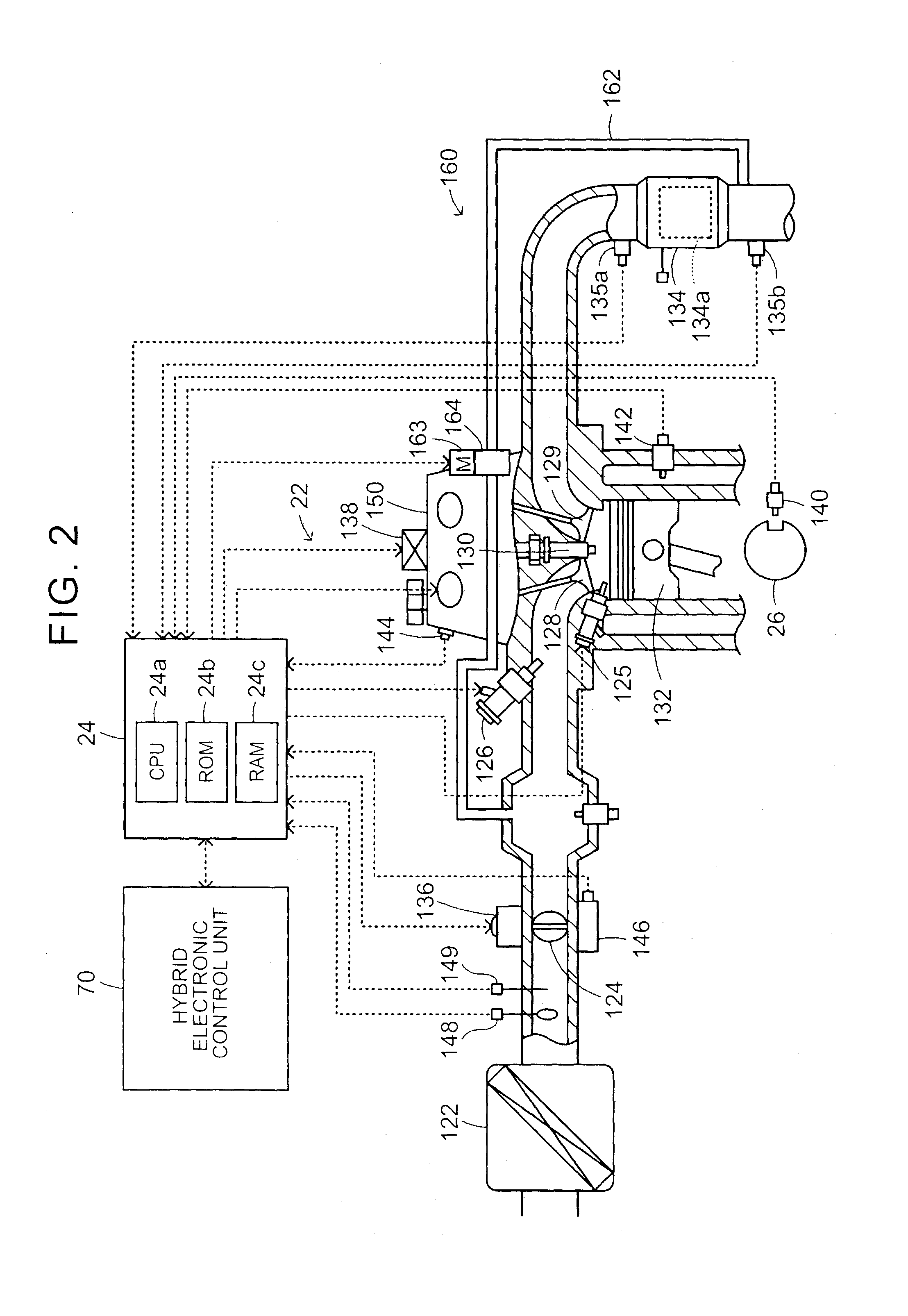

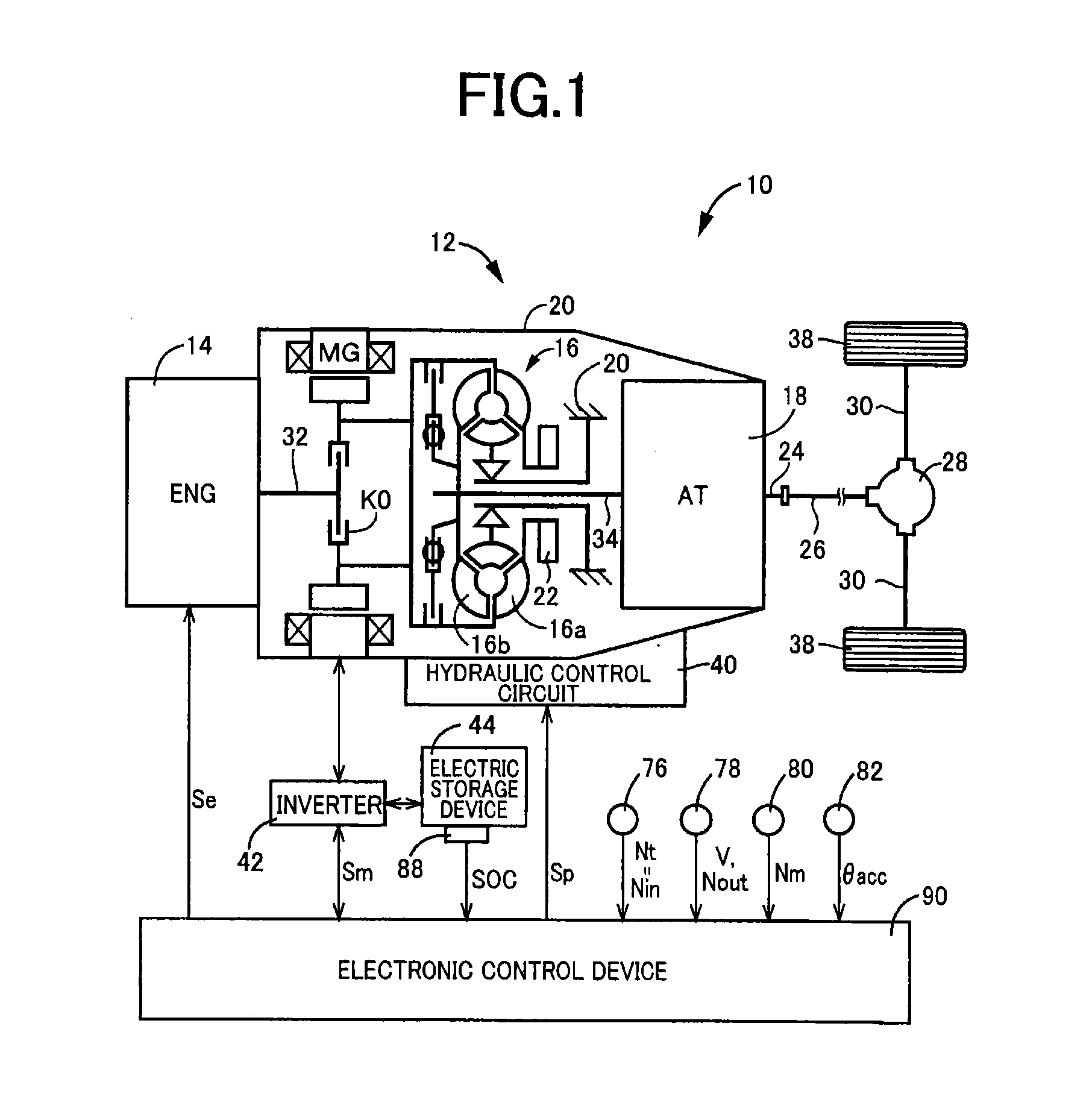

Internal combustion engine control for a hybrid vehicle

ActiveUS20150239464A1Accelerates atomization and vaporizationEngine startability can be improvedHybrid vehiclesElectrical controlExternal combustion engineInternal combustion engine

When an engine is to be started, operation of the engine is started with injection of fuel from a port fuel injection valve, without injecting fuel from an in-cylinder fuel injection valve (S100). If a gear rattling noise is produced (S110), the engine is operated with fuel injection, from the in-cylinder fuel injection valve, without injecting fuel from the port fuel injection valve (S120). This restrains occurrence of a gear rattling noise.

Owner:TOYOTA JIDOSHA KK

Variable valve timing control apparatus of internal combustion engine

InactiveUS20060231052A1Engine startability can be improvedValve arrangementsYielding couplingStart upInternal combustion engine

A variable valve timing control apparatus of an internal combustion engine includes a drive rotary member, a driven rotary member, and a phase-change mechanism disposed between the drive and driven rotary members. The phase-change mechanism changes a relative phase between the drive and driven rotary members by an operating force, and returns the relative phase to an engine start-up phase suitable for the engine start-up at the engine starting. The phase-change mechanism has a phase-change characteristic that a phase-change rate reduces near the engine start-up phase when the relative phase is returned to the engine start-up phase.

Owner:HITACHI LTD

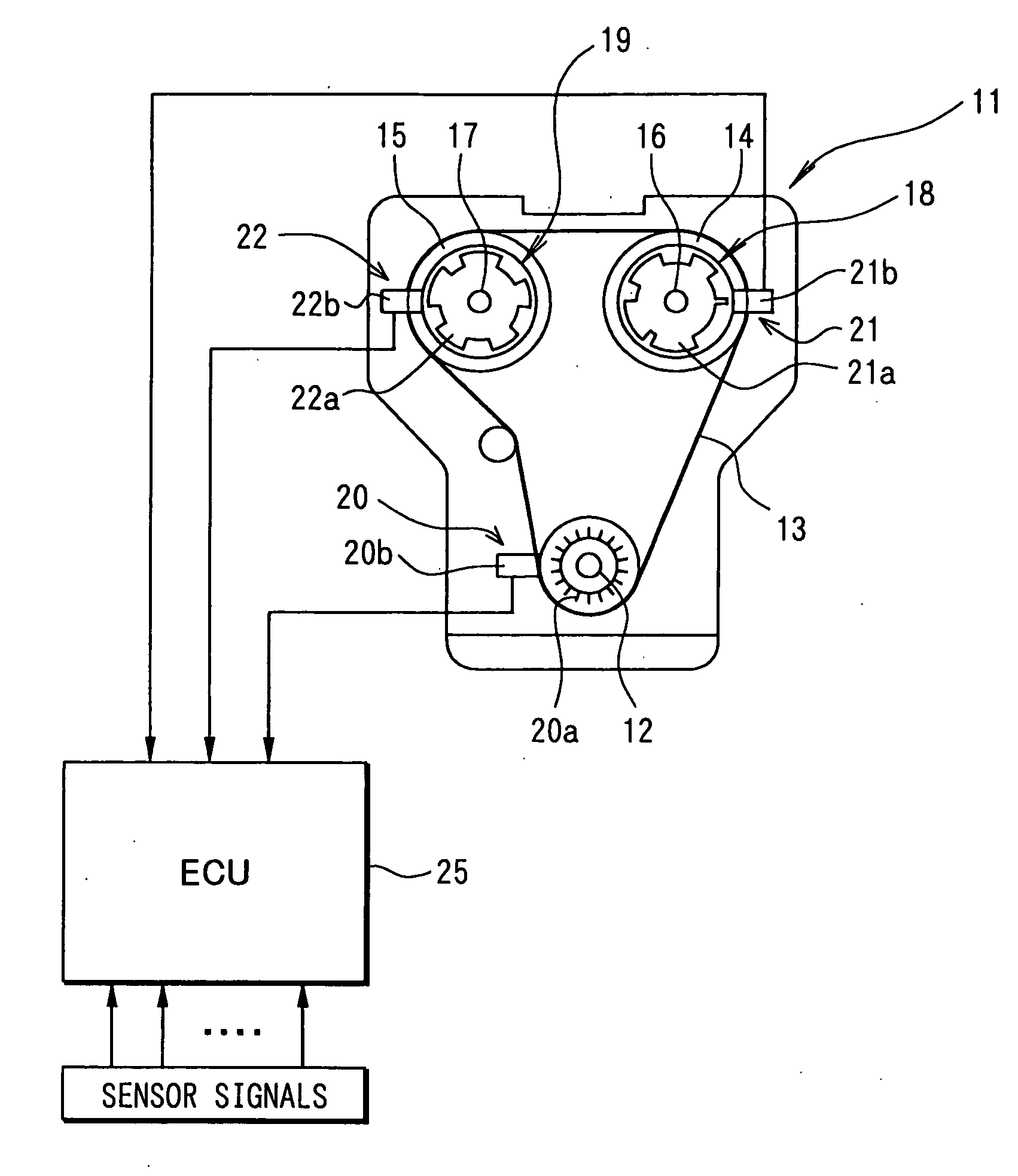

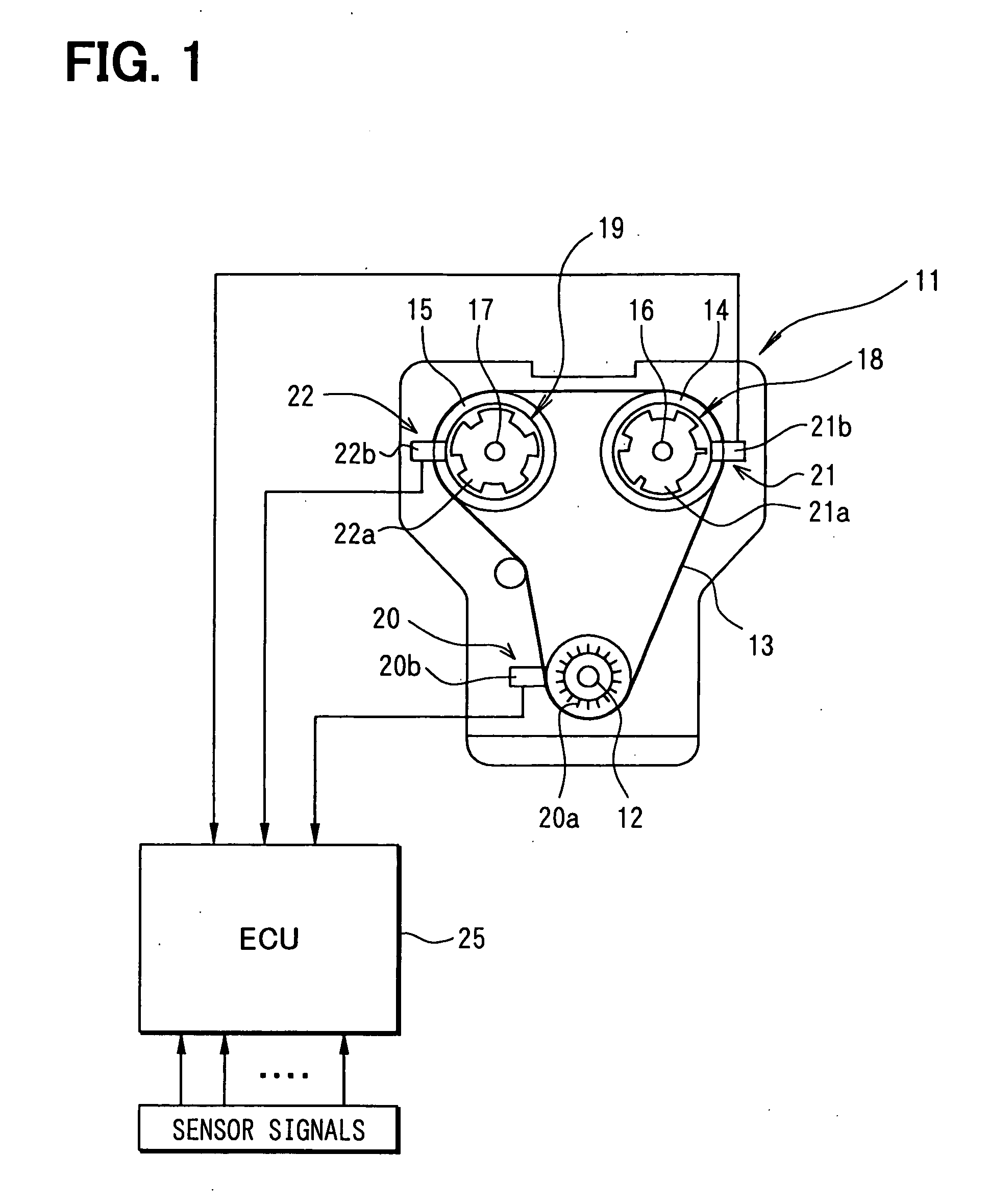

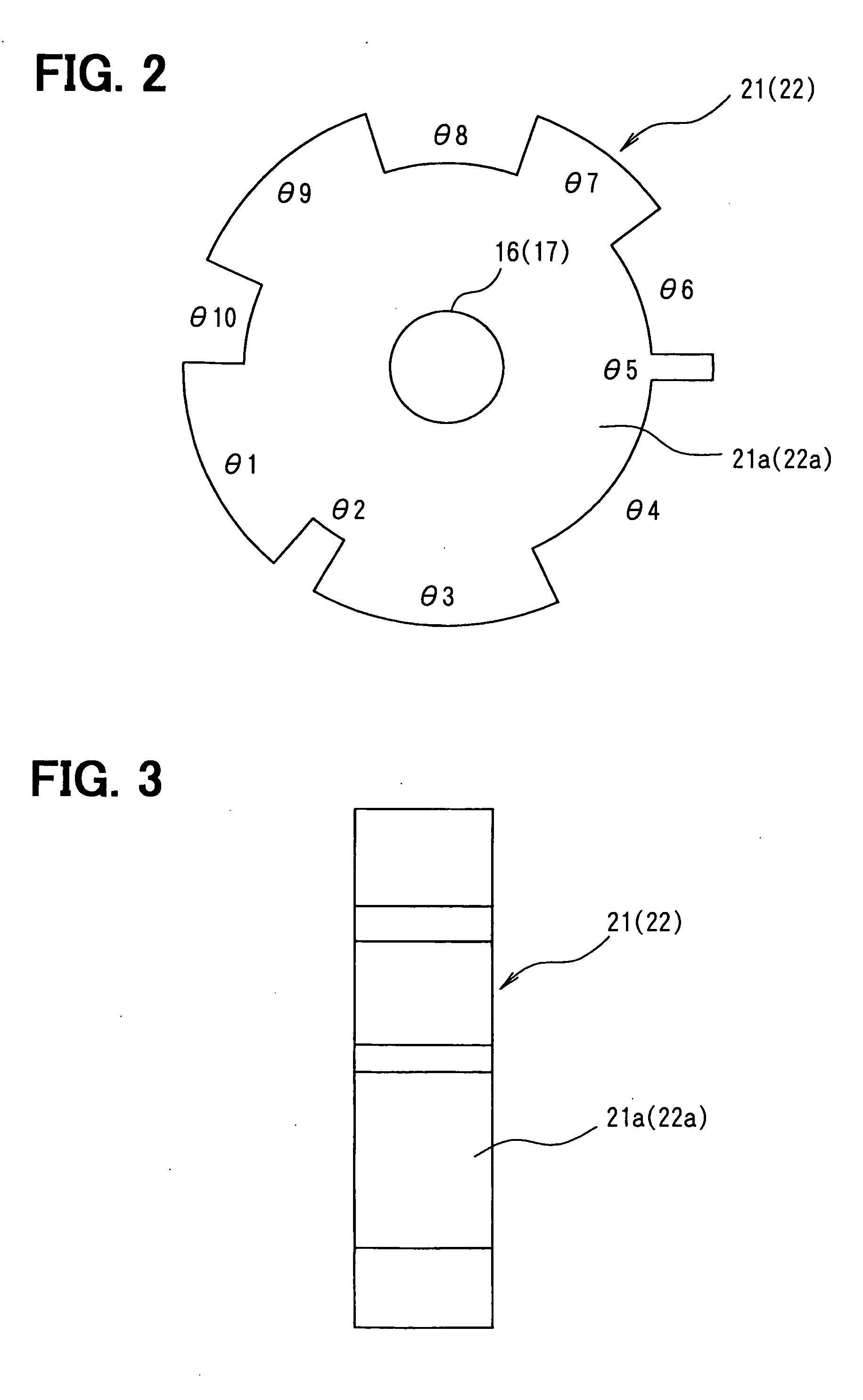

Cylinder identification device for internal combustion engine

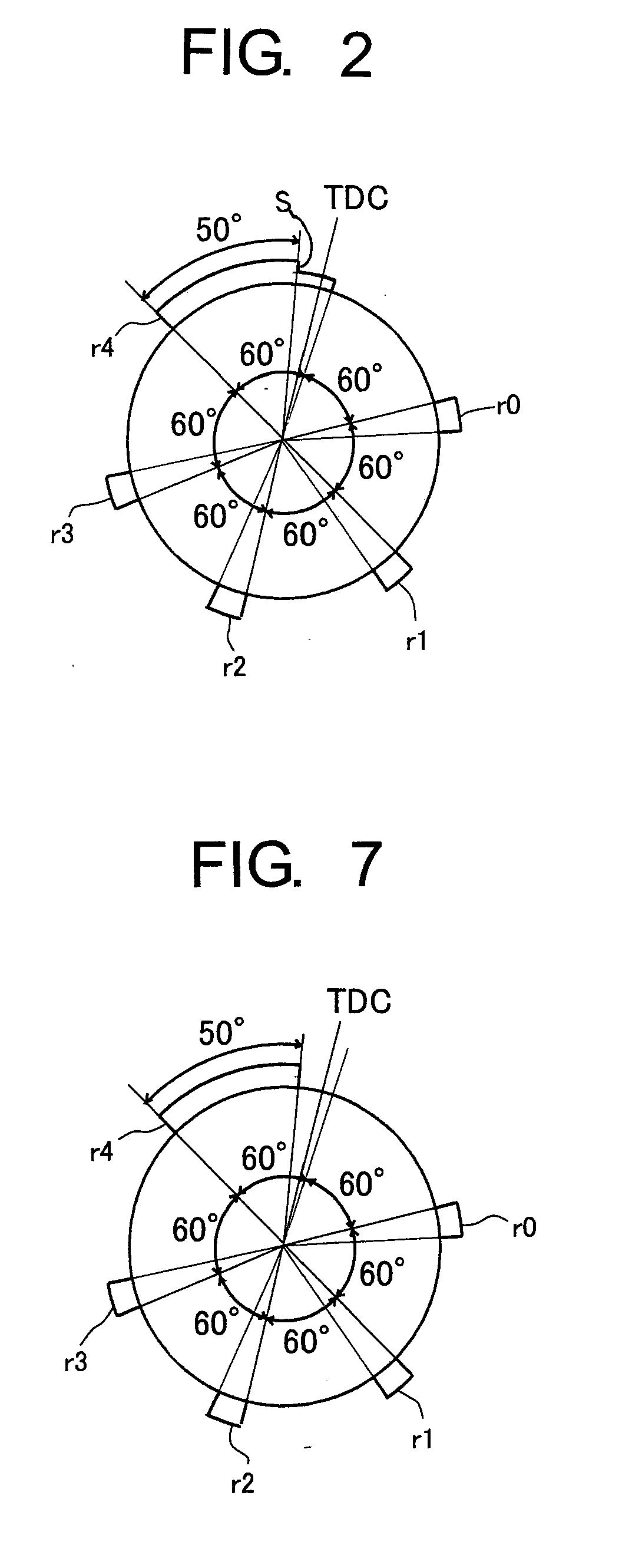

InactiveUS20050212509A1Engine startability can be improvedStartability is improvedDigital data processing detailsSolid-state devicesEngineeringIdentification device

A cylinder identification device has an intake cam sensor and an exhaust cam sensor which output signals indicative of a rotation angle of the camshaft. The levels of the output signals are varied according to the rotation angle of the crankshaft. The cylinder identification is conducted based on an order of combination variation of the output signal levels. The changing positions of the output signal levels of at least one of the intake cam sensor and the exhaust cam sensor are arranged in such a manner to correspond to positions or right before positions in which the fuel can be initially injected at the time of the engine starting. Thus, the cylinder identification device can identify the initial cylinder in a short period, into which the fuel is initially injected at the time of the engine starting, whereby the startability of the engine is enhanced.

Owner:DENSO CORP

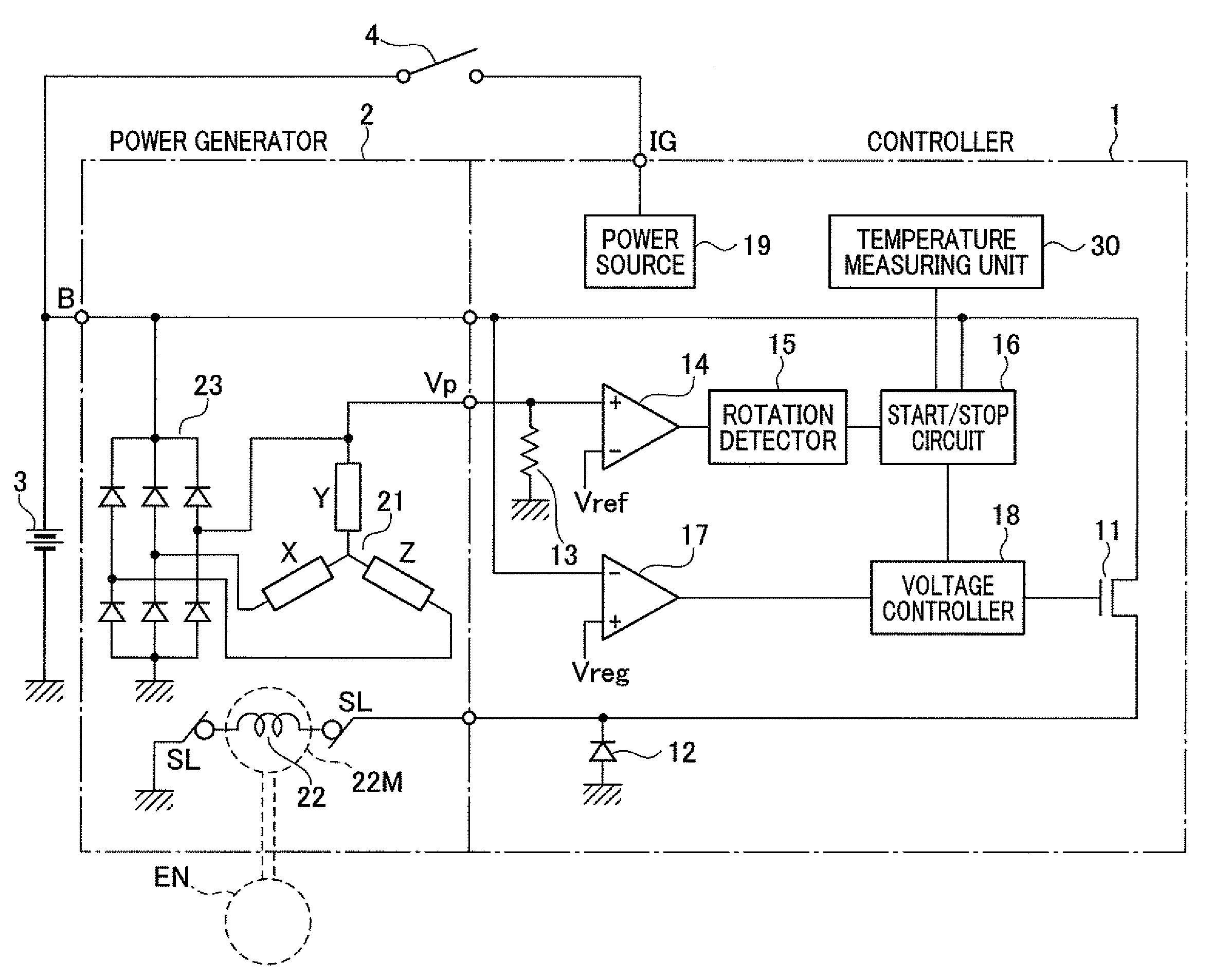

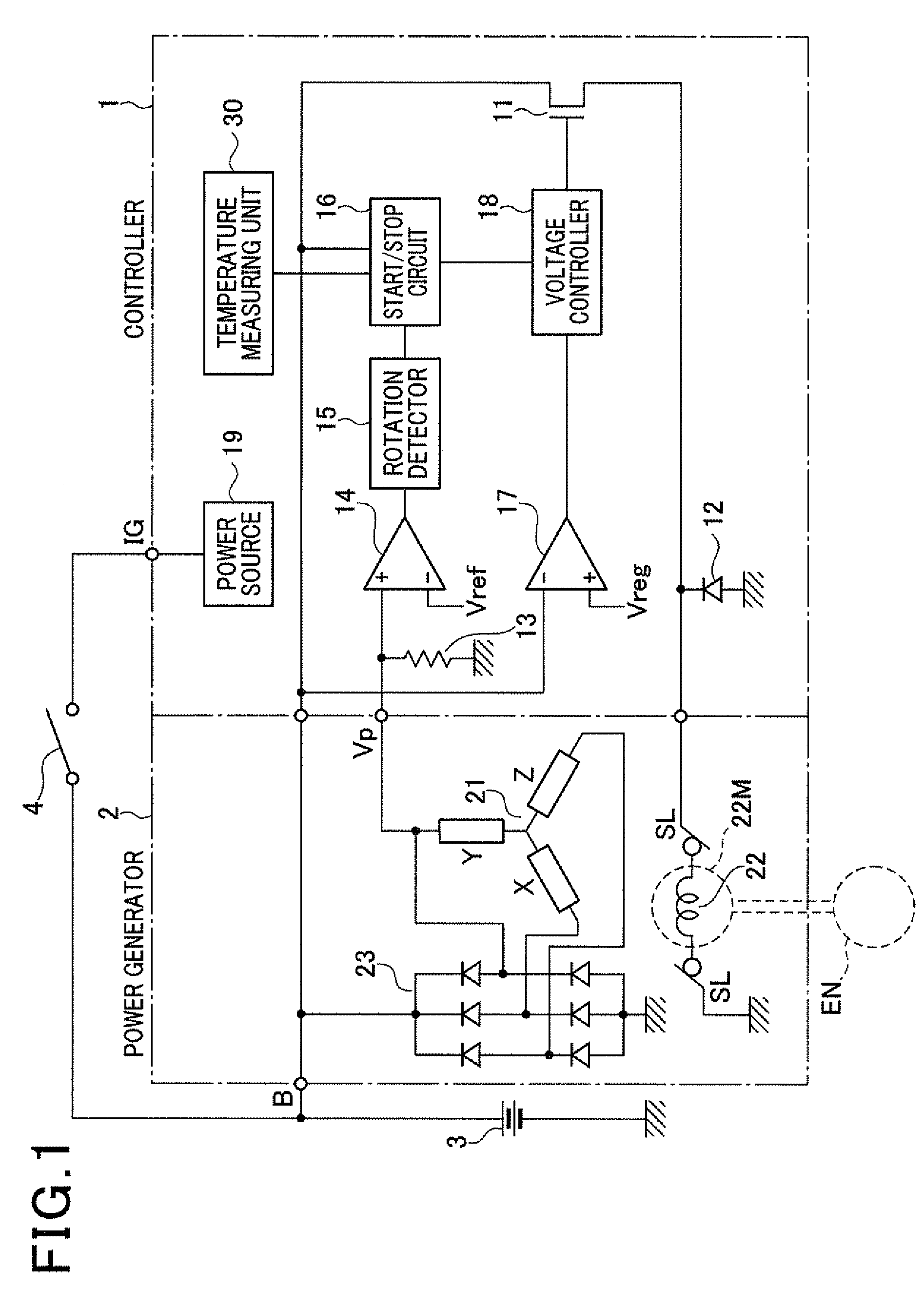

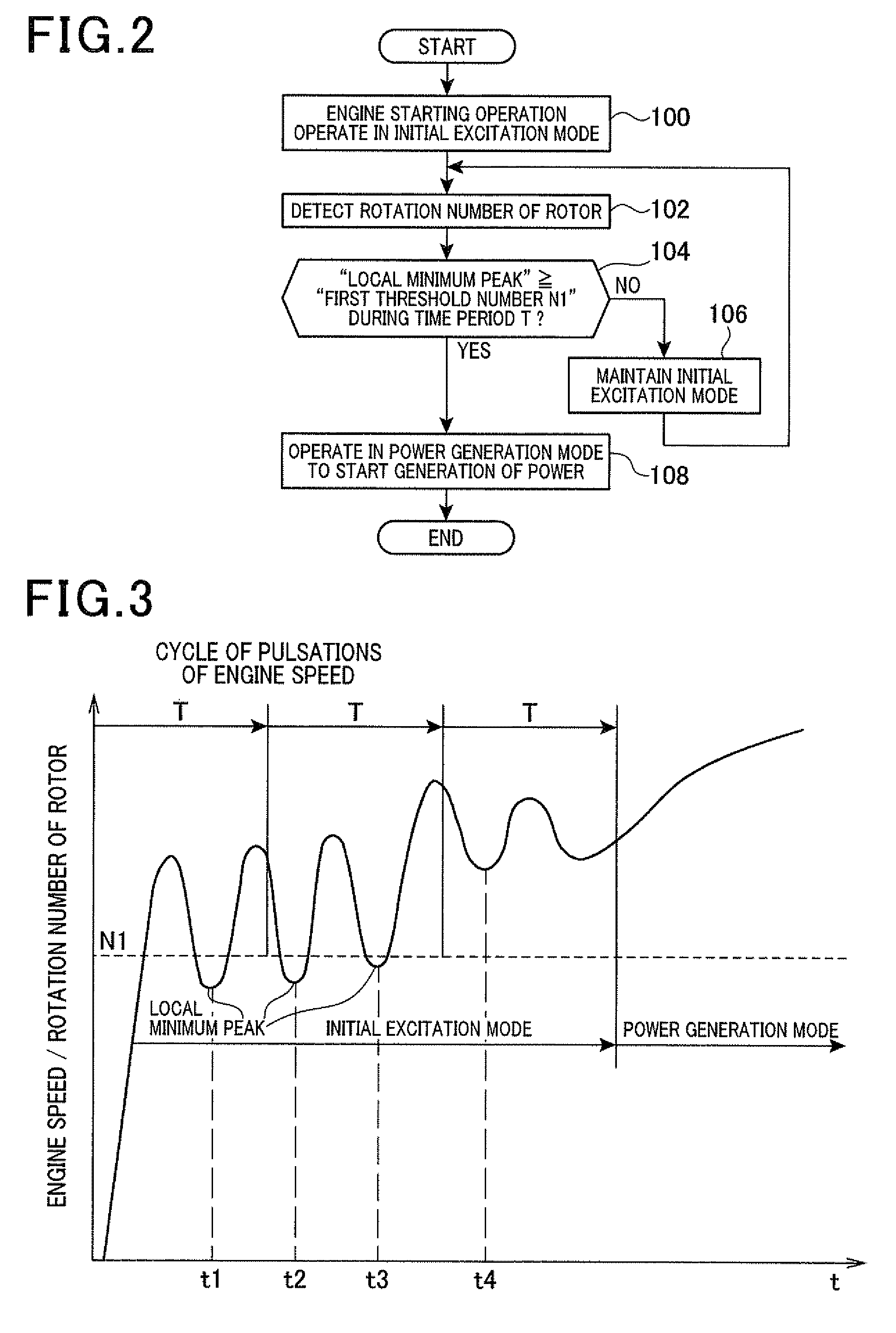

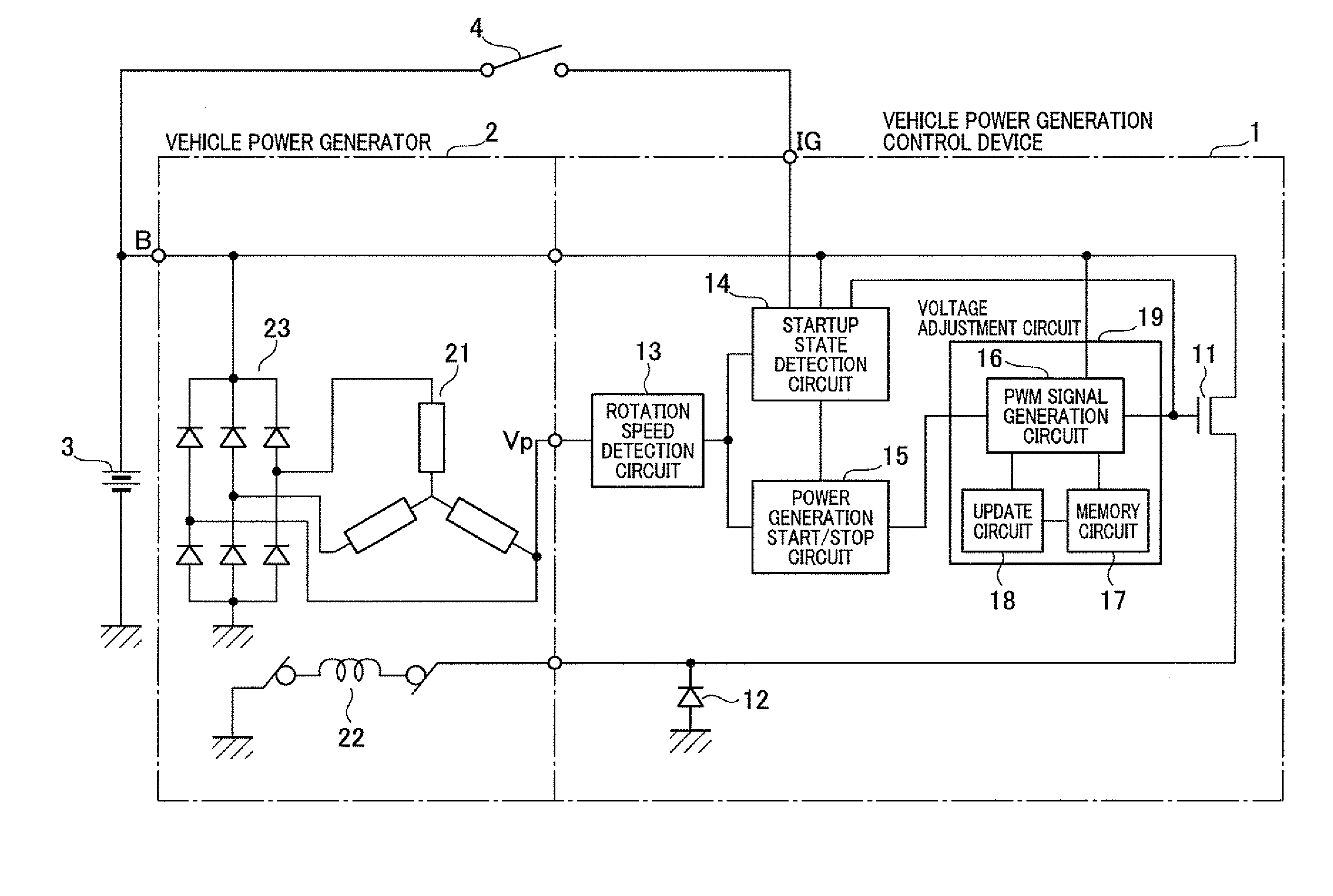

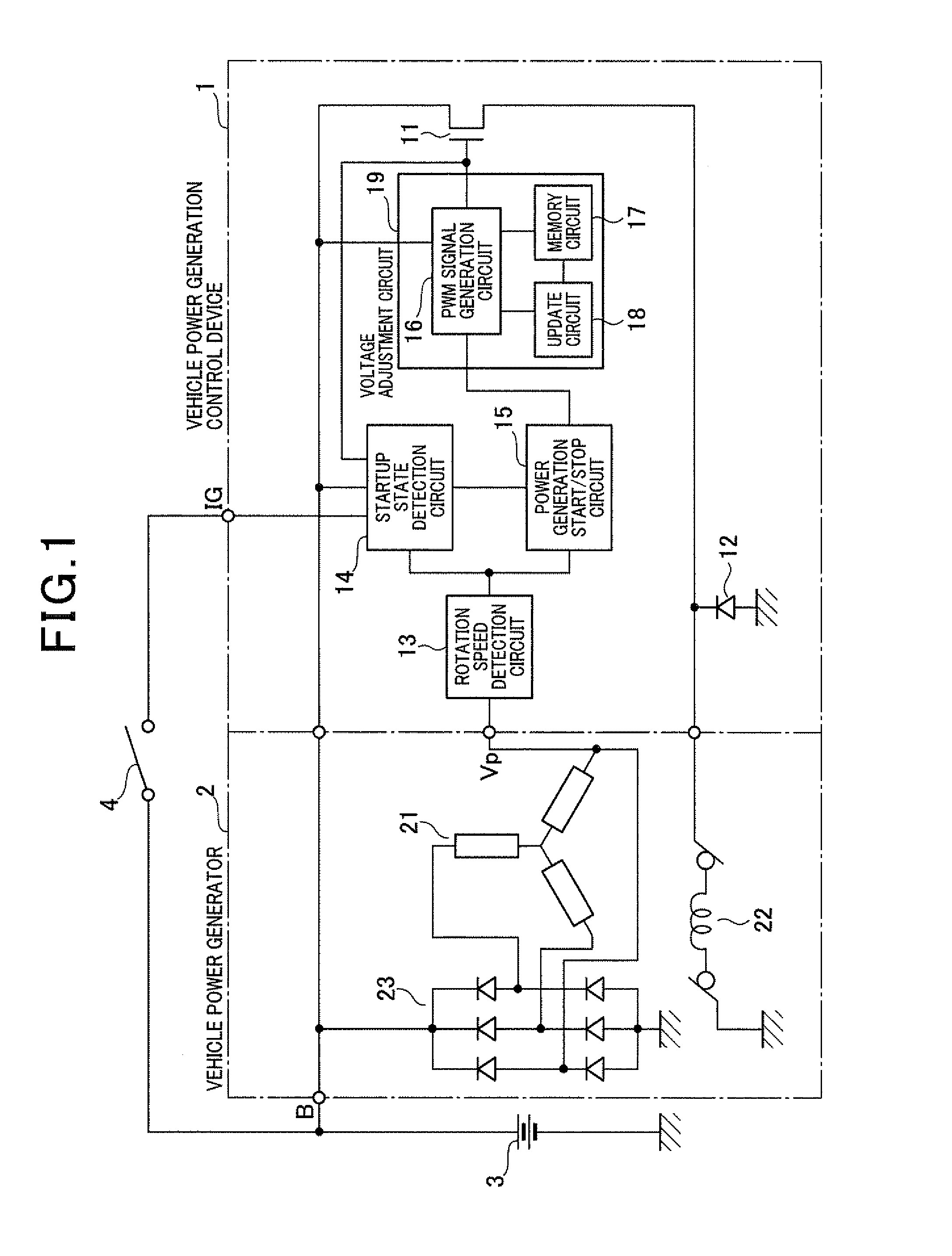

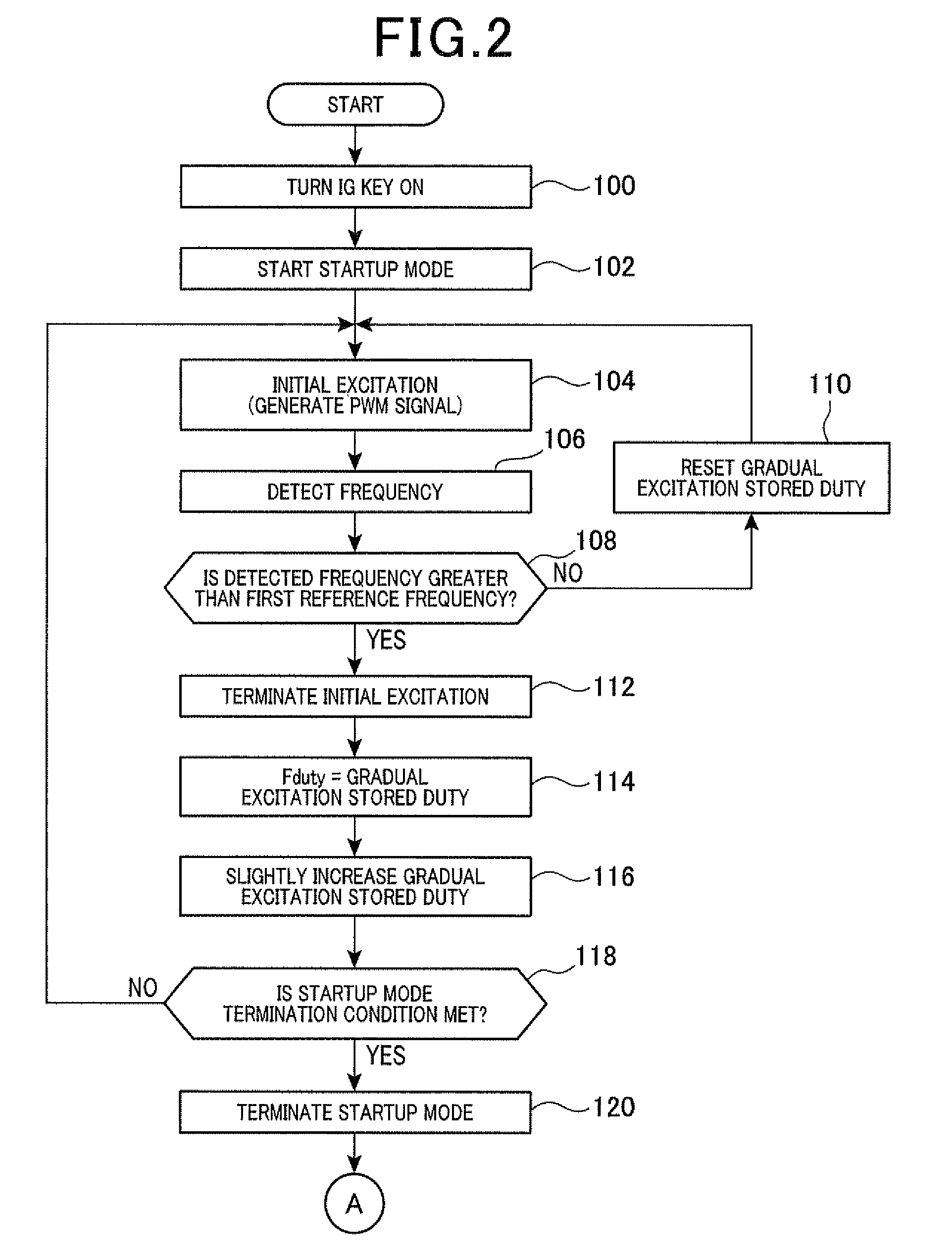

Controller for controlling power generator driven by rotational power of engine

ActiveUS8773081B2Engine startability can be improvedHigh pulsationMotor/generator/converter stoppersEmergency protective circuit arrangementsControl powerTime segment

In a controller, a voltage controller operates, in an initial excitation mode, to turn selectively on and off a switch to supply an excitation current as an initial excitation current to the field winding, and operates, in a power generation mode, to selectively increase and reduce the excitation current to be supplied to the field winding to regulate an output voltage of the power generator to a target value. A mode-shift determiner determines, while the voltage controller operates in the initial excitation mode, whether to shift an operation mode of the voltage controller from the initial excitation mode to the power generation mode based on: a measured rotation number of a rotor, a threshold rotation number of the rotor, and a preset time period, the time period being equal to or longer than an expected maximum value of cycle of pulsations of rotation of the engine.

Owner:DENSO CORP

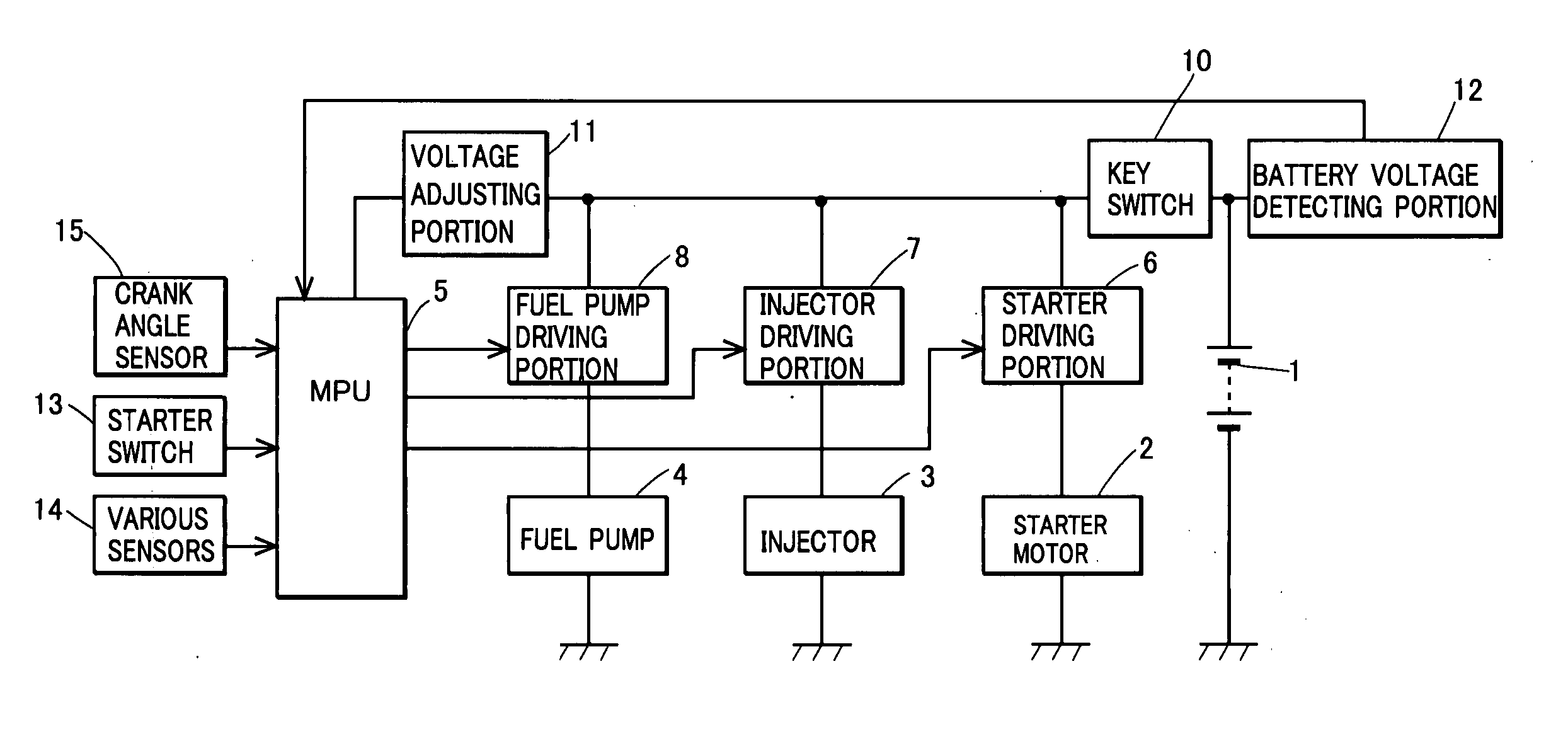

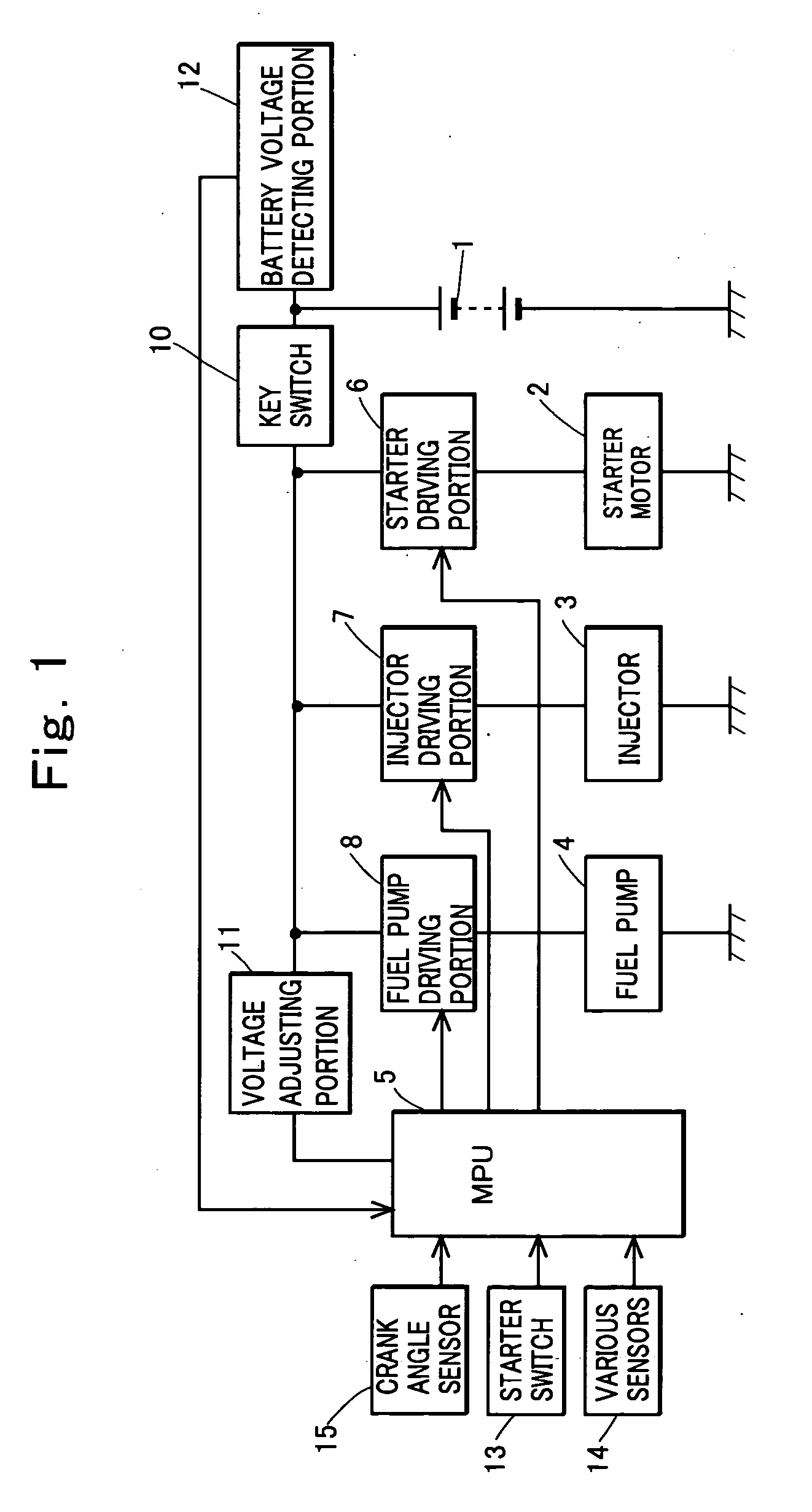

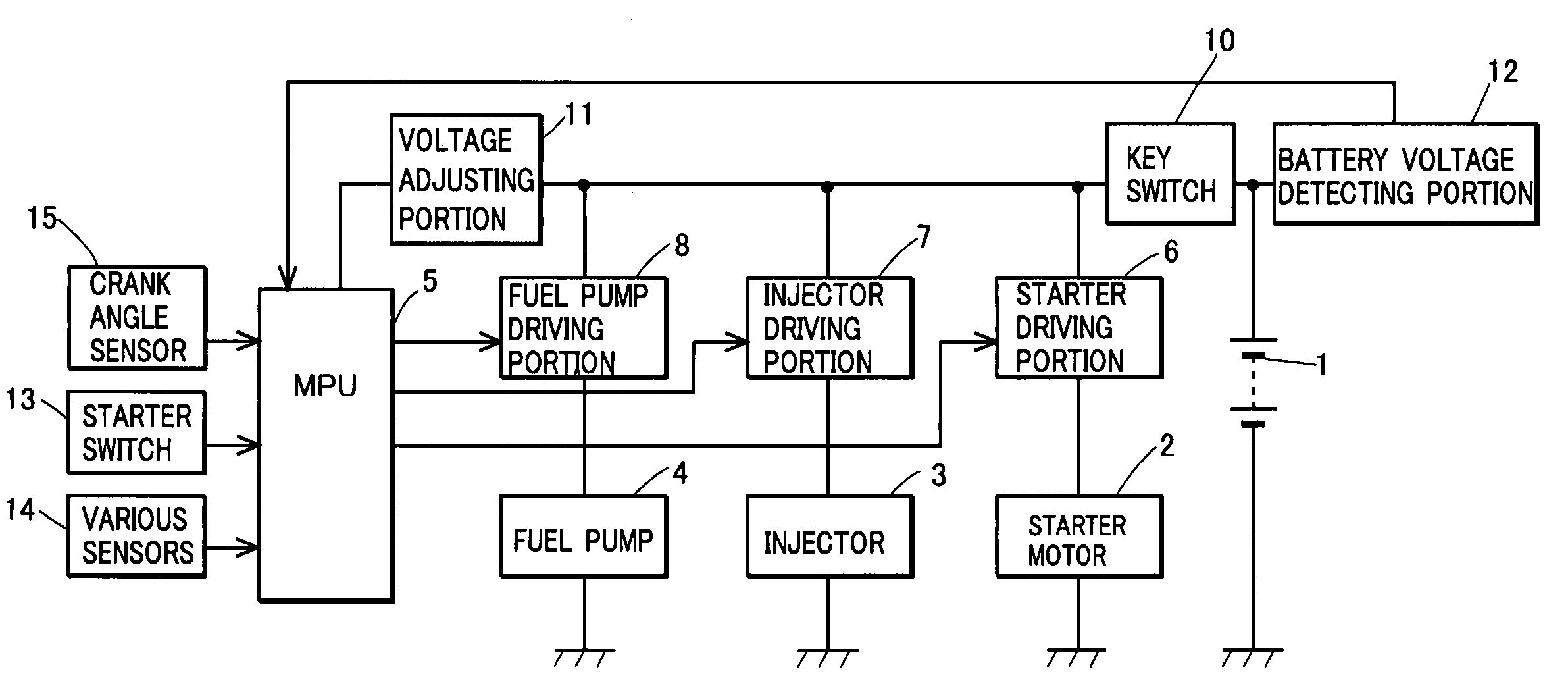

Engine control device

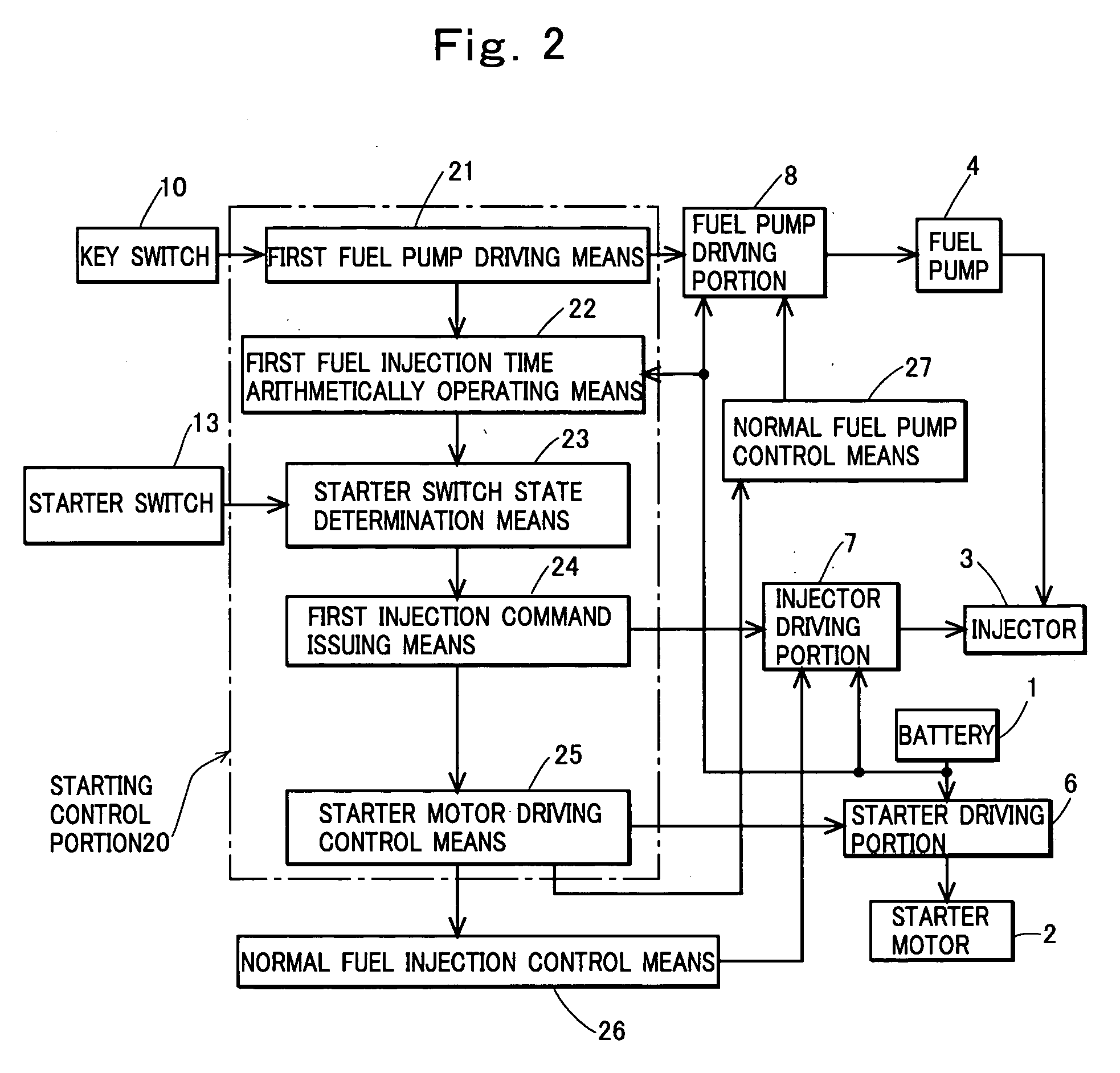

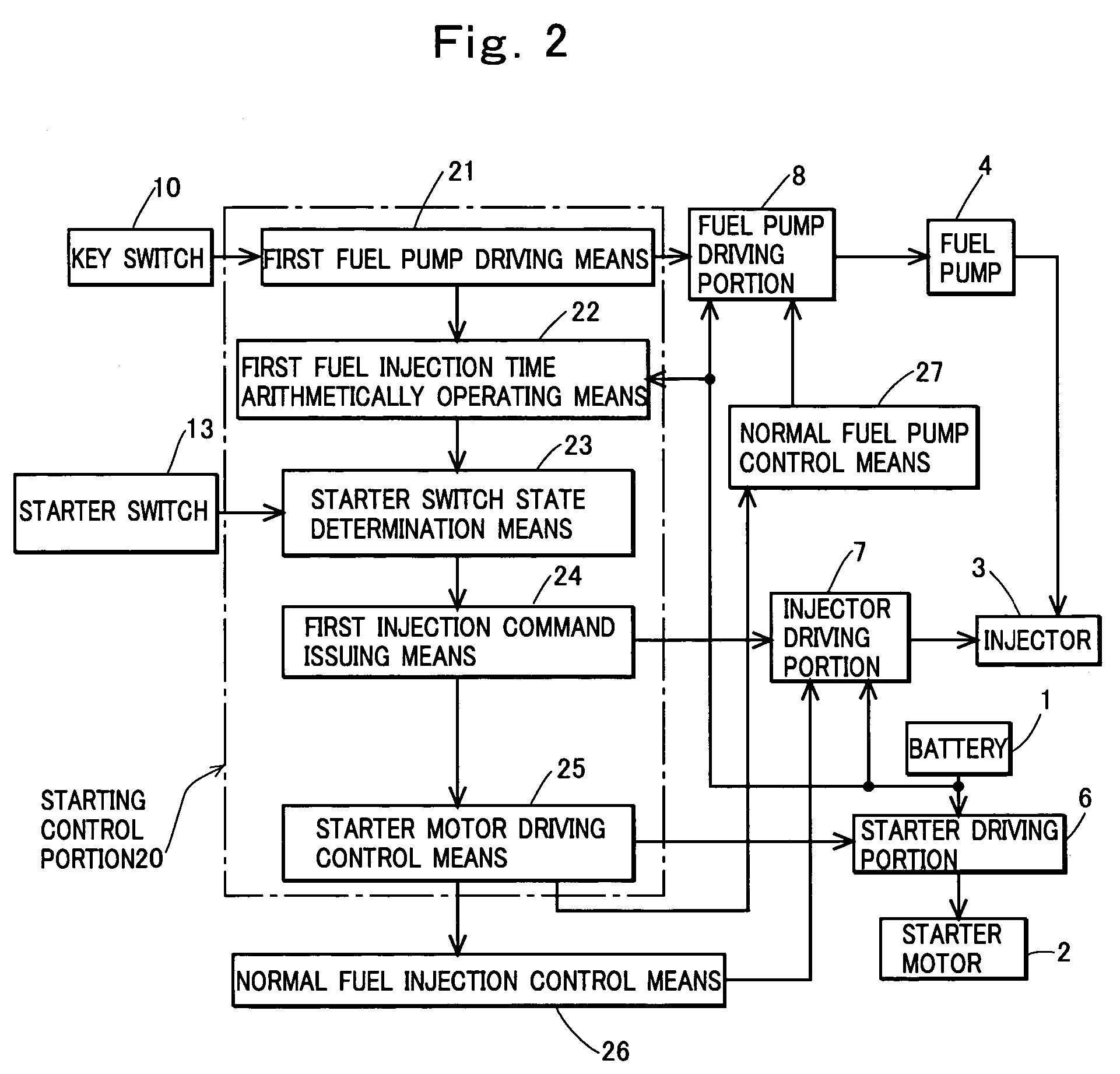

ActiveUS20070062477A1Improve accuracyReduce in quantityElectrical controlFuel injection apparatusFuel injectionMicroprocessor

An engine control device that controls, using a microprocessor, a fuel injection device including an injector and a fuel pump, and a starter motor that starts an engine, including: first fuel pump driving means for driving the fuel pump only during set time at power-on of the microprocessor; and first fuel injection control means for causing the injector to perform first fuel injection before driving of the starter motor when it is confirmed that the driving of the fuel pump by the first fuel pump driving means is completed and that a start command for commanding the start of the engine is given.

Owner:MAHLE INT GMBH

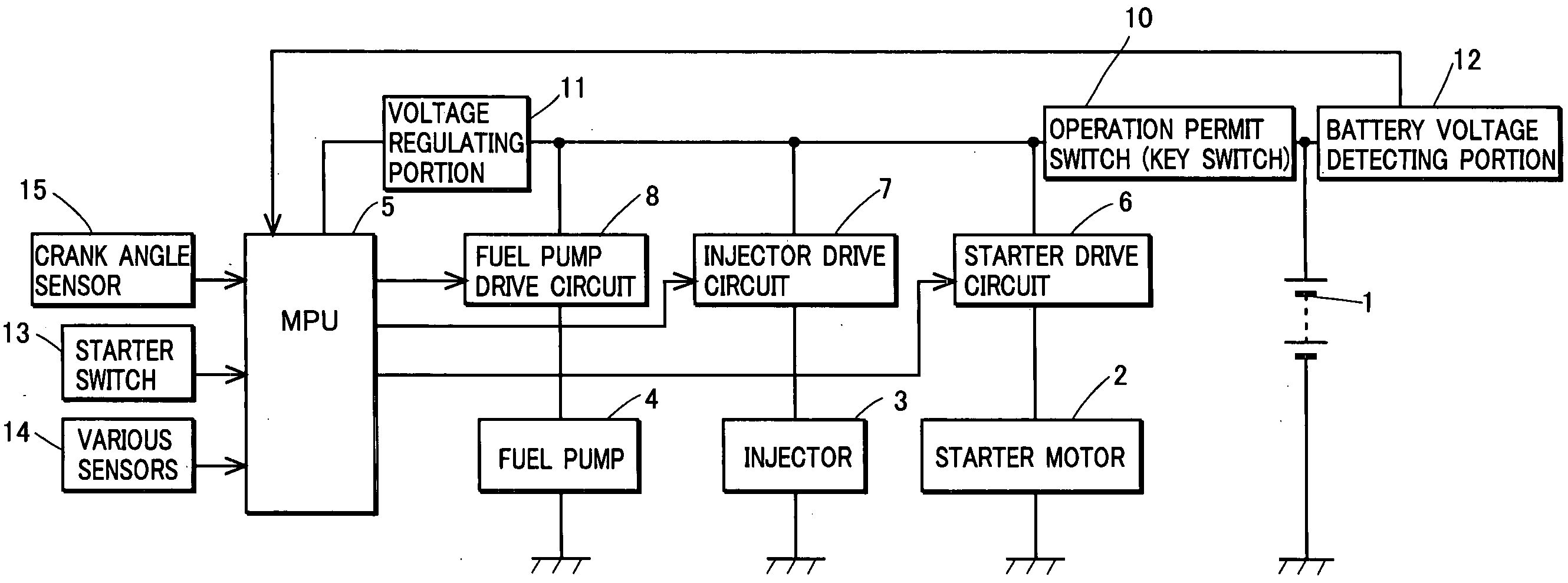

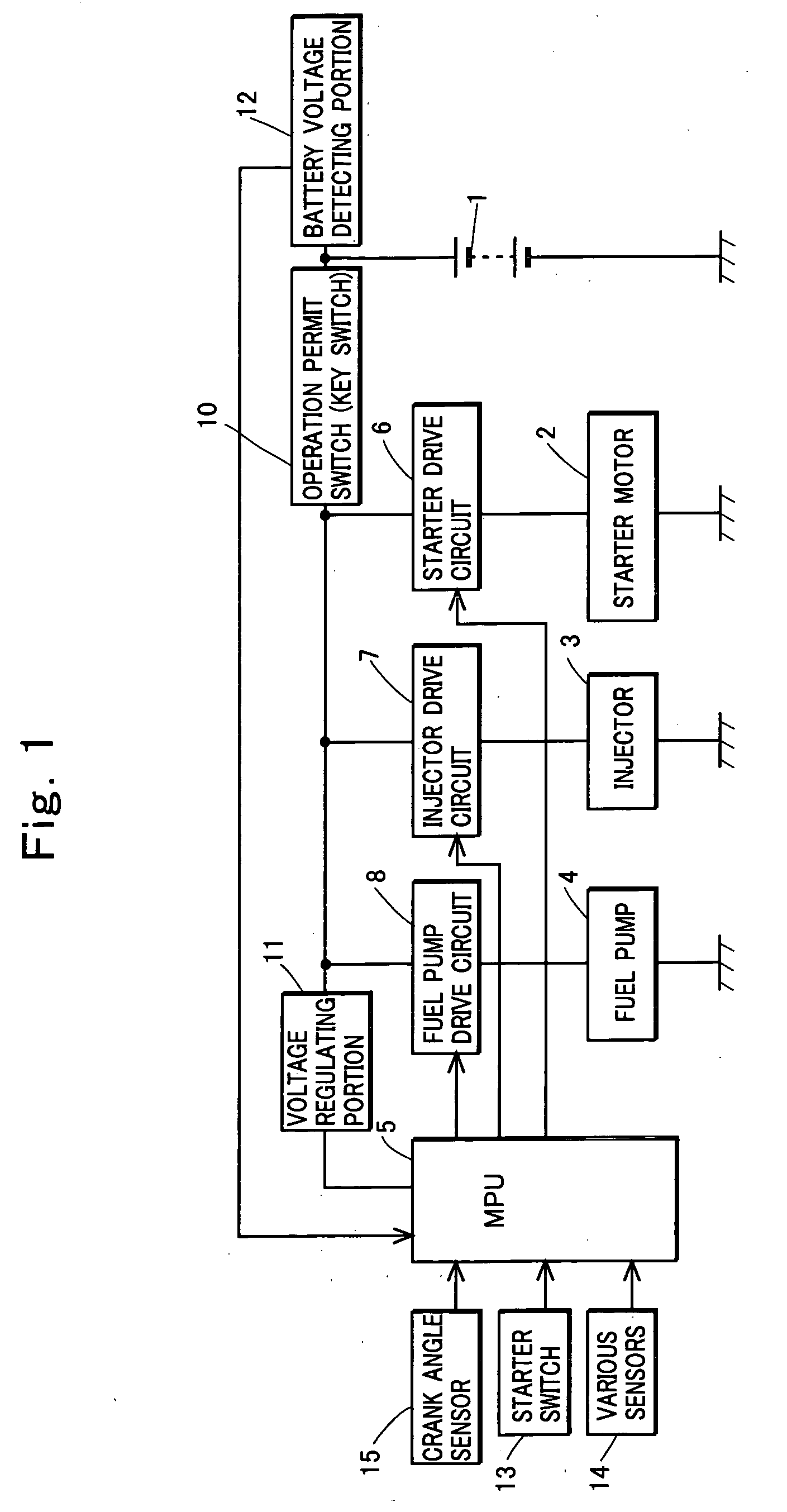

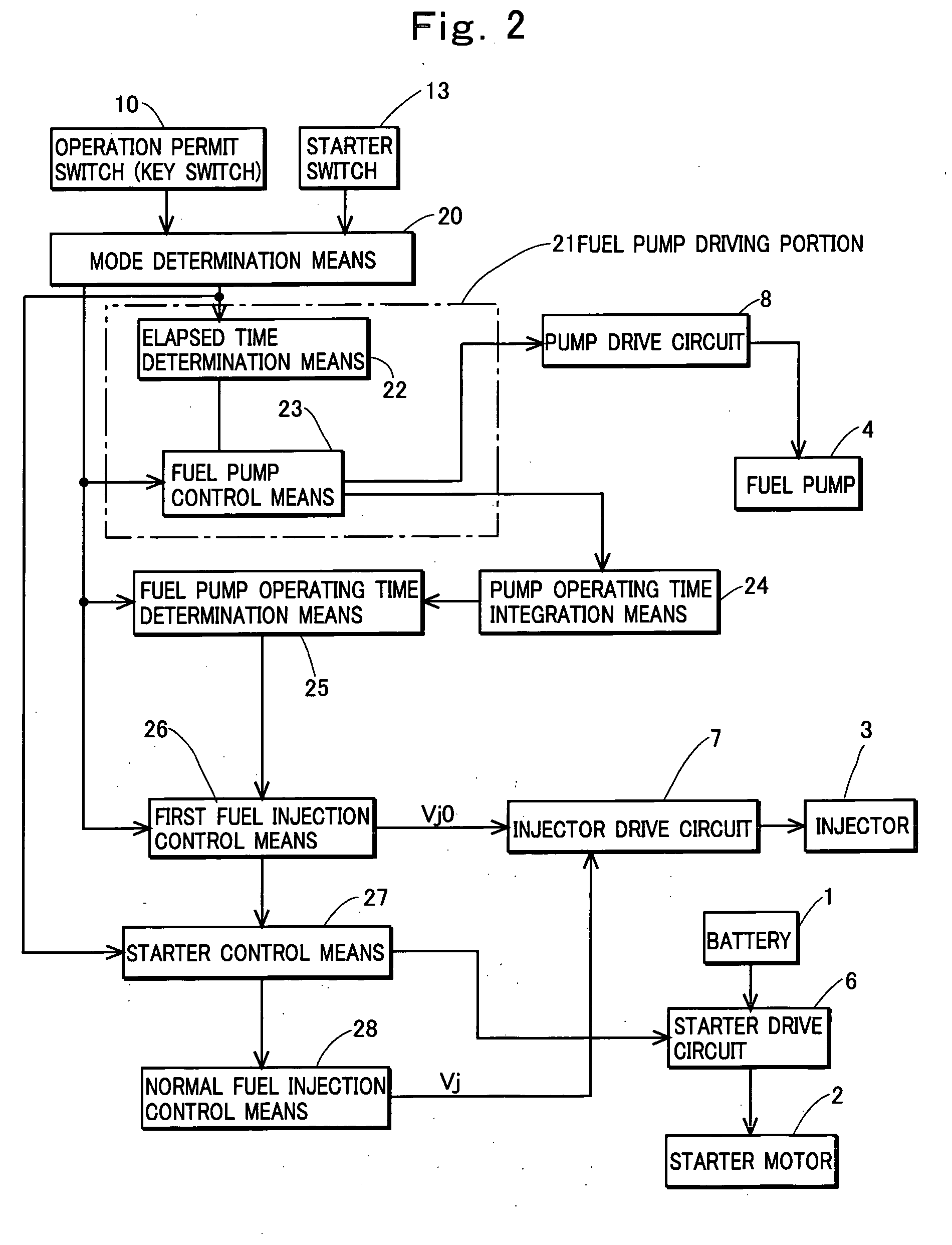

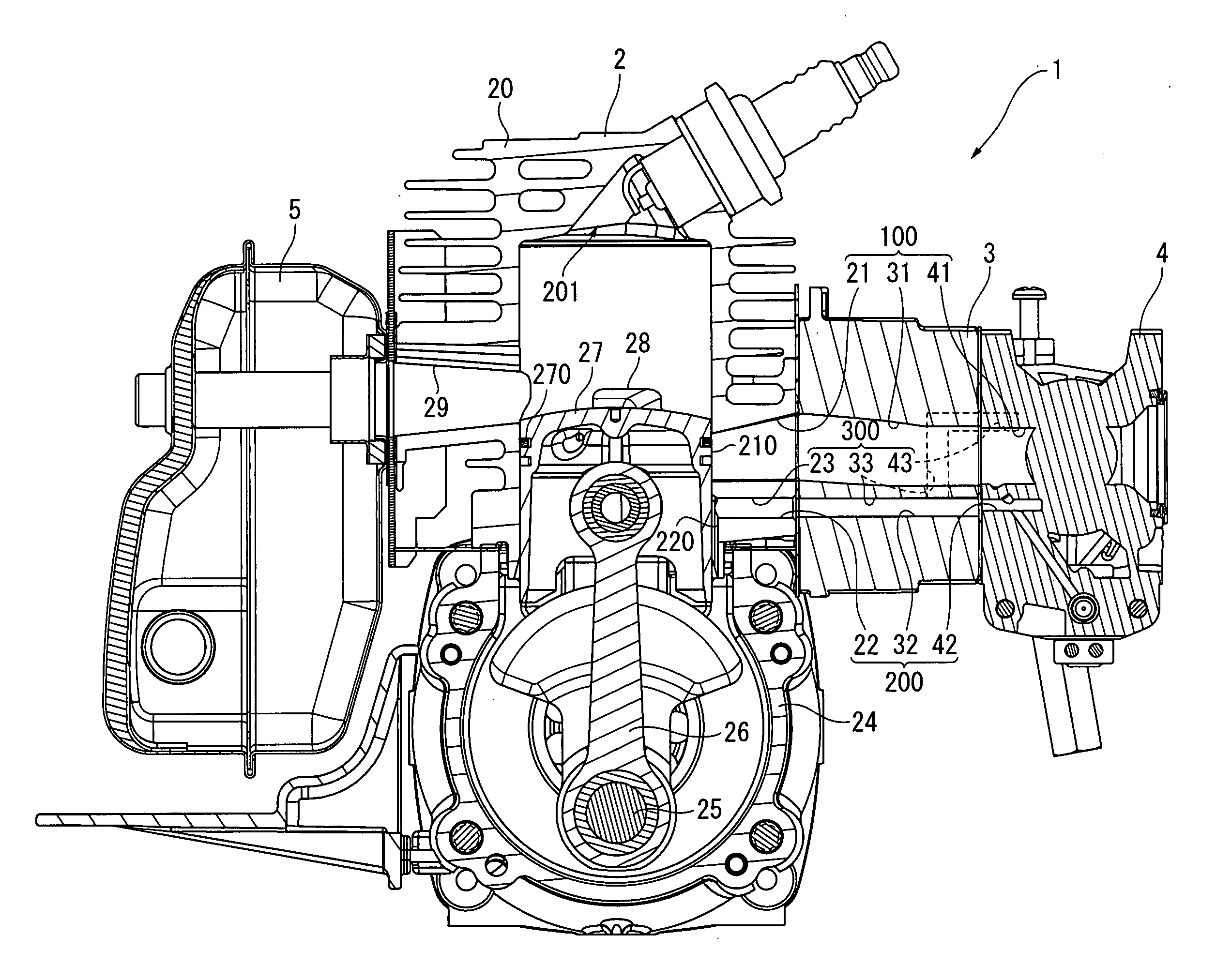

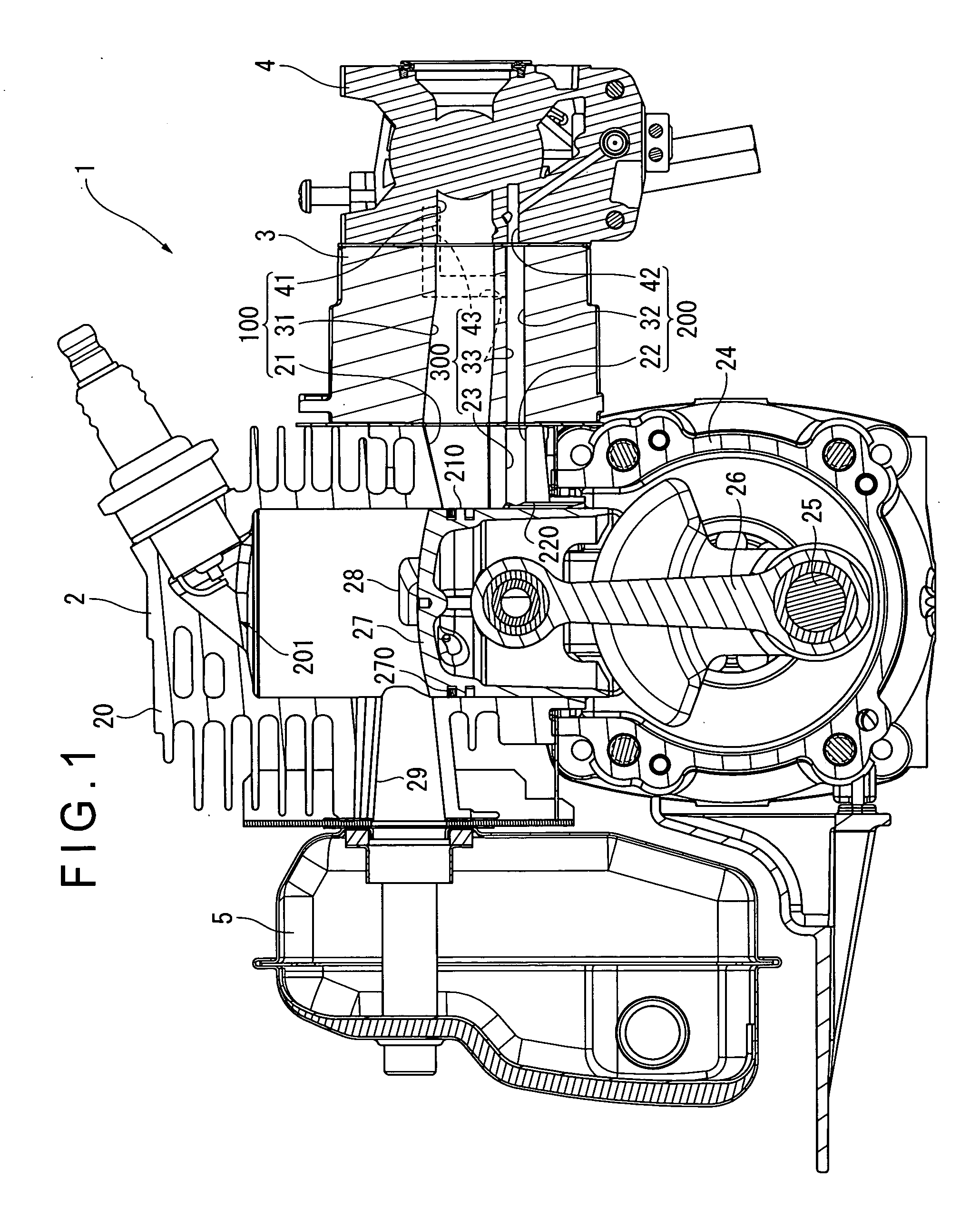

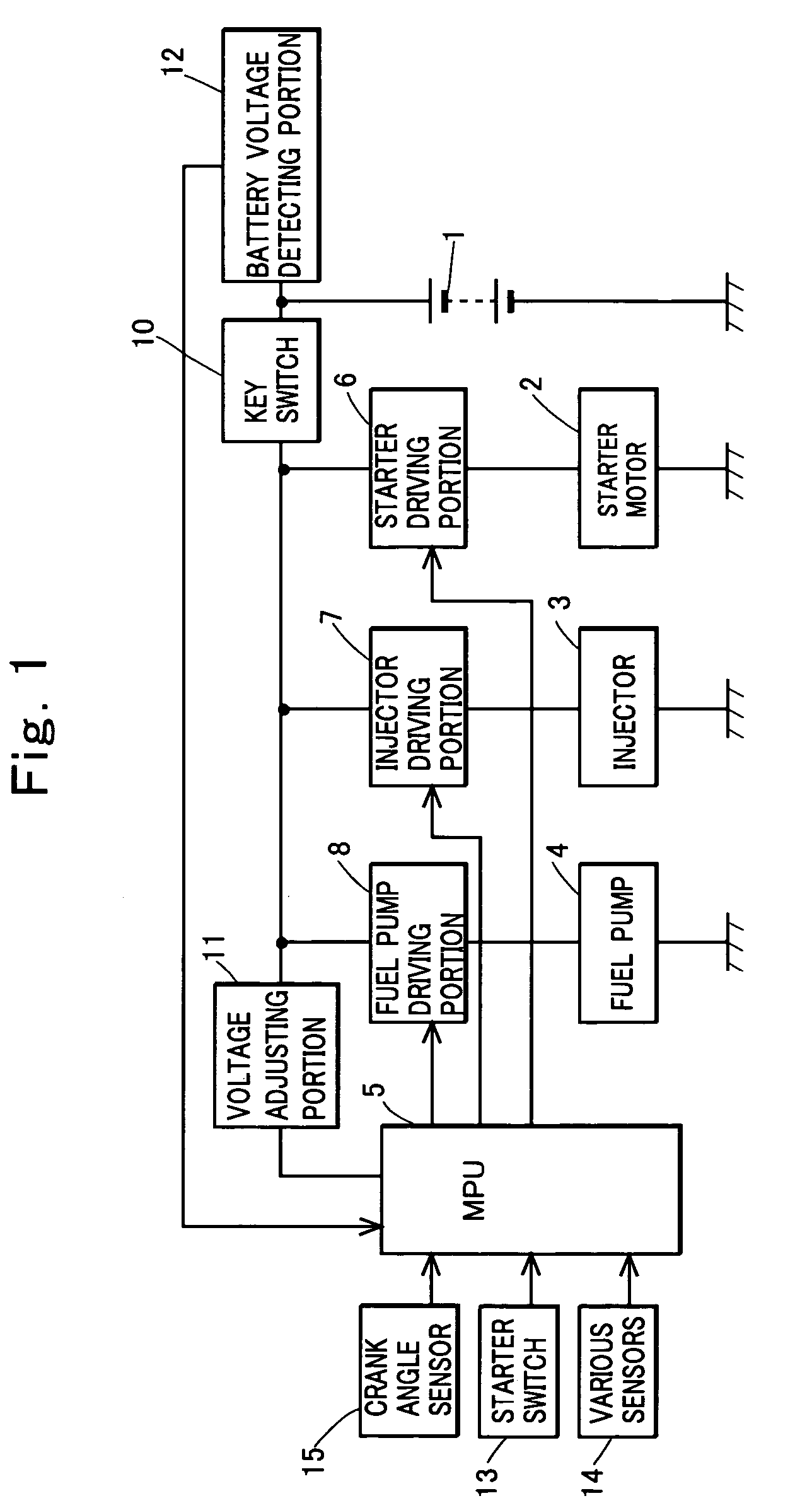

Engine control device

InactiveUS20070175454A1Improve accuracyReduce in quantityElectrical controlInternal combustion piston enginesElectric machineFuel injection

An engine control device including: a fuel pump driving portion that starts operating a fuel pump between when an operation permit switch is turned on and an operation permit command is given and when a starter switch is closed and a start command is given, and continuously operates the fuel pump after the start command is given; the first fuel injection control portion that causes an injector to perform first fuel injection at the start of an engine when both conditions are met that the start command is given and that the fuel pump is continuously operated for a set time or longer; and a rotating electric machine control portion that starts driving a rotating electric machine that operates as an engine starting motor when the first fuel injection is completed, and stops driving the rotating electric machine when the start of the engine is completed.

Owner:KOKUSAN DENKI CO LTD

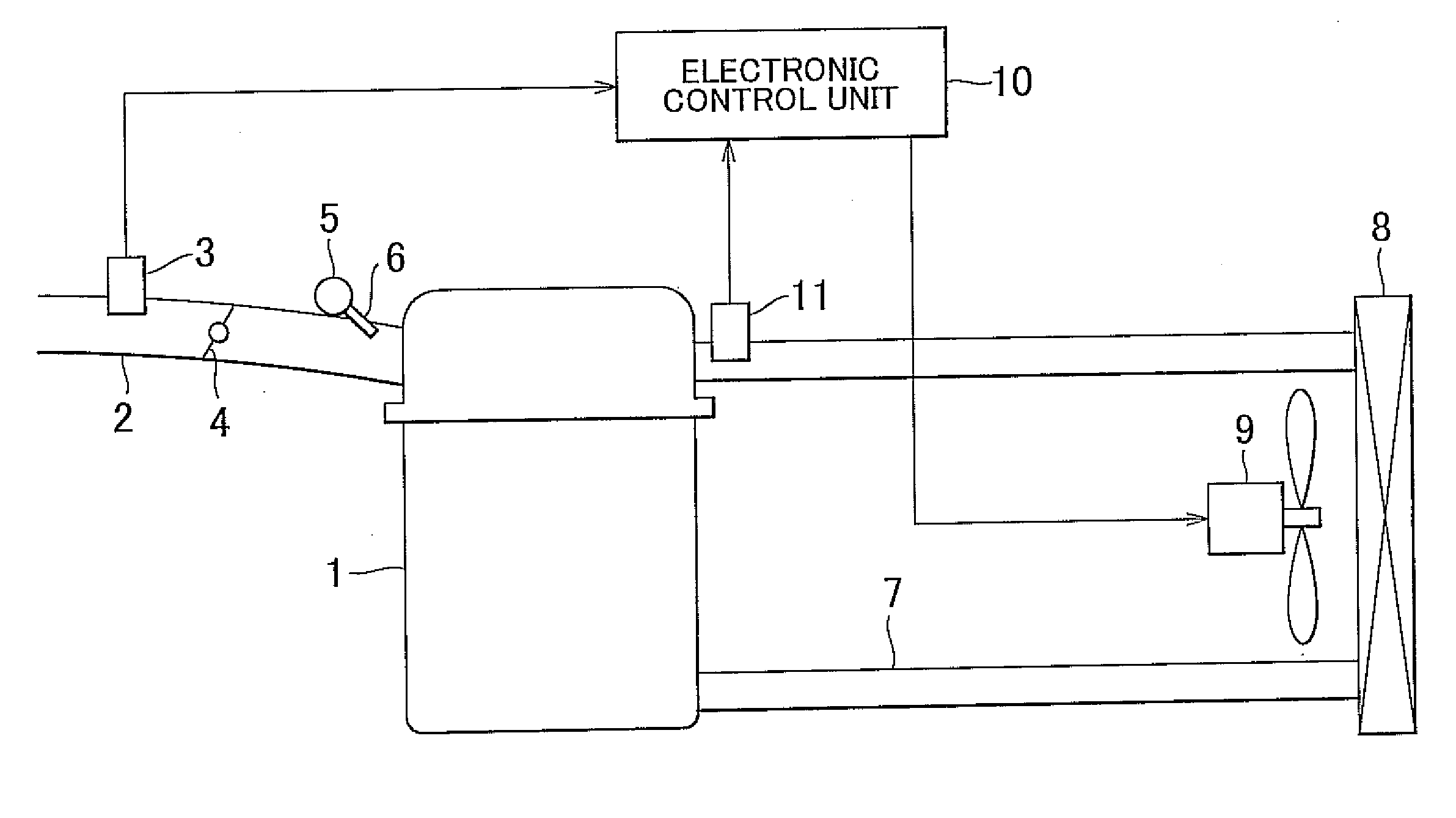

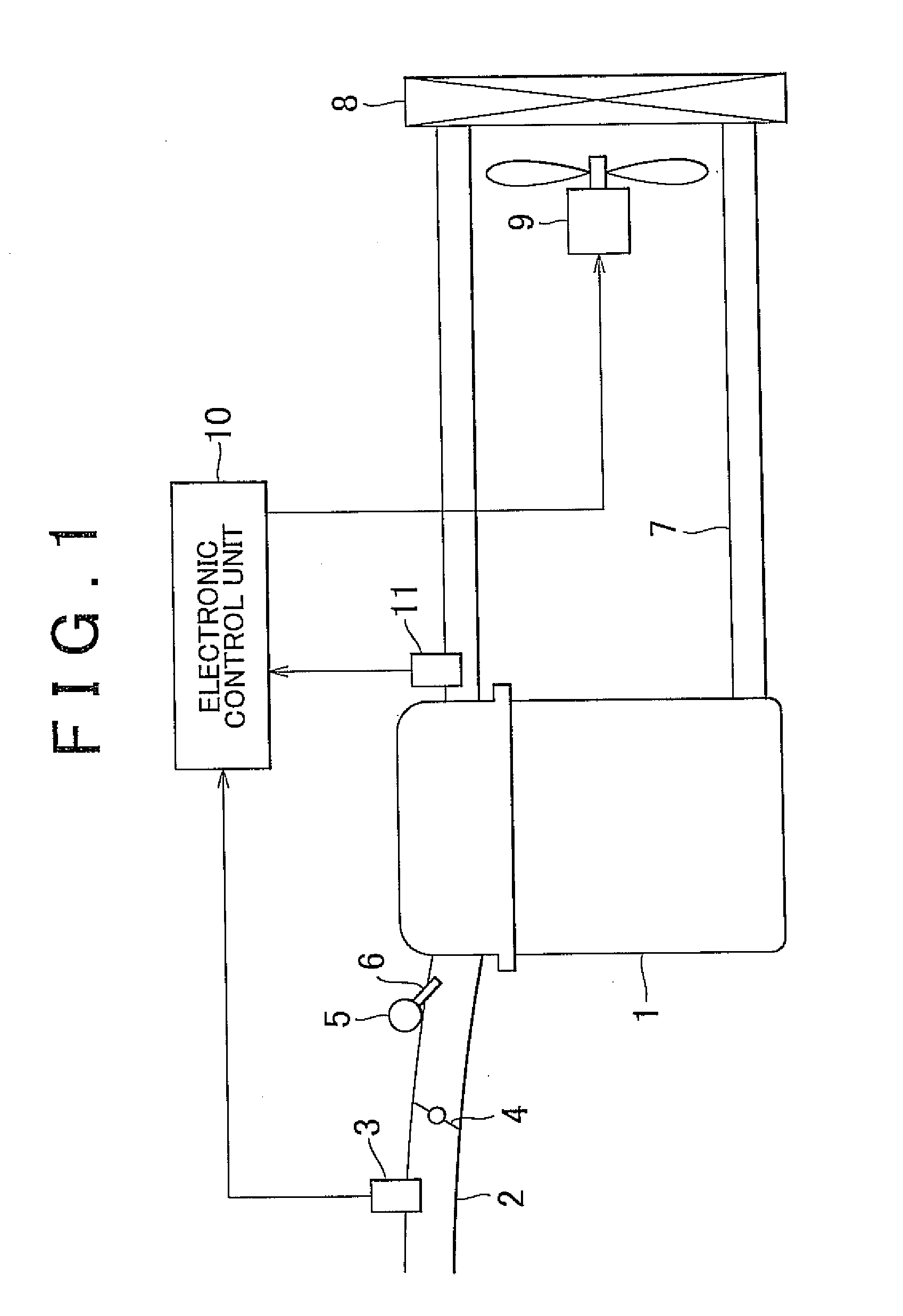

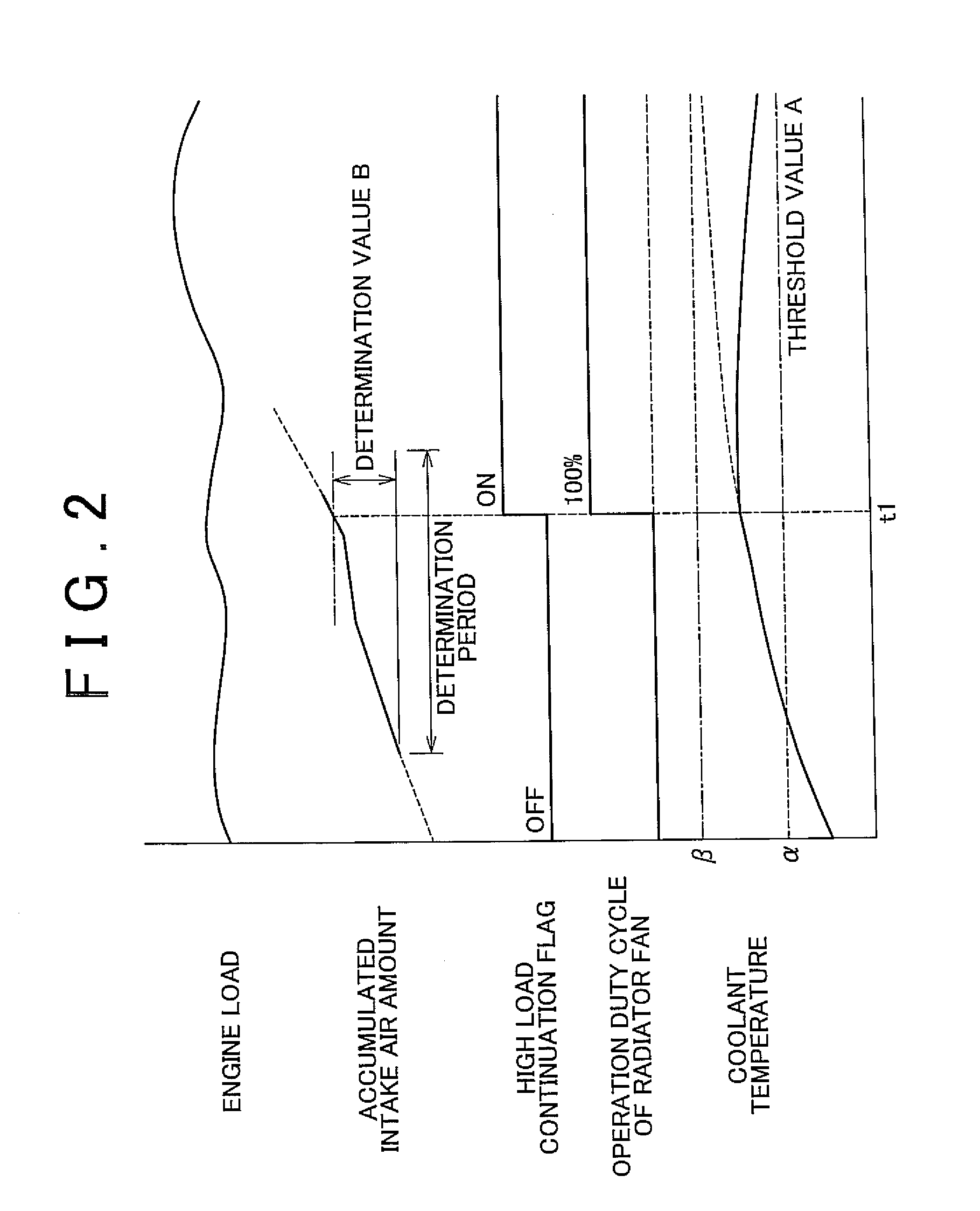

Cooling apparatus for water-cooled engine and method of controlling cooling apparatus for water-cooled engine

InactiveUS20110220042A1Startability is improvedReduce the temperatureCoolant flow controlAir coolingHigh loadCoolant temperature

A cooling apparatus for a water-cooled engine includes a radiator that cools coolant that has been circulated in the engine; a radiator fan that delivers air to the radiator; a determination portion that determines whether the engine is operated under a high load; and a setting portion. If the determination portion determines that the engine is operated under a high load, the setting portion sets an operation rate of the radiator fan at a time point at which the determination portion determines that the engine is operated under a high load, to a value higher than a normal operation rate at the same coolant temperature as a coolant temperature at the time point.

Owner:TOYOTA JIDOSHA KK

Variably operated valve apparatus for internal combustion engine, start system for internal combustion engine, and start control apparatus for internal combustion engine

InactiveUS20120037105A1Good dispersionEngine startability can be improvedValve arrangementsInternal combustion piston enginesExternal combustion engineValve actuator

A variably operated valve apparatus for use in an internal combustion engine comprises: a variable valve actuator configured to variably adjust at least a closure timing of an intake valve; and a mechanically stabilizing section configured to mechanically stabilize the closure timing of the intake valve at a position more retardation angle side than a most retardation angle position which is a limit of a control range of the stop position of the piston at the time of the stop of the engine. In addition, in start system and start control apparatus for the internal combustion engine, crank position control means controls a stop position of a piston at a position more advance angle side than the closure timing of the intake valve, at a time of stop of the engine.

Owner:HITACHI AUTOMOTIVE SYST LTD

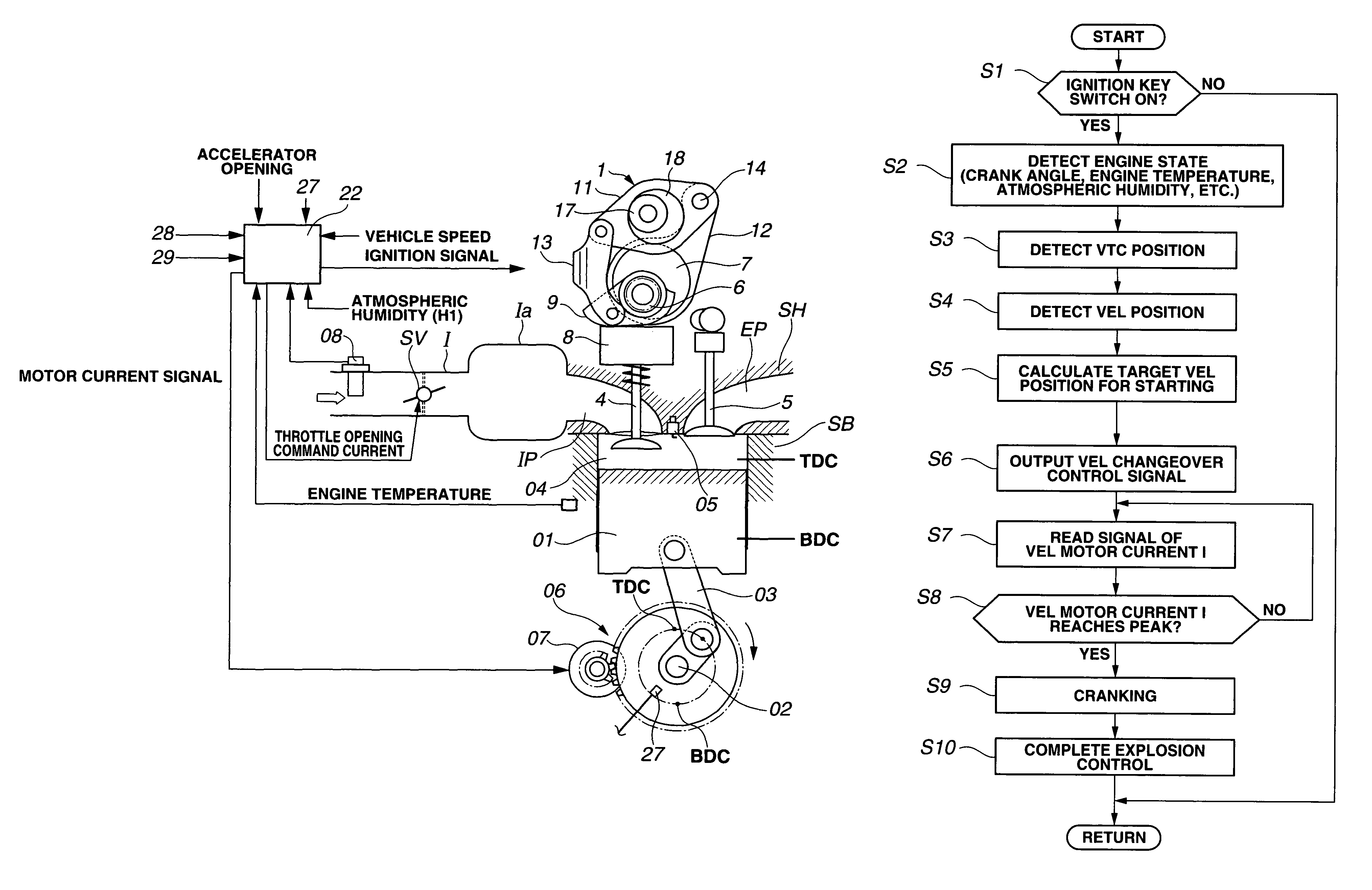

Variable valve actuating apparatus and process for internal combustion engine

InactiveUS20070283911A1Startability is improvedImprove performanceValve arrangementsInternal combustion piston enginesExternal combustion engineEngineering

A variable valve actuating apparatus for an internal combustion engine includes a first valve actuating mechanism to vary a first valve operating condition, and a second valve actuating mechanism to vary a second valve operating condition. A controller controls the first valve actuating mechanism to satisfy a predetermined engine starting condition before a start of a cranking operation or during the cranking operation, with respect to an engine operating condition including the second valve operating condition controlled by the second valve actuating mechanism.

Owner:HITACHI LTD

Two-Cycle Engine

InactiveUS20090050124A1Structure of engine can be simplifiedEasy to manufactureElectrical controlCylinder headsPistonFuel supply

A two-cycle engine includes a starting fuel supply passage for supplying a starting fuel to a crankcase from a starting fuel reservoir, and a flow passage opening and closing unit provided in a midway portion of the starting fuel supply passage. The starting fuel supply passage is opened to be constantly in communication with the crankcase. Accordingly, simultaneously with the generation of a negative pressure within the crankcase when a piston starts to ascend from a bottom dead center, the starting fuel starts to be supplied to the crankcase. Since the starting fuel is supplied to the crankcase for a relatively long time as compared to a conventional engine, a sufficient amount of the fuel is supplied for starting and startability of the two-cycle engine is improved.

Owner:HUSQVARNA ZENOAH

Vehicular power supply device

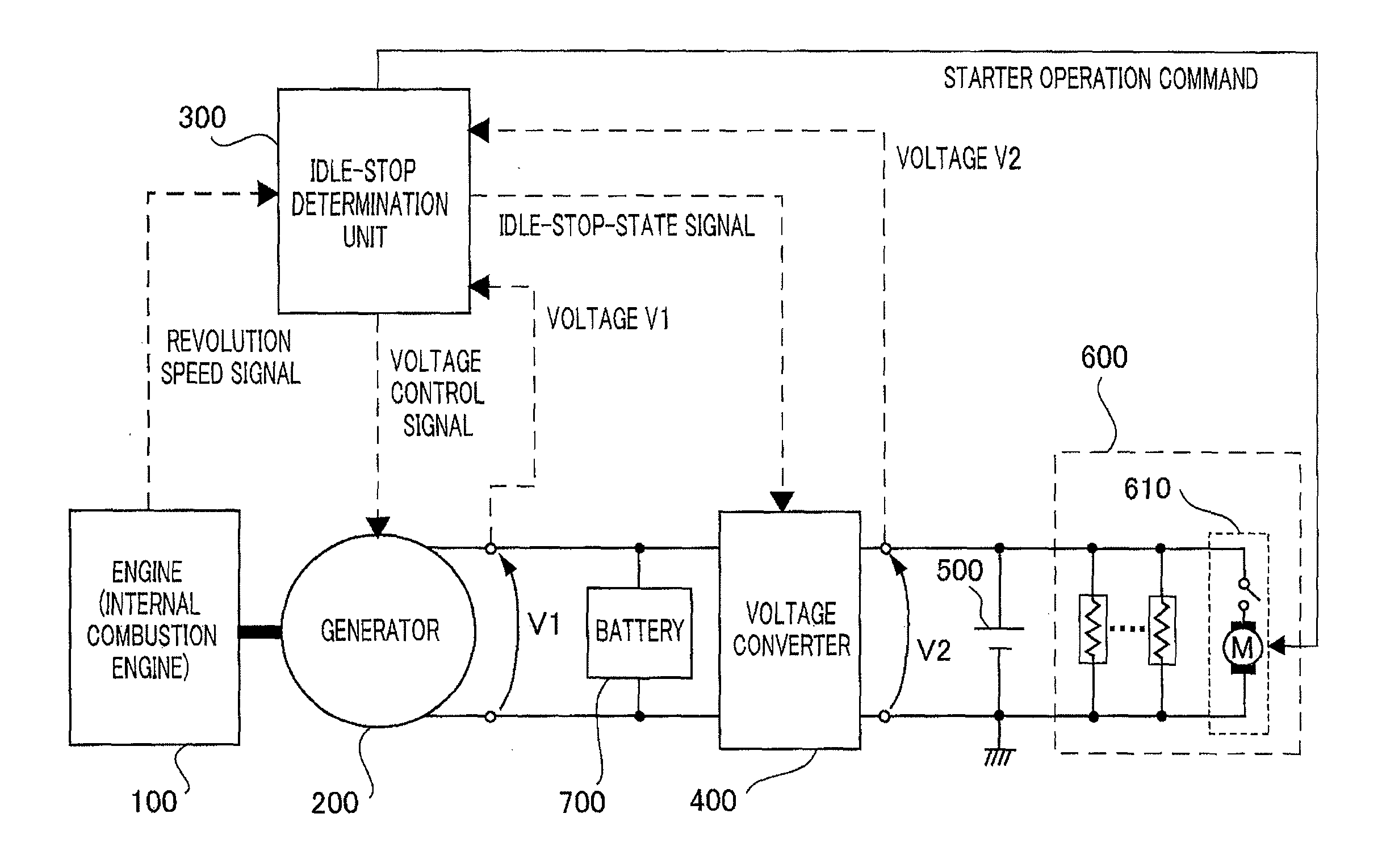

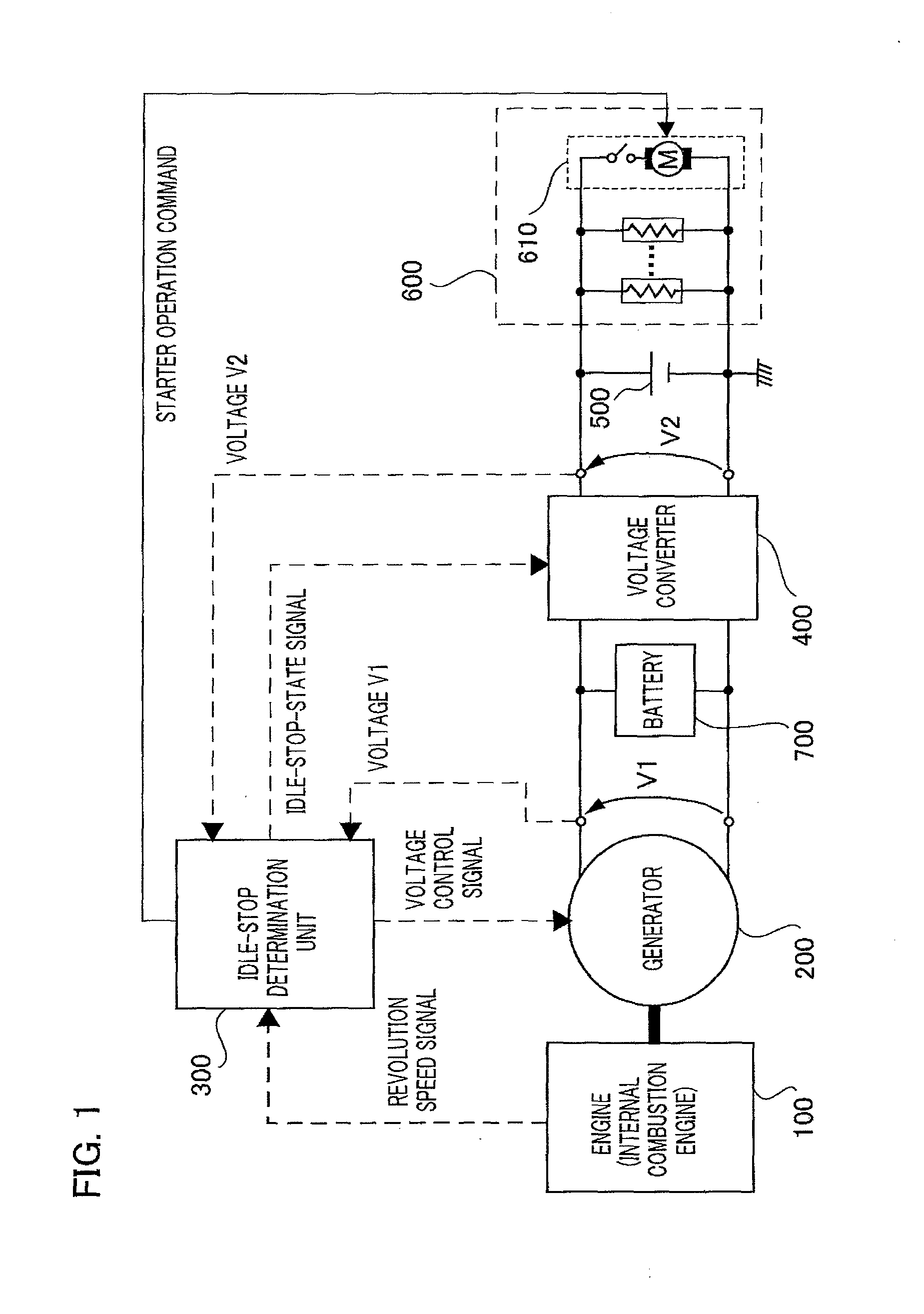

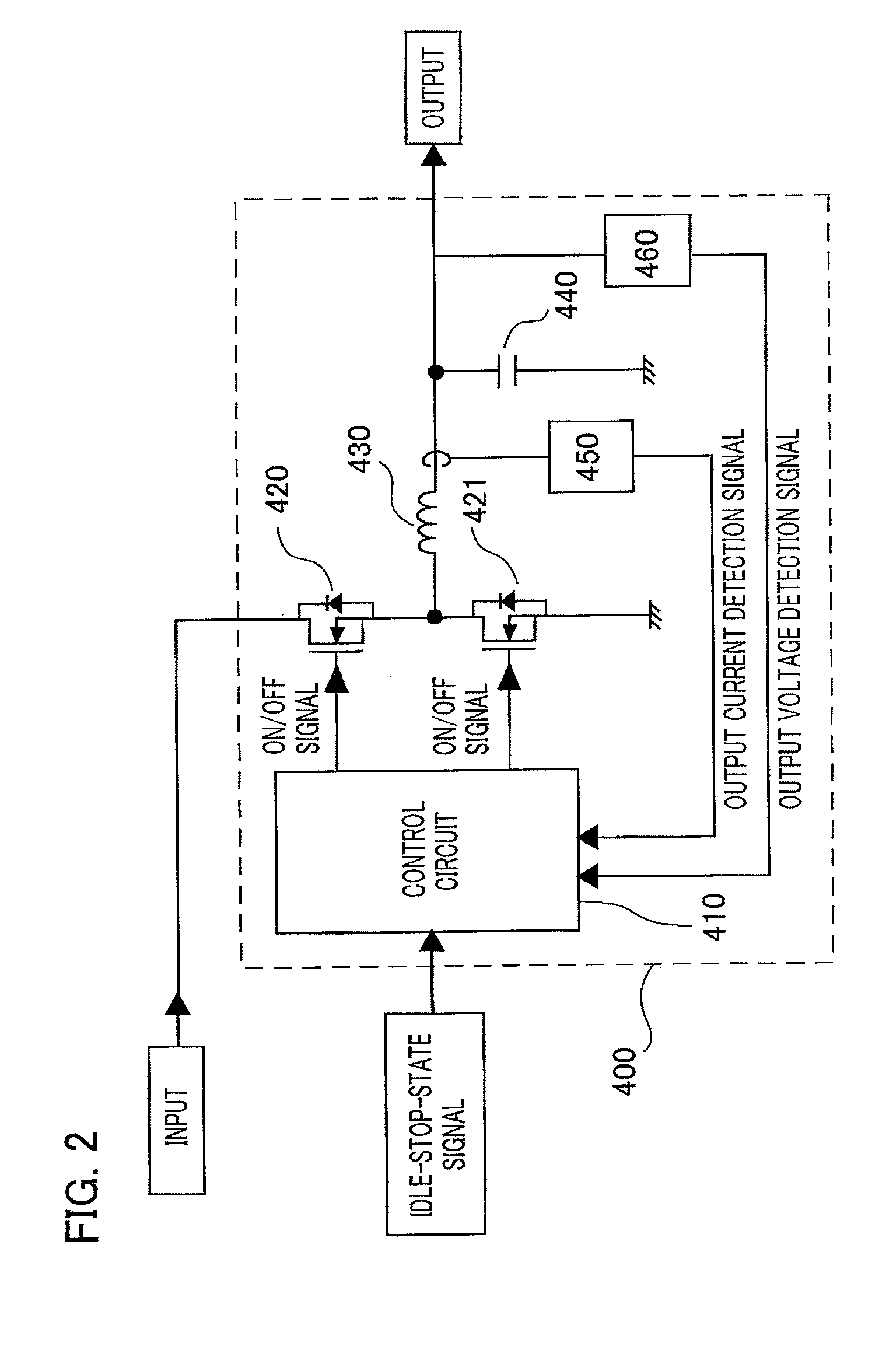

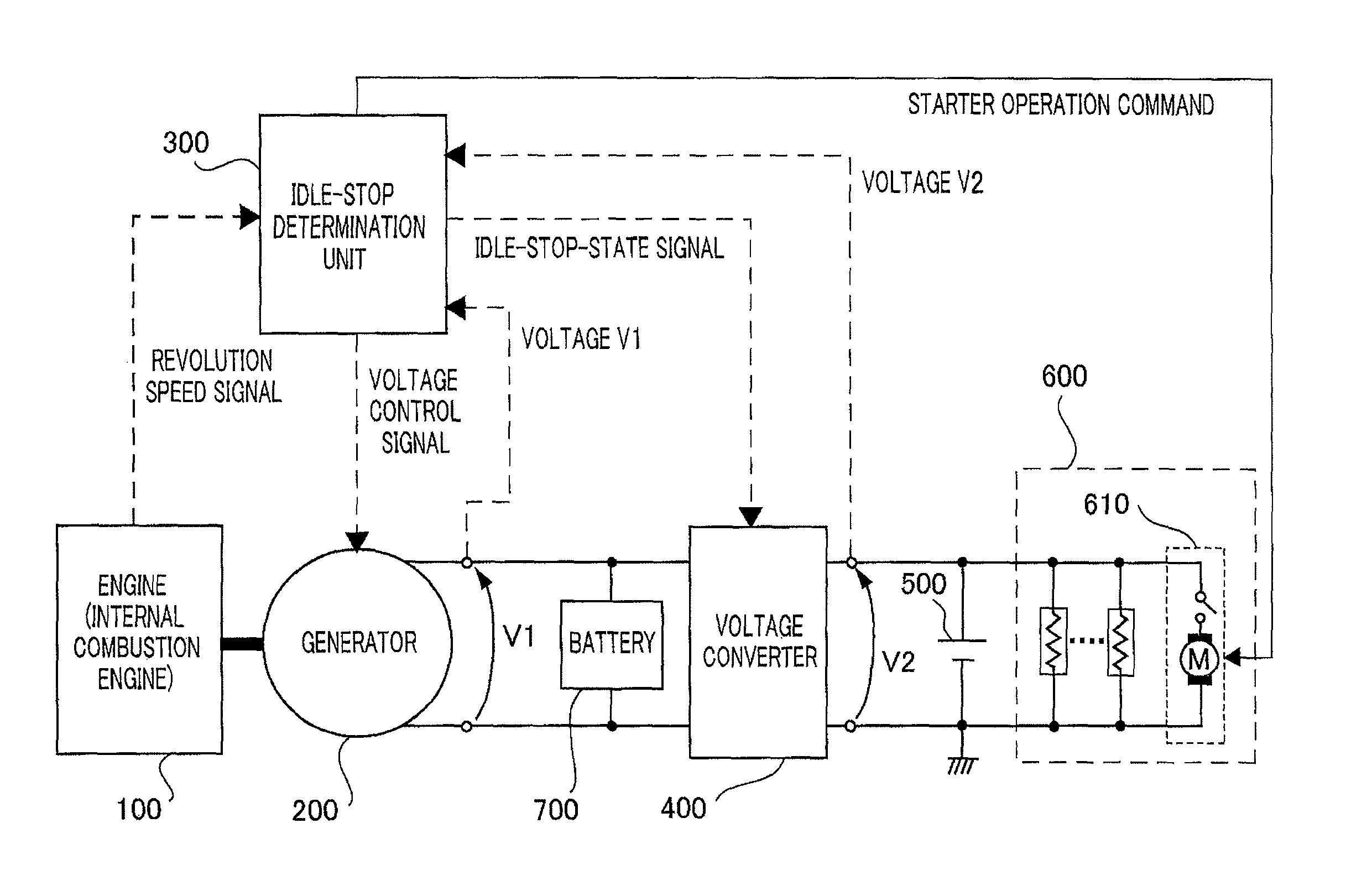

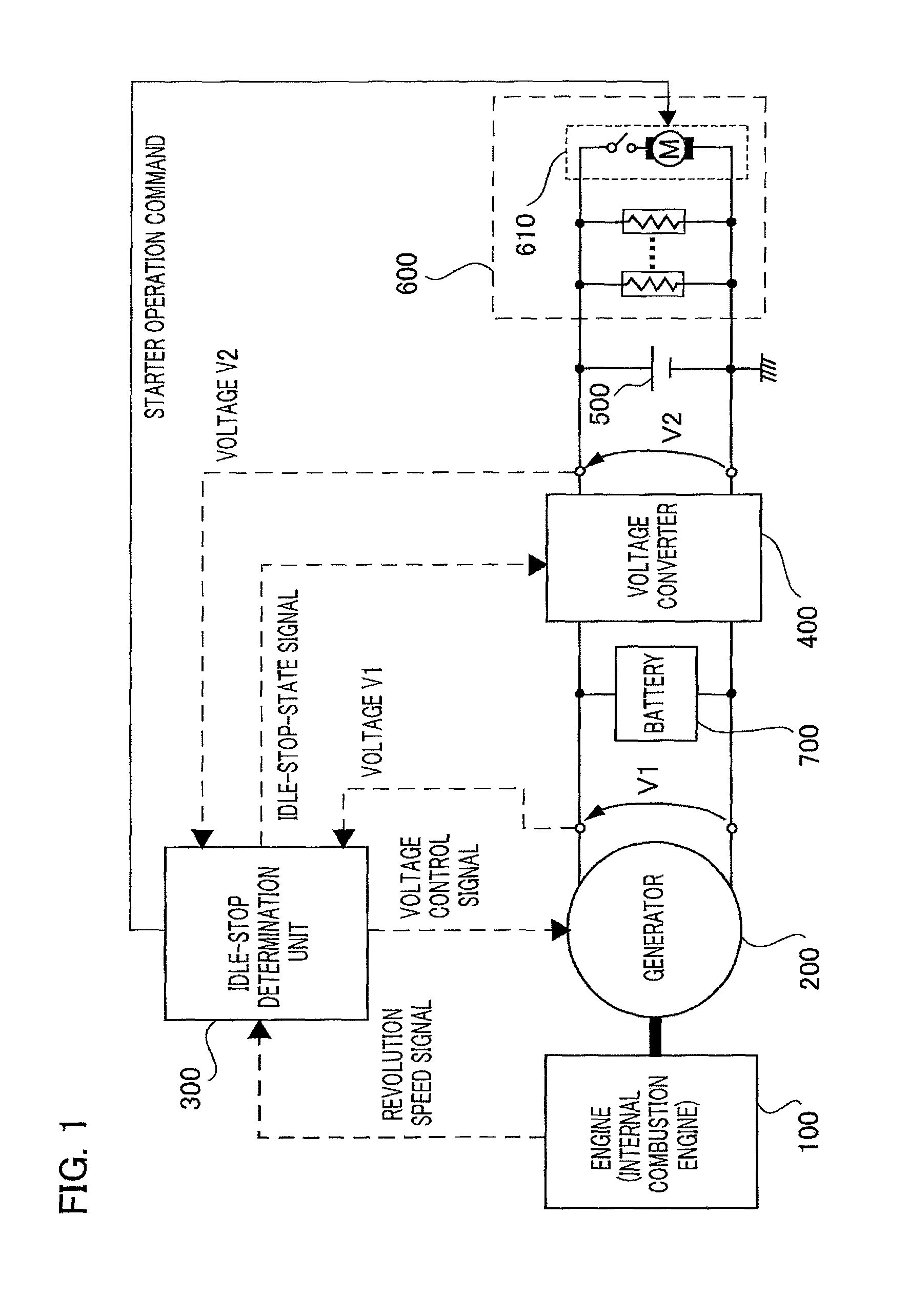

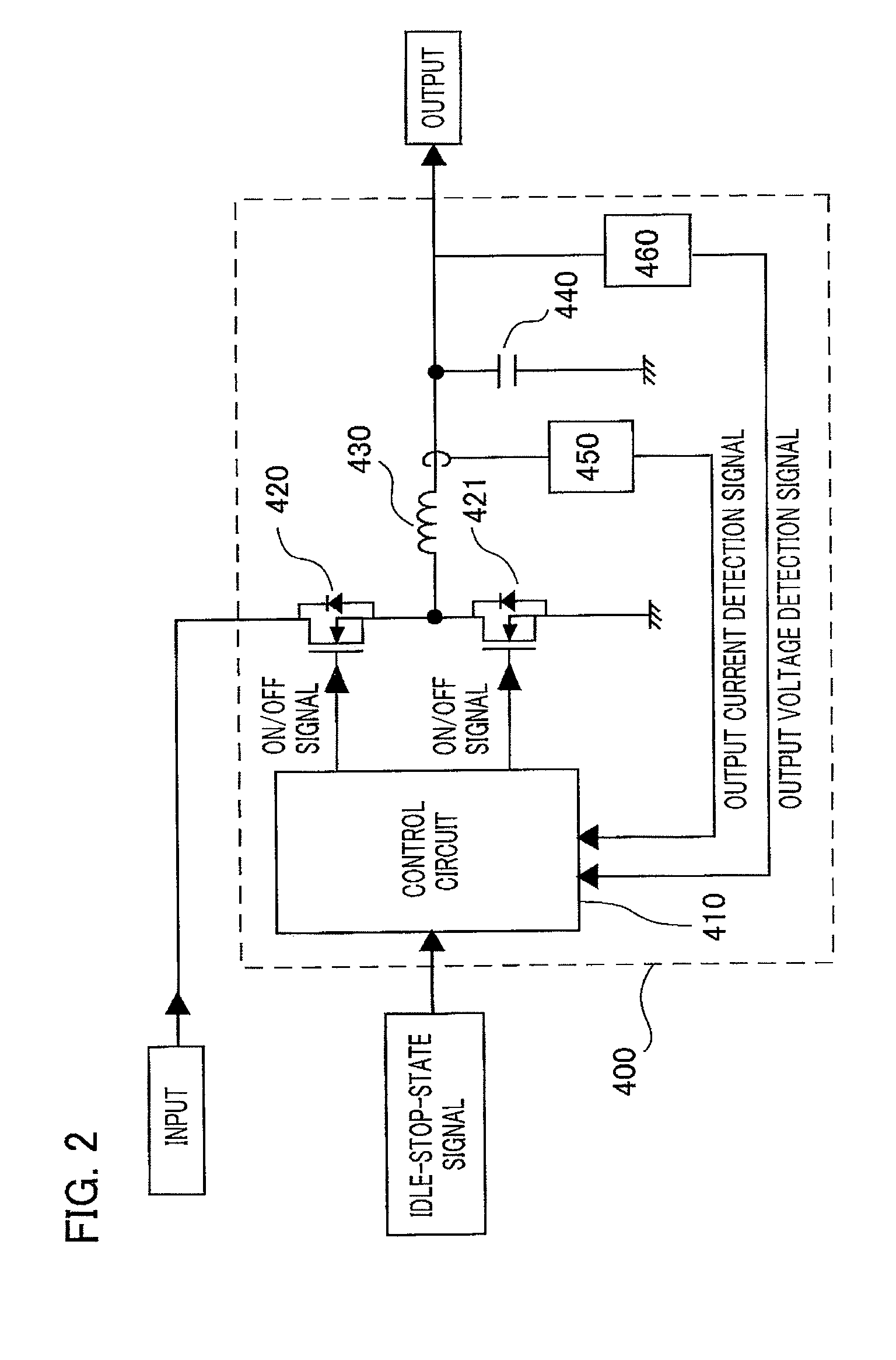

ActiveUS20120316749A1Engine startability can be improvedReduce energy consumptionAnalogue computers for vehiclesProgramme-controlVoltage converterElectricity

A vehicular power supply device mounted on a vehicle equipped with an idle stop function is provided that enhances engine startability and suppresses a voltage drop at a battery driving the starter, so as to reduce energy consumption by the engine or other drive sources. The device includes a voltage converter for converting a DC voltage V1 output from a generator into a DC voltage control value V2 and for outputting the value, and when the idle-stop determination unit determines that the engine is in the idle stop state, the voltage converter outputs, depending on a current and voltage supplied to an electrical load including a starter, a second DC voltage control value V2a higher than a first DC voltage control value V2 that is a target output voltage for the battery.

Owner:MITSUBISHI ELECTRIC CORP

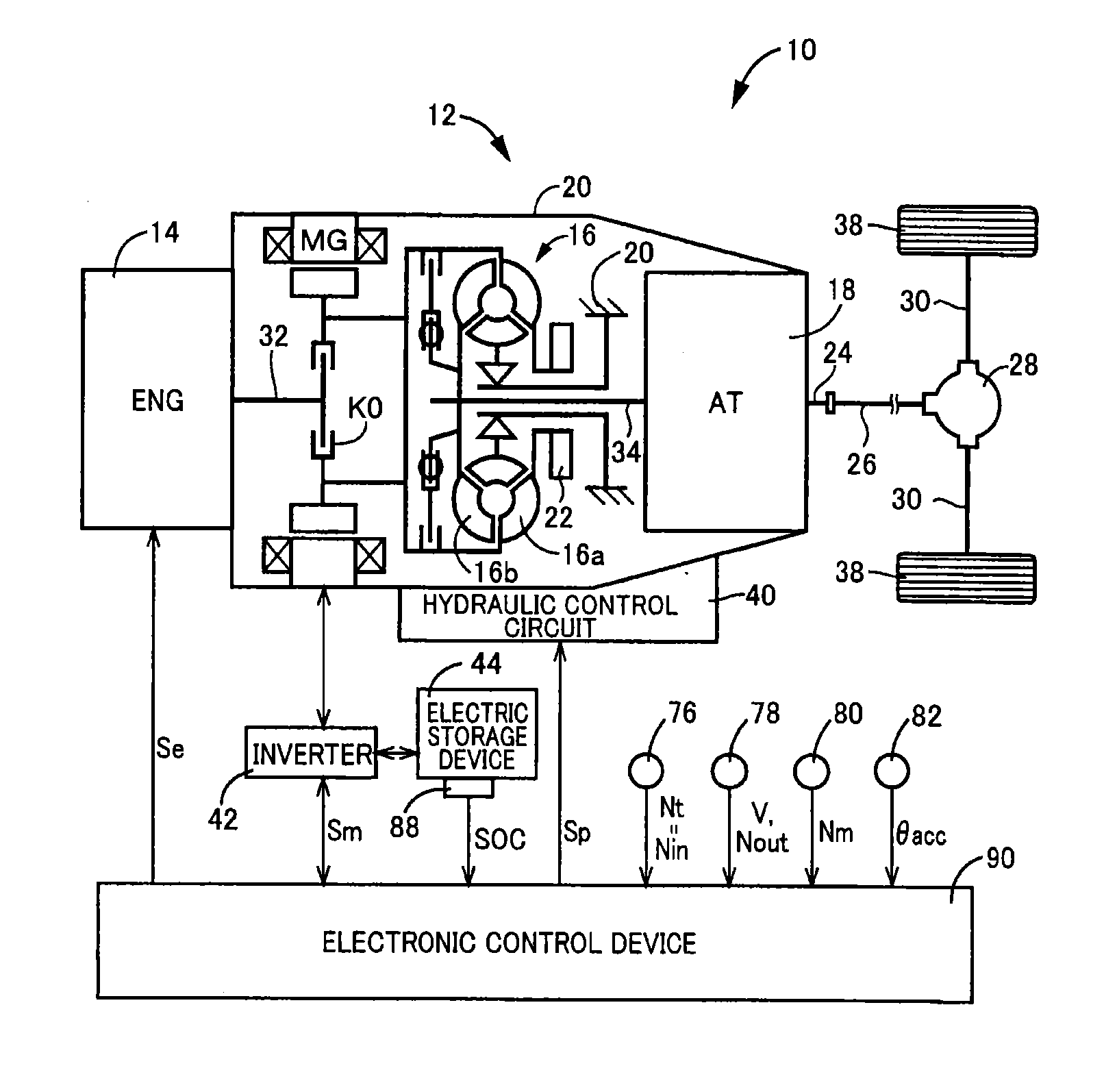

Vehicle control device

ActiveUS20160003207A1Engine startability can be improvedHigh explosionHybrid vehiclesPower operated startersExhaust valveCombustion

A control device of a vehicle including an engine, an electric motor, and a clutch disposed on a power transmission path between the engine and the electric motor, the control device of a vehicle performing an ignition start causing combustion in a cylinder of the engine to rotate the engine at a start of the engine, the control device of a vehicle switching a cylinder in which combustion is first caused in the engine based on an actuation during a rotation stop process of the engine of an exhaust valve in a cylinder stopped in an expansion stroke, when performing the ignition start at the start of the engine.

Owner:TOYOTA JIDOSHA KK

Engine control device

ActiveUS7412953B2Avoid shortageEngine startability can be improvedElectrical controlFuel injection apparatusElectric machineFuel injection

An engine control device that controls, using a microprocessor, a fuel injection device including an injector and a fuel pump, and a starter motor that starts an engine, including: first fuel pump driving means for driving the fuel pump only during set time at power-on of the microprocessor; and first fuel injection control means for causing the injector to perform first fuel injection before driving of the starter motor when it is confirmed that the driving of the fuel pump by the first fuel pump driving means is completed and that a start command for commanding the start of the engine is given.

Owner:MAHLE INT GMBH

Device for controlling power generation of on-vehicle power generator

ActiveUS20120119713A1Simple configurationEngine startability can be improvedEmergency protective circuit arrangementsDynamo-electric converter controlDynamoControl power

A device for controlling an on-vehicle power generator is provided with switching means, detecting means, voltage control means, startup control means and normal state control means. The voltage control means controls the output voltage of the power generator together with the switching means. The detecting means detects state of the power generation including a startup state where the engine is in startup condition and a normal state where normal power generation has been performed. The startup control means controls the voltage control means to start / stop of the power generation based on the frequency of the phase voltage of the power generator in the startup state. The normal state control means controls the voltage control means in the normal state such that the normal state control means controls the voltage control means to continue the power generation or stops the power generation based on the frequency of the phase voltage.

Owner:DENSO CORP

Vehicular power supply device

ActiveUS8862365B2Engine startability can be improvedReduce energy consumptionAnalogue computers for vehiclesProgramme-controlVoltage converterElectricity

Owner:MITSUBISHI ELECTRIC CORP

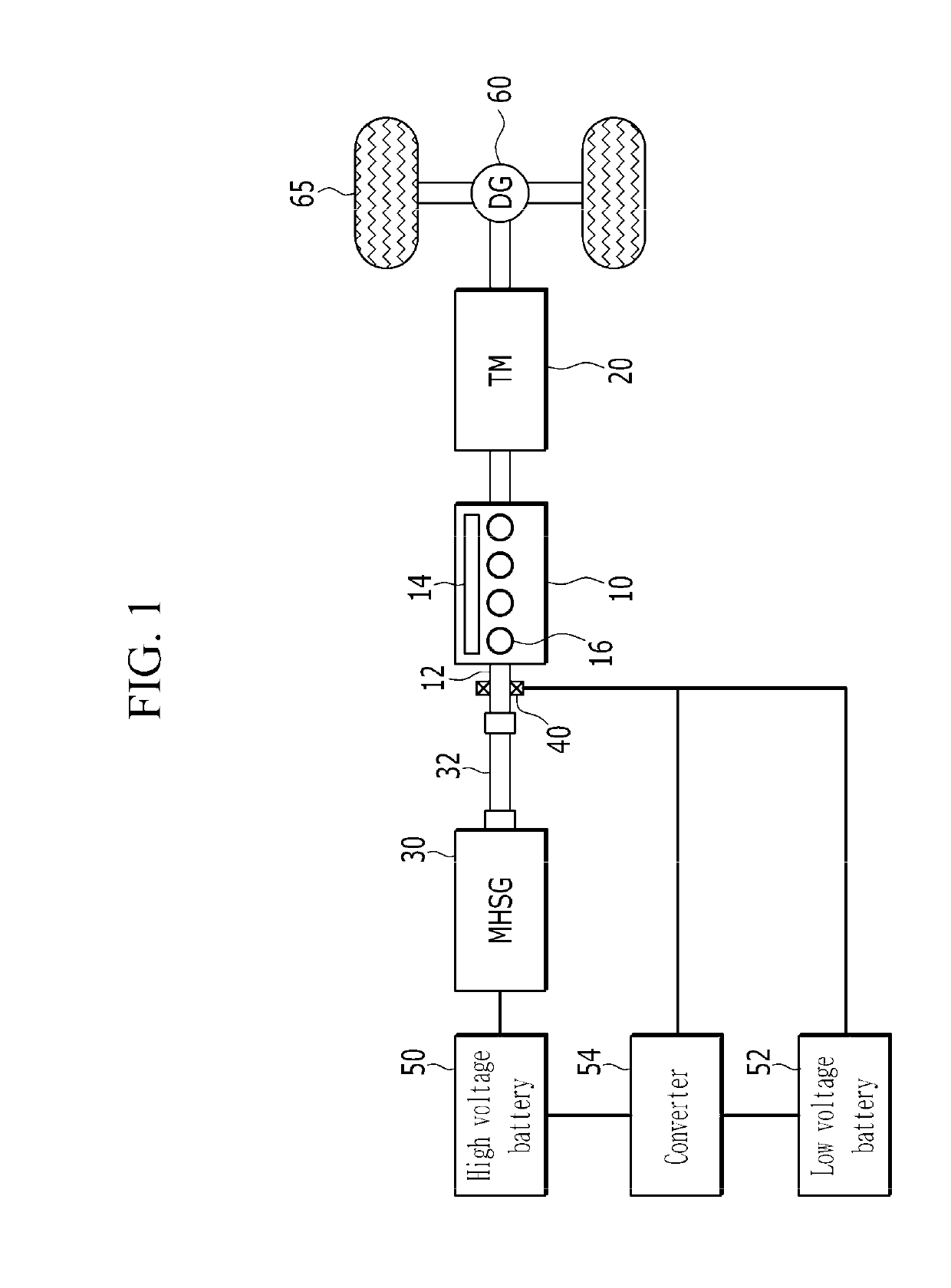

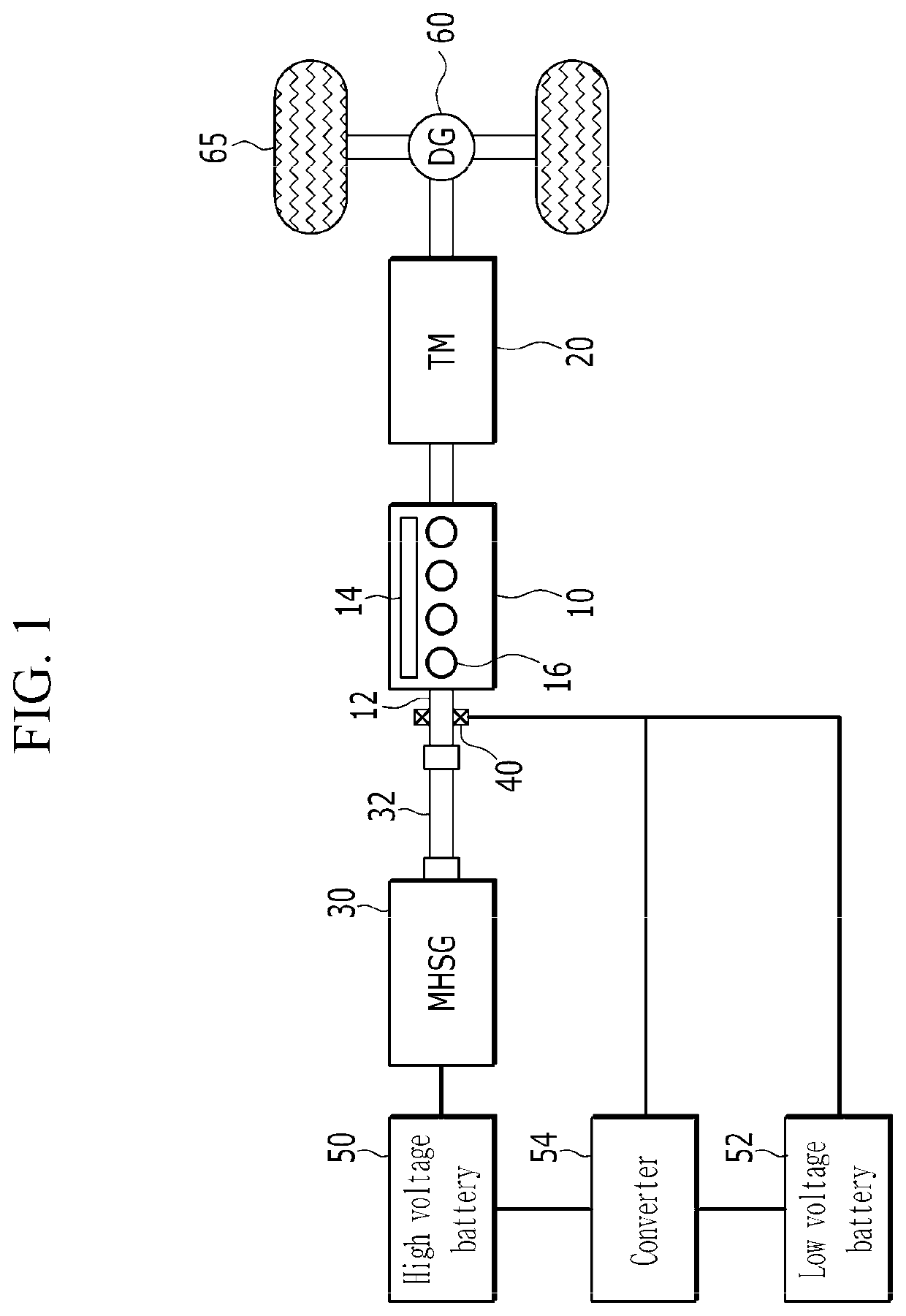

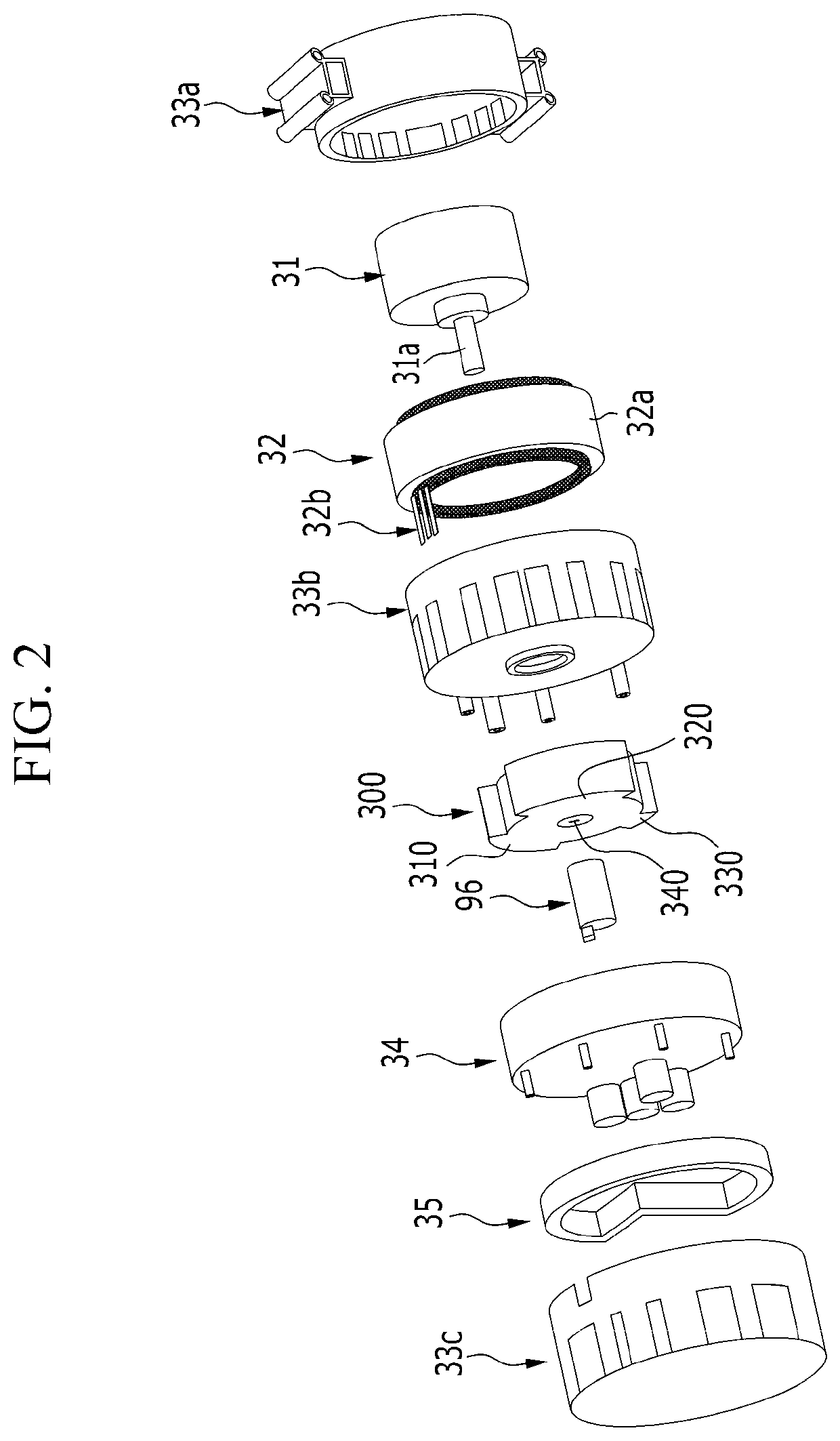

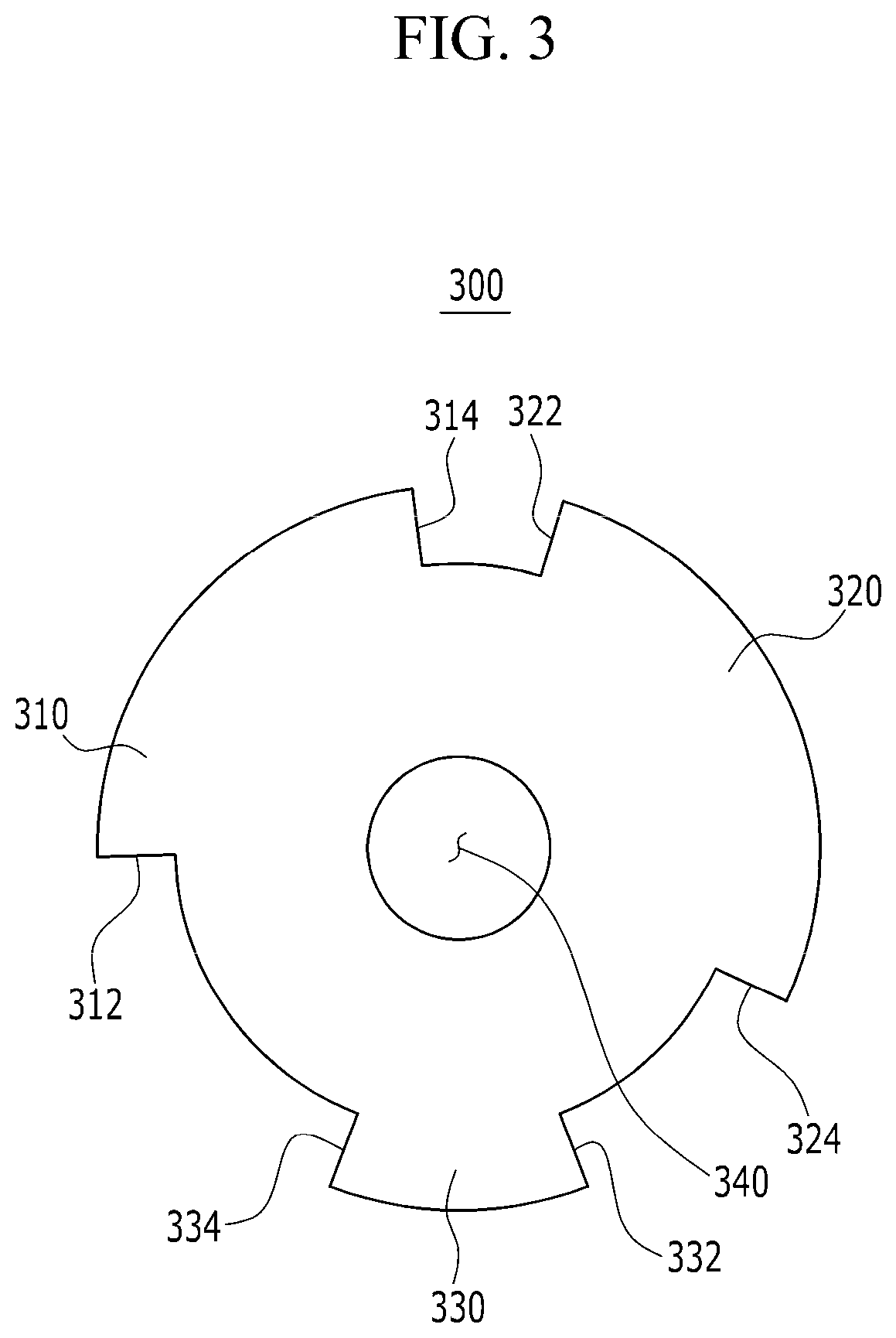

Apparatus and method for starting engine of mild hybrid electric vehicle

ActiveUS20190184972A1Engine startability can be improvedHybrid vehiclesVehicle sub-unit featuresElectrical batteryLow voltage

An apparatus for starting engine of mild hybrid electric vehicle may include: an ignition switch; an ambient temperature detector; a state of charge (SOC) detector; a mild starter & generator (MHSG) including a stator and a rotor mounted inside the stator; a starter which is configured to start the engine independently of the MHSG; a converter which is configured to voltage-drop an electric power of a high voltage battery and supply it to the low voltage battery or the starter; an MHSG wheel rotating integrally with the rotor; an MHSG position detector; and a controller configured for determining a top dead center (TDC) of a predetermined cylinder based on a signal of the MHSG position detector.

Owner:HYUNDAI MOTOR CO LTD +1

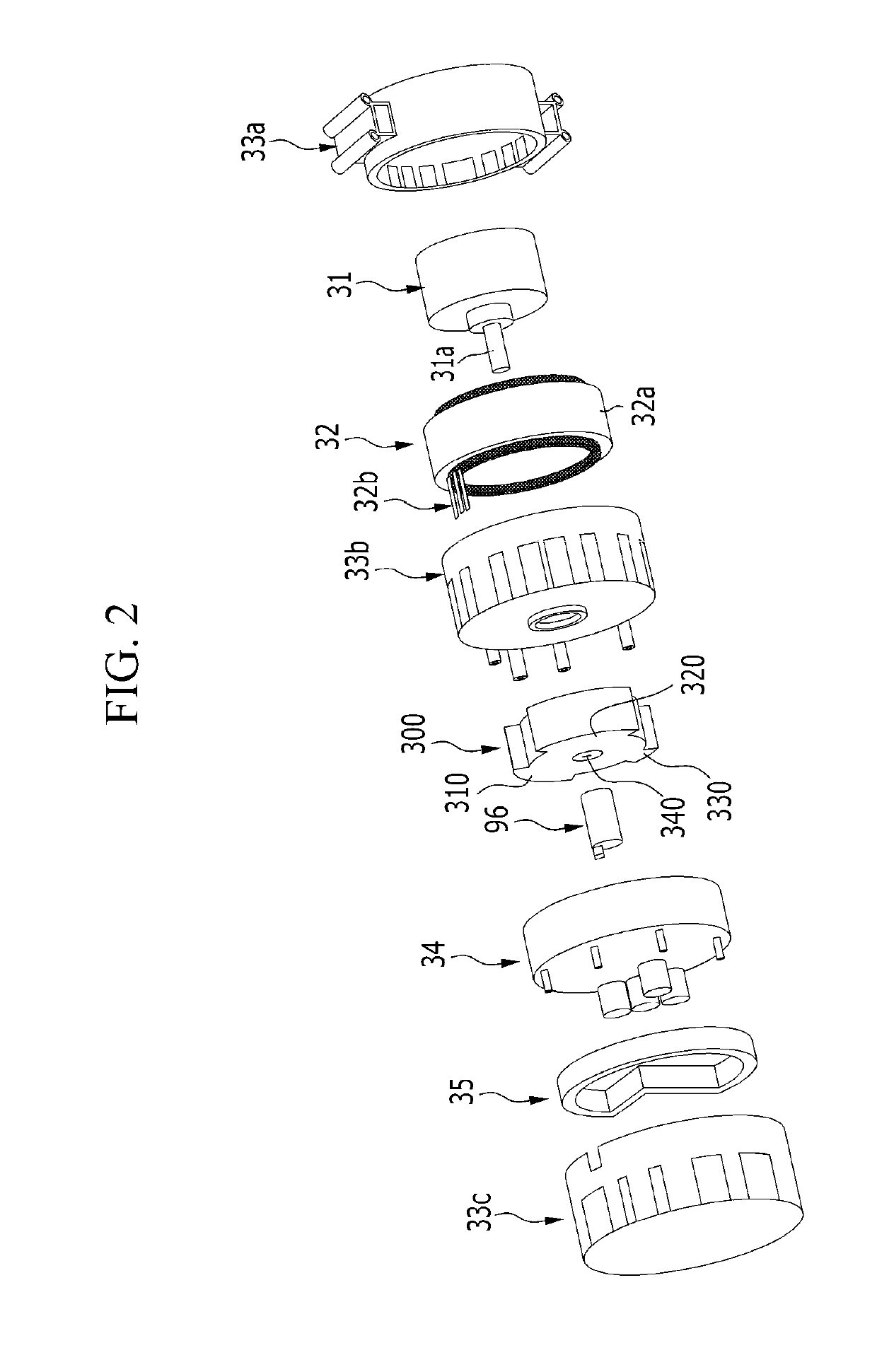

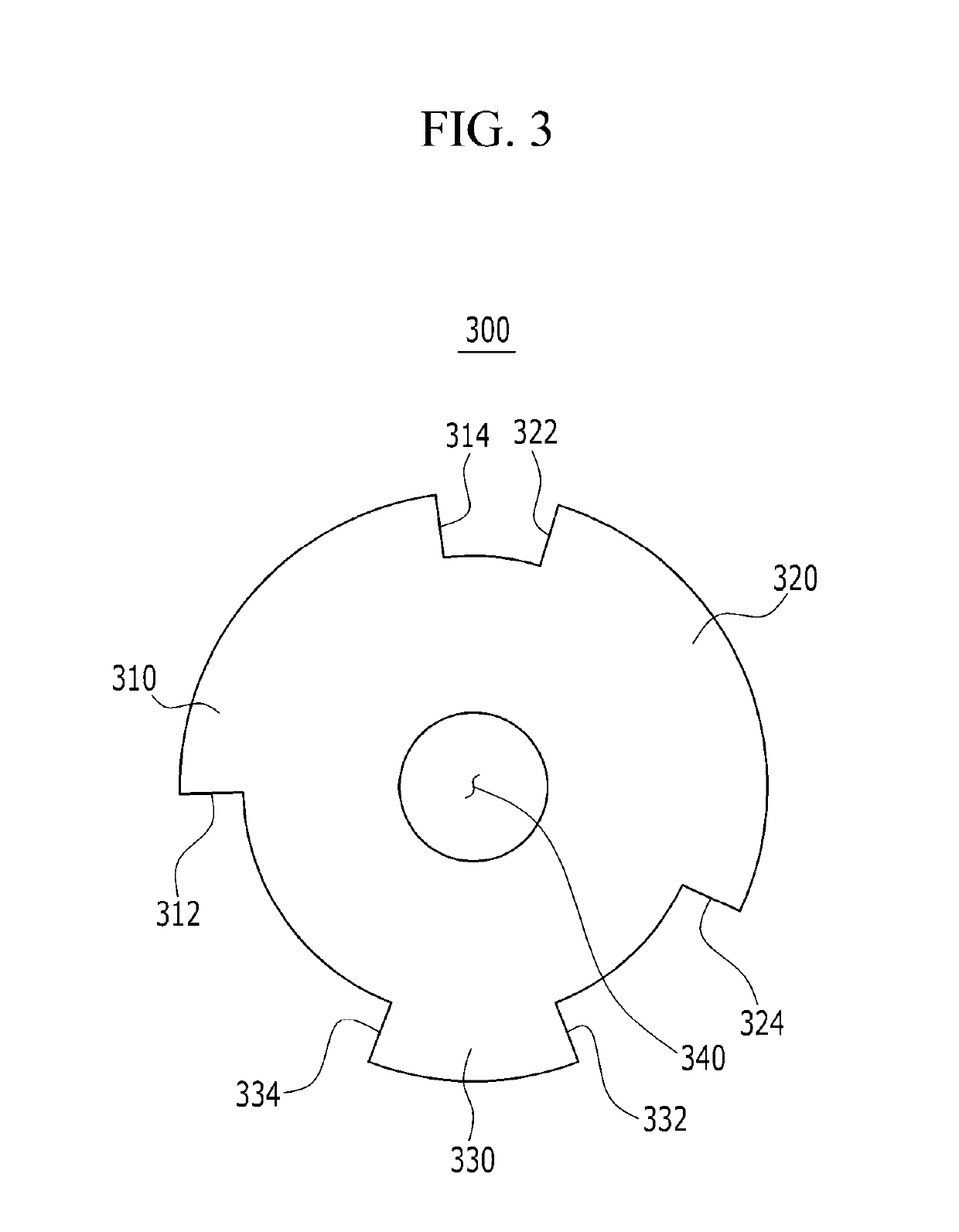

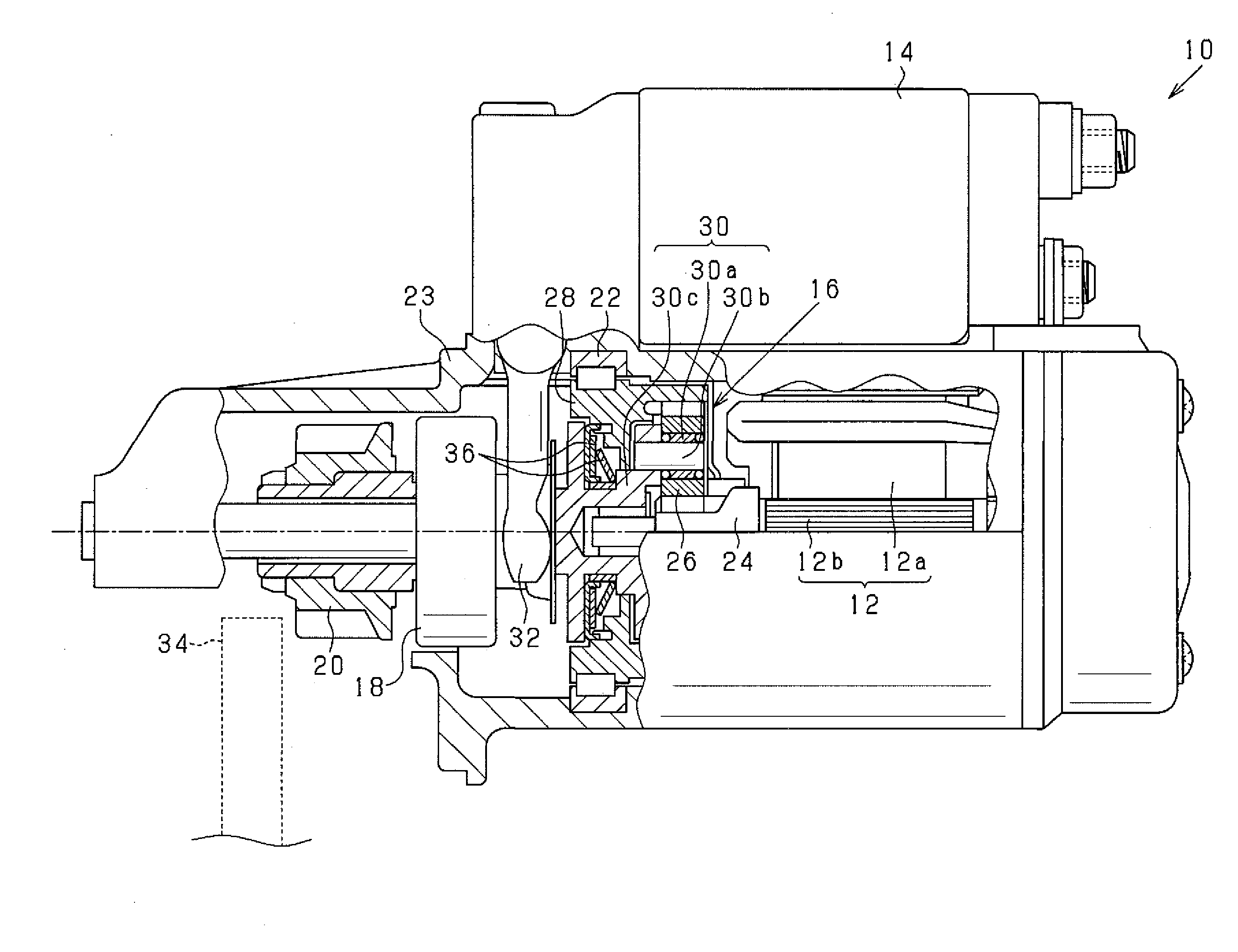

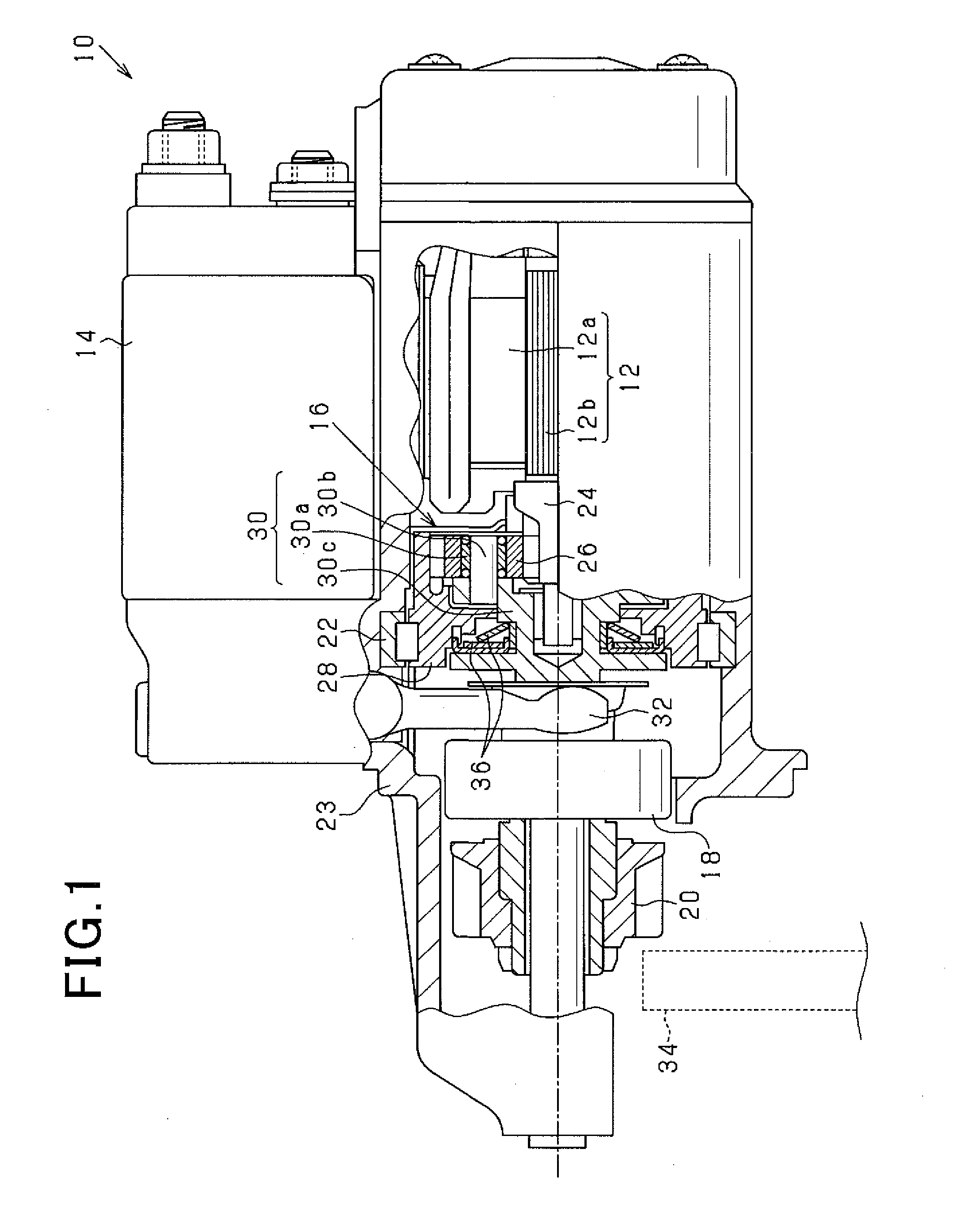

Engine starter with torque variator

ActiveUS20150275842A1Startability be improveIncrease torquePower operated startersToothed gearingsVariatorPlanet

A starter for an engine is equipped with a planetary gear train as a torque variator to change torque used to start the engine. The torque variator is capable of changing the degree of torque which is transmitted between a planetary carrier and an outer gear of the planetary gear train, thereby changing a ratio of speed of a sun gear to speed of the planetary carrier of the planetary gear train to increase or decrease the degree of torque required to start the engine. This ensures the stability in starting the engine, for example, in cold conditions and achieves a quick start of the engine as needed.

Owner:DENSO CORP

Engine ignition control device

ActiveUS20120291764A1Engine startability can be improvedHigh start-up torqueElectrical controlInternal combustion piston enginesControl theoryCrankshaft

An engine ignition control device comprising: a start-up ignition controller having a function for preventing the occurrence of kickback by either delaying an ignition position of an engine or stopping ignition; start-up rotation angle detection means for detecting a rotation angle of a crankshaft of the engine after initiation of a start-up operation of the engine; and switching means for switching control specifics of the start-up ignition controller in accordance with the detected start-up rotation angle so that when the detected start-up rotation angle is less than a set angle, there is created a kickback-preventive effect within a range at which engine startability is not compromised, and when the detected start-up rotation angle is equal to or greater than the set angle, there is created a kickback-preventive effect that is greater than the kickback-preventive effect for when the start-up rotation angle is equal to or less than the set angle.

Owner:MAHLE INT GMBH

Apparatus and method for starting engine of mild hybrid electric vehicle

ActiveUS10981559B2Engine startability can be improvedHybrid vehiclesGas pressure propulsion mountingConvertersElectrical battery

An apparatus for starting engine of mild hybrid electric vehicle may include: an ignition switch; an ambient temperature detector; a state of charge (SOC) detector; a mild starter & generator (MHSG) including a stator and a rotor mounted inside the stator; a starter which is configured to start the engine independently of the MHSG; a converter which is configured to voltage-drop an electric power of a high voltage battery and supply it to the low voltage battery or the starter; an MHSG wheel rotating integrally with the rotor; an MHSG position detector; and a controller configured for determining a top dead center (TDC) of a predetermined cylinder based on a signal of the MHSG position detector.

Owner:HYUNDAI MOTOR CO LTD +1

Variable valve actuating apparatus and process for internal combustion engine

InactiveUS7802546B2Improve performanceImprove startabilityValve arrangementsInternal combustion piston enginesExternal combustion engineEngineering

A variable valve actuating apparatus for an internal combustion engine includes a first valve actuating mechanism to vary a first valve operating condition, and a second valve actuating mechanism to vary a second valve operating condition. A controller controls the first valve actuating mechanism to satisfy a predetermined engine starting condition before a start of a cranking operation or during the cranking operation, with respect to an engine operating condition including the second valve operating condition controlled by the second valve actuating mechanism.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com