System for influencing the sliding properties of a sliding pair

A technology of sliding characteristics and sliding pairs, which is applied in the control of lubricant pressure, the lubrication of engines with compressed fuel-air mixture in the crankcase, engine components, etc. It can solve problems such as wear and wrong lubrication of sliding pairs, and achieve Effect of high service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

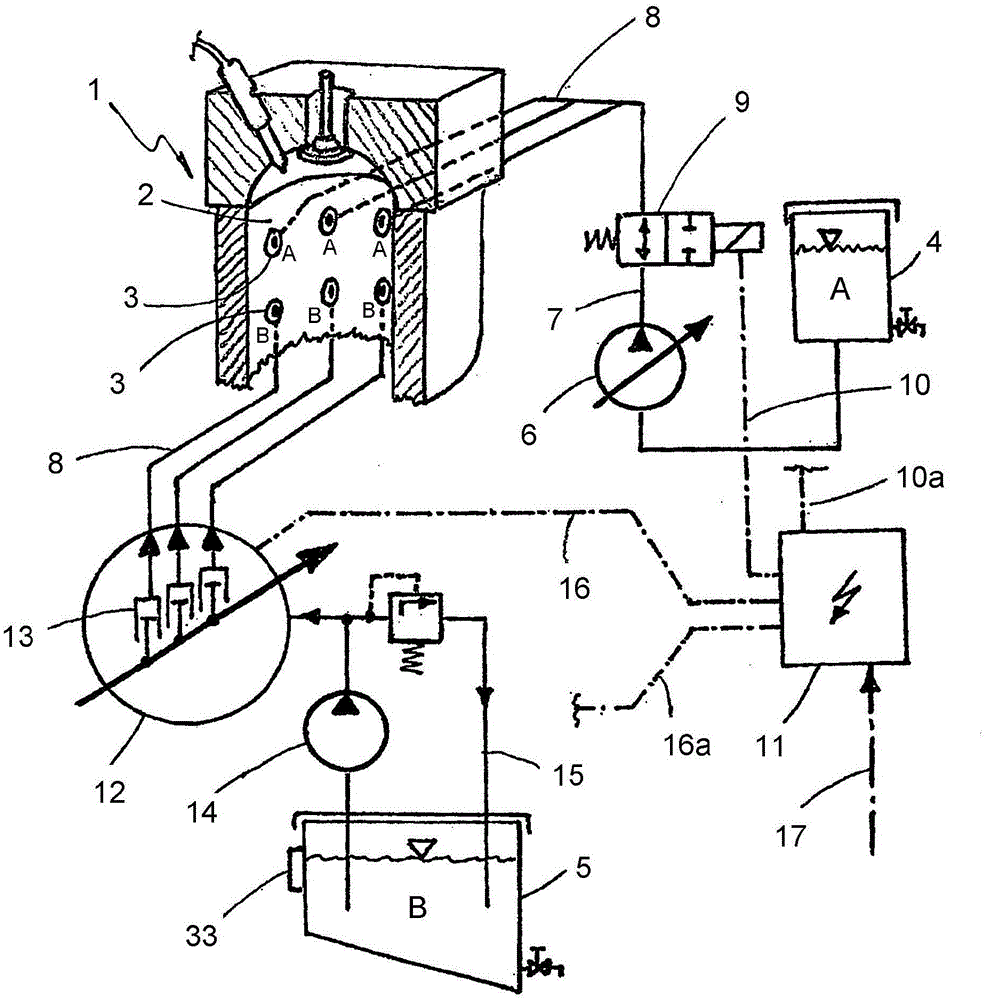

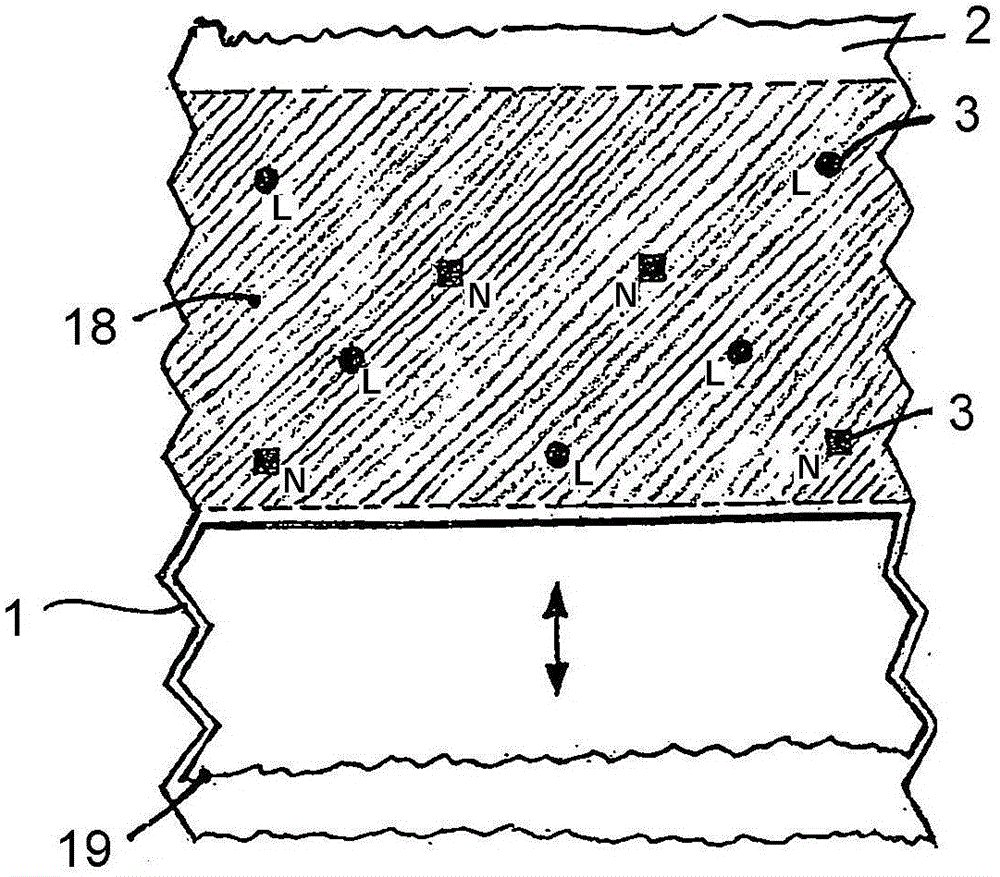

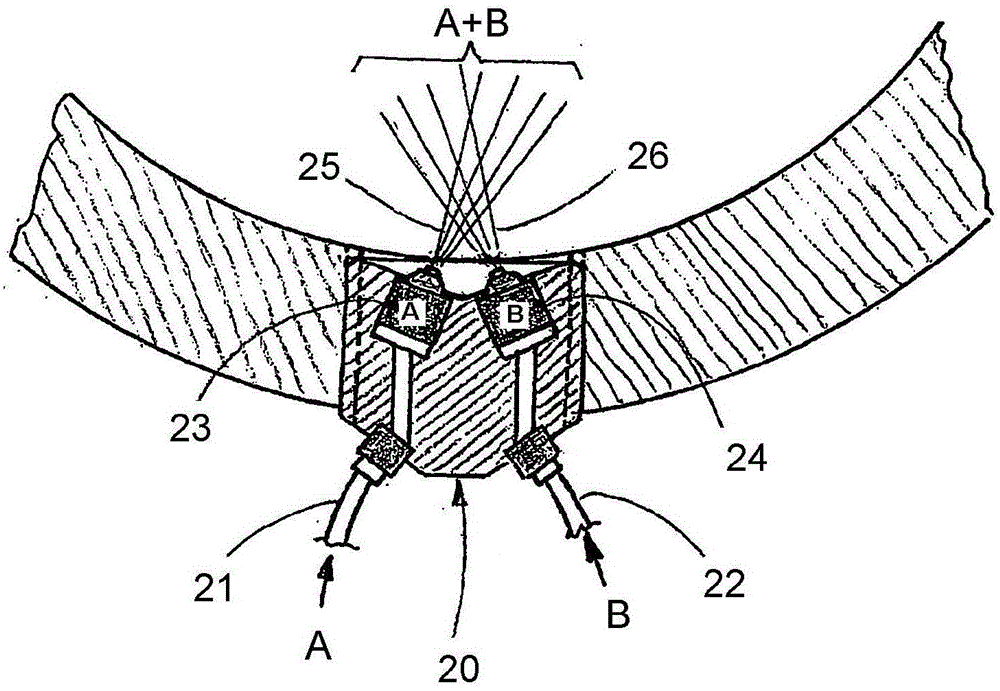

[0023] A preferred application example of the system according to the invention is the sliding surfaces of large machines with reciprocating pistons, in particular compressors, air engines, steam engines, diesel engines, gasoline engines, natural gas engines and other working stroke machines, here An example is the cylinder liner of a two-stroke large diesel engine and the sliding surfaces of the pistons running therein. The following example descriptions are based on this engine, but should not be so limited. Normally, however, the relevant engines have as a common feature a lubrication environment for the bearings on the crankshaft, which is separate from the applied system according to the invention. Furthermore, the individual parallel vertical cylinder axes of the cylinders of the engine are generally arranged in a row on a main shaft axis perpendicular thereto. However, the orientation of each cylinder axis and each relative positioning of the respective possible axes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com