Lubricating system for a rotary engine

A rotor engine and lubrication system technology, applied in the direction of engine lubrication, engine speed, engine components, etc., can solve the problems of seal friction and wear, seal failure, lubrication difficulties, etc., to ensure lubrication, ensure reliable sealing, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

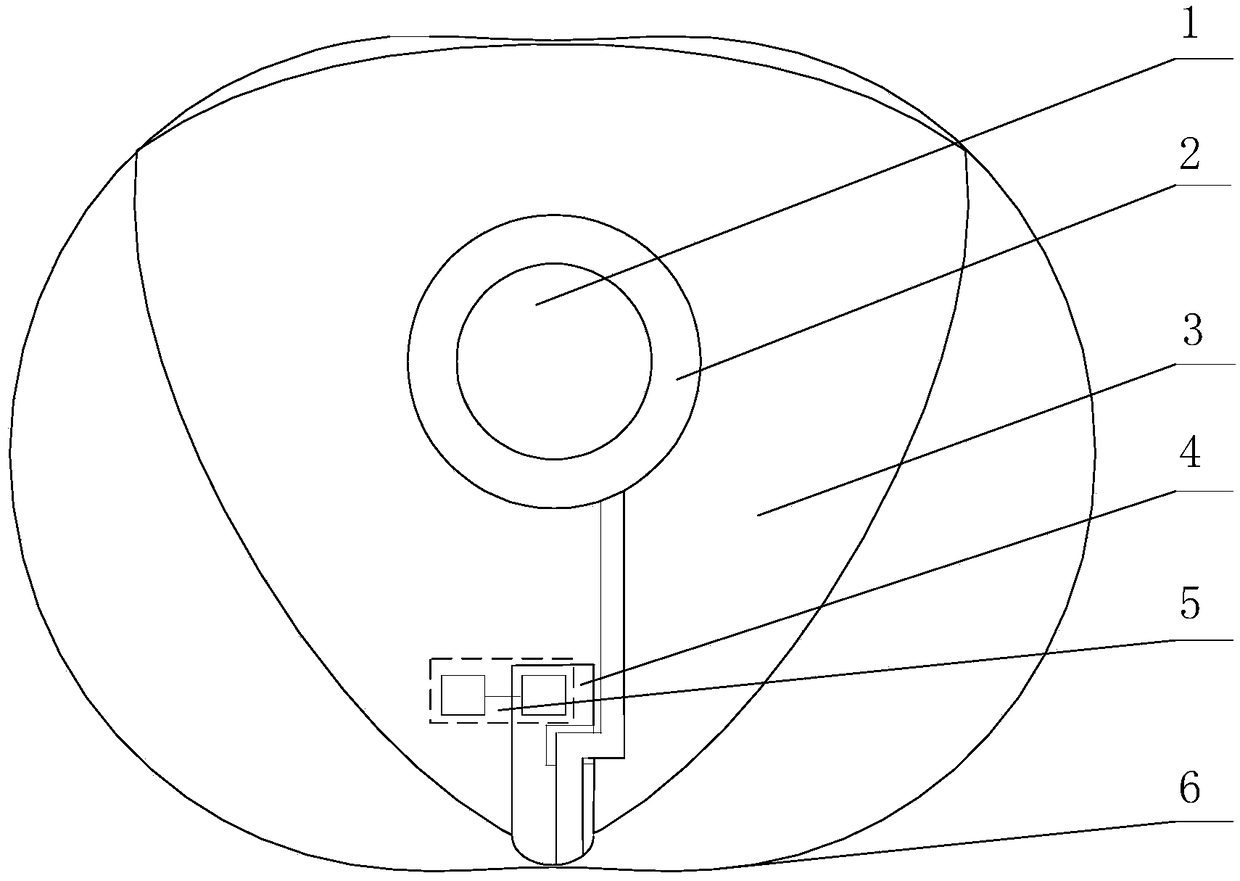

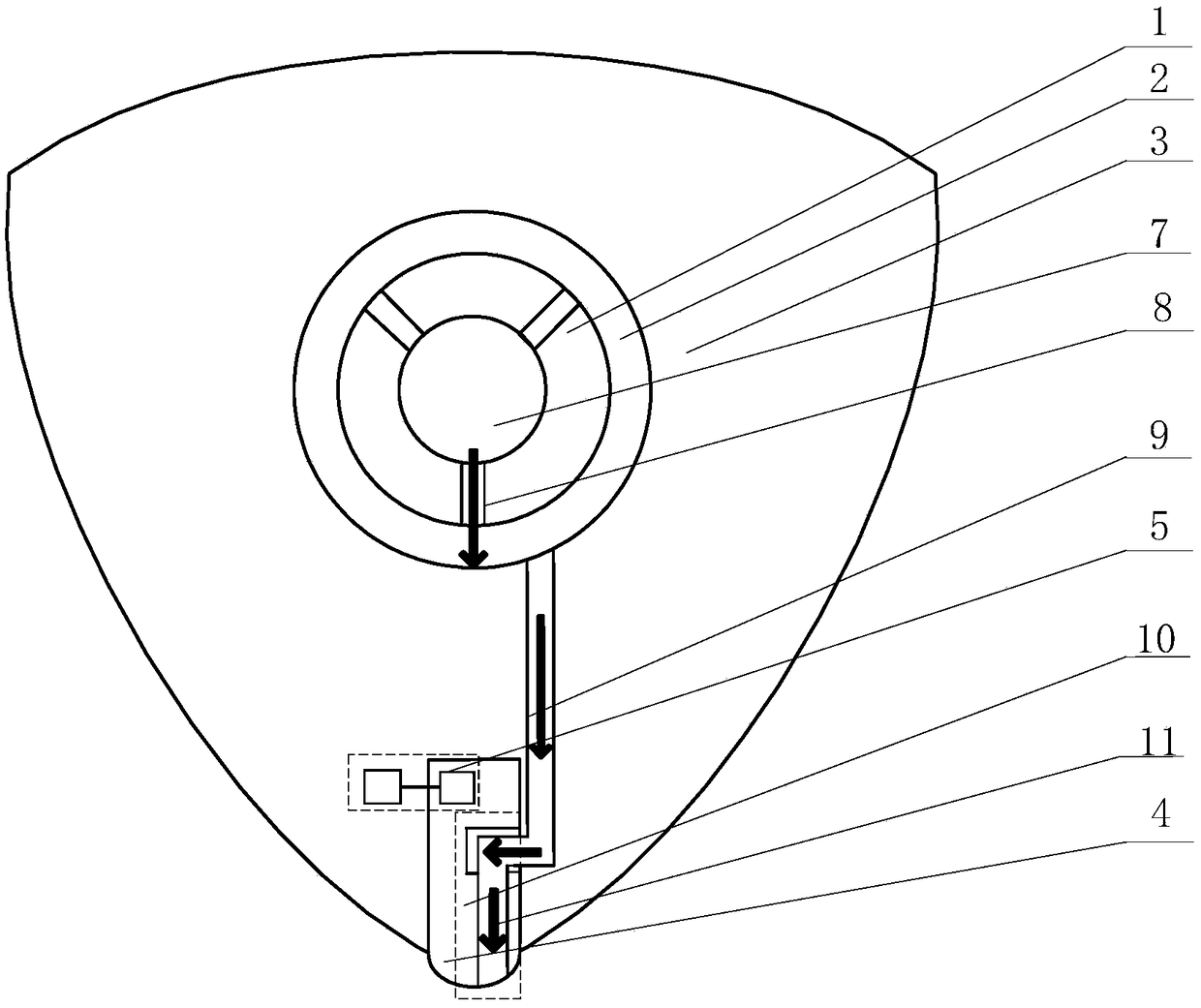

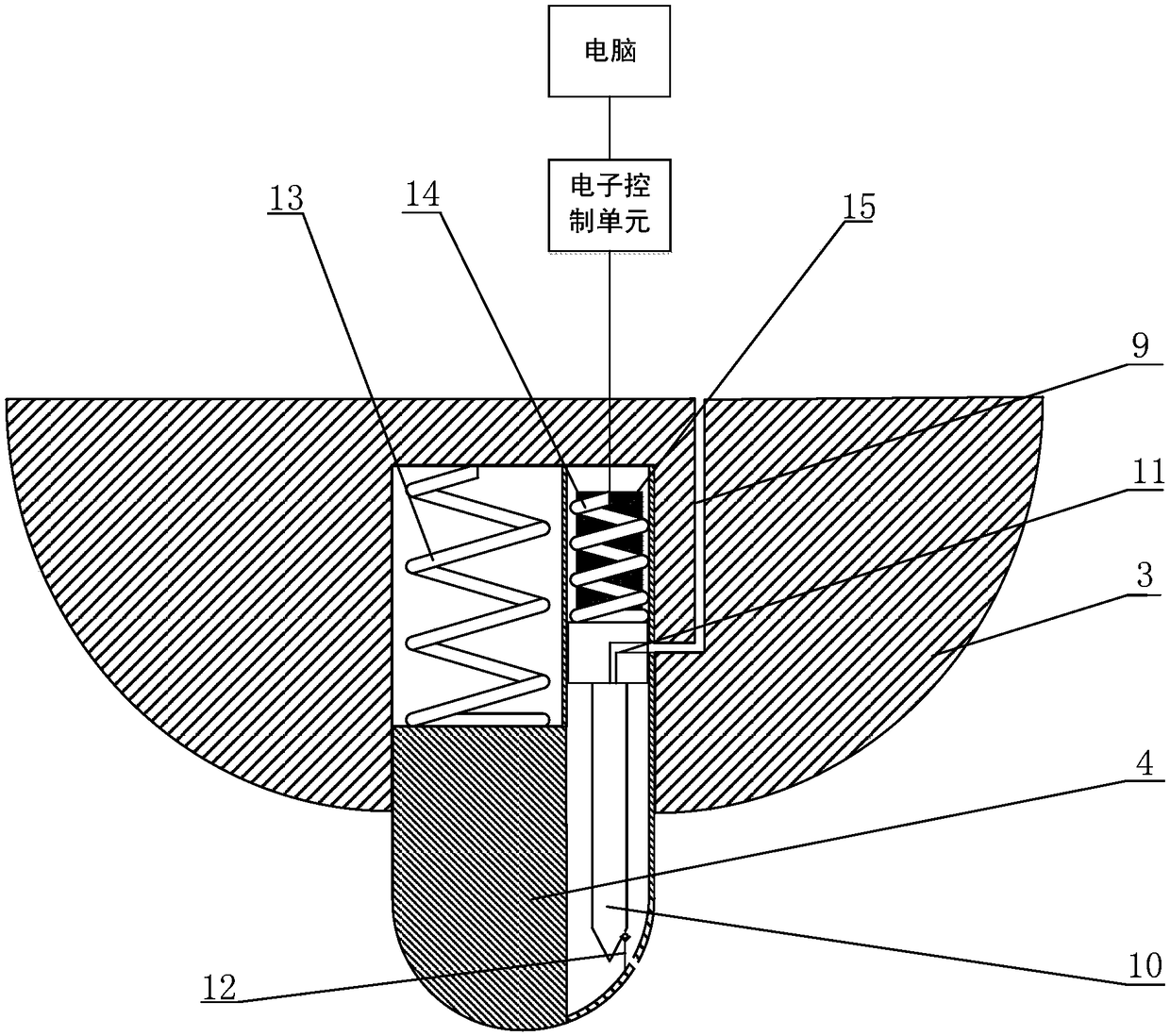

[0023] A lubrication system for a rotary engine disclosed in this embodiment includes a crankshaft 1, a bearing 2, a rotor 3, a sealing plate 4 and a supporting electronic control unit assembly 5 for controlling oil supply.

[0024] The crankshaft is processed with an eccentric shaft center oil passage 7 and an eccentric radial oil passage 8. The top ends of the rotors 3 are respectively processed with sealing sheet installation grooves. The inner side of the rotor is radially processed with an oil channel communicating with the crankshaft. The sealing sheet 4 includes a sealing sheet base, a slider oil needle integral part 10 , a one-way valve 12 , a first sealing elastic device 13 and a second sealing elastic device 14 , and a solenoid valve 15 . The first sealing elastic device 13 is located between the sealing plate base and the rotor 3, the second sealing elastic device 14 is located between the slider oil needle integral part 10 and the rotor 3, and the solenoid valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com