Direct resistance heating equipment applicable to heat treatment of slab metal specimen

A strip-shaped metal and resistance heating technology, applied to heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problems that the annealing process cannot be carried out, the surface reaction is difficult to control accurately, and the adjustment of process parameters is not flexible, so as to ensure the sample preparation requirements, excellent temperature control accuracy and repeatability, and the effect of saving experimental time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] The direct resistance heating equipment suitable for the heat treatment of strip-shaped metal samples includes a heat preservation shell 1 , a main body 2 arranged in the heat preservation shell 1 , and a control device 3 .

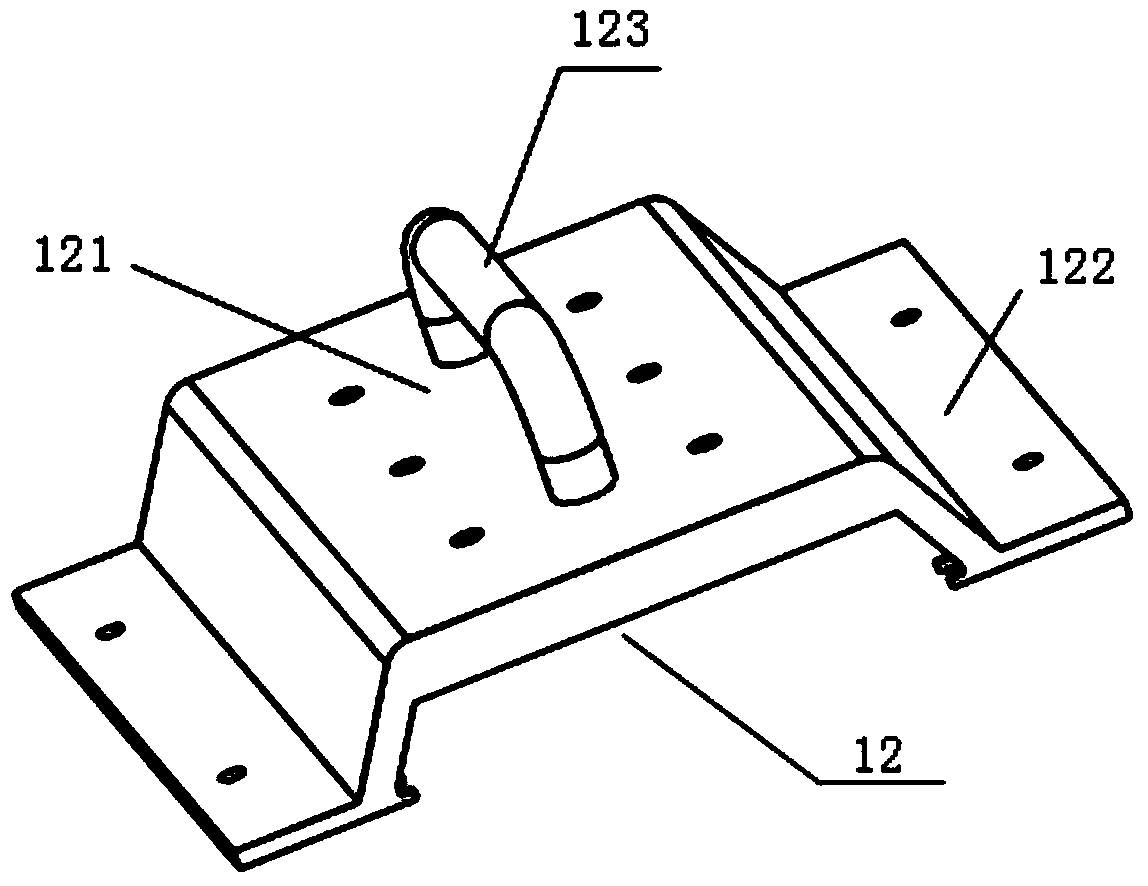

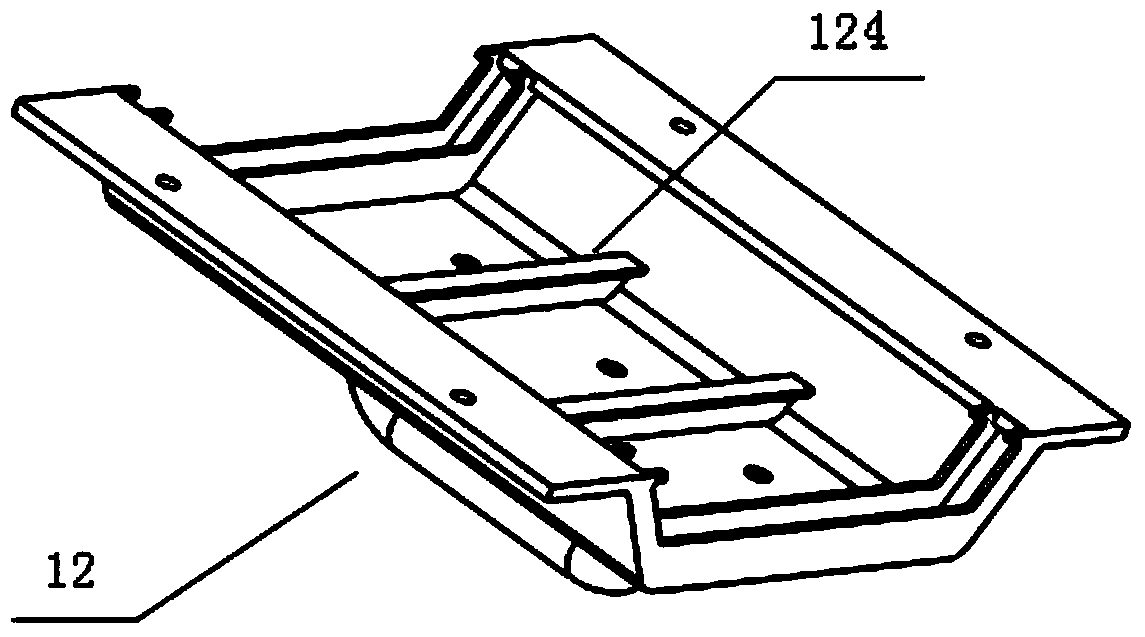

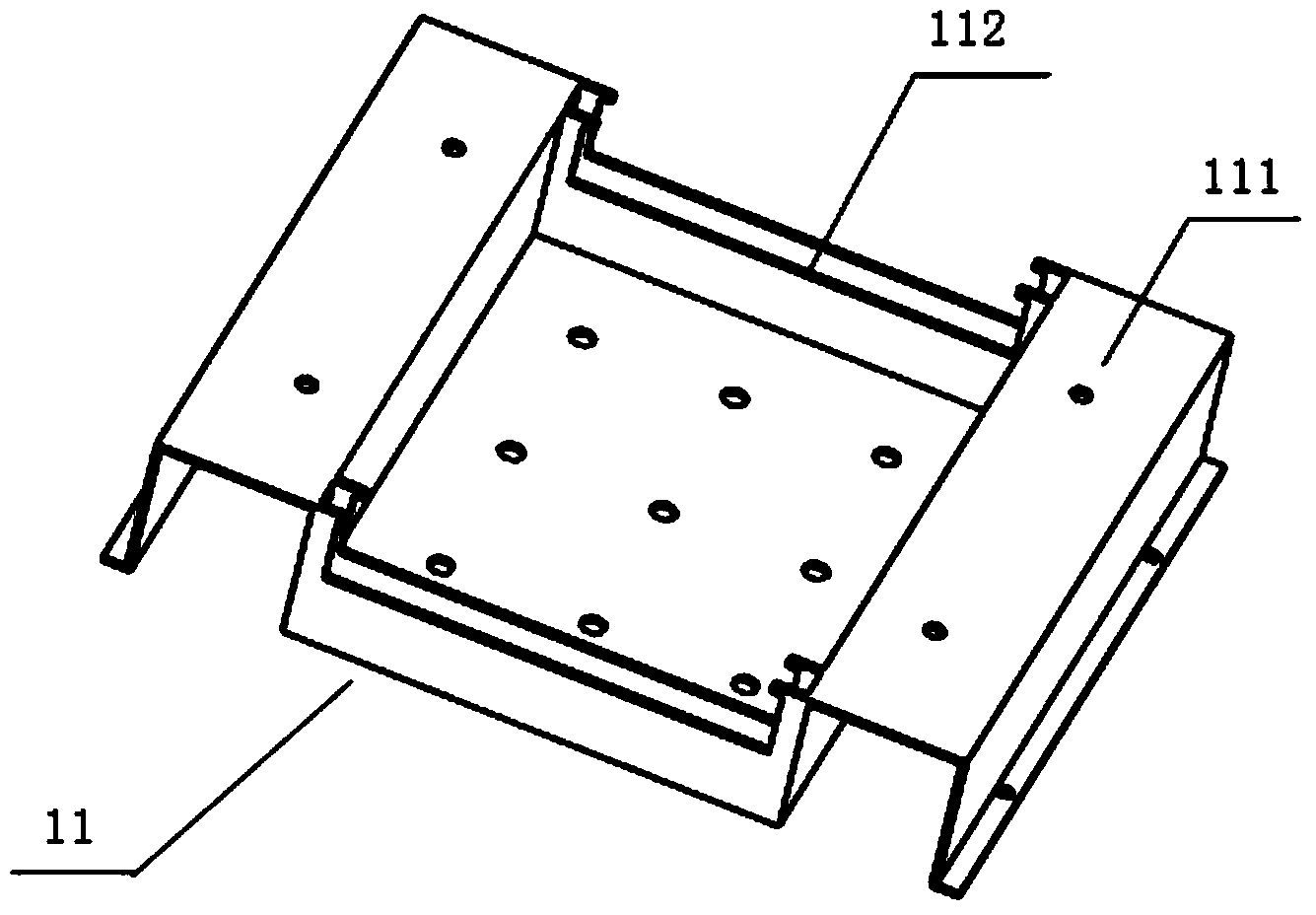

[0038] The thermal insulation shell 1, see Figure 1-3 , including a box body 11, an upper cover 12, and a high-temperature heat-resistant heat-insulating coating provided in the housing 11 and the upper cover 12, the box body 11 includes a main box body 111 and box end ribs arranged in parallel in the main box body 111 Plate 112; the upper cover 12 includes a cover top plate 121, a bead plate 122 arranged on the opposite side of the cover top plate 121, a handle 123 located at the top of the cover top plate 121 and a cover rib plate 124 located at the bottom of the cover top plate.

[0039] The subject 2, see Figure 4 , comprising a bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com