Impact test box and impact mode thereof

A technology of impact test chamber and high temperature chamber, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, measuring devices, instruments, etc. Large and other problems, to achieve accurate and stable flow and pressure, accurate control time, and reduce work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

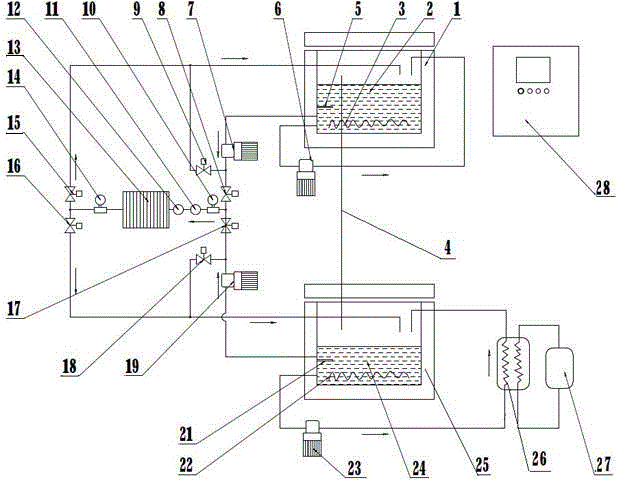

[0030] see figure 1 , the present invention relates to an impact test chamber, specifically a double-pump liquid circulation cold and heat shock test chamber, which includes a high temperature chamber 1, a low temperature chamber 25 and a control system 28, the high temperature chamber 1 is provided with a high temperature liquid 2, a high temperature chamber Heating device 3, high temperature box temperature sensor 5, the high temperature liquid 2 is heated by the high temperature box heating device 3, the high temperature box temperature sensor 5 measures the temperature of the liquid, and the temperature control is realized by the control system 28, the high temperature box 1 is connected with a high temperature stirring device 6, The high temperature stirring device 6 is a stirring pump or a blade stirring motor, the stirring pump is connected outside the high temperature box 1, the blade of the blade stirring motor is placed in the high temperature box 1, and the liquid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com