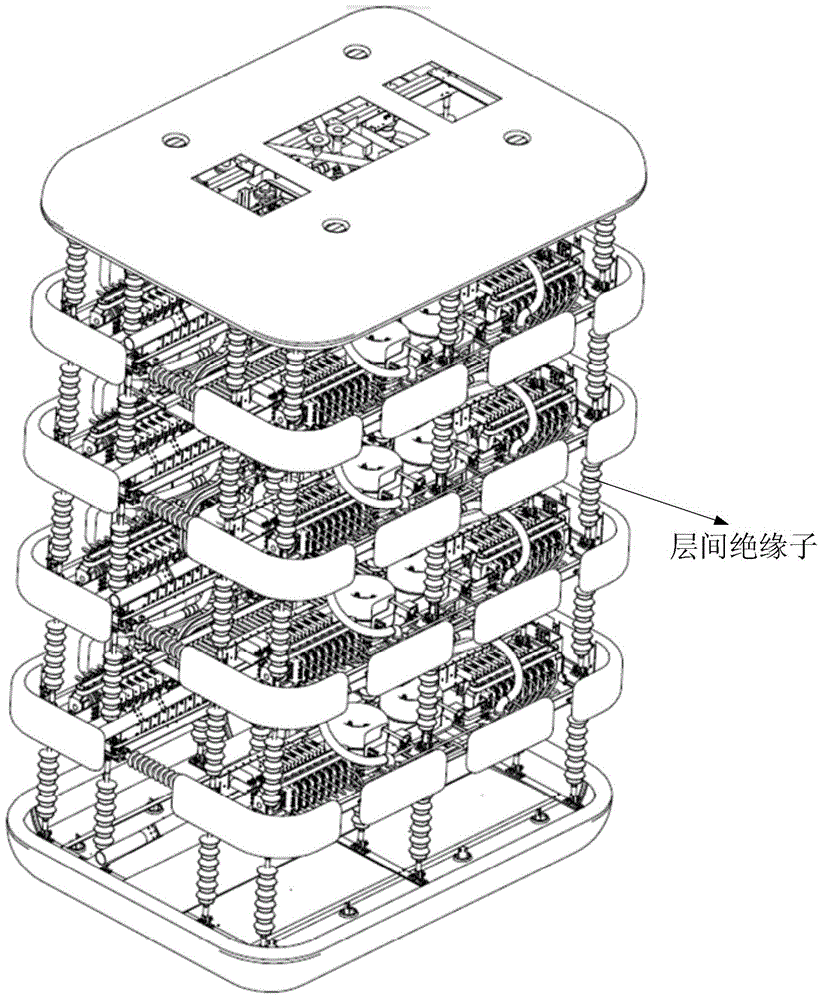

Interlayer insulator for converter valve tower and mandril core

A technology of interlayer insulation and converter valve, applied in insulators, suspension/strain insulators, electrical components, etc., can solve the problems of difficult installation of insulators, time-consuming and laborious, and achieve the effect of uniform force, easy installation, and quick fine-tuning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

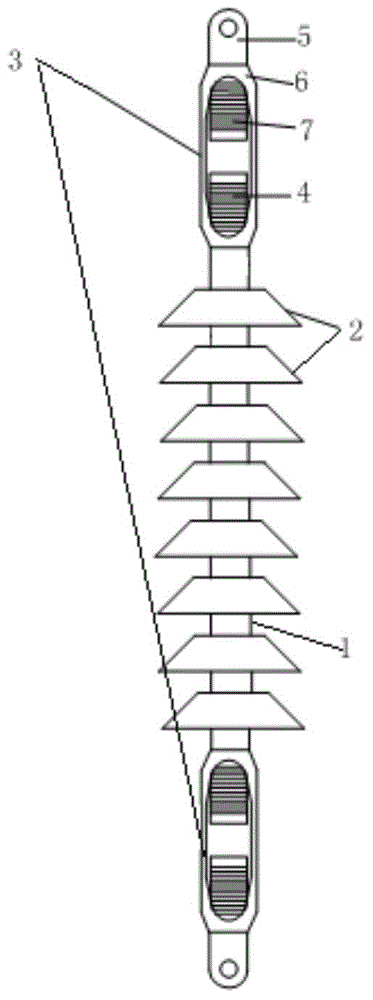

[0015] See figure 1 The interlayer insulator rod core for the converter valve valve tower includes a rod core body; one end of the rod core body is provided with threads to form a rod core threaded rod; or both ends of the rod core body are provided with threads to form Two rod-core threaded rods; further comprising a metal connecting end connected to the rod-core threaded rod; the metal connecting end includes a tie rod and a turnbuckle bolt; one end of the tie rod is also provided with threads to form a tie rod threaded rod; The threaded rod is adapted to the flower basket bolt and screwed into the flower basket bolt from the other end of the flower basket; when the flower basket bolt is rotated, the length of the metal connecting end can be adjusted to adjust the valve tower Use the length of the interlayer insulator rod core for fine adjustment. The other end of the tie rod is a cylindrical nut structure.

[0016] As a preferred solution, both ends of the core body 1 are pro...

Embodiment 2

[0019] See figure 1 The interlayer insulator for the converter valve tower includes a rod core and an umbrella disk sleeved on the rod core; the rod core is the same as the interlayer insulator rod core for the converter valve tower in Example 1, so The umbrella plate is sleeved on the core body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com