A crawler-type trimming robot

A crawler-type, robot technology, applied in manipulators, agricultural machinery and implements, gardening, etc., can solve the problems of small pruning range, large pruning blind area, single structure and function, etc., to enhance the operating ability, ensure the pruning effect, and improve the operating radius. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

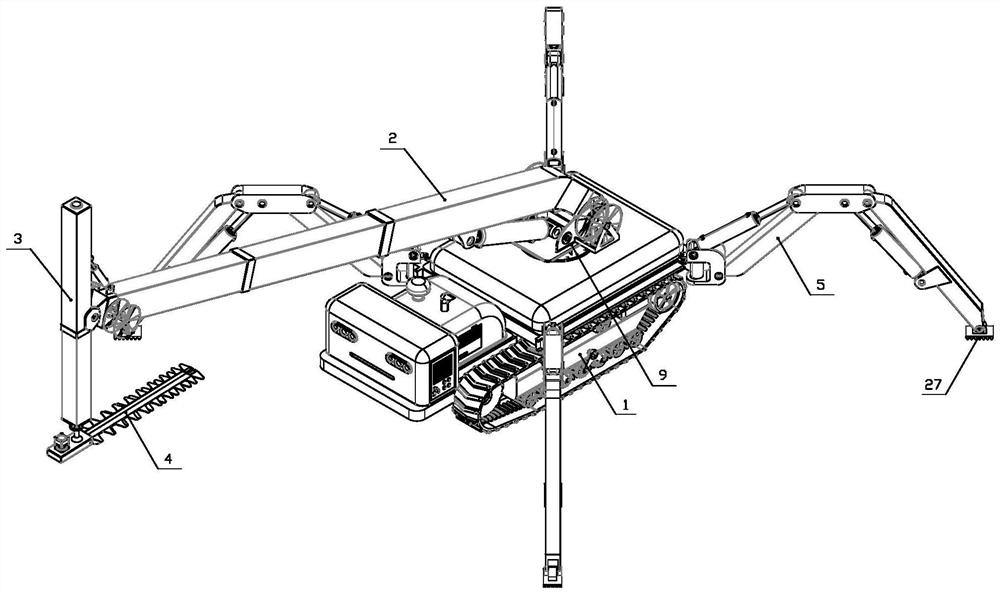

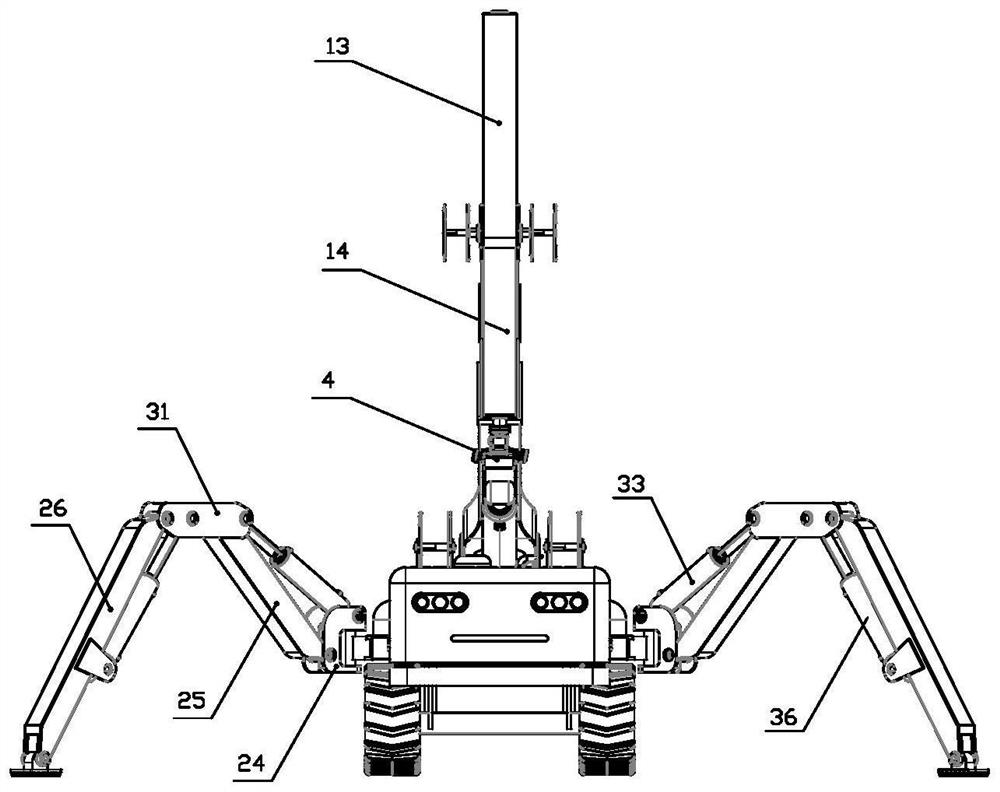

[0088] This embodiment describes a crawler pruning robot. Such as figure 1 As shown, the crawler-type pruning robot includes a crawler-type carrier chassis 1 , a main boom 2 , an auxiliary boom 3 , a pruning mechanism 4 and a foldable hydraulic support leg 5 .

[0089] Wherein, the crawler-type carrying chassis 1 is used to realize the walking of the crawler-type pruning robot.

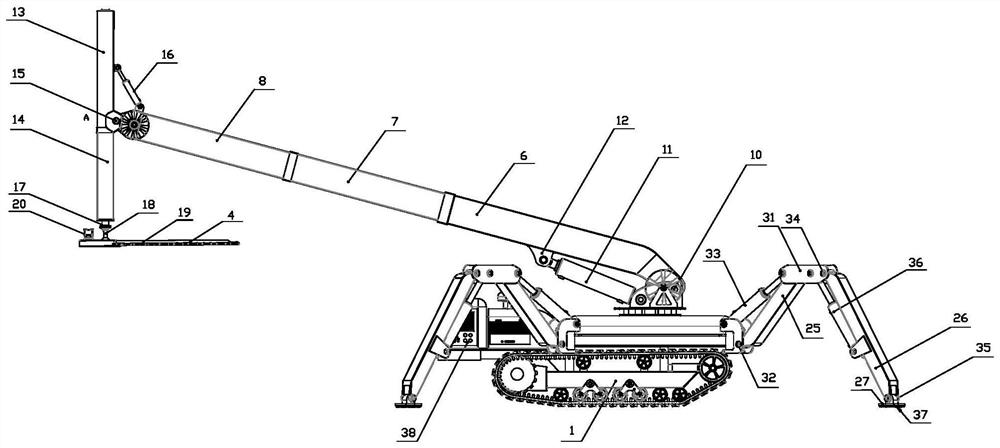

[0090] Such as figure 2 As shown, the main boom frame 2 adopts a length-extensible structure, that is, it includes a first-stage main arm 6, a second-stage main arm 7, and a third-stage main arm 8; wherein, the first-stage main arm 6, the second-stage main arm The arm 7 and the third-stage main arm 8 are nested in sequence.

[0091] A first telescoping mechanism is provided in the main boom frame 2 to realize the extension and retraction of the second-stage main arm 7 and the third-stage main arm 8 (from the first-stage main arm 6 ). Wherein, the first telescopic mechanism adopts a hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com