A Rapidly Assembled, Modular Autonomous Crane

A modular crane technology, applied in the direction of cranes, etc., can solve the problems of crane operating radius limitation, small slewing coverage, and limited crane arm length, etc., to achieve enlarged operating radius and slewing coverage, quick disassembly and assembly, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

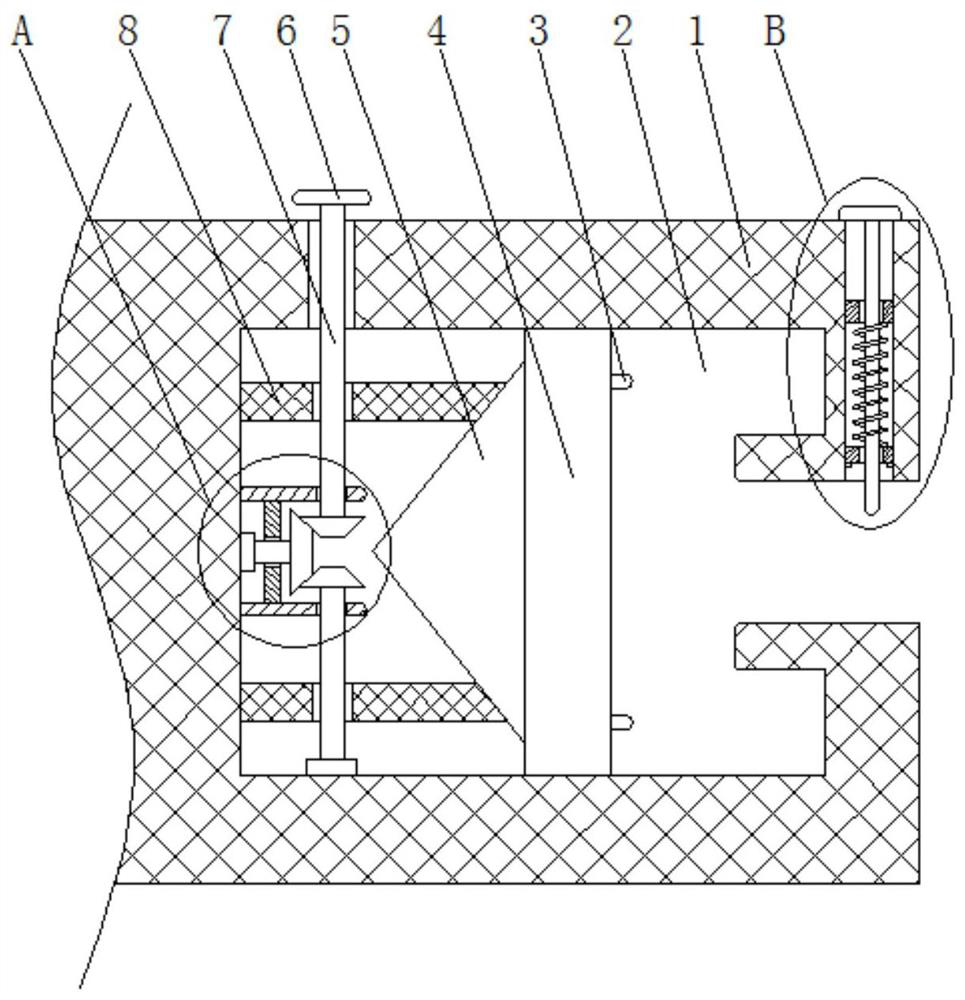

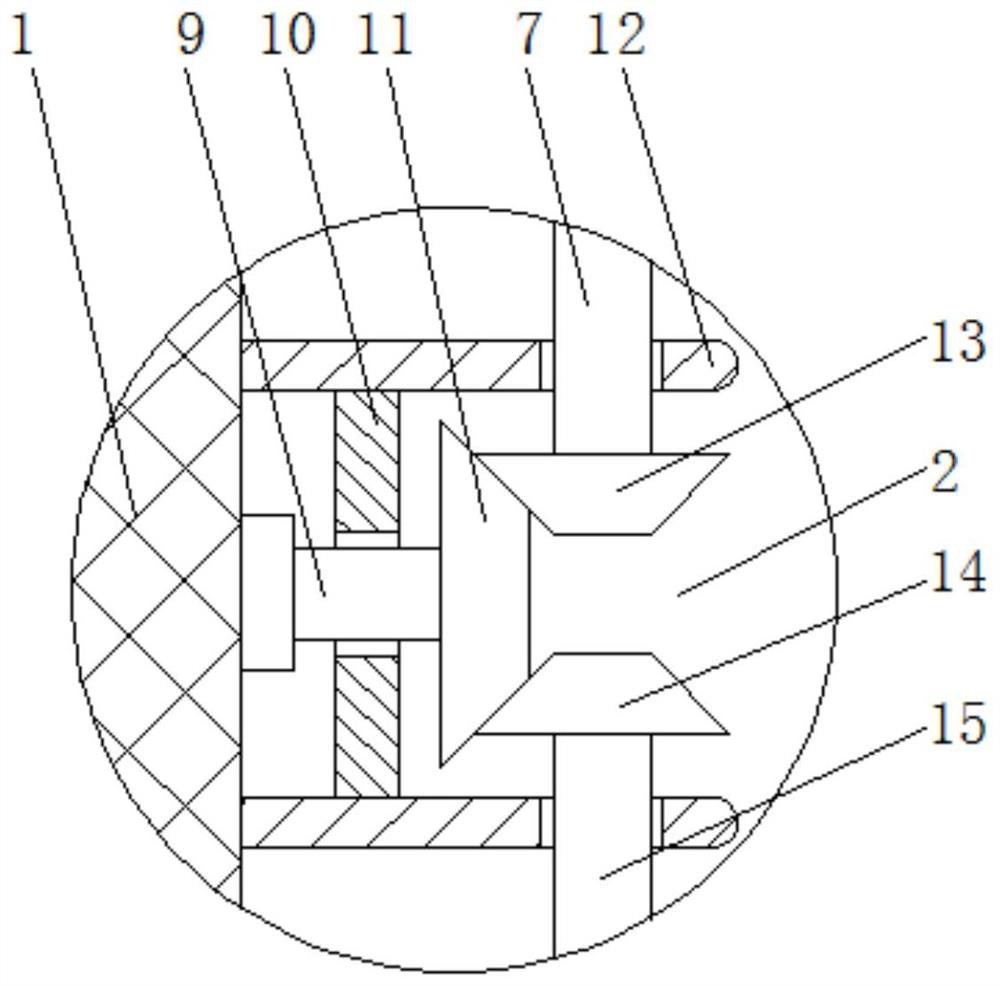

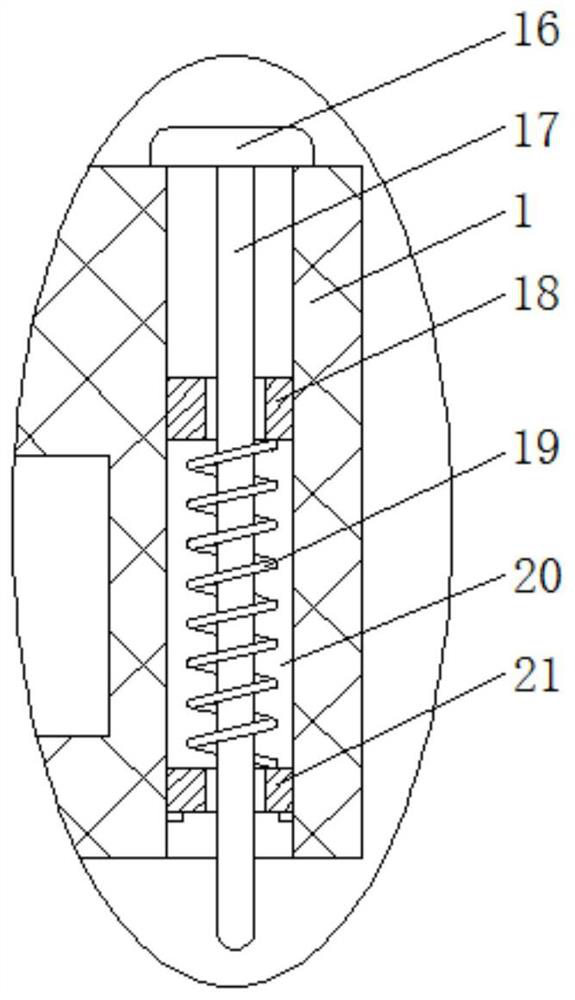

[0024] This embodiment proposes a modular automatic crane that can be quickly assembled, including a first boom 1 and a second boom 25, the first boom 1 is provided with a slot 2, the top inner wall of the slot 2 and the bottom The same moving plate 4 is slidably connected on the inner wall, and one side of the moving plate 4 is welded with a triangular plate 5, and two sliding plates 8 are symmetrically slidably connected on the inner wall of one side of the card slot 2, and one side of the two sliding plates 8 is respectively connected to the The two sides of the triangular plate 5 are in contact, and the first through holes are arranged on the two sliding plates 8, and the first screw rod 7 and the second screw rod 15 are respectively threaded on the inner walls of the two first through holes, and the second screw rod The bottom end of 15 is rotatably connected with the bottom inner wall of the slot 2, the top end of the first screw 7 penetrates the top inner wall of the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com