A circular positioning feeding device

A feeding device and a circular technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of low production efficiency, positioning of mesh covers with different diameters, etc., and achieve the effect of stable product positioning and enhanced working radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

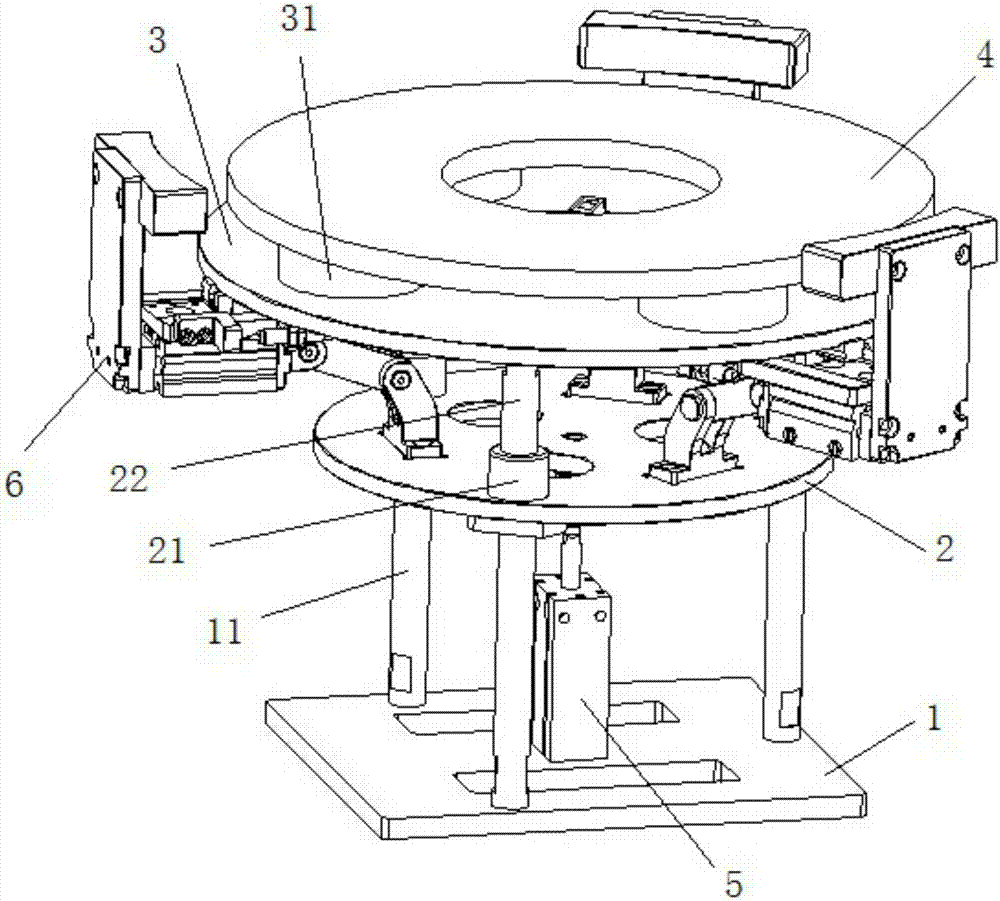

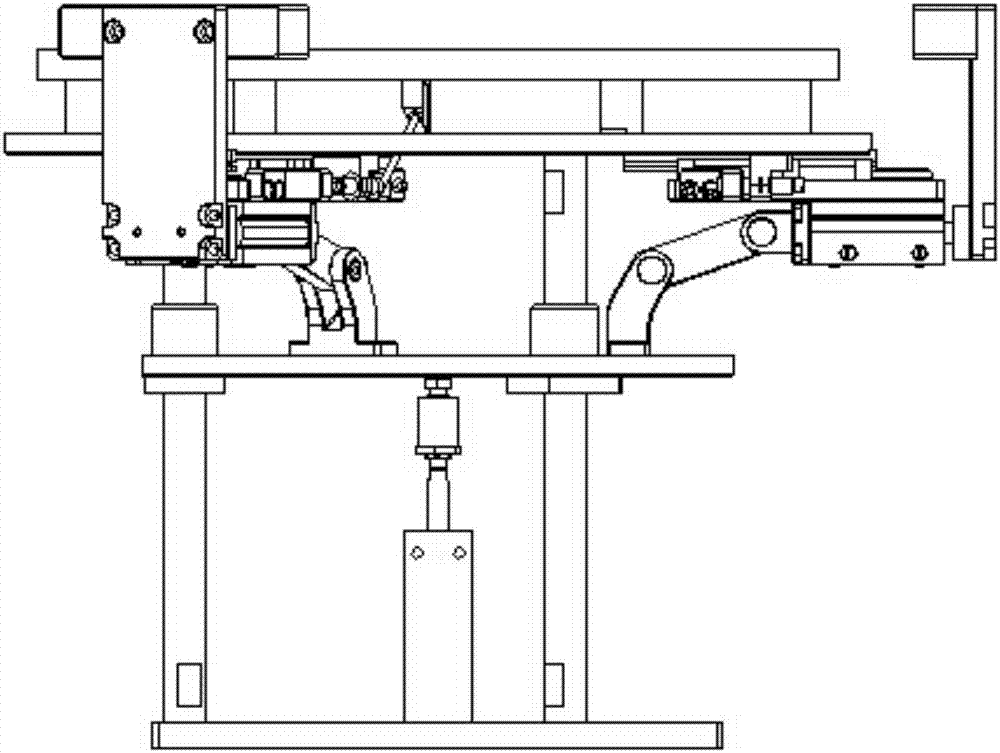

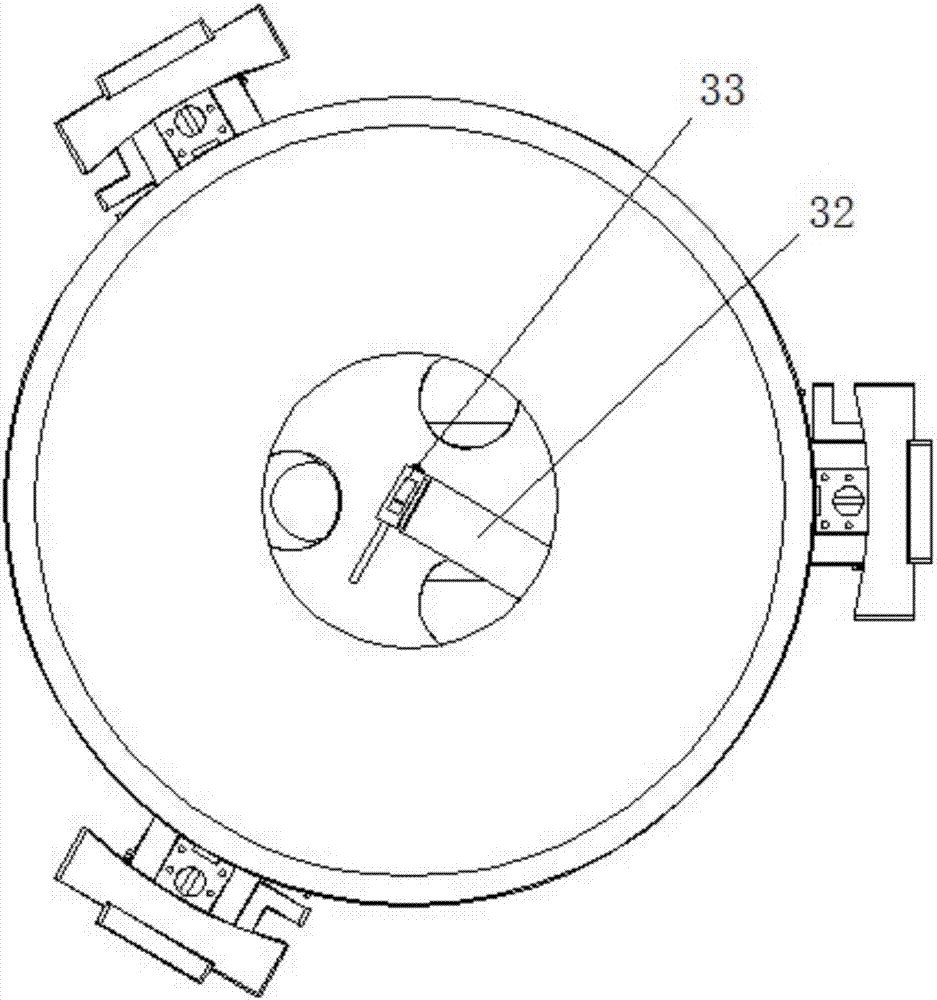

[0020] see Figure 1 to Figure 5 , a circular positioning feeding device, including a base plate 1, a movable plate 2 positioned above the base plate 1, three linear bearings 21 are provided on the movable plate 2, guide shafts 22 are provided in each linear bearing 21, and a guide shaft 22 is provided on the base plate 1. Three columns 11, the tops of the three columns 11 are respectively connected with the bottoms of the three guide shafts 22, the guide shafts 22 and the columns 11 are located on the same straight line, the top of the guide shafts 22 is provided with a support plate 3, and the support plate 3 is provided with four supports Block 31, the top of four supporting blocks 31 is provided with positioning plate 4, base plate 1, movable plate 2, support plate 3, positioning plate 4 are all horizontally arranged, and three columns 11 and three guide shafts 22 are all vertically arranged. Base plate 1 is provided with jacking cylinder 5, and jacking cylinder 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com