Multifunctional engineering ship

An engineering ship, multi-functional technology, used in ship accessories, special purpose ships, cranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

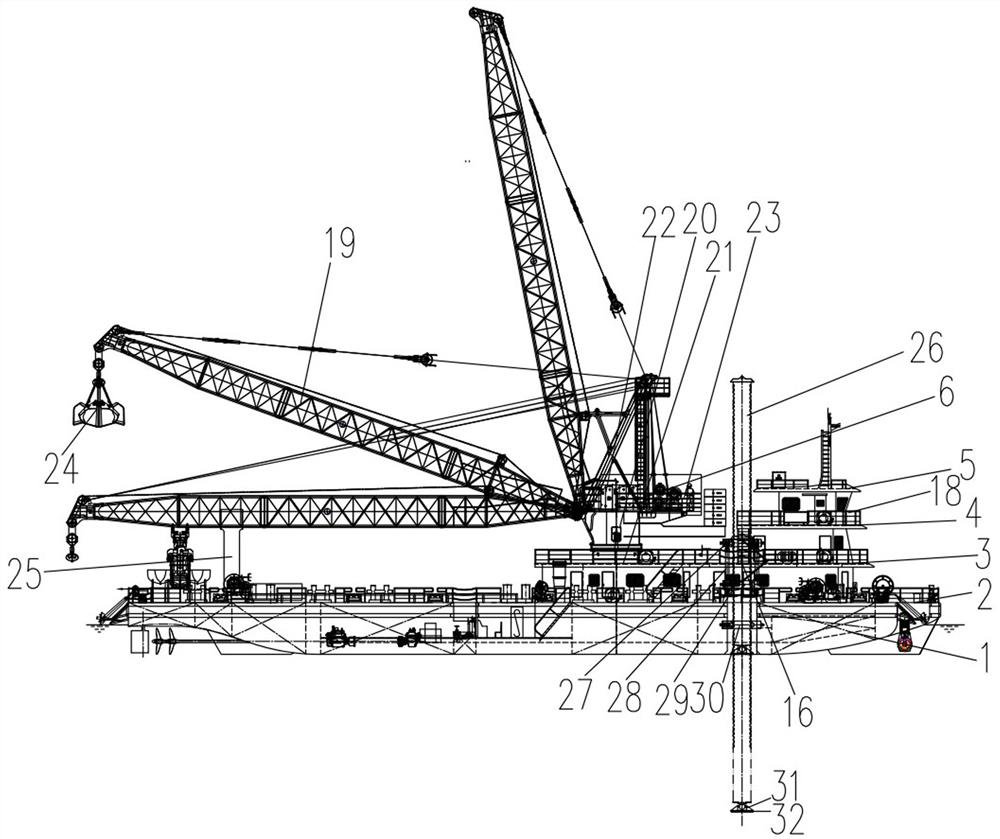

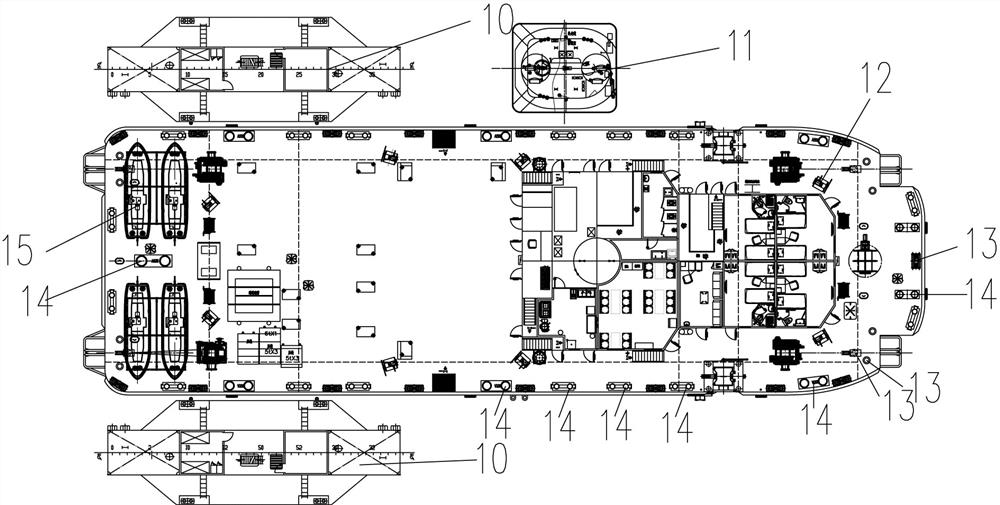

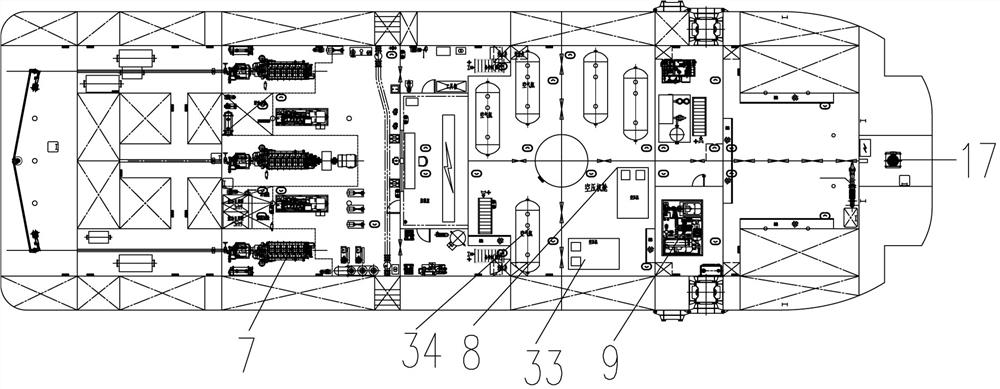

[0023] Combine below figure 1 , 2 , 3, the preferred embodiment of the present invention is described in further detail, a kind of multifunctional engineering ship of this preferred embodiment, comprises hull 1, is provided with floating crane 6, hydraulic pile positioning system 16, operating compressed air system 8 on hull 1 , towing and lashing equipment, bow thruster 17, propulsion device 7, two-wing console 18 and hydraulic pump station 9. There are three layers of deckhouses on the main deck 2 of the hull 1, which are respectively the working deck 3, the driving deck 4, and the compass deck 5. The floating crane 6 is arranged near the front part of the hull 1. The floating crane 6 includes a boom 19, a slewing bearing 20, a turntable device 21, a machine room 22, a cab 23, a hook / grab bucket 24 and a counterweight, and a support frame 25 for supporting the boom 19 is arranged on the main deck 2 . The hydraulic pile positioning system 16 is arranged on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com