Double-speed seventh shaft for robot

A double-speed, robot technology, applied in the field of machinery and robots, can solve problems such as insufficient running speed, insufficient working range, and insufficient operating radius, so as to achieve fast operating speed, improve operating radius and work The effect of range, serviceability and ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

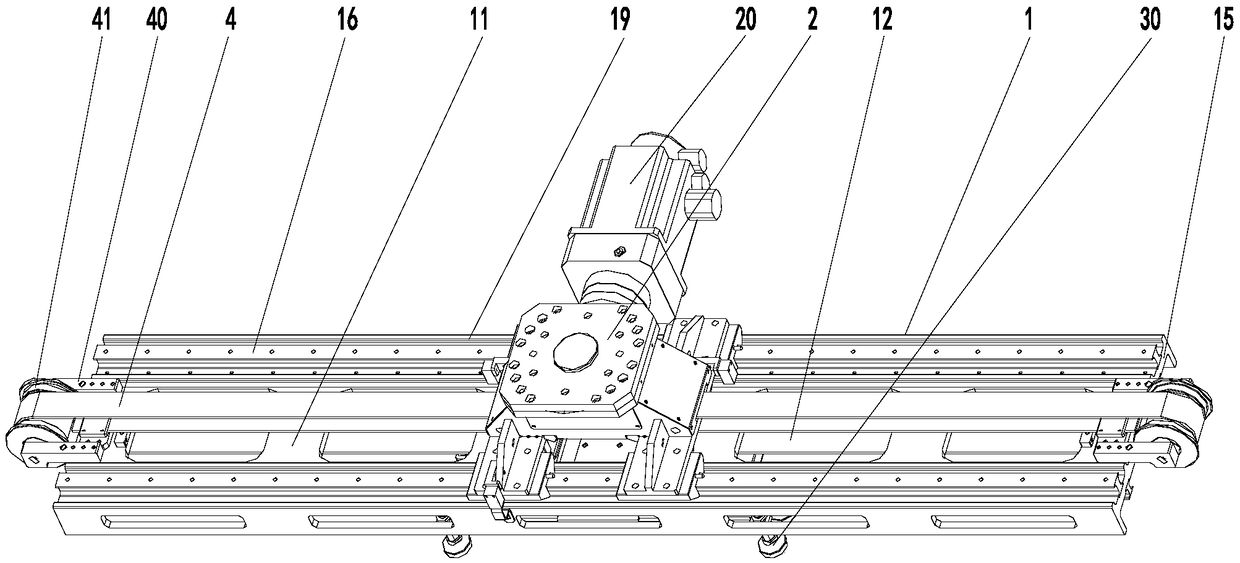

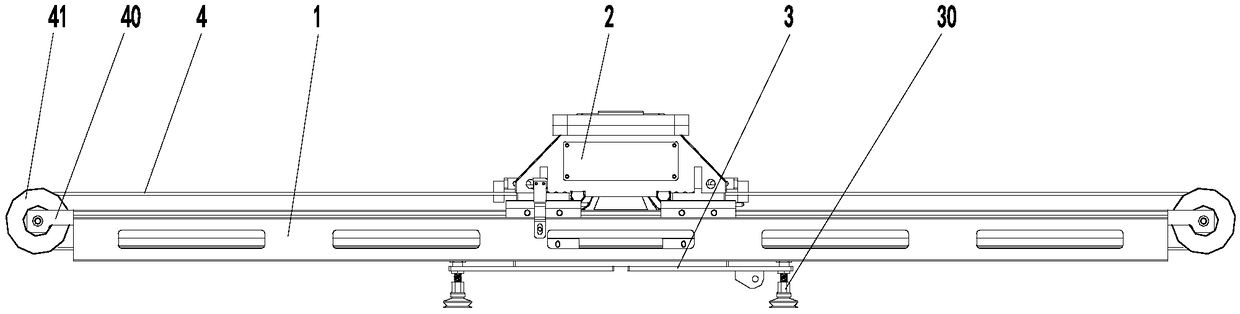

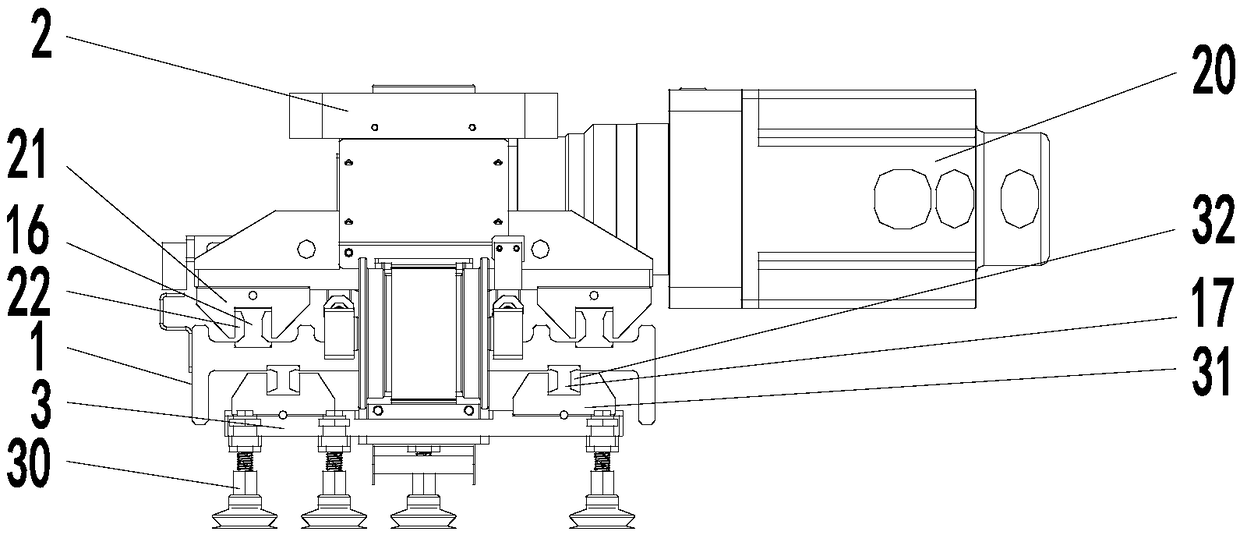

[0016] refer to figure 1 , figure 2 and image 3 , the present invention is a double-speed seventh axis for a robot, comprising a main rail 1, a transmission box 2, a servo motor 20, a mounting block 3, and a suction arm 30. The cross section of the main rail 1 is I-shaped, and the main rail 1 is formed by The plate 11 and the strip body 15 are composed, the middle plate 11 is an elongated plate body, each of the long side sides of the middle plate 11 is fixed with a strip body 15, and the two short sides of the middle plate 11 are fixed with a fixing frame 40 , rollers 41 are installed on the fixed frame 40, and a synchronous belt 4 is set on the two rollers 41. The upper surface of the synchronous belt 4 is located above the middle plate 11, and the lower surface of the synchronous belt 4 is located below the intermediate plate 11. , the upper end of the main body rail 1 is equipped with a transmission box 2, the transmission box 2 is connected with a servo motor 20, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com