Durability test device capable of realizing automobile door opening and closing sealing force

A technology for durability testing and door opening and closing, which is applied in vehicle testing, measuring devices, testing of mechanical components, etc. It can solve problems such as large parking spaces, customer discomfort, and inability to meet the number of tests, so as to improve test efficiency. Small footprint, strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

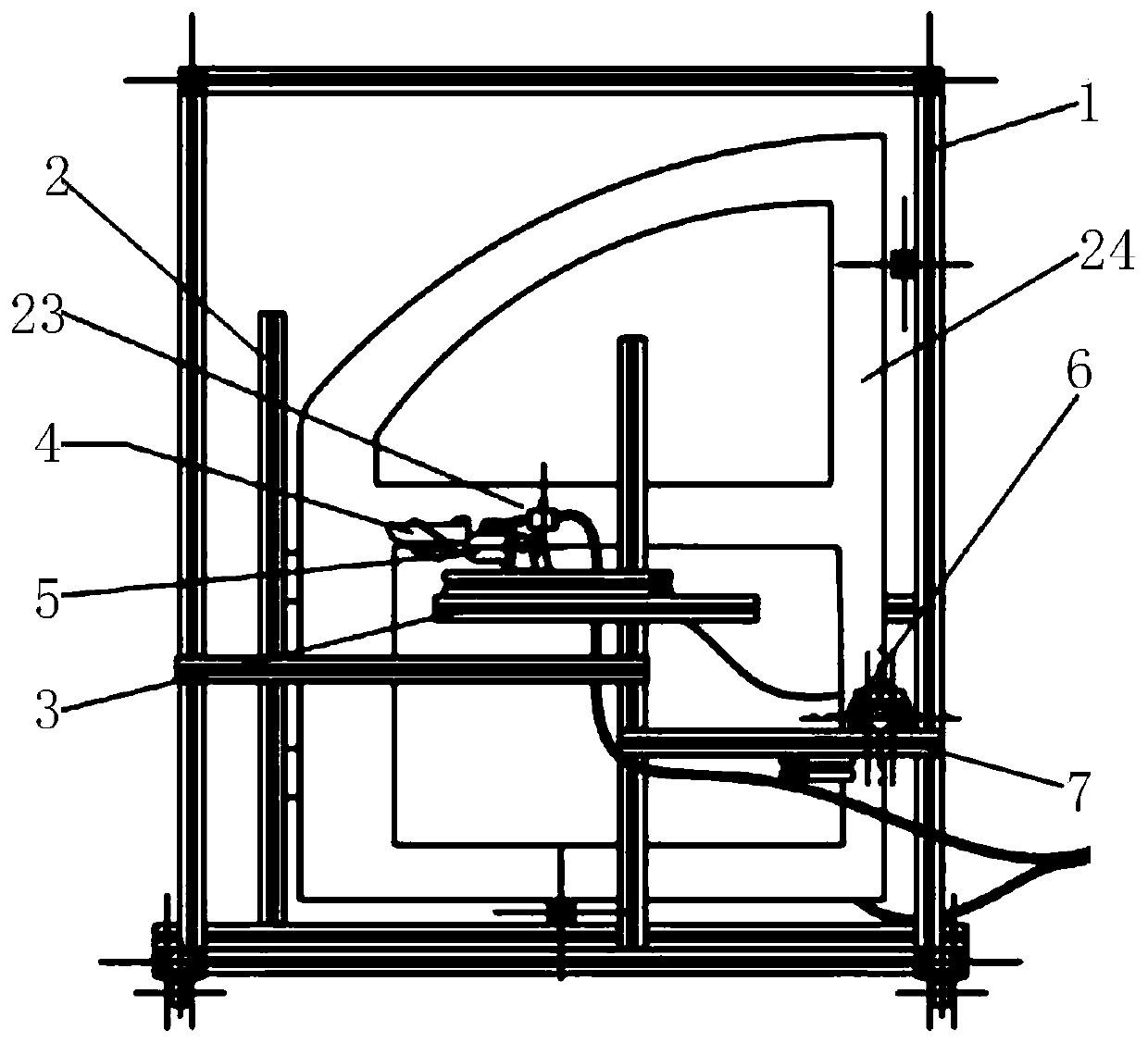

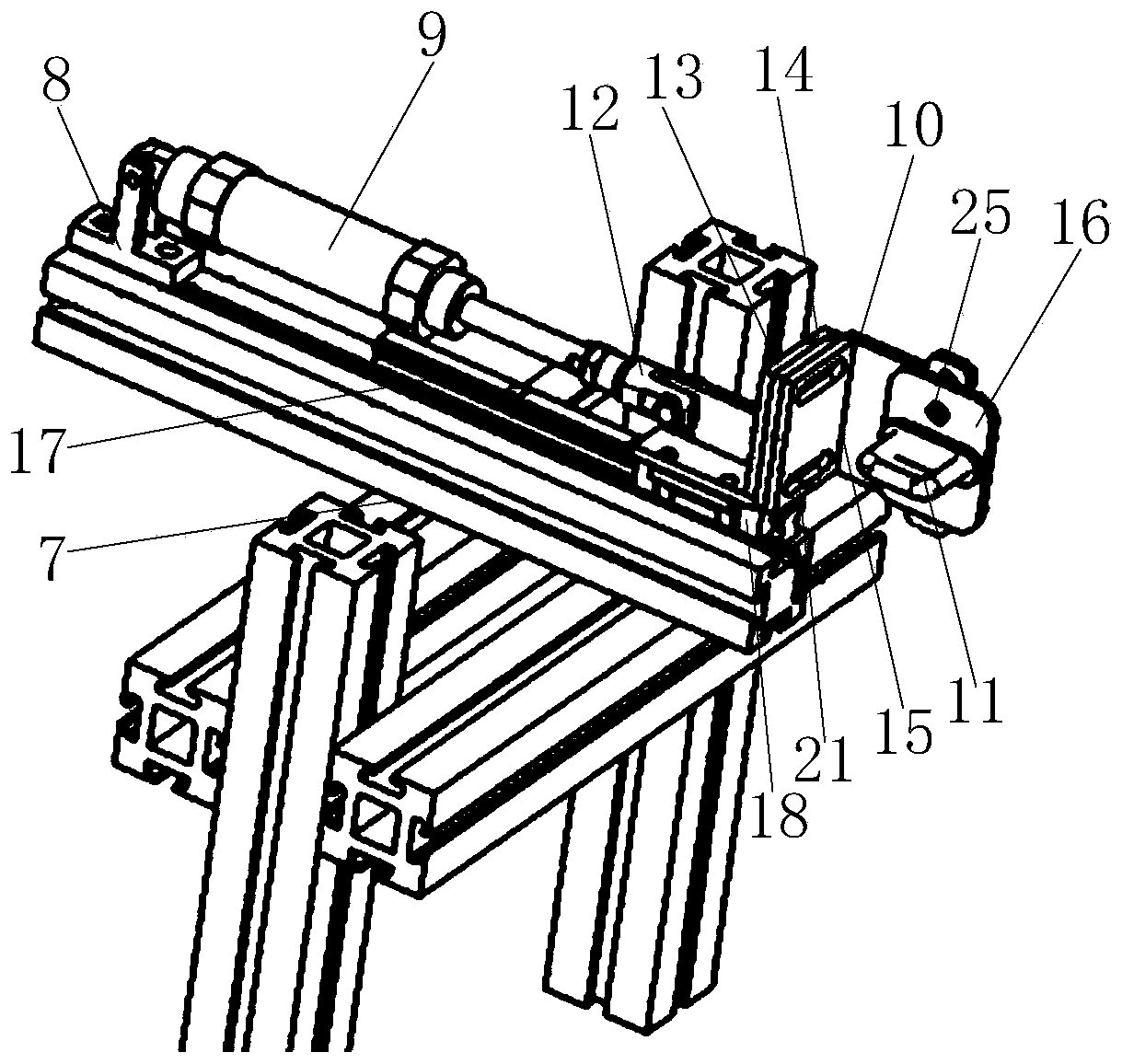

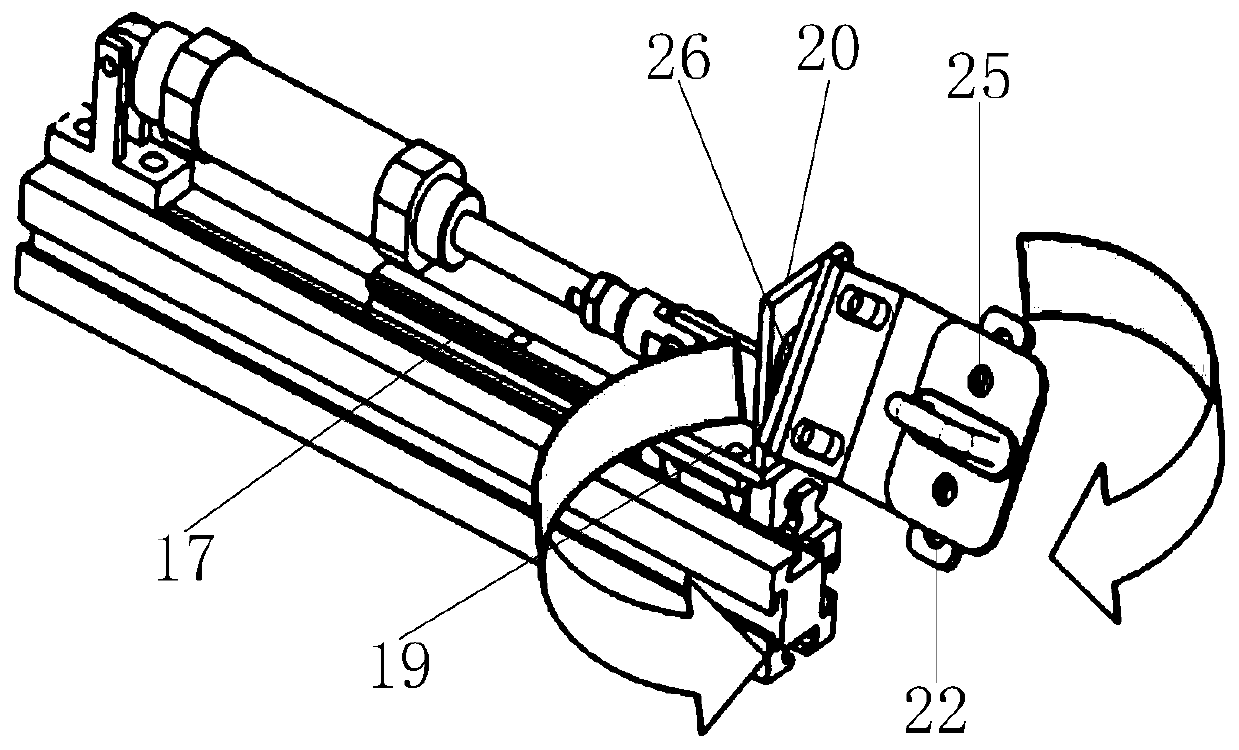

[0021] Specific embodiments of the present invention are described with reference to the above drawings.

[0022] Such as Figure 1-4 As shown, a kind of durability test device that can realize the sealing force of the automobile door opening and closing in the present embodiment comprises the frame 1 that is used to fix the car door 24, the fixing bracket 2 that is installed on the described frame 1, is arranged on the described fixing bracket 2, the first support frame 3 on the first support frame 3 and the first air cylinder 5 connected with the inward opening handle 4 of the door 24, the unlocking device 6 arranged on the side of the door 24 and the The unlocking device 6 is electrically connected to the controller (not shown in the figure) of the first cylinder 5, the other side of the door 24 is hinged with the fixed bracket 2, and the unlocking device 6 includes a The second support frame 7, the sliding mechanism arranged on the second support frame 7, the second cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com