Engine lubricating system and control method thereof

A lubrication system and engine technology, which is applied in the direction of engine lubrication, engine load, engine speed, etc., and can solve problems such as the control strategy of the piston cooling nozzle check valve that is not clearly stated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following specific embodiments are used to further describe the technical solution of the claims of the present invention in detail, so that those skilled in the art can understand the claims more clearly. The protection scope of the present invention is not limited to the following specific examples. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments.

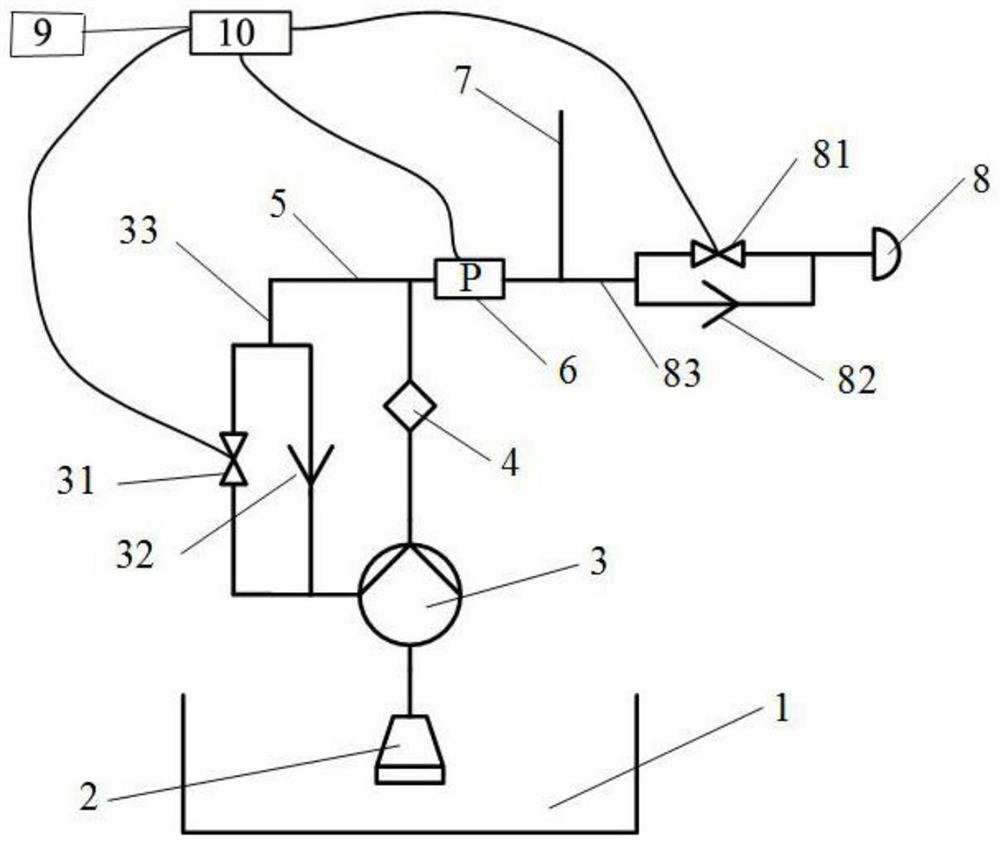

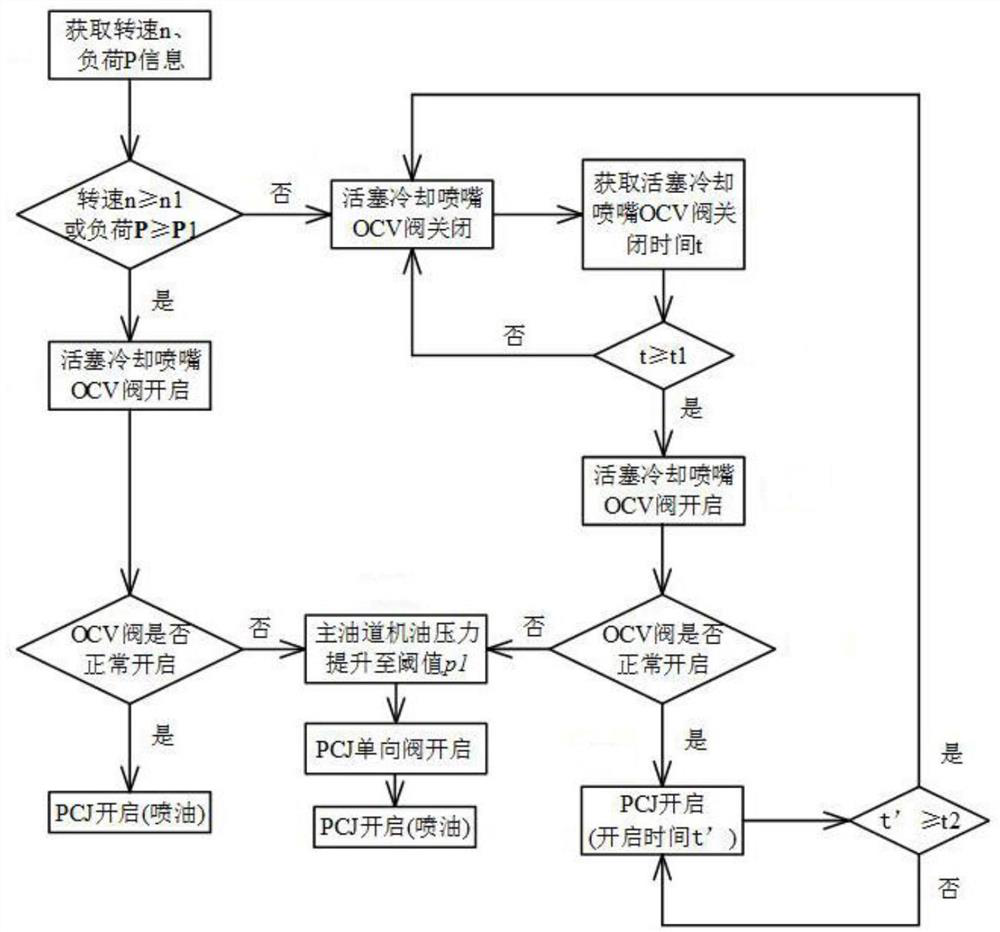

[0028] Such as figure 1 As shown, an engine lubricating system includes a variable displacement oil pump 3, an oil filter 4, and a cylinder body main oil passage 5 connected in sequence. One end of the cylinder body main oil passage 5 passes through the oil pump feedback oil passage 33, The oil pump OCV valve 31 is connected to the oil return port of the variable displacement oil pump 3, and the other end is connected to the piston cooling nozzle 8 through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com