Systems and methods for crankcase system diagnostics

A crankcase and air intake system technology, applied in the field of systems and methods for crankcase system diagnosis, capable of solving problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

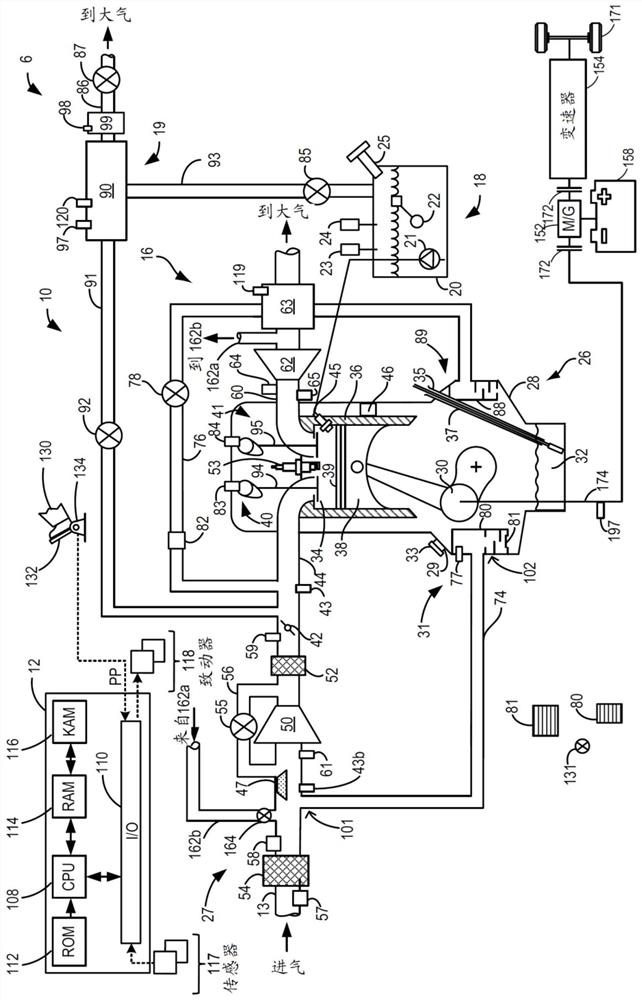

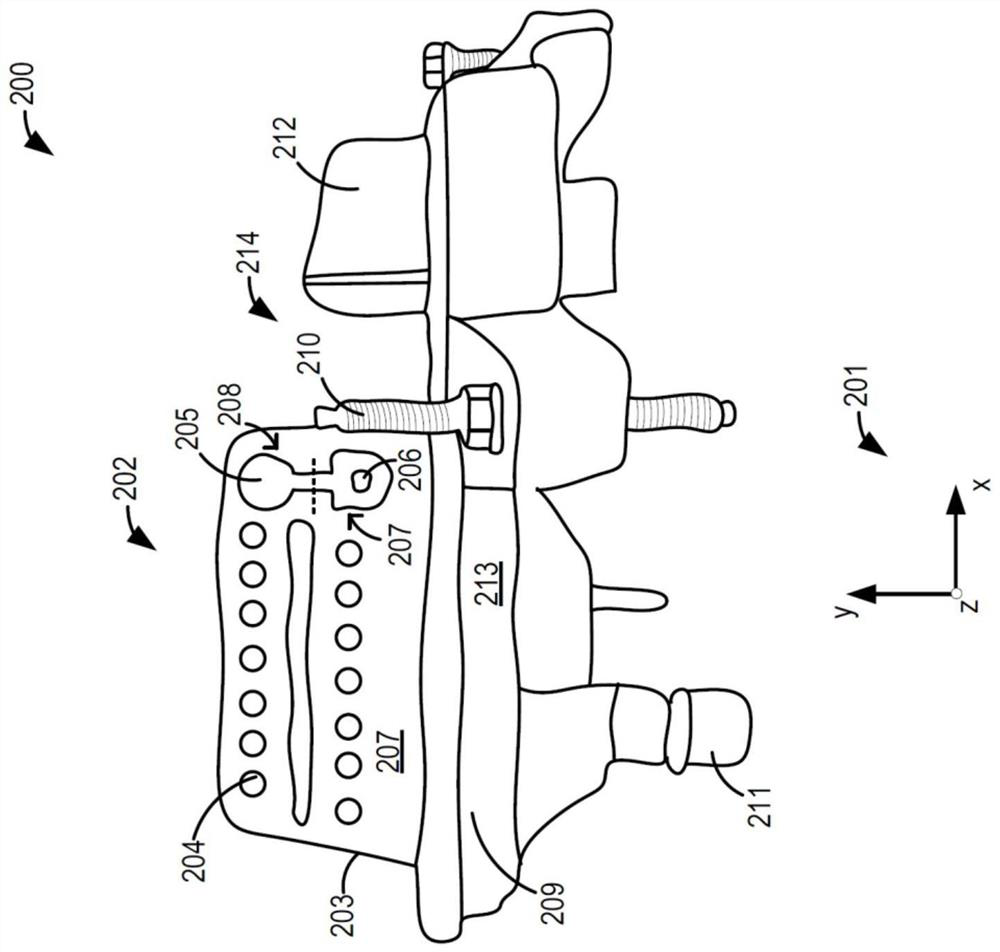

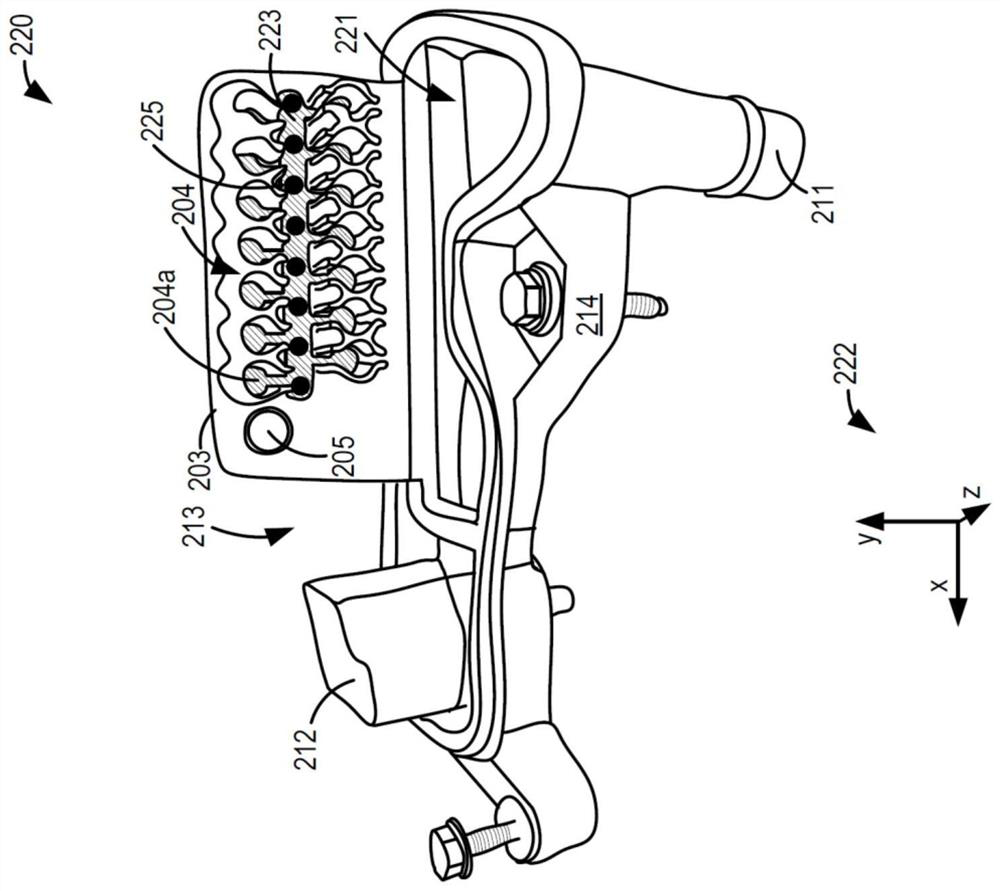

[0020] The following description relates to systems and methods for inferring whether there is degradation associated with a PCV ventilation hose fluidly coupling an engine crankcase to an intake system. therefore, figure 1 An exemplary engine is depicted that includes a PCV system having a ventilation hose fluidly coupling the engine's crankcase to an air intake system. To effectively diagnose the presence or absence of deterioration associated with the ventilation hose, the ventilation hose may be positioned between the intake system and the crankcase pressure (CKCP) sensor, rather than, for example, at a location on the ventilation hose Includes CKCP sensor. The oil-air separator may be included in the crankcase of the engine and may include one or more sealing baffles that may respond to pressure differentials (eg, between the ventilation hose and the crankcase) Respond so that the oil separator effectively seals the ventilation hose from the crankcase when there is no p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com