Submarine cable underwater synchronous paying-off underwater vehicle

A technology for submersibles and submarine cables, which is applied to instruments, cable laying ships, three-dimensional position/channel control, etc., can solve problems such as obstacles in laying links, increased risks, and large time consumption, and achieves a high degree of integration and automation. The effect of high and low laying tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific examples.

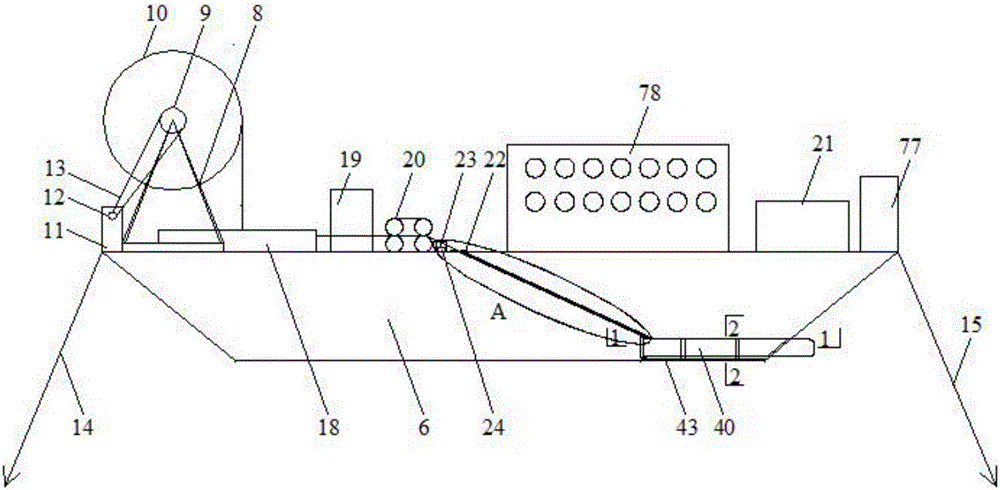

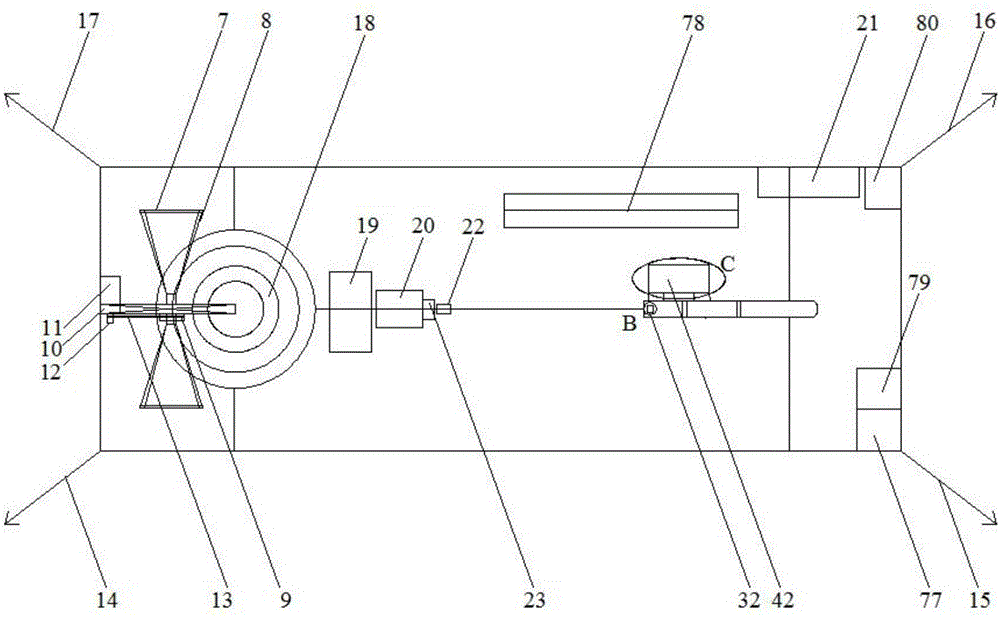

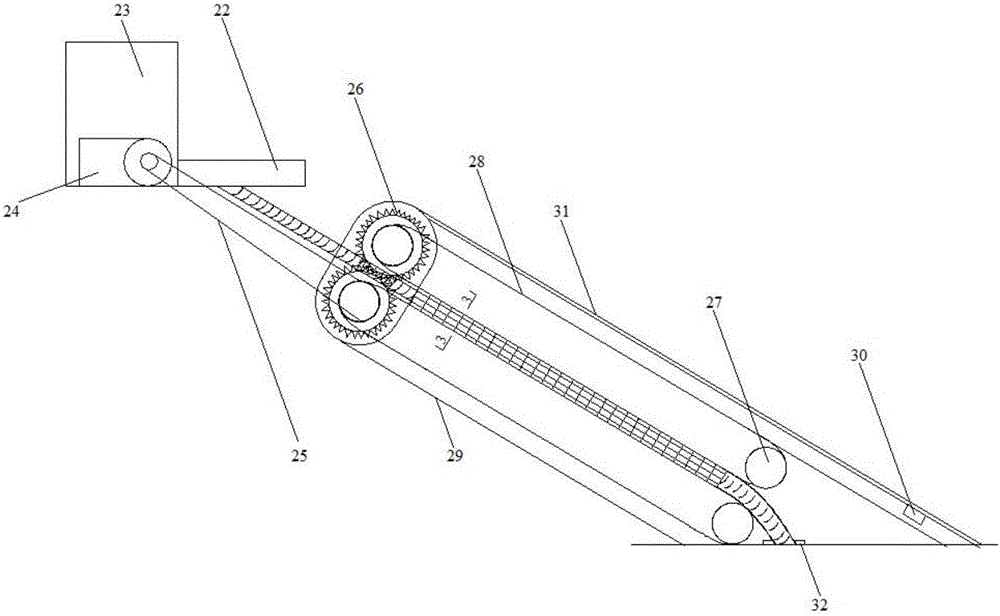

[0042] refer to Figure 1-11 , a submarine cable underwater synchronous release submersible, comprising a ship-borne mechanical system 1, a synchronous push system 2, a pneumatic launch system 3, a calculation central control system 4 and a towed submersible system 5, the synchronous push system 2, a pneumatic The launch system 3 and the calculation central control system 4 are all fixed on the shipboard mechanical system 1, and the towing stealth system 5 can move away from the hull.

[0043]The shipborne mechanical system 1 is used for the transportation of the synchronous push system 2, the pneumatic launch system 3, the towed submerged system 5 and the submarine cable, and can pull the submarine cable from the submarine cable storage box 18 to the synchronous push system 2, which includes a barge 6. Load-bearing plate 7, support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com