Deep-sea cable laying system of manned submersible

A manned submersible and operating system technology, applied in the field of manned submersible deep-sea cable laying operation system, can solve problems such as easy detection and recording of the path of the cable laying ship, exposure of the submarine information network, suspension or accumulation of submarine cables, etc. , to achieve the effect of ensuring the laying quality, compact structure and improving concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

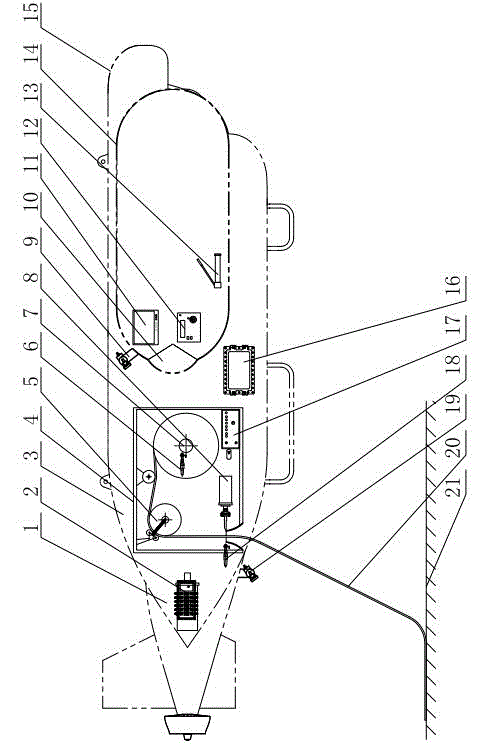

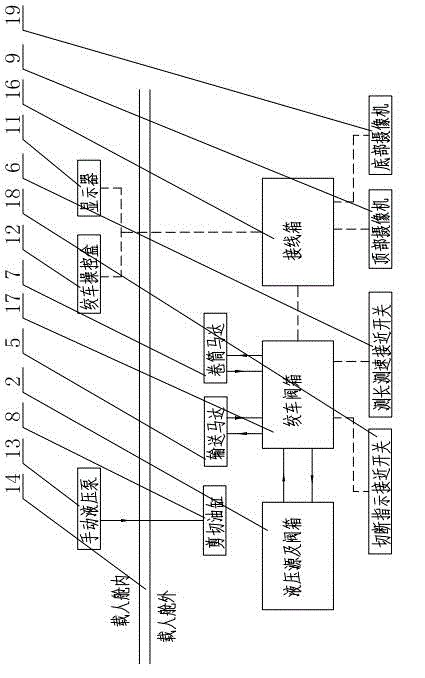

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 and figure 2 As shown, the manned submersible deep-sea cable laying operation system of the present embodiment includes a manned submersible 15, and the inside of the manned submersible 15 is sequentially formed with a manned cabin 14, a submersible operation cabin 3 and a submersible. end of device 1,

[0023] A hydraulic source and a valve box 2 are installed in the submersible tail 1,

[0024] A cable-laying winch 4 is installed in the submersible operation cabin 3, and the cable-laying winch 4 includes a box body. A drum motor 7 for driving the drum rotation and a delivery motor 5 for driving the delivery wheel to rotate are installed in the box. Speed measuring proximity switch 6, a shearing oil cylinder 8 equipped with a shearing knife at one end of the box body, a winch valve box 17 is installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com