Steering knuckle forging molding process of heavy truck

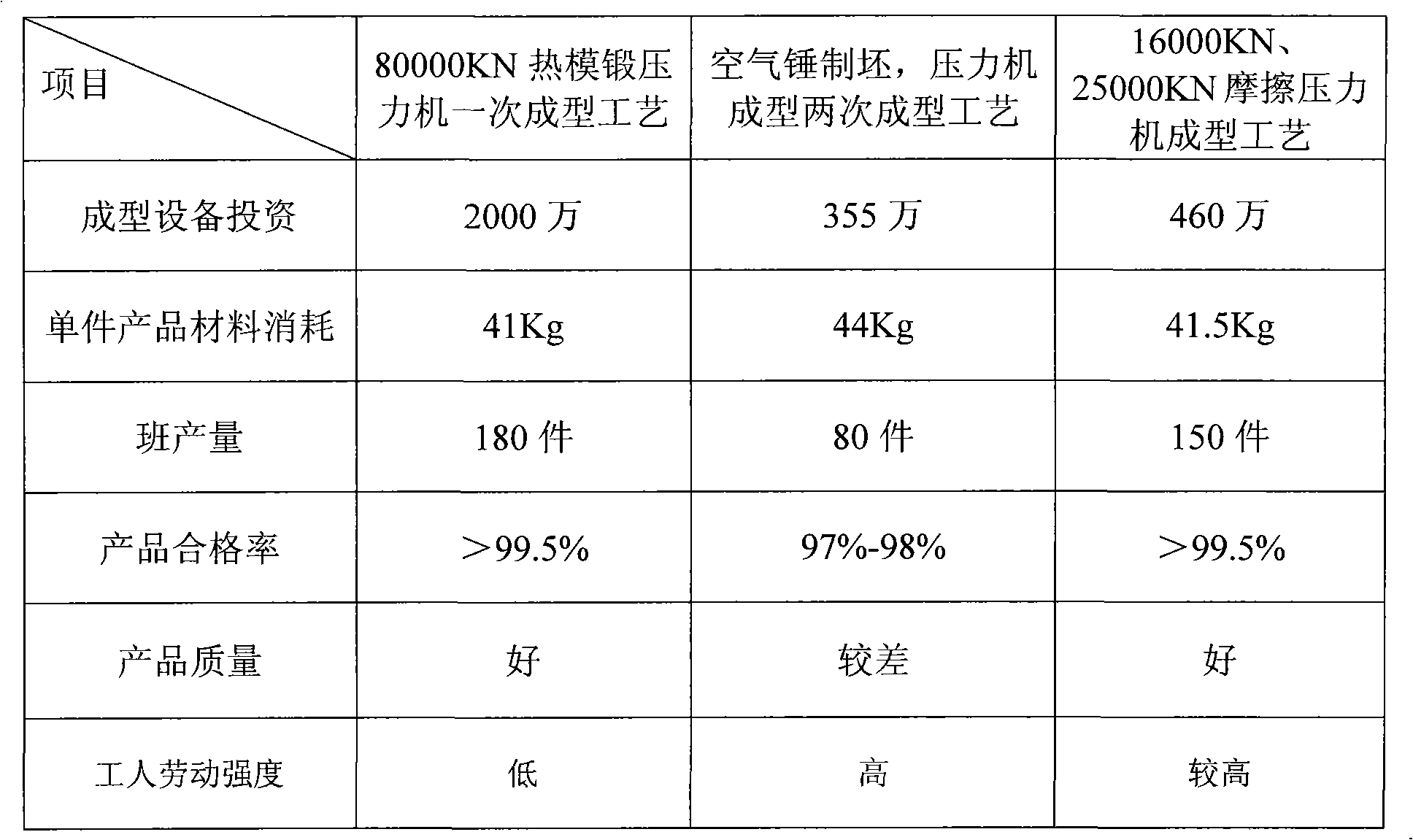

A heavy-duty truck and forging forming technology, which is applied in the field of forging technology, can solve the problems of low production cost, affecting production efficiency, and high raw material consumption, and achieve the effect of reducing the requirements for production equipment, reducing equipment investment costs, and reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

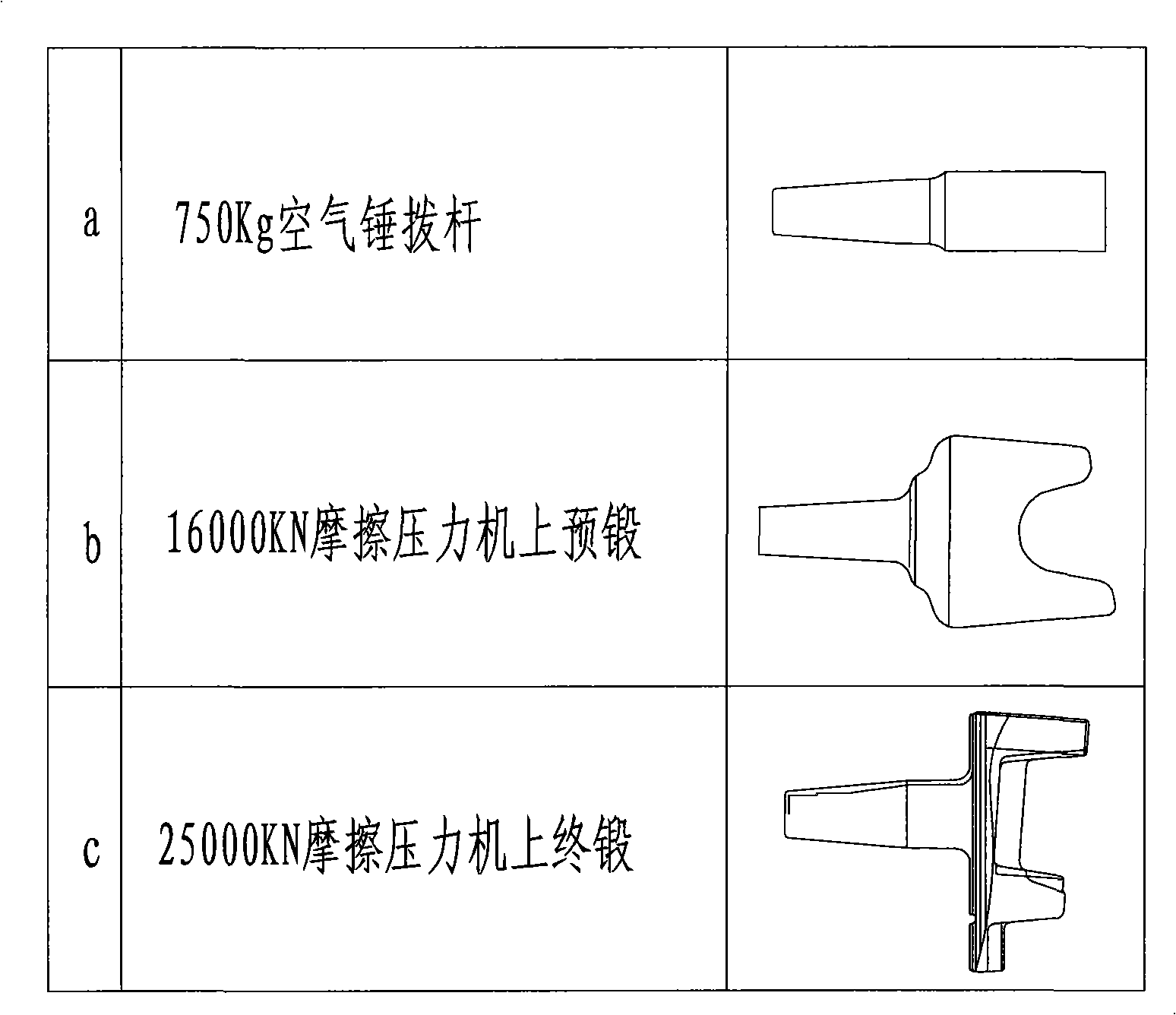

[0015] Accompanying drawing is the forming step figure of the present invention, as shown in the figure: the forging forming process of the steering knuckle of the heavy truck of the present embodiment, the final forming shape and size of the steering knuckle are known, and its material is known to be 42CrMo, including the following steps:

[0016] a) Rod pulling: Use a 750Kg air hammer to pull out a Φ130 round steel billet to form a workpiece consisting of a cylindrical section and a circular table section;

[0017] b) Pre-forging pier roughness and material distribution: place the workpiece after drawing the bar on the pre-forging die of a 16000KN friction press for pre-forging, and perform upsetting and material distribution on the cylindrical section, so that the cylindrical section can be formed into a bifurcated structure at one time ;

[0018] c) Final forging: place the pre-forged workpiece on the forming die of a 25000KN friction press for final forging, and form the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com