Grout stop pad construction method for kilometer vertical shaft grouting for water control

A construction method and a technology of grout stop pads, which are applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as imperfect technical measures and wellbore collapse, and achieve the effect of speeding up and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described with reference to the accompanying drawings.

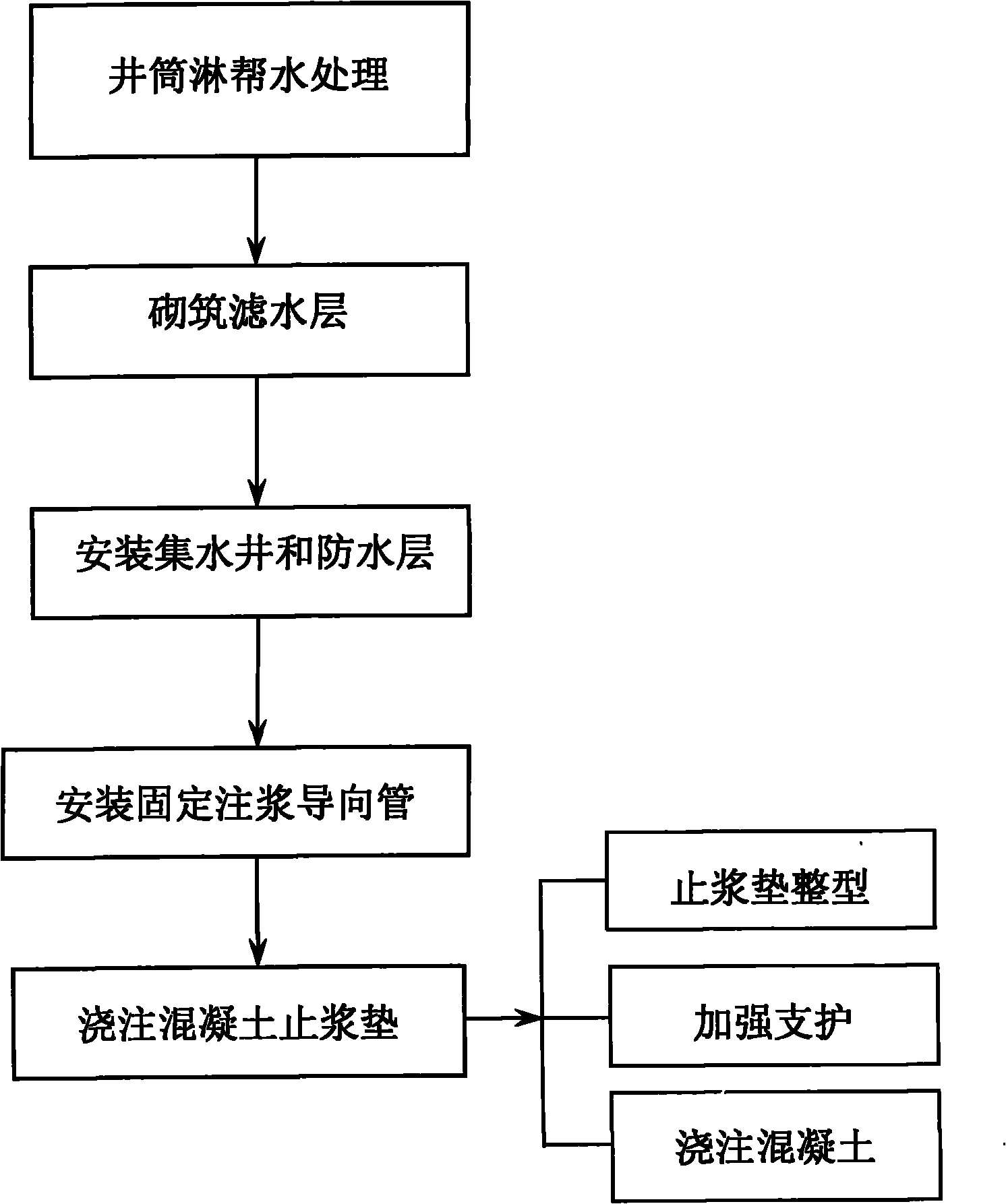

[0022] According to the construction method of the stop grout pad in the process of grouting and water plugging in the thousand-meter-deep shaft of the present invention, the construction process is as follows figure 1 shown, including

[0023] The first step: wellbore shower water treatment;

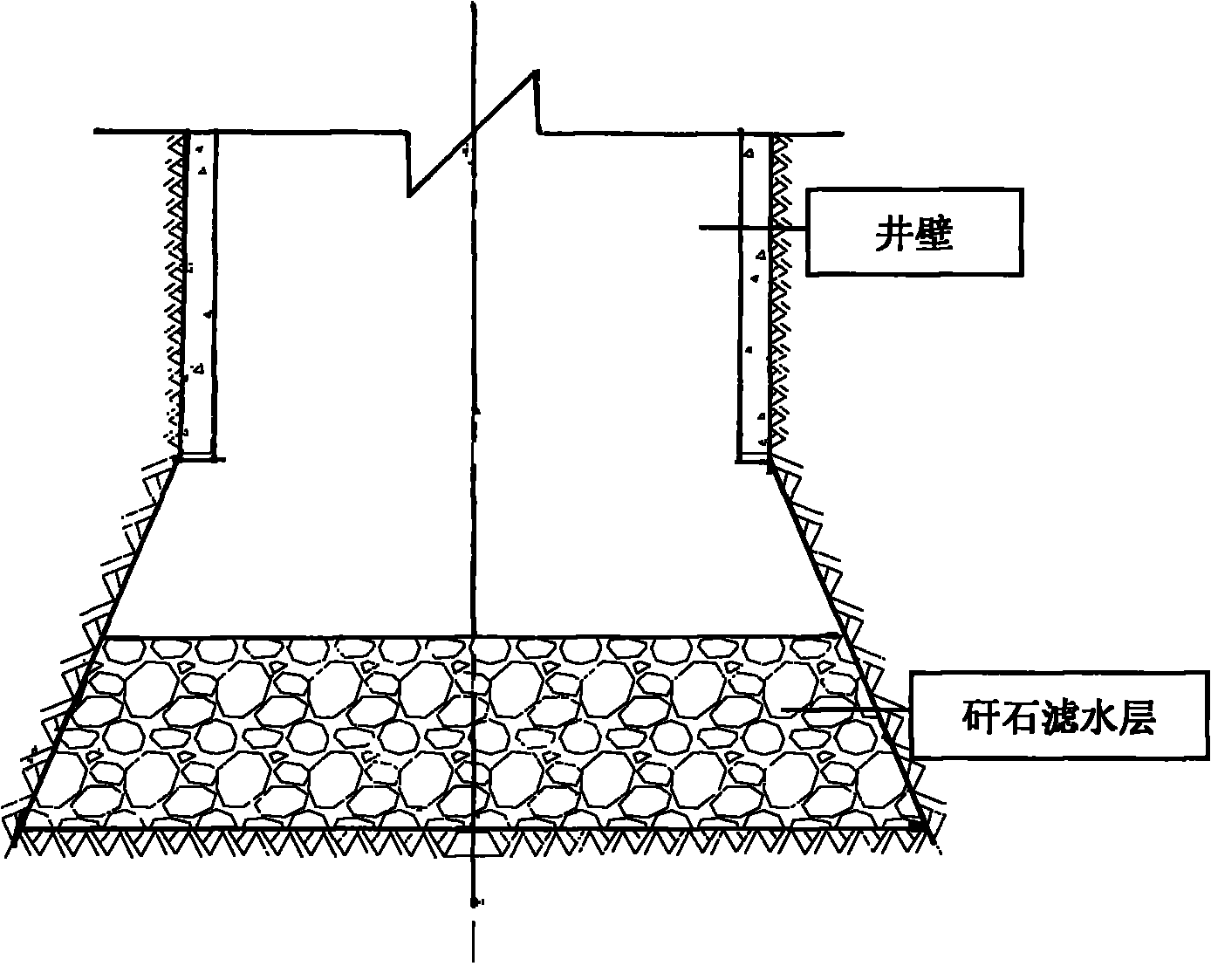

[0024] The second step: build the water filter layer;

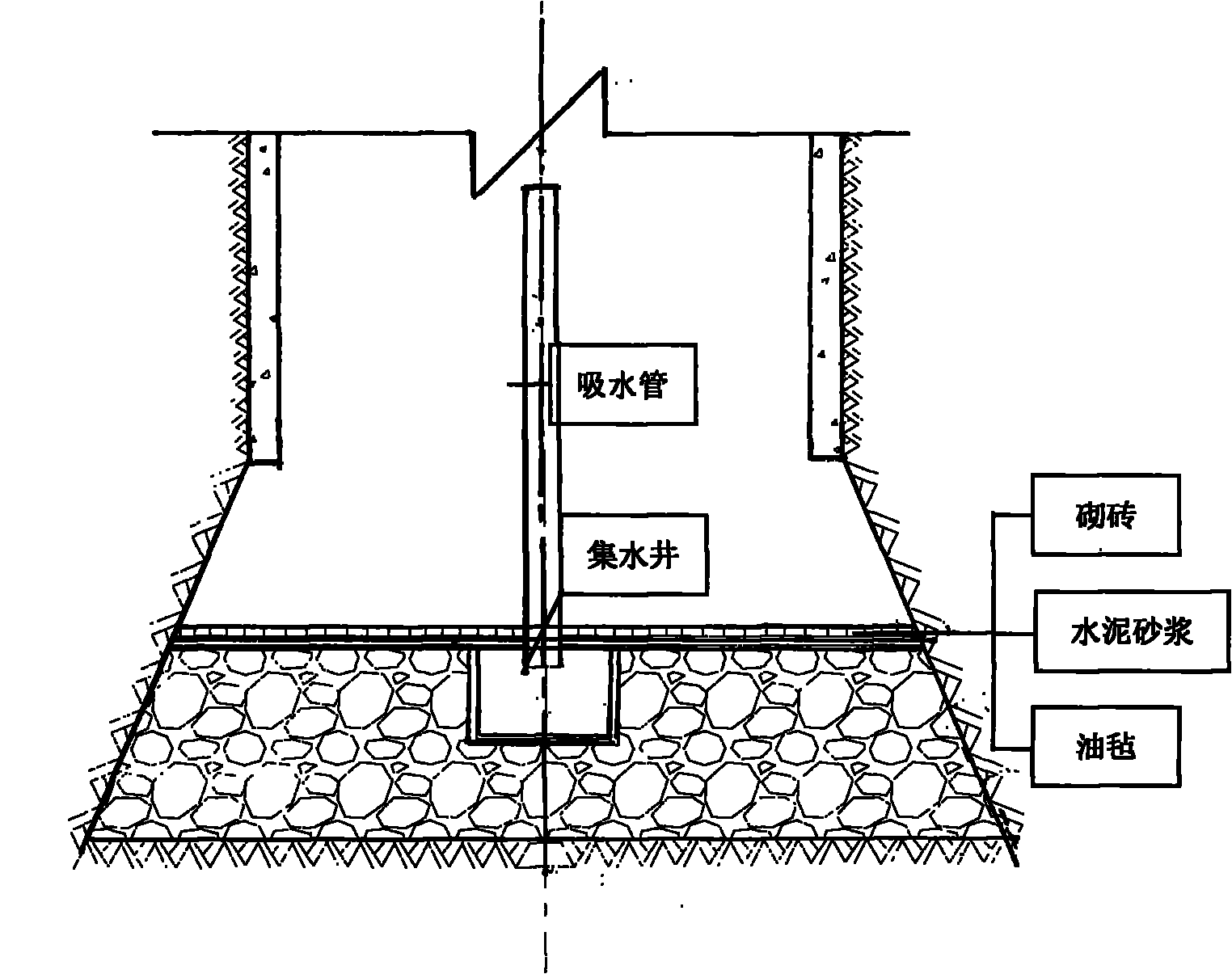

[0025] The third step: install the water collection well and waterproof layer;

[0026] Step 4: Install and fix the grouting guide pipe;

[0027] Step 5: Pouring concrete grout pad;

[0028] The specific operation content of the step 1 is as follows: figure 2 Shown: The method of grouting behind the well wall is used to block the side water in the wellbore. If there is still some water after the grouting behind the wall, it is necessary to install a water interception tank to intercept the water so that the side water does not ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com