Reactor and method for preparing propylene by method of group feeding of heavy oil and light olefin

A technology for reactors and light olefins, which is applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, and hydrocarbon oil treatment. It can solve problems such as reducing reaction time, affecting reaction effects, and decreasing fluidized density of catalysts, so as to improve contact efficiency. , improve the yield and selectivity, and shorten the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

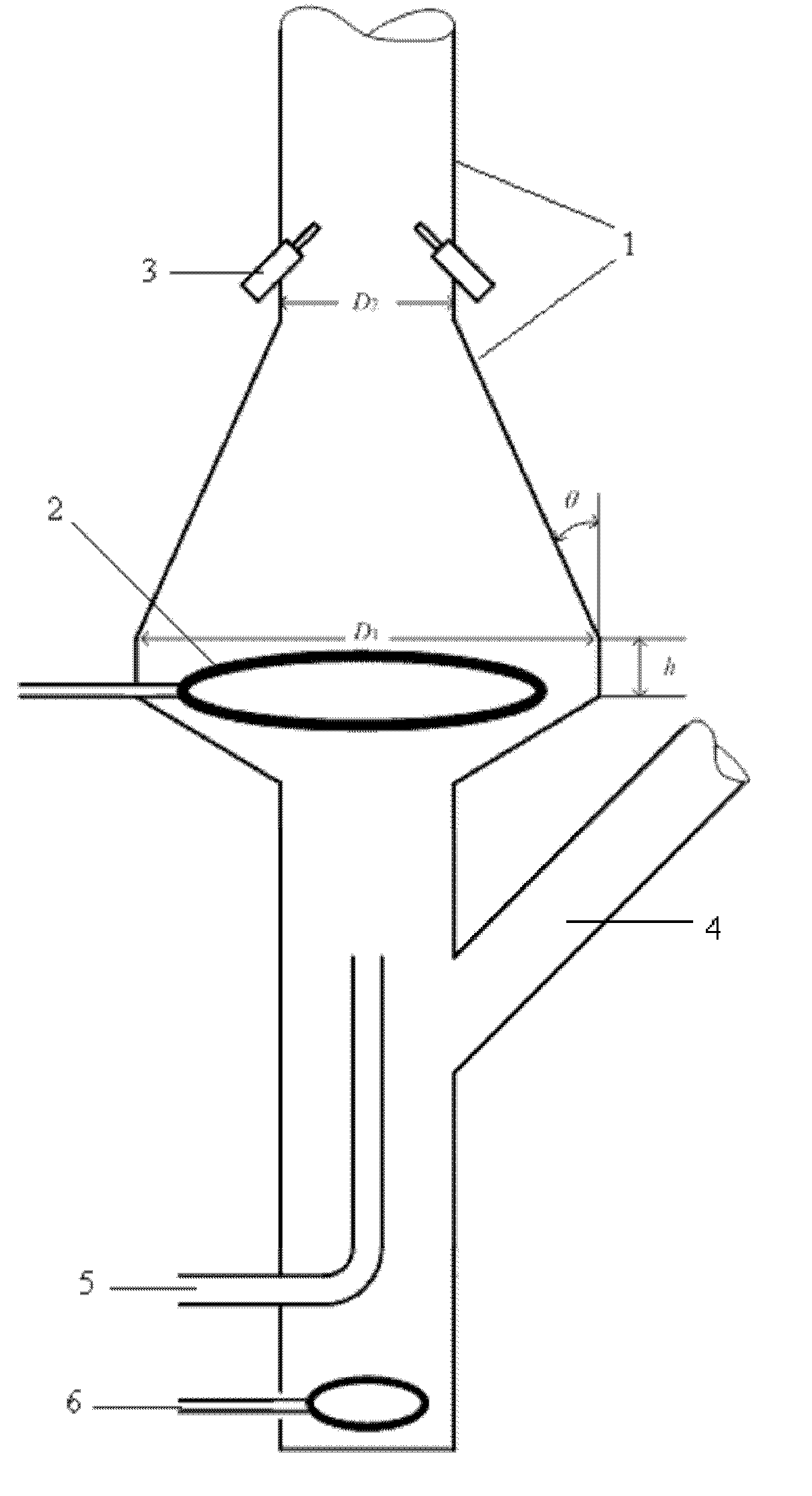

[0045] The invention provides a riser reactor of a riser circulating fluidized bed device, with figure 1 It is a structural schematic diagram of the riser reactor of the present invention.

[0046] Such as figure 1 As shown, the riser reactor 1 includes upper and lower pipelines. The upper pipeline is a straight pipe, and the lower pipeline is a diameter-expanding section. The angle between the busbar and the axis is preferably 5-30°, the height of the round table is 10mm-5000mm, preferably 2000mm-3000mm, and the diameter of the cross-section of the straight pipe part depends on the actual industrial processing capacity, as long as it can meet the requirements The linear velocity of the gas is 3-25m / s. in the attached figure 1 Among them, the diameter of the upper bottom surface of the circular platform is equal to the diameter of the straight pipe, and the diameter of the upper bottom surface of the circular platform can also be larger than the diameter of the straight pip...

Embodiment 2

[0049] In this example, propylene is prepared in the riser circulating fluidized catalytic cracking (FCC) reaction regeneration system of the riser reactor described in Example 1.

[0050] Light olefins and heavy oil are fed into the riser reactor through the nozzle of the annular feed pipe and the heavy oil atomization nozzle respectively. Light olefins account for 20% of the raw material weight. The preheating temperature is 240°C, the axial average gas velocity in the expanding section of the riser is 1.0m / s, the axial velocity of the straight pipe is 15m / s, and the outlet temperature of the riser is 520°C. In the cracking (FCC) reaction regeneration system, the high-temperature regenerated catalyst from the regenerator flows upwards along the riser under the action of pre-fluidized and pre-lifted steam, and after mixing with the atomized raw material injected from the nozzle, it is Cracking reactions occur during the continued upward flow, yielding products containing prop...

Embodiment 3

[0052] In this example, propylene is prepared in the riser circulating fluidized catalytic cracking (FCC) reaction regeneration system of the riser reactor described in Example 1.

[0053] Light olefins and heavy oil are fed into the riser reactor through the nozzle of the annular feed pipe and heavy oil atomizing nozzle respectively. Light olefins account for 5% of the raw material weight. The preheating temperature is 150°C, the axial average gas velocity in the expanding section of the riser is 0.2m / s, the axial velocity of the straight pipe is 20m / s, and the outlet temperature of the riser is 460°C. In the cracking (FCC) reaction regeneration system, the high-temperature regenerated catalyst from the regenerator flows upwards along the riser under the action of pre-fluidized and pre-lifted steam, and after mixing with the atomized raw material injected from the nozzle, it is Cracking reactions occur during the continued upward flow, yielding products containing propylene. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com