Kapok fiber adsorbent, preparation method and application thereof

A kapok fiber and adsorbent technology, which is applied in the field of kapok fiber adsorbent and its preparation, can solve problems affecting the development of the nervous system, damage to the brain and optic nerves, bone pain, etc., and achieve easy desorption, regeneration, use, and modification effects Good, high resorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

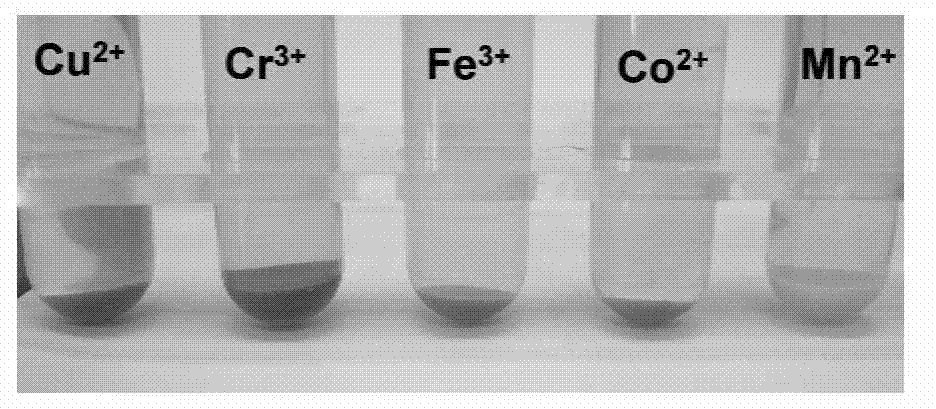

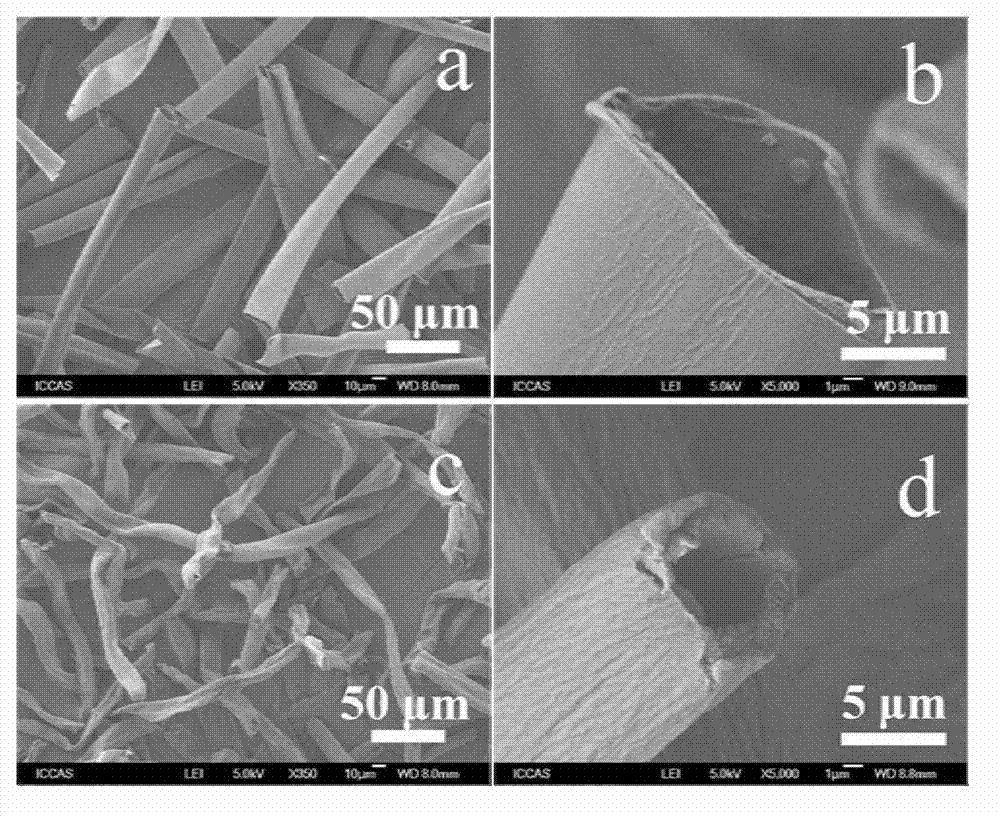

[0021] Embodiment 1, preparation and application of kapok fiber adsorbent

[0022] Add 2.0 g of kapok fibers (50 μm in length and 95% hollowness) into 100 mL of dichloromethane for hydrophilic treatment, soak for 10 minutes and then filter. Wash three times, filter and dry naturally. Take 1.5 g of kapok fiber treated with hydrophilicity and add it into 100 mL of aqueous sodium hydroxide solution (5 mol / L), and stir at 30° C. for 12 hours. After filtration, the kapok fibers were washed with deionized water until the filtrate was neutral. Then wash with ethanol and acetone, and dry in an oven at 60°C to obtain alkalized kapok. Take 1.0 g of alkalized kapok and 4.4 g of DTPA, disperse them in 100 mL of anhydrous DMF, stir, raise the temperature to 75°C and react for 24 hours. Then filter, wash with DMF, deionized water, saturated sodium bicarbonate solution, deionized water, ethanol and acetone in sequence, and finally dry at 80° C. for 2 hours to obtain kapok fiber adsorbent....

Embodiment 2

[0027] Embodiment 2, preparation and application of kapok fiber adsorbent

[0028] Add 2.0g of kapok fiber (100μm in length, 89% hollowness) into 150mL of n-hexane for hydrophilic treatment, soak for 10 minutes and then filter. Wash three times, filter and dry naturally. Take 1.5 g of kapok fiber treated with hydrophilicity and add it into 100 mL of potassium hydroxide aqueous solution (3 mol / L), and stir at 20° C. for 24 hours. After filtration, the kapok fibers were washed with deionized water until the filtrate was neutral. Then wash with ethanol and acetone, and dry in an oven at 60°C to obtain alkalized kapok. Take 1.0 g of alkalized kapok and 3.5 g of DTPA, disperse them in 100 mL of anhydrous DMF, raise the temperature to 85° C., and react for 25 hours. Then filter, wash with DMF, deionized water, saturated sodium bicarbonate solution, deionized water, ethanol and acetone in sequence, and finally dry at 80° C. for 2 hours to obtain kapok fiber adsorbent.

[0029] Ta...

Embodiment 3

[0031]Embodiment 3, preparation and application of kapok fiber adsorbent

[0032] Add 2.0g kapok fiber (length 200, hollowness 93%) into 200mL ether for hydrophilic treatment, soak for 10 minutes and then filter. Wash three times, filter and dry naturally. Take 1.5 g of kapok fiber treated with hydrophilicity and add it into 100 mL of aqueous sodium hydroxide solution (2 mol / L), and stir at 25° C. for 20 hours. After filtration, the kapok was washed with deionized water until the filtrate was neutral. Then wash with ethanol and acetone, and dry in an oven at 60°C to obtain alkalized kapok. Take 1.0 g of alkalized kapok and 2.2 g of DTPA, disperse them in 100 mL of anhydrous DMF, raise the temperature to 65°C and react for 16 hours. Then filter, wash with DMF, deionized water, saturated sodium bicarbonate solution, deionized water, ethanol and acetone in sequence, and finally dry at 80° C. for 2 hours to obtain kapok fiber adsorbent.

[0033] Take 20 mg of the kapok fiber a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com