Ceramic gland mold and manufacturing method thereof

A technology of capping mold and manufacturing method, which is applied in the directions of manufacturing tools, capping, forming tools, etc., can solve the problems of reduced surface smoothness, peeling off of protective film, abrasion, etc., and achieves large thermal expansion coefficient, good implementation effect, and excellent wear resistance. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

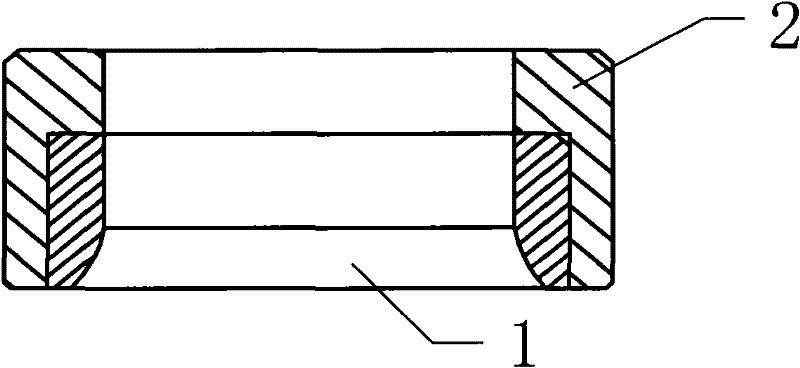

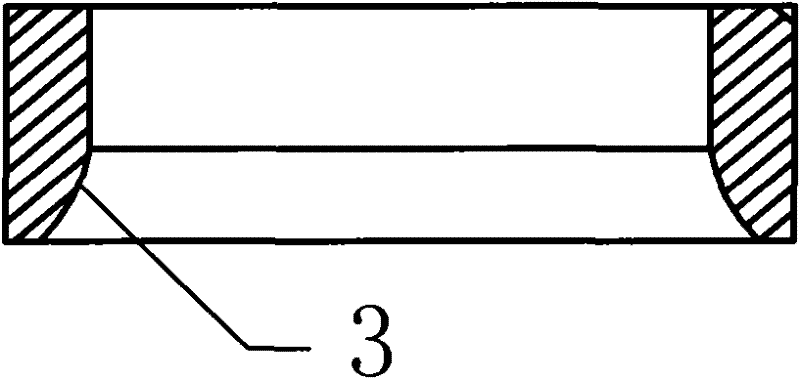

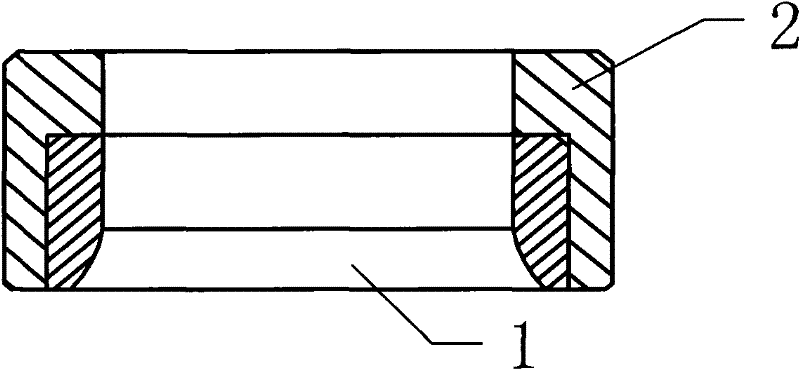

[0026] Such as figure 1 , figure 2 The shown ceramic capping die includes a capping die body, which is provided with an inner opening. The difference is that the capping die body uses ceramics as the main material. Rare earth oxide is added as a stabilizer to form a solid solution and a complex; the ceramics in the arc of the inner opening form a tetragonal and cubic phase of a twin crystal structure.

[0027] Further, in order to improve the service life conveniently, a protective cover can be provided outside the gland mold body. At the same time, in order to form a perfect bottle cap, the arc of the inner mouth and the body of the capping mold are smoothly transitioned.

[0028] At the same time, in order to meet the needs of processing, the ceramics include aluminum oxide, silicon oxide, zirconium oxide, and silicon nitride. Stabilizers include CeO 2 , Y 2 o 3 , ZrO 2 and Al 2 o 3 . Moreover, the smoothness of the inner arc is less than or equal to 0.2 μm. Of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com