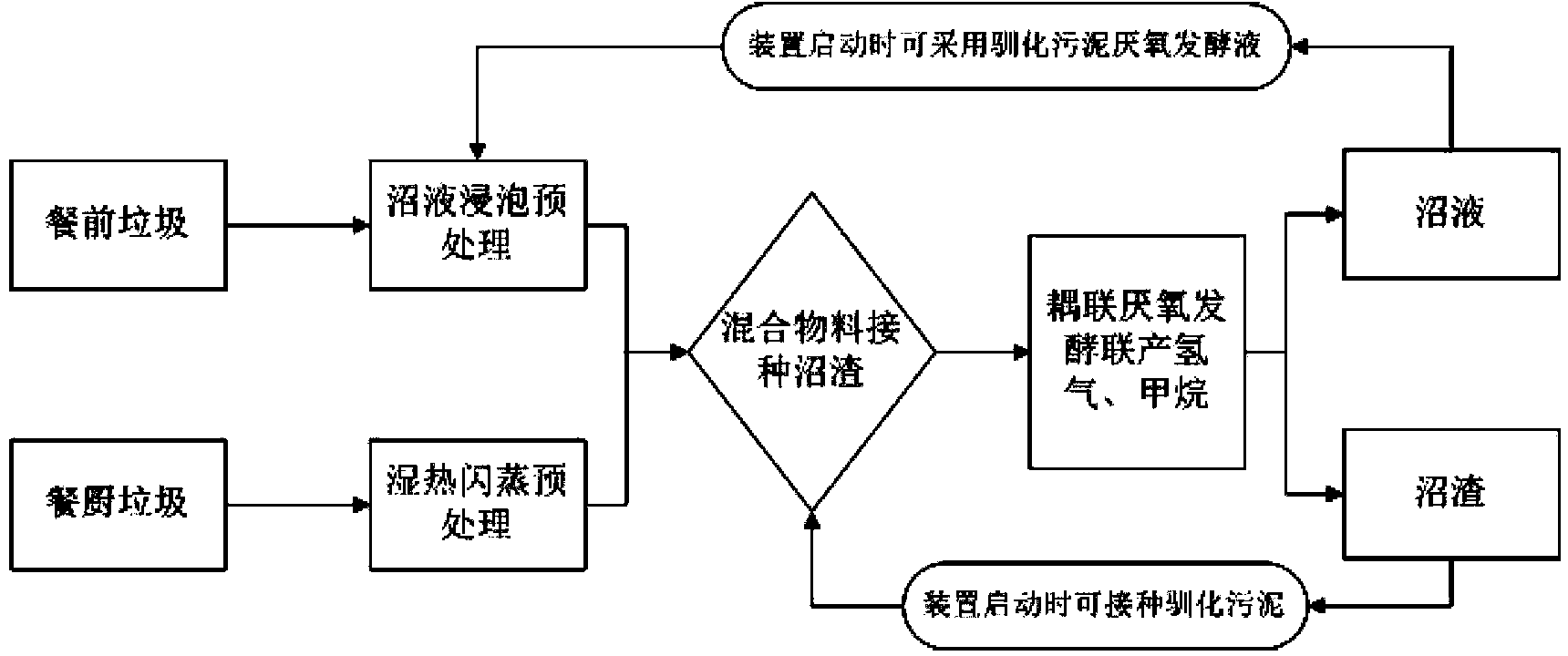

Method for jointly producing hydrogen and methane by carrying out coupling anaerobic fermentation on preprandial garbage and kitchen garbage

A technology for kitchen waste and pre-meal waste, applied in fermentation, biosynthesis, waste fuel, etc., can solve the problems of increasing the cost of anaerobic fermentation, fast acidification, slow system startup, etc., to improve energy utilization efficiency, The effect of increasing organic load and shortening start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

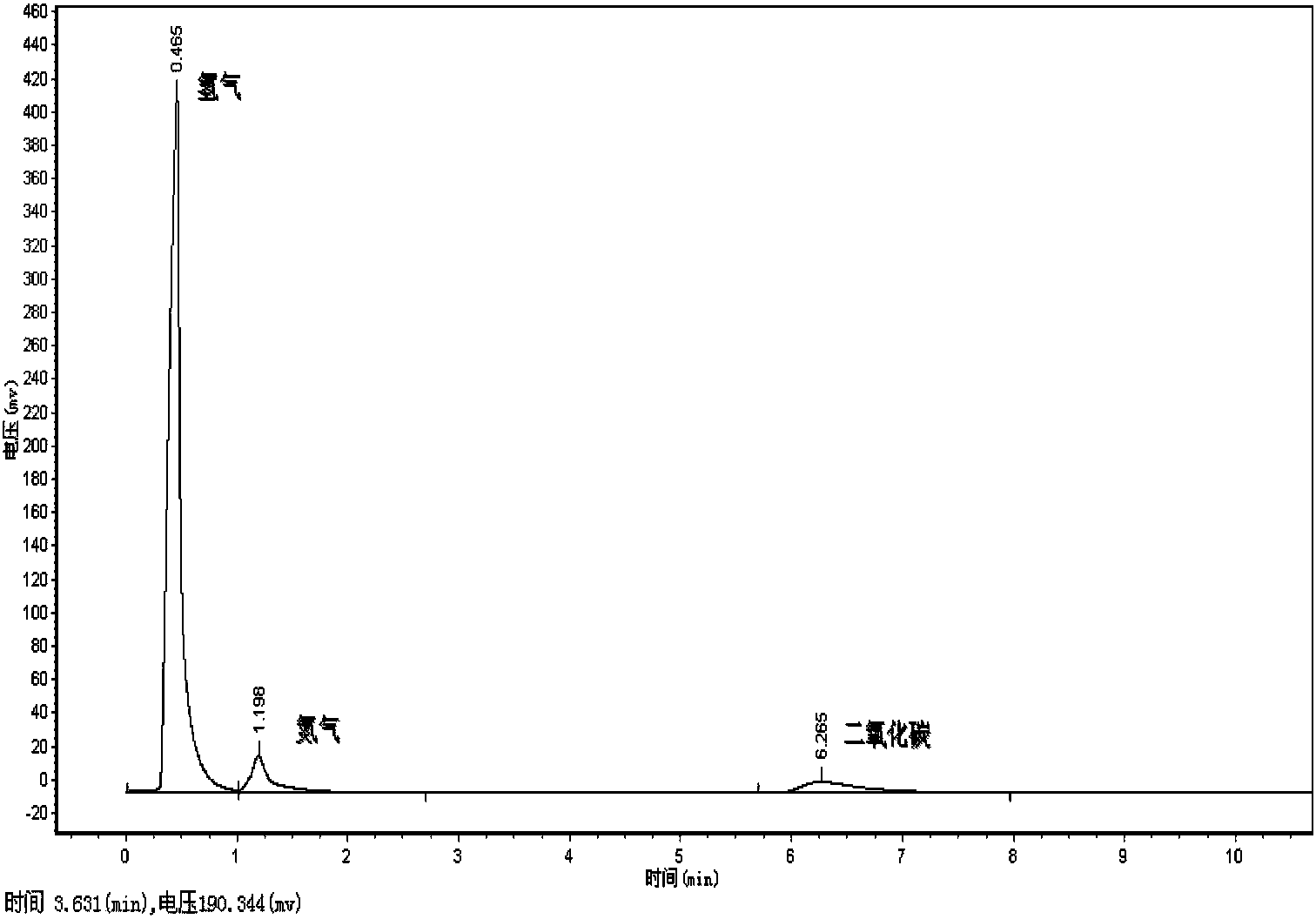

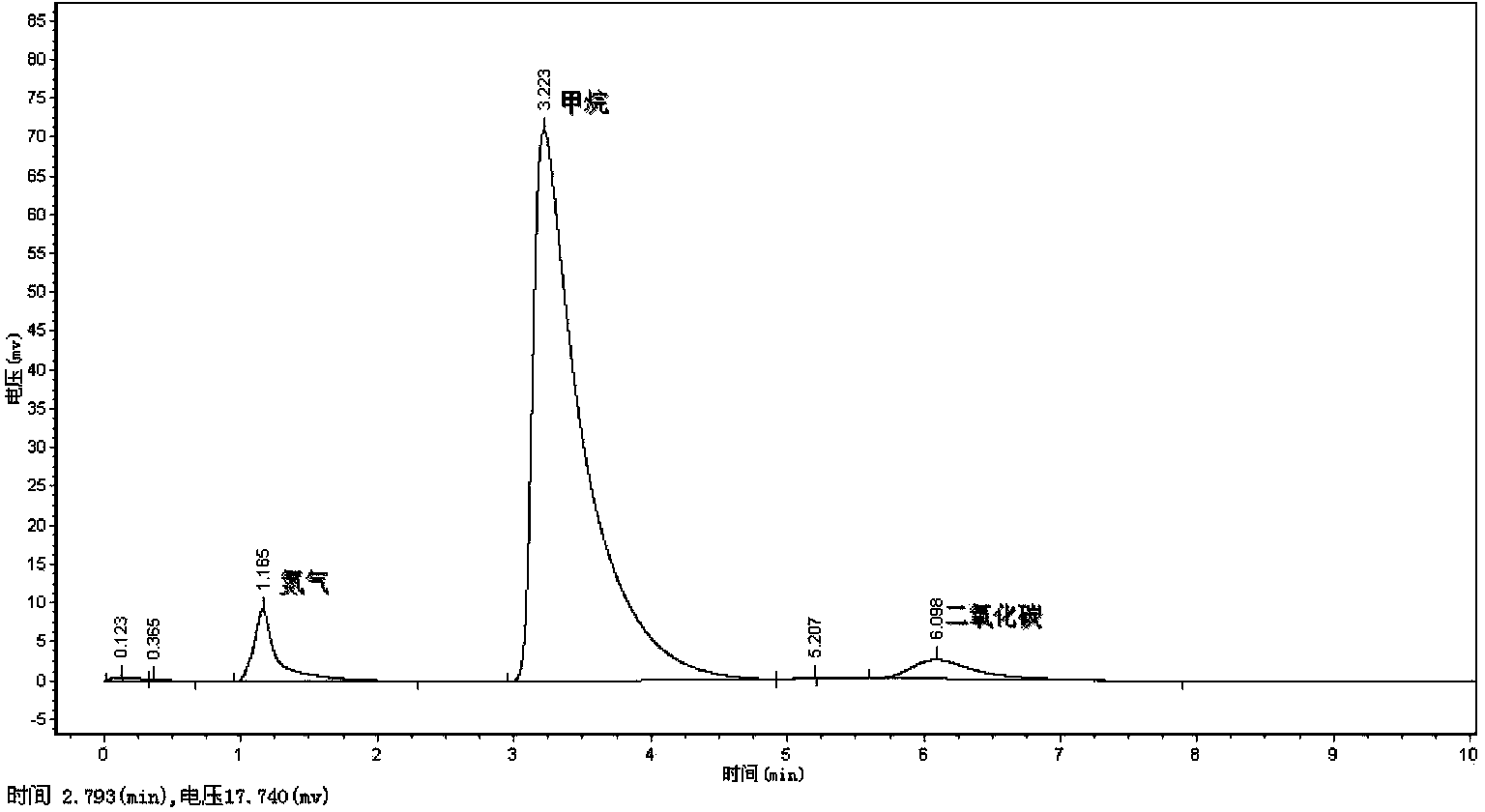

Examples

Embodiment 1

[0029] Use pre-meal waste and kitchen waste from canteens.

[0030] The pre-meal garbage is crushed to a particle size of 2-20mm, and the anaerobic fermentation broth is filtered through a sieve with a pore size of 1mm to obtain the filtrate, and anaerobic is maintained during the sieve filtration process; the pre-meal garbage and the anaerobic fermentation broth are in a mass ratio of 1: 2 proportion mixing, the mass of pre-meal garbage is calculated on a dry basis; blow with high-purity nitrogen for 5 minutes, and maintain an anaerobic environment, keep the temperature at about 35°C, stir at a rate of 80r / min, stir for 10 minutes per hour, soak for 2 God, to be used;

[0031] Crush the food waste to a particle size of 2-40mm, add water at a rate of 50%, keep the pressure at 2Pa, stir at a rate of 100r / min, heat at 90°C for 30 minutes in wet heat pretreatment, and centrifuge at 8000r / min to remove the buoyant waste after cooling to room temperature. oil, spare;

[0032] The k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com