Melting incineration process system for hazardous waste disposal

A technology of hazardous waste and process system, applied in the field of hazardous waste treatment, can solve the problems of inability to dispose of hazardous waste on a large scale, consume heat energy, increase transportation costs, etc., achieve harmless and resource utilization, and solve secondary treatment. Problems, the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

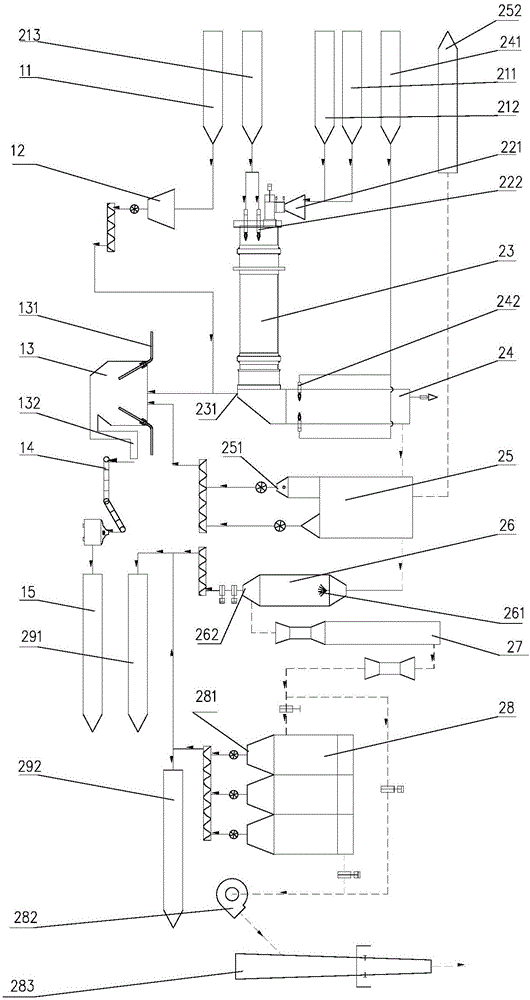

[0036] Such as figure 1 As shown, an incineration and melting process system for hazardous waste disposal includes a hazardous waste incineration line system and a high-temperature melting furnace system;

[0037] The hazardous waste incineration line system includes an incineration kiln 23, a secondary combustion chamber 24, a waste heat recovery device 25, a semi-dry acid removal reactor 26 and a dust collector 28 connected in sequence;

[0038] The kiln head of the incineration kiln 23 is provided with a feeding device 221 and a first spray gun 222, and the feeding device 221 is provided with a corresponding second feed end 211 and a third feed end 212, which are respectively used for adding solid waste and semi-dry The ash produced by the acid reactor 26 and the dust remover 28; the first spray gun 222 communicates with the fourth feed end 213, and the fourth feed end 213 is used for adding waste liquid. The kiln tail of the incineration kiln 23 is provided with a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com