High stability and high strength catalyst for synthesis of methanol and preparation method thereof

A technology for synthesizing methanol with high stability, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems such as the performance gap of catalysts for synthesizing methanol, and achieve improved reaction activity and stability, scientific design, The effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

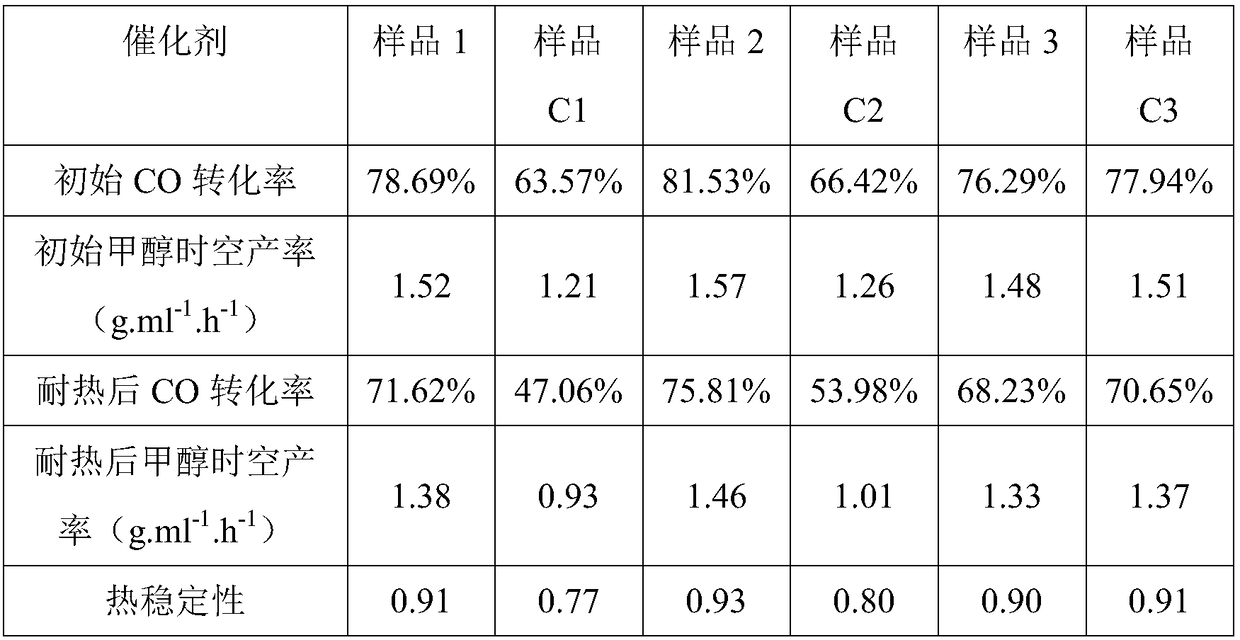

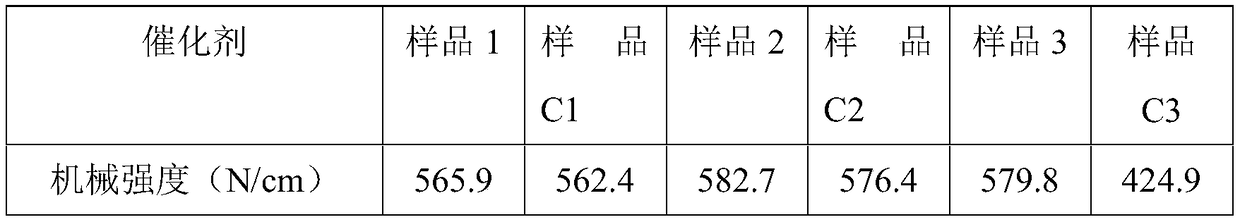

Embodiment 1

[0032] The present embodiment provides the preparation of the high-stability and high-strength synthetic methanol catalyst of the present invention, specifically:

[0033] Weigh 52.89g Zn(NO 3 ) 2 ·6H 2 O, 66.71g Al(NO 3 ) 3 9H 2 O, dissolved in 500ml deionized water, stirred to make it completely dissolved, and prepared as salt solution A. Weigh 272.6g Cu(NO 3 ) 2 ·3H 2 O, 92.11g Zn(NO 3 ) 2 ·6H 2 O, 66.71g Al(NO 3 ) 3 9H 2 O and 28.86g Mg(NO 3 ) 2 ·6H 2 O, dissolved in 1500ml deionized water, stirred to make it completely dissolved, and prepared as salt solution B. Weigh 233.78g NaCO 3 Dissolve in 2000ml of deionized water, and stir to make it completely dissolved, and prepare alkaline solution C.

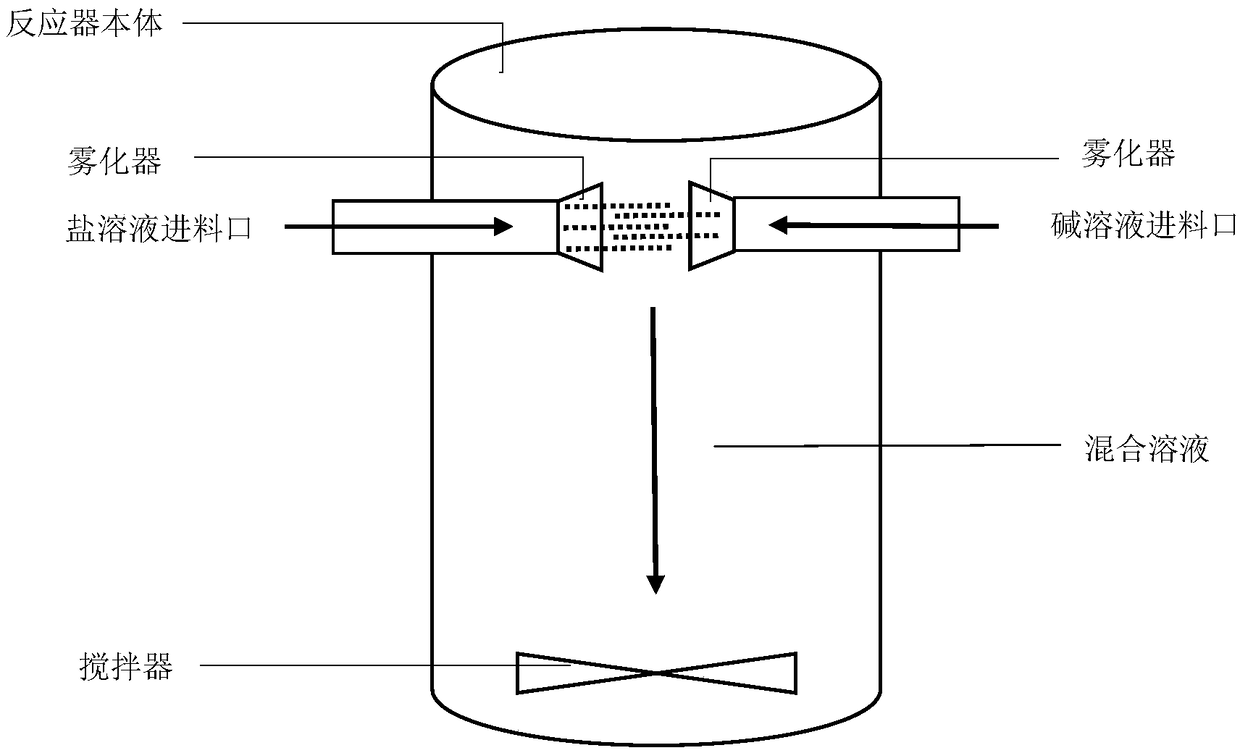

[0034] Preheat salt solution A, B and alkali solution C to 70°C, add appropriate amount of bottom water to the reactor, and preheat to 70°C as well. Both the salt and alkali feed inlets of the reactor are equipped with atomizers. The salt solution A and the al...

Embodiment 2

[0039] The present embodiment provides the preparation of the high-stability and high-strength synthetic methanol catalyst of the present invention, specifically:

[0040] Weigh 29.89g Zn(NO 3 ) 2 ·6H 2 O, 75.4g Al(NO 3 ) 3 9H 2 O, dissolved in 500ml deionized water, stirred to make it completely dissolved, and prepared as salt solution A. Weigh 289.73g Cu(NO 3 ) 2 ·3H 2 O, 86.11g Zn(NO 3 ) 2 ·6H 2 O, 75.4g Al(NO 3 ) 3 9H 2 O and 23.17g Mg(NO 3 ) 2 ·6H 2 O, dissolved in 1500ml deionized water, stirred to make it completely dissolved, and prepared as salt solution B. Weigh 304.62g KCO 3 Dissolve in 2000ml of deionized water, and stir to make it completely dissolved, and prepare alkaline solution C.

[0041] Preheat salt solution A, B and alkali solution C to 85°C, add appropriate amount of bottom water into the reactor, and preheat to 85°C as well. Add salt solution A and alkali solution B to the reactor dropwise. Simultaneously, the reactor was stirred and...

Embodiment 3

[0053] The present embodiment provides the preparation of the high-stability and high-strength synthetic methanol catalyst of the present invention, specifically:

[0054] Weigh 18.39g Zn(NO 3 ) 2 ·6H 2 O, 69.58g Al(NO 3 ) 3 9H 2 O, dissolved in 500ml deionized water, stirred to make it completely dissolved, and prepared as salt solution A. Weigh 347.7g Cu(NO 3 ) 2 ·3H 2 O, 68.6g Zn(NO 3 ) 2 ·6H 2 O, 69.58g Al(NO 3 ) 3 9H 2 O and 5.74g Mg(NO 3 ) 2 ·6H 2 O, dissolved in 1500ml deionized water, stirred to make it completely dissolved, and prepared as salt solution B. Weigh 233.78g NaCO 3 Dissolve in 2000ml of deionized water, and stir to make it completely dissolved, and prepare alkaline solution C.

[0055] Preheat salt solution A, B and alkali solution C to 80°C, add appropriate amount of bottom water into the reactor, and preheat to 80°C as well. Both the salt and alkali feed inlets of the reactor are equipped with atomizers. The salt solution A and the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com