Carbon-ceramic based brake pad

A technology of brake pads and ceramic bases, applied in the field of carbon ceramic base brake pads, can solve the problems of easy stripping and reduction of shear force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

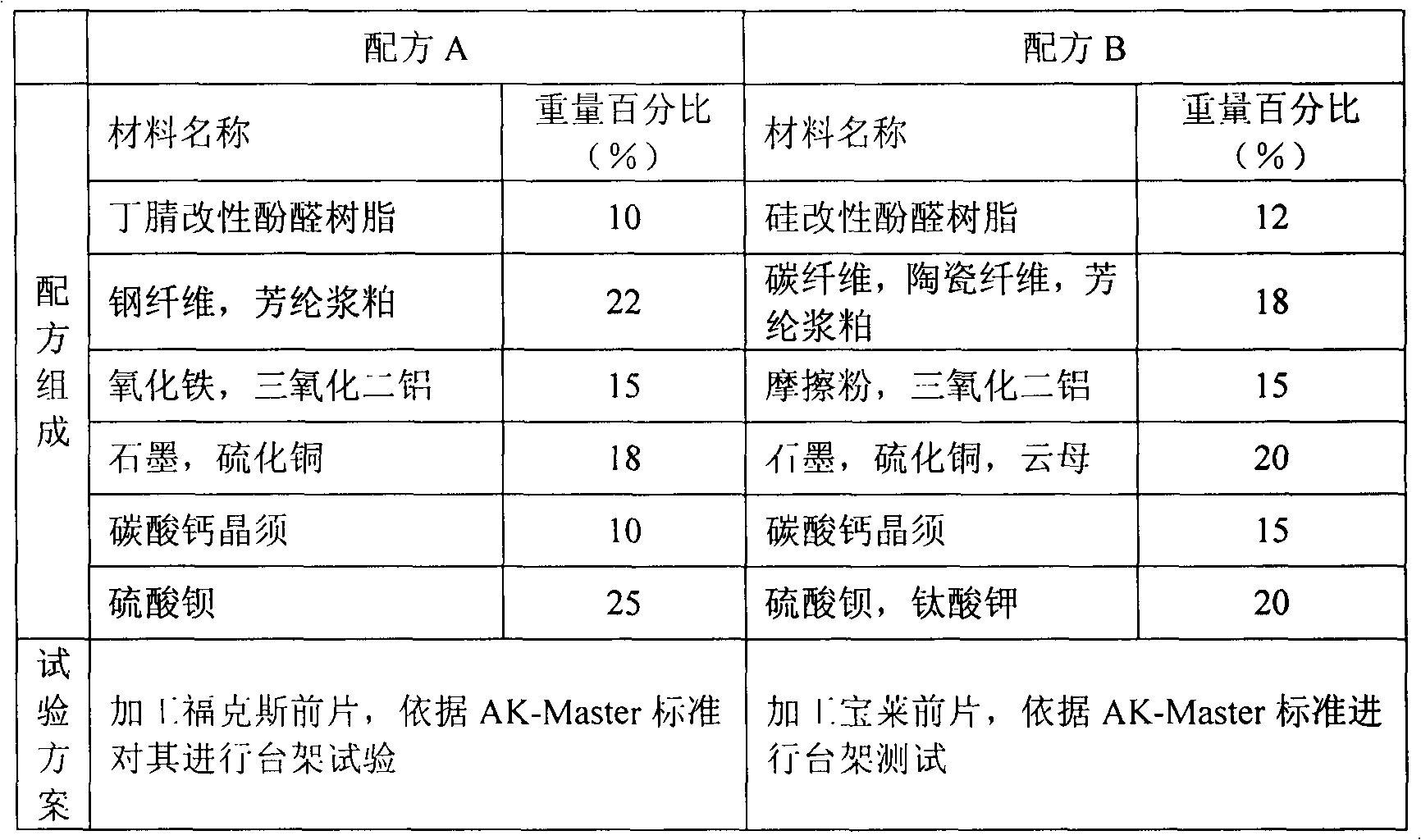

Embodiment 1

[0004] Embodiment 1, the carbon-ceramic-based brake pad formula includes binders, reinforcing materials, friction performance regulators and fillers. The binders include phenolic resins, silicon-modified phenolic resins and nitrile modified phenolic resins. The weight percentage of the binder is 5%; the reinforcement material is carbon fiber, ceramic fiber and aramid pulp, and the weight percentage of the reinforcement material is 20%; the friction performance regulator includes abrasives and lubricants, and the abrasives include aluminum oxide, oxide Iron, magnesium oxide and friction powder, the lubricant includes graphite, sulfide and mica, and the friction performance modifier is 20% by weight; the filler includes barium sulfate, potassium titanate and magnesium oxide, and the weight percentage of the filler is 30%.

Embodiment 2

[0005] Embodiment 2, the formula of the carbon-ceramic brake pad includes binder, reinforcing material, friction performance modifier and filler, and the binder includes phenolic resin, silicon-modified phenolic resin and nitrile modified phenolic resin. The weight percentage of the binder is 15%; the reinforcing material is carbon fiber, ceramic fiber and aramid pulp, and the weight percentage of the reinforcing material is 30%; the friction performance regulator includes abrasives and lubricants, and the abrasives include aluminum oxide, oxide Iron, magnesium oxide and friction powder, the lubricant includes graphite, sulfide and mica, and the friction performance modifier is 30% by weight; the filler includes barium sulfate, potassium titanate and magnesium oxide, and the weight percent of the filler is 50%.

Embodiment 3

[0006] Embodiment 3, the formula of the carbon-ceramic-based brake pad includes binders, reinforcing materials, friction modifiers and fillers. The binders include phenolic resins, silicon-modified phenolic resins and nitrile modified phenolic resins. The weight percentage of the binder is 10%; the reinforcing material is carbon fiber, ceramic fiber and aramid pulp, and the weight percentage of the reinforcing material is 25%; the friction performance regulator includes abrasives and lubricants, and the abrasives include aluminum oxide, oxide Iron, magnesia and friction powder, the lubricant includes graphite, sulfide and mica, the friction performance modifier is 25% by weight; the filler includes barium sulfate, potassium titanate and magnesia, and the weight percent of the filler is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com