Patents

Literature

35results about How to "Does not change the internal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

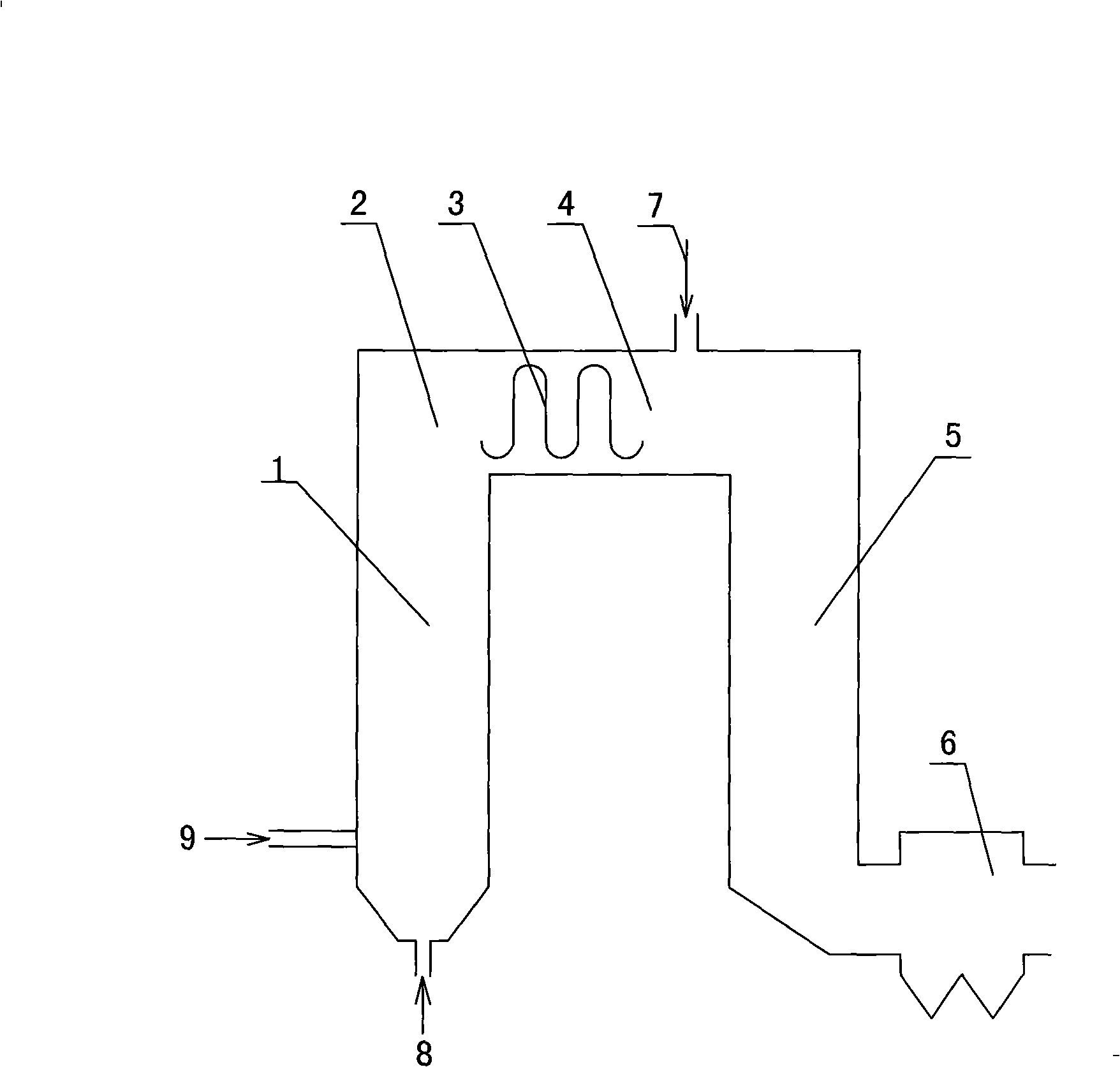

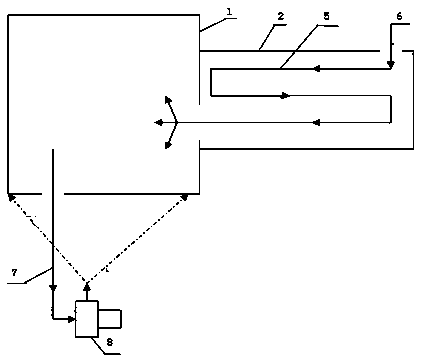

Circulating fluid bed boiler flue calcium injection and desulfurization process

InactiveCN101311628AChange internal structureDoes not affect performance indicatorsLighting and heating apparatusSocial benefitsFlue gas

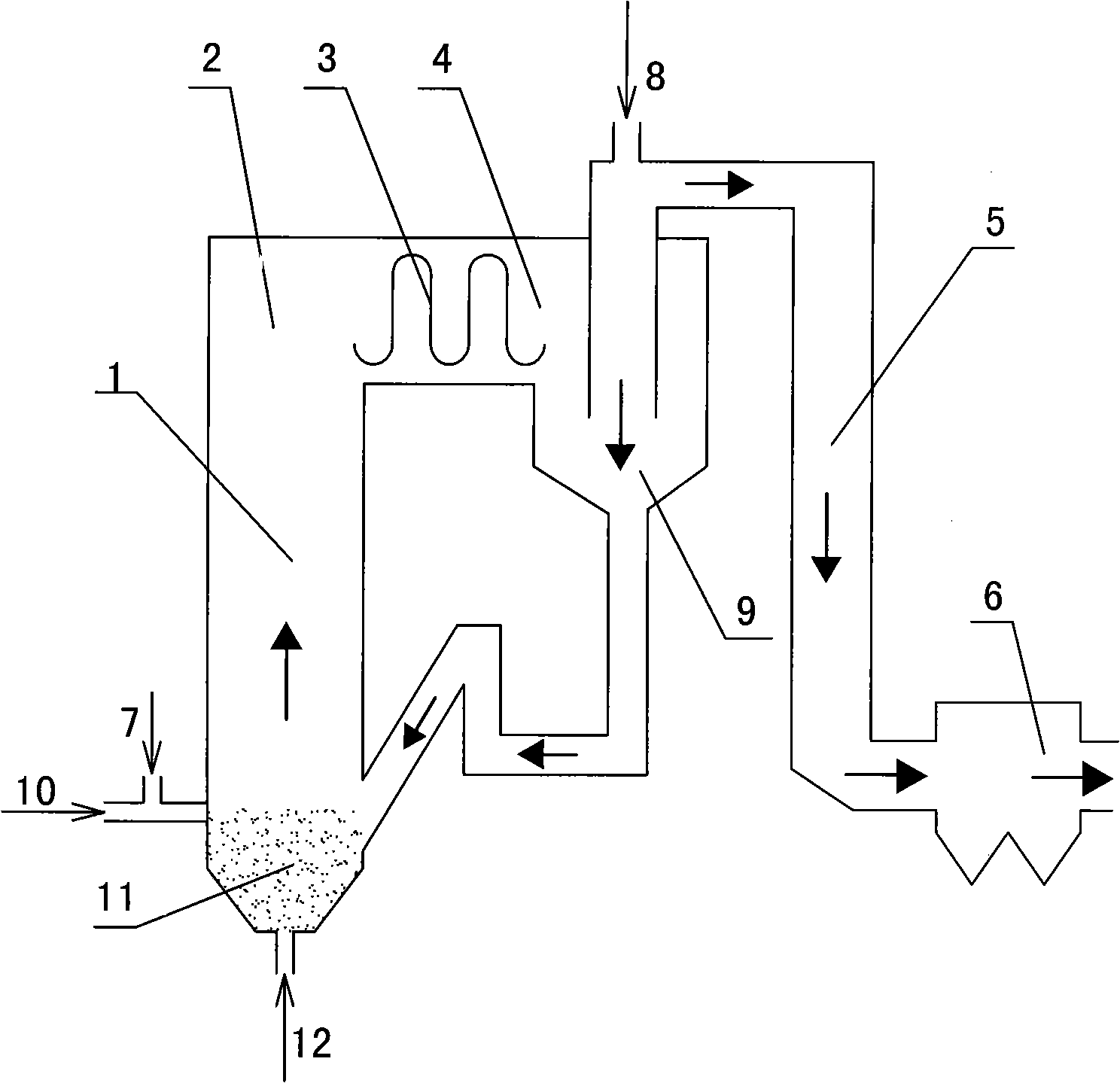

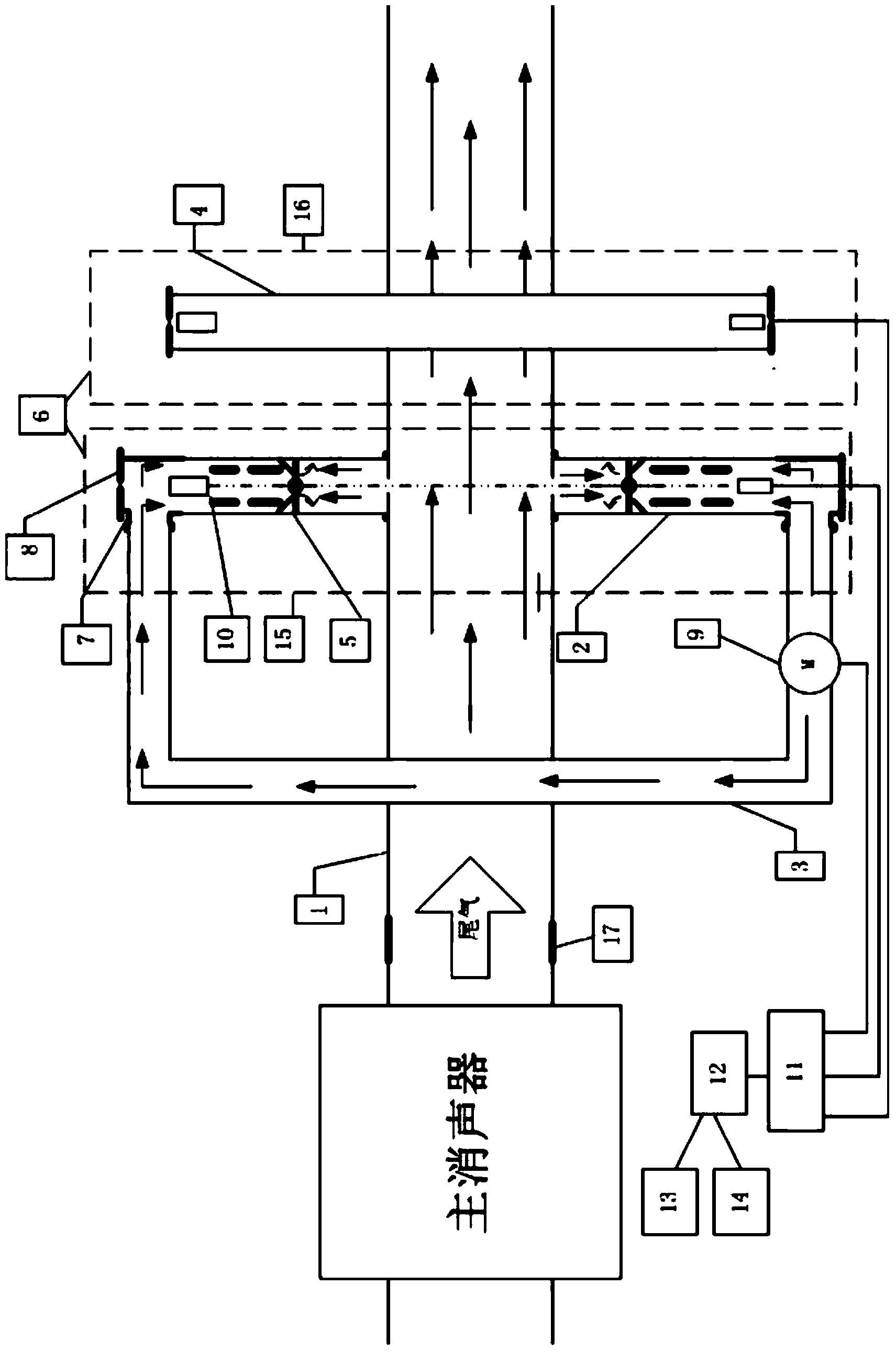

The flue gas injection calcium desulphurization process in a circulating fluidized bed boiler of the invention is characterized by sending CaO power to a horizontal flue of a cyclone separator with the temperature being equal or lesser than 850 DEG C or a first-level steam superheater or / and tail flue to carry out the desulphurization reaction for desulphurization. The concrete method is as following: spraying the desulfurizer power with the particle size being 100 to 800 items and the preference being 200 to 800 items to a furnace cavity through an overgrate air inlet, the middle part or the upper part of the furnace cavity of the boiler; wherein, the desulfurizer is limestone powder, raw lime powder or hydrated lime in powder. The device of the invention has the advantages of having a simple structure, not changing the inner structure of the boiler basically, not affecting the normal-index operation of the boiler, having high desulphurization efficiency, needing little investment and having low running cost, thereby realizing the ideal goal of low-cost desulphurization, achieving the perfect combination of economic benefit and social benefit of environmental-protection and discharging-reduction and having great popularization value.

Owner:YANKUANG GUOHONG CHEM

Dynamic correcting device of digital analog converter

InactiveCN103297049AImprove dynamic performanceReduce Harmonic DistortionAnalogue/digital conversion calibration/testingDigital analog converterCorrection method

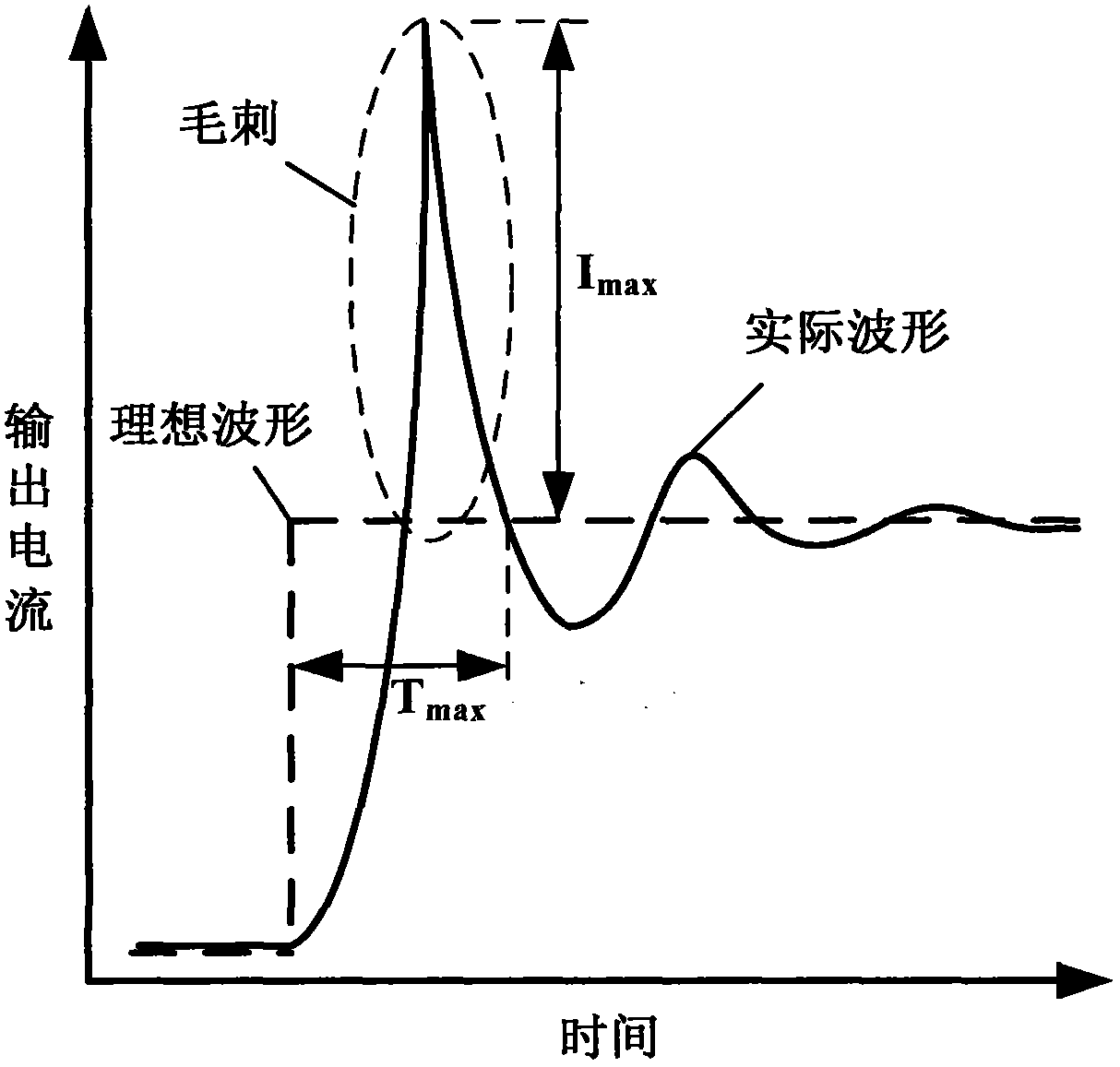

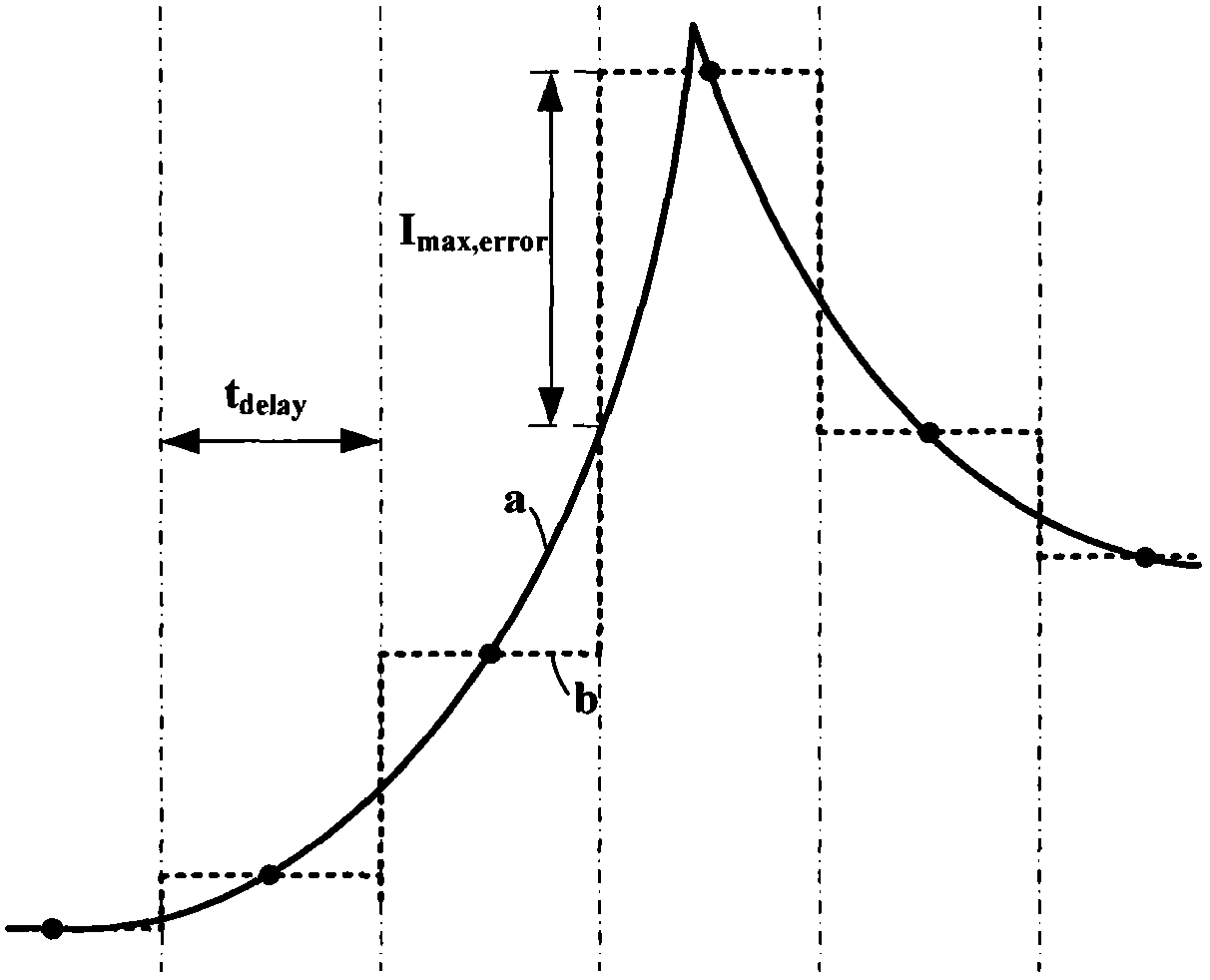

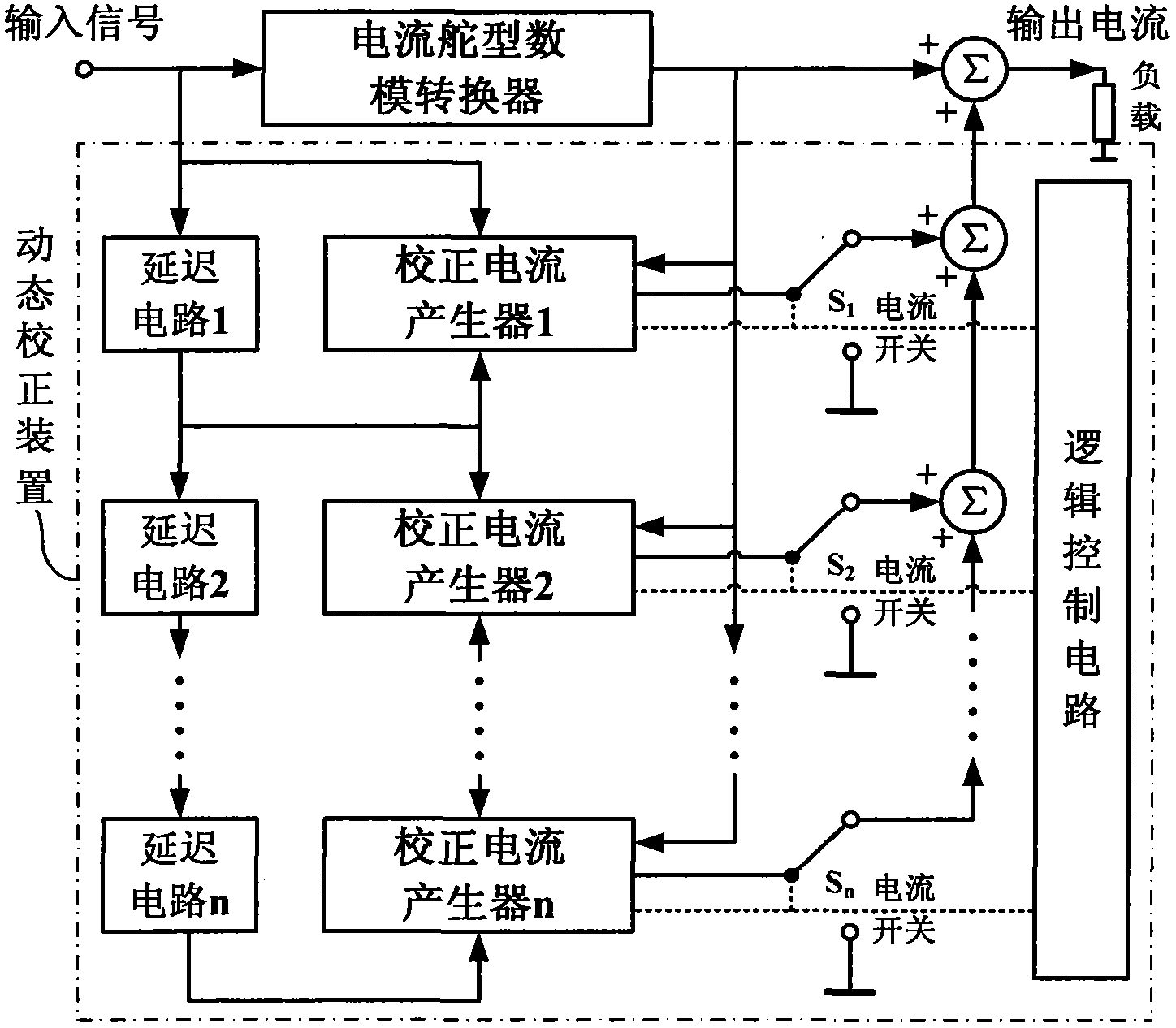

The invention provides a dynamic correcting device of a digital analog converter. The dynamic correcting device is added between input and output of a current-steering digital analog converter and comprises delay circuits, correcting current generators, current switches and a logic control circuit. Number of layers of correction channels formed by the delay circuits, the correcting current generators and the current switches can be flexibly set according to correction accuracy. A dynamic correcting method of the digital analog converter includes: in a correction preparation stage, sampling burrs, converting the burrs into correction information and storing the correction information; and in a normal working stage, reading the correction information, and outputting current pulses to compensate burr signals. Multiplex correction current pulses are superposed to correct output current of the digital analog converter successively in a time-phased mode, burrs of the output current are compensated and offset, the technical problem of over-low dynamic performance caused by the burrs is solved, and the internal structure of the digital analog converter is unchanged; the circuit dynamic performance is improved, impact on circuit speed and accuracy is small, and range of use is wide.

Owner:XIDIAN UNIV

Fume eject-calcium desulfurizing techinique in pulverized coal fired boiler

InactiveCN101306305ADoes not change the internal structureDoes not affect operationDispersed particle separationBoiler furnaceEconomic benefits

The invention relates to a desulphurization process of limestone injection into a furnace for a pulverized coal boiler. The desulphurization process is characterized in that desulphurization agent powder with the particle size of 100 to 800 meshes is injected into the furnace from a horizontal flue behind a first-stage steam superheater of the boiler, the desulphurization reaction is carried out in the flue for desulphurization, and the desulphurization agent is limestone powder, lime powder or hydrated lime powder. A device of the invention is simple and has no change of the internal structures of the boiler or the impacts on the operation of the boiler according to normal indicators. The desulphurization efficiency is high, the investment is low, the operation cost is low and the ideal target of low-cost desulphurization is realized, thereby achieving the perfect combination of economic benefits and social effects of environmental protection and emission reduction, and having great popularization value.

Owner:YANKUANG GUOHONG CHEM

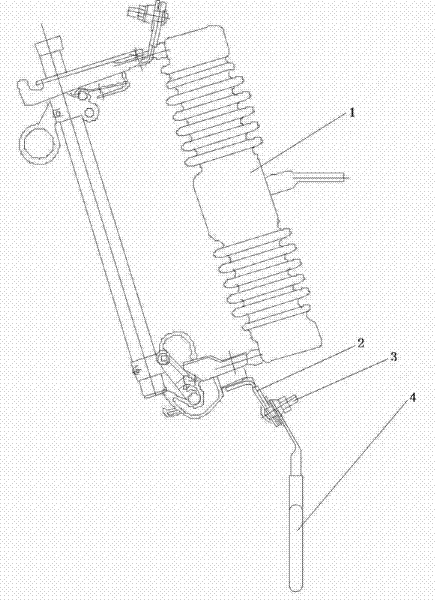

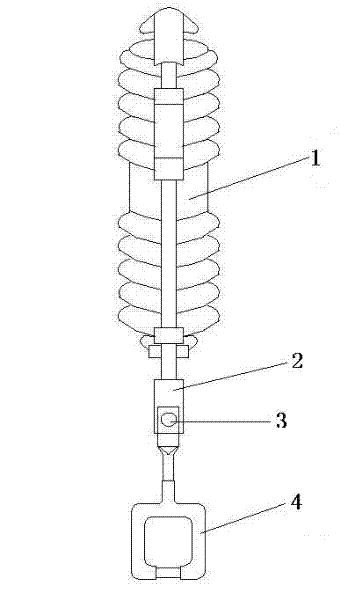

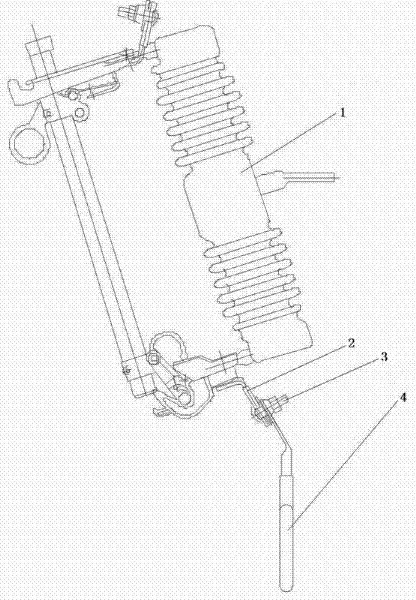

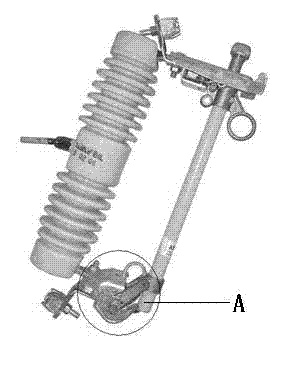

Grounding device for falling-type fuse

InactiveCN102354639AEasy to installEasy to useEmergency protective devicesEngineeringMechanical engineering

Owner:NINGYANG POWER SUPPLY

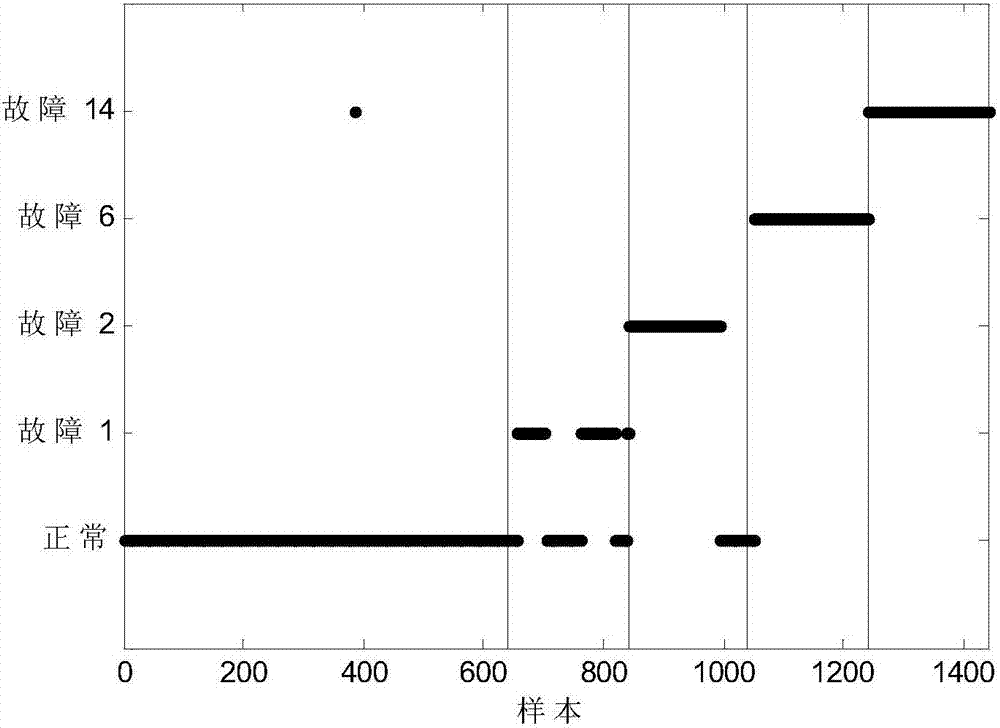

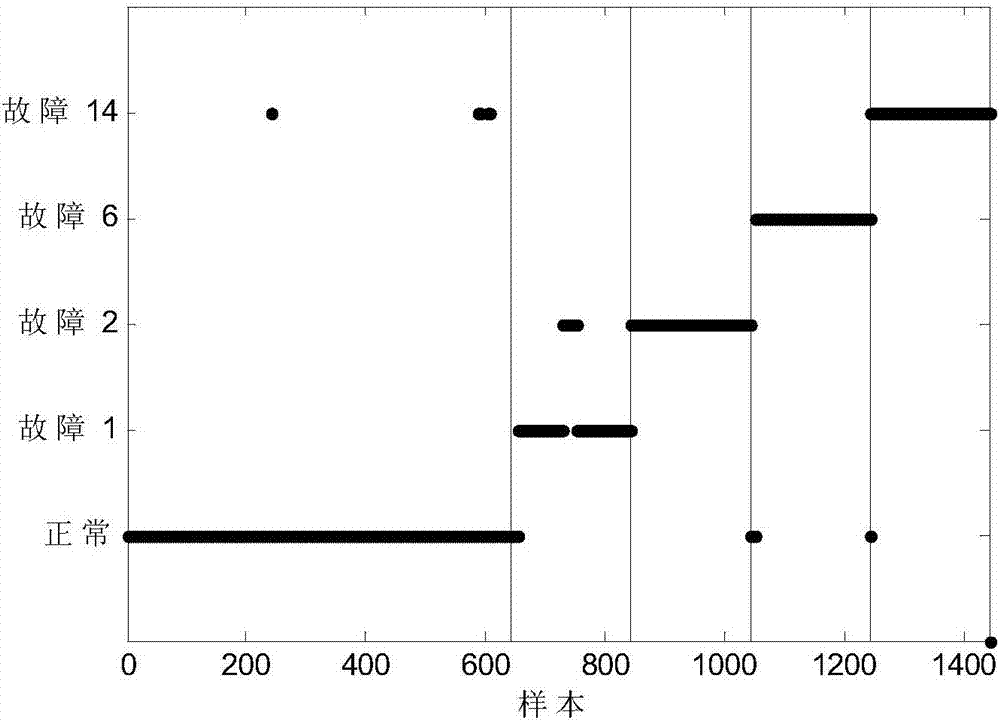

Imbalanced data industrial fault classification method based on k-means

InactiveCN107239789AChange internal structureSolve classification problemsCharacter and pattern recognitionMajority classNaive Bayes classifier

The invention discloses an imbalanced data industrial fault classification method based on k-means. The method comprises the following steps: first, utilizing the k-means; based on the imbalance degrees, clustering the classes with relatively big data; dividing the majority classes into N sub-classes; combining the N sub-classes with M minority classes to serve as a multi-classification problem for an (M+N) classification; and finally, performing learning according to a naive bayes classifier. Compared with other existing methods in prior art, the method of the invention keep the information of the original data to the largest extent and better resolves the problem with imbalanced class data classification under the condition that over-fitting is prevented. Therefore, compared with other methods, the classification precision is increased, and the phenomenon of over-fitting can be reduced.

Owner:ZHEJIANG UNIV

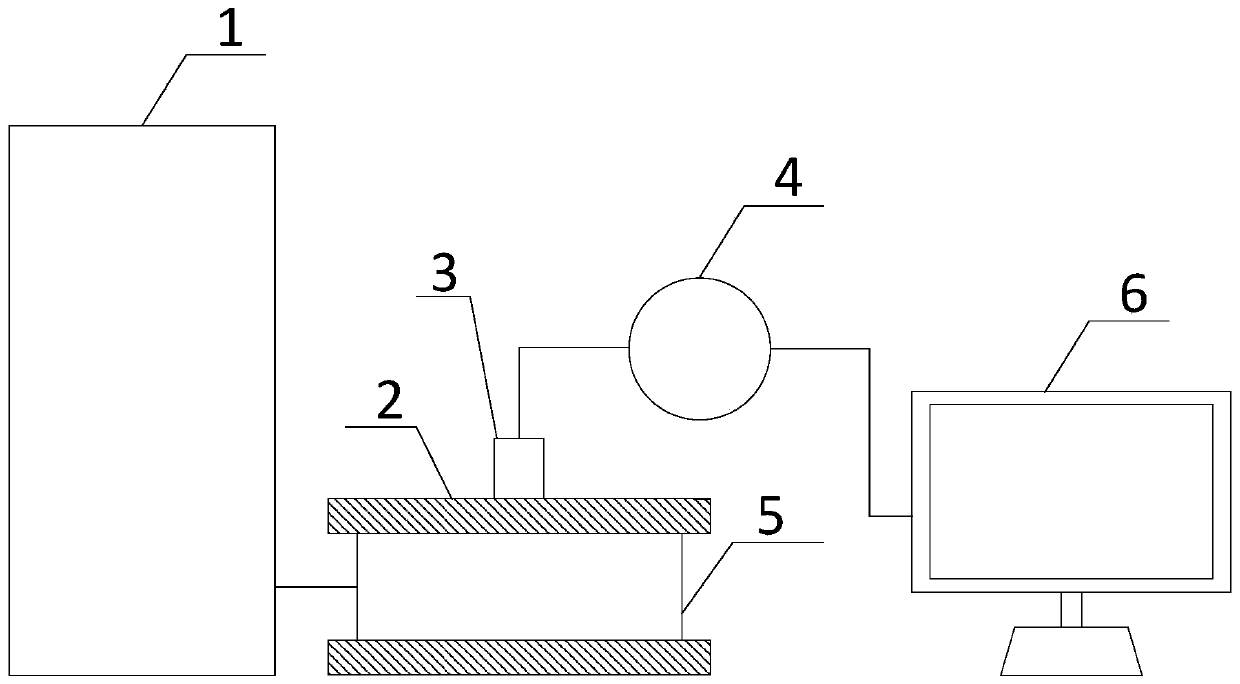

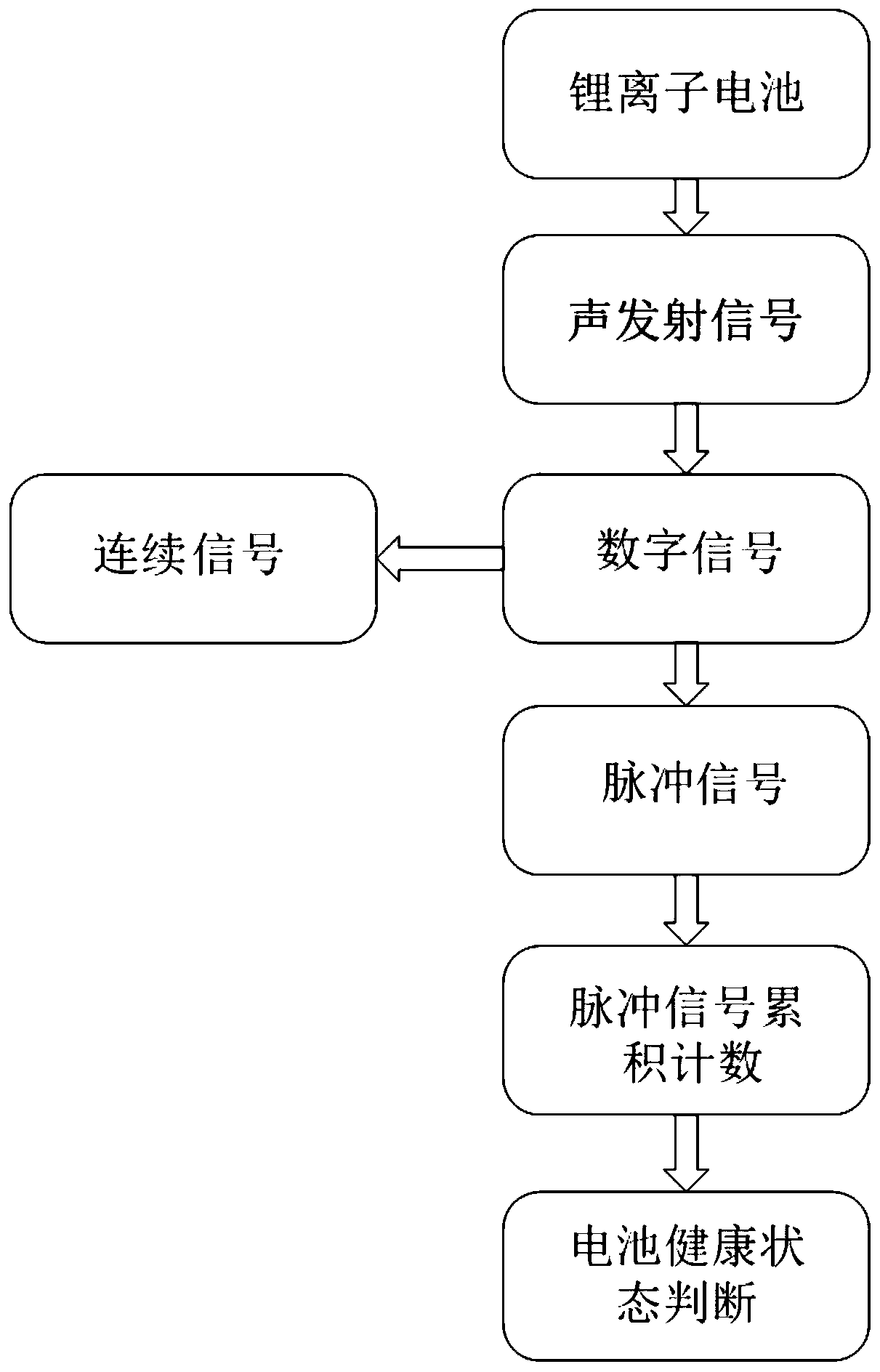

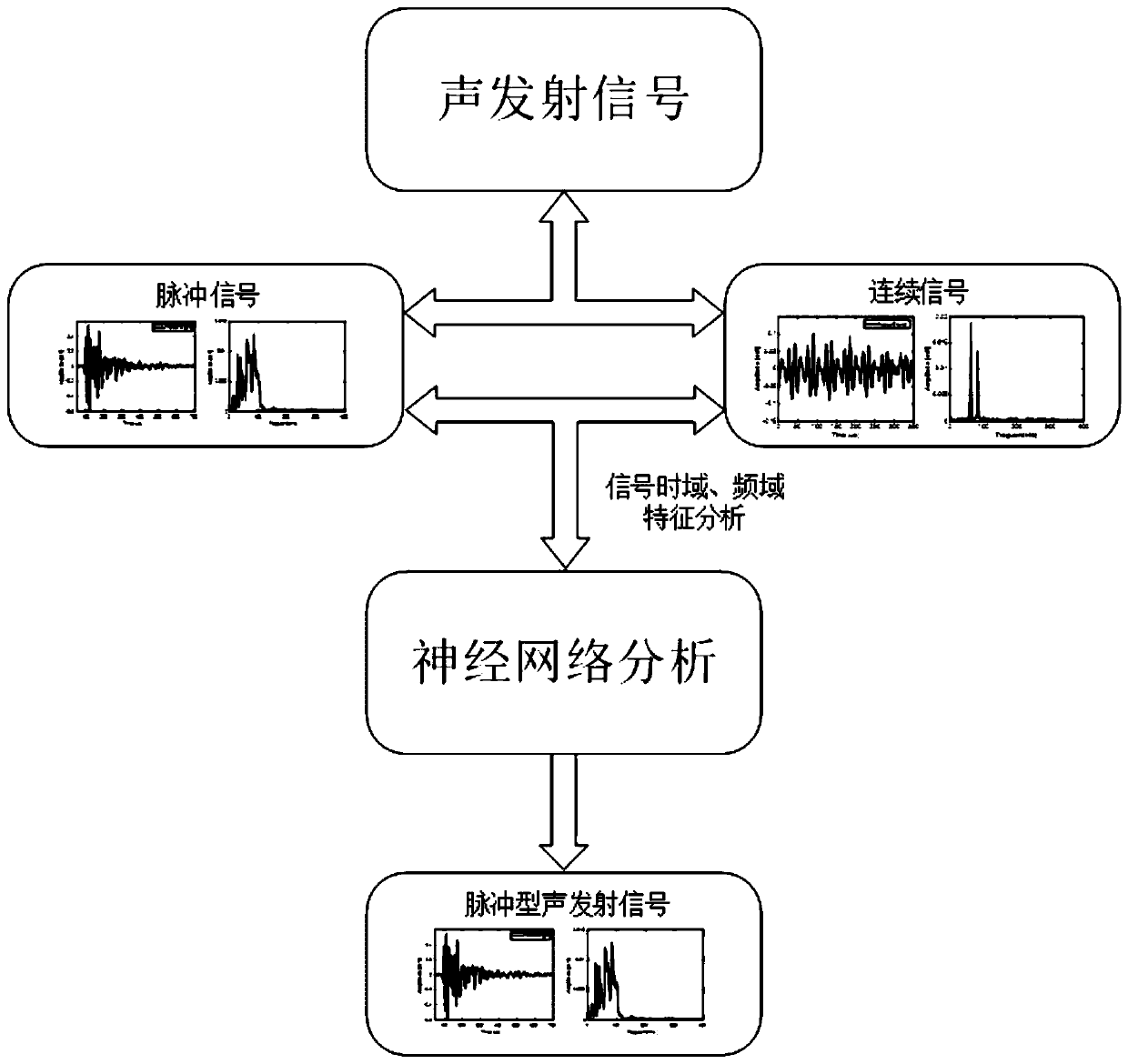

System and method for detecting health state acoustic emission of lithium ion battery

PendingCN110441707AImprove securityDoes not change the internal structureMaterial analysis using acoustic emission techniquesElectrical testingElectrical batteryCharge and discharge

The invention provides a system for detecting the health state acoustic emission of a lithium ion battery. The charging and discharging equipment is electrically connected with the lithium ion batteryand is used for charging or discharging the lithium ion battery; an acoustic emission sensor is used for receiving an acoustic emission signal inside the lithium ion battery and converting the acoustic emission signal into an electric signal; a processing terminal is electrically connected with the acoustic emission sensor; and the processing terminal is used for receiving the electric signal output by the acoustic emission sensor. The system belongs to non-embedded detection, does not change the internal structure of the lithium ion battery, and improves the safety of the detection of the lithium ion battery.

Owner:SHENZHEN POLYTECHNIC

Manufacturing process for antistatic hard coating plastic film

ActiveCN102199305AChange internal structureNo change in basic performanceElectrically-conductive paintsPolyester coatingsLiquid-crystal displayUltraviolet

Disclosed is a manufacturing process for an antistatic hard coating plastic film, comprising a first step of coating an antistatic hard coating onto the surface of a plastic film substrate and a second step of irradiating the antistatic hard coating with ultraviolet rays so as to react organosilicon with multifunctional acrylate monomers under the condition of an initiator. The antistatic hard coating plastic film provided in the invention has not only excellent antistatic performance, but also good sharpness and scratch resistance. Therefore, such antistatic hard coating plastic films can beused in liquid crystal display devices or be used as films for the protection of various image display devices.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

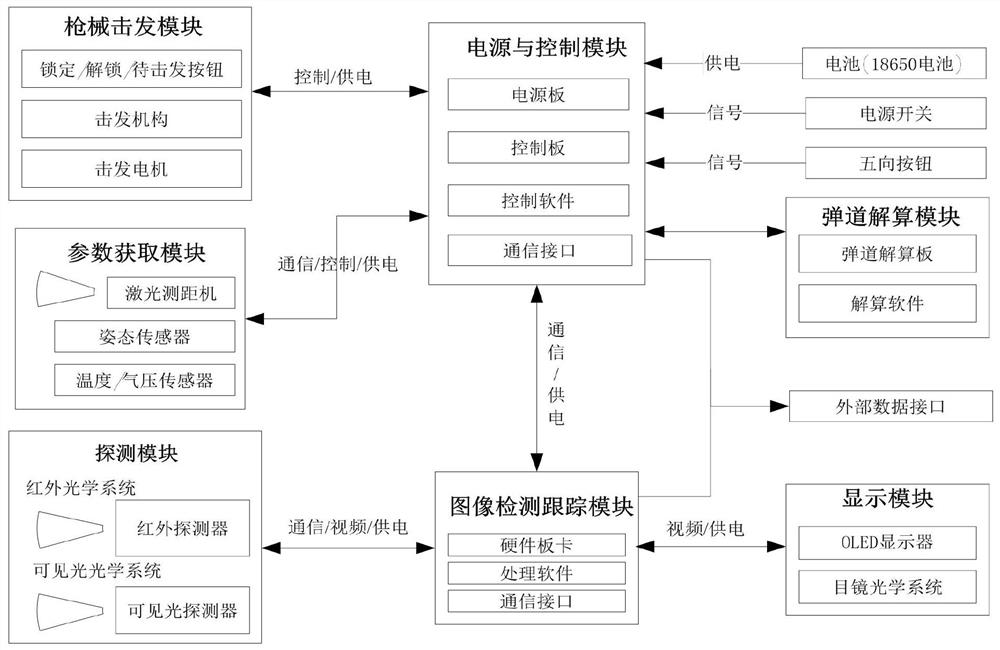

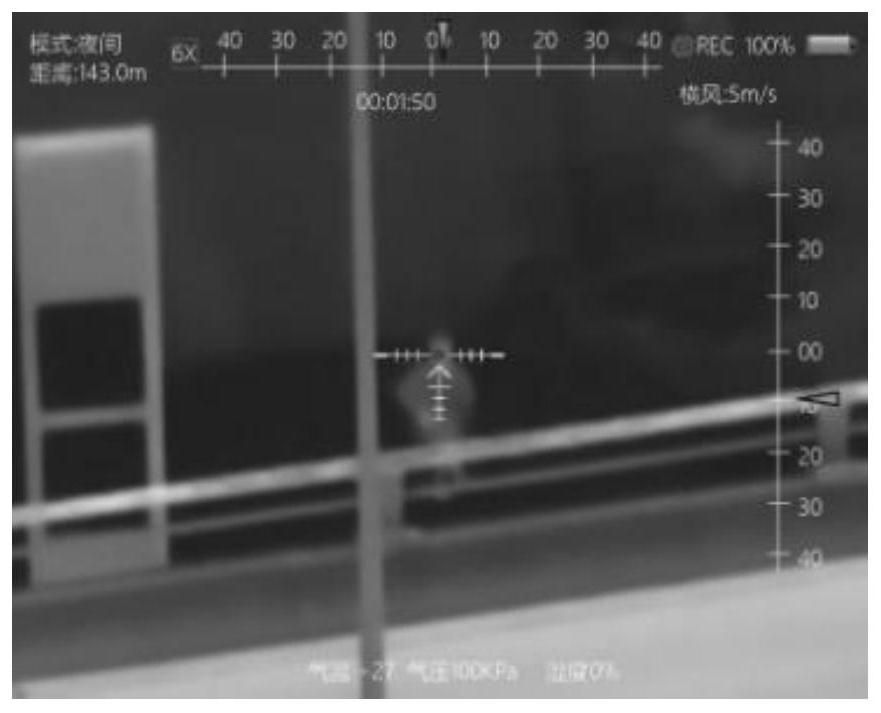

Day and night intelligent sighting telescope system

PendingCN112378291ARealize automatic perceptionDoes not change the shape and structureSighting devicesOptical detectionImage detectionEngineering

The invention discloses a day and night intelligent sighting telescope system, and belongs to the technical field of intelligent sighting equipment. The day and night intelligent sighting telescope system comprises a detection module, a trajectory calculation module, an image detection tracking module, a display module, a power supply and control module, a parameter acquisition module and a firearm firing module. According to the day and night intelligent sighting telescope system provided by the invention, the functions of day and night target detection, environmental parameter automatic sensing, automatic recognition and tracking, intelligent ballistic calculating, target mark and aiming point matching and intelligent firing are achieved while the appearance and the internal structure ofan original firearm are not changed, and the first hit rate is increased to 90% or above; and a shooter can select intelligent shooting or original manual shooting by himself / herself. And meanwhile,the day and night intelligent sighting telescope system can be suitable for various gun types such as 5.8mm gun types, 7.62mm gun types, 8.6mm gun types, 12.7mm gun types and 35mm gun types in domestic active service, and only firing tables of the corresponding gun types need to be input.

Owner:江苏北方湖光光电有限公司

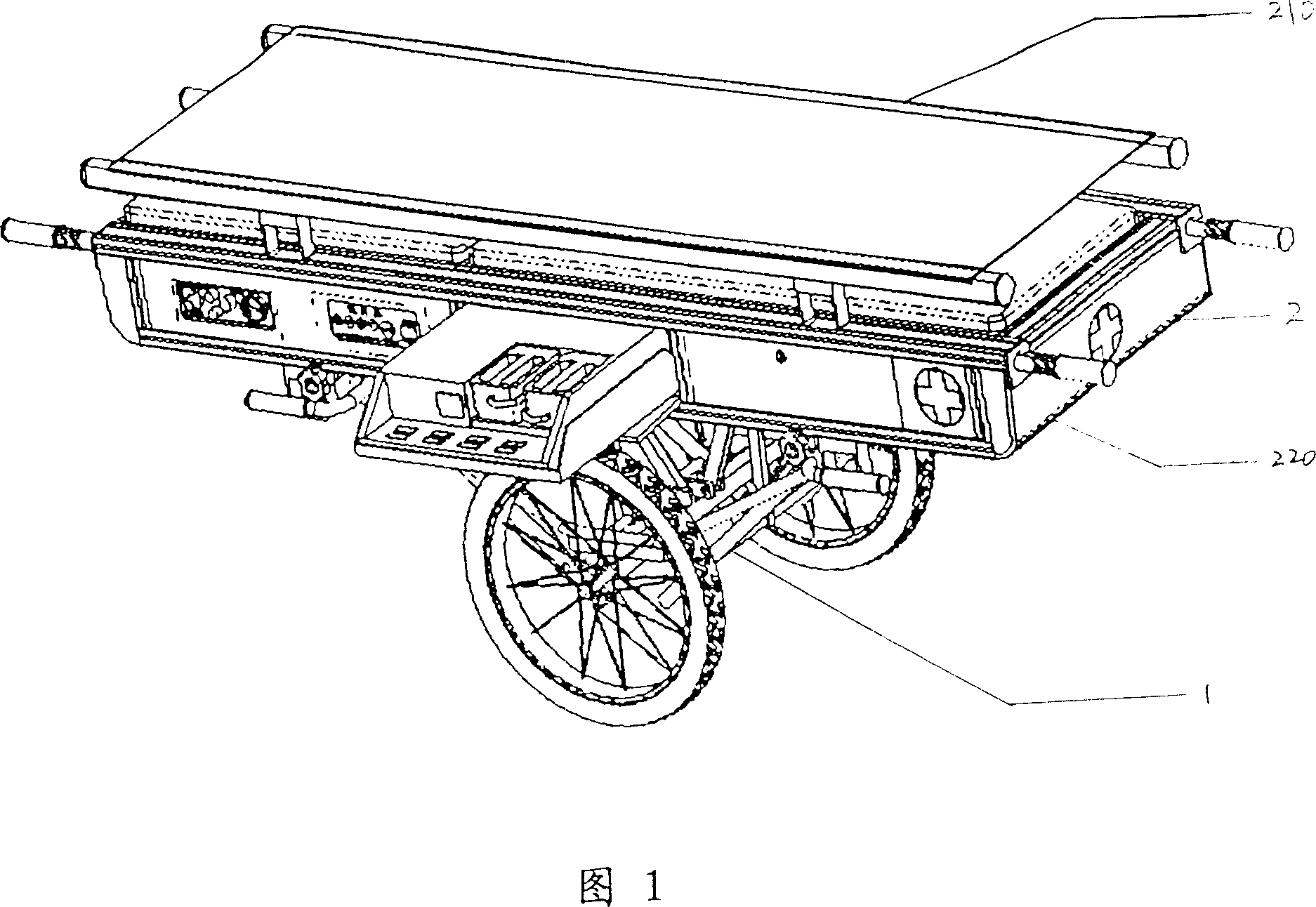

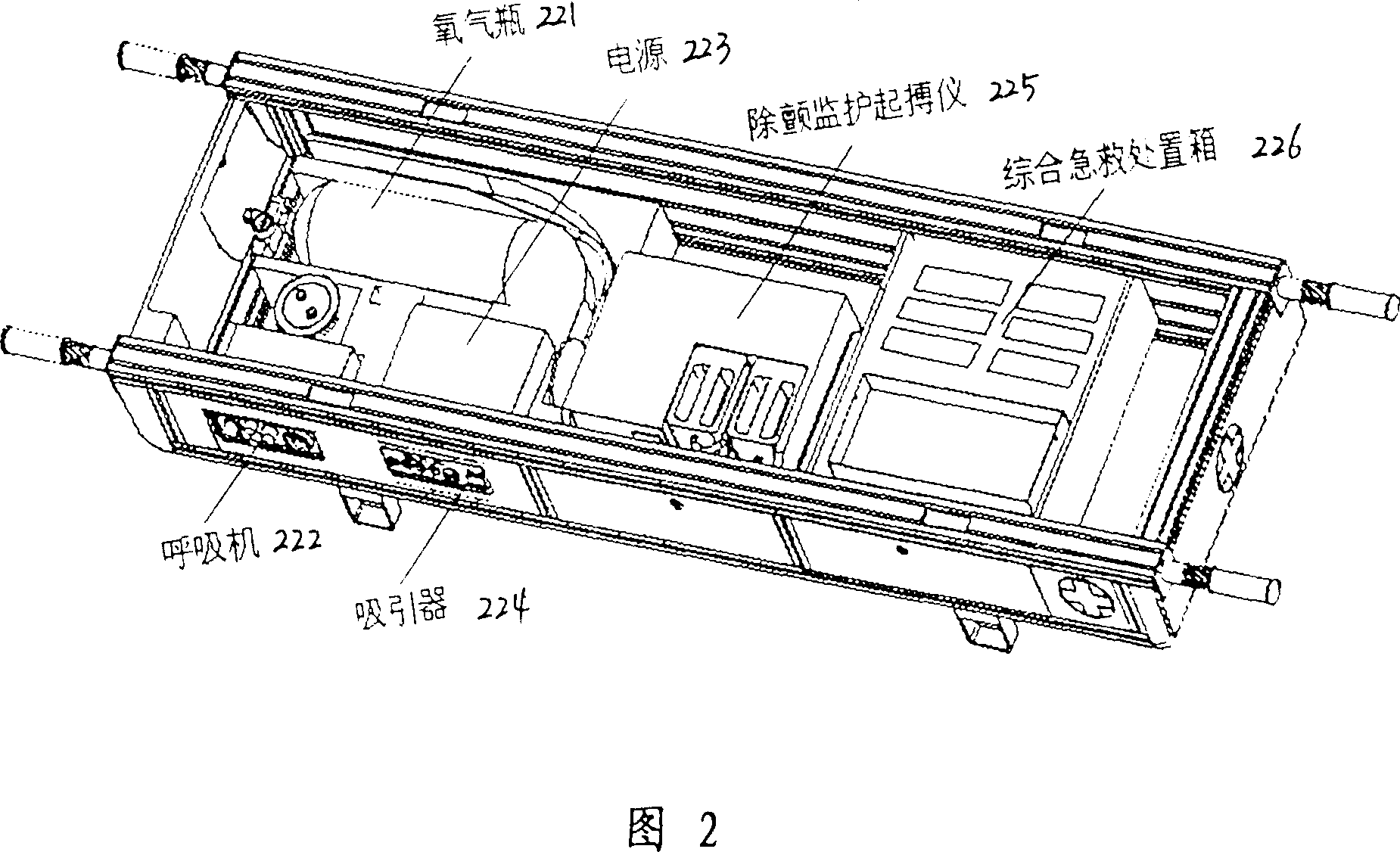

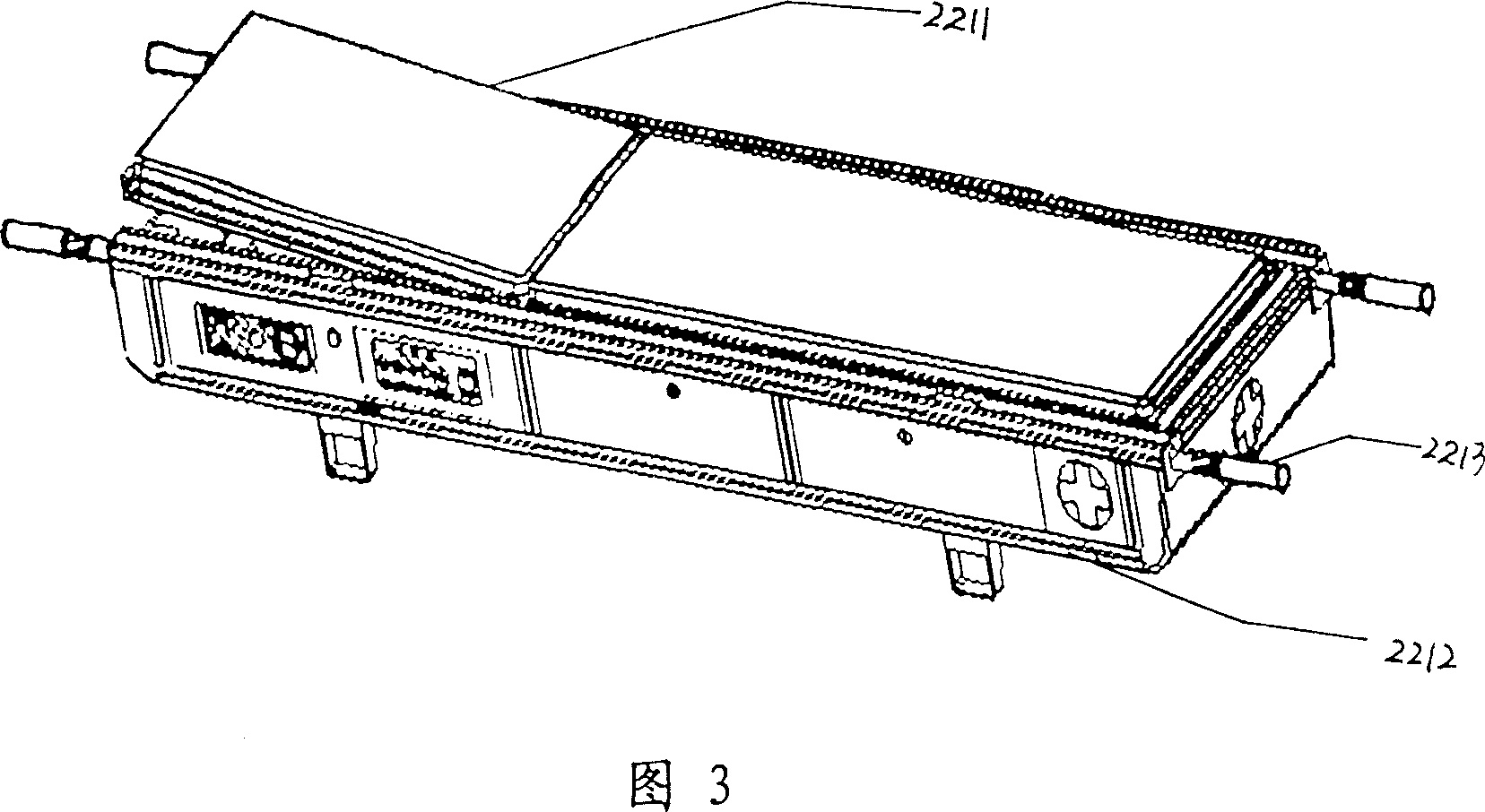

Stretcher assembly type complex emergency treatment system

InactiveCN1305454CEnsure timelinessEnsure continuityStretcherFirst-aid kitsEmergency treatmentElectromagnetic interference

The integrated stretcher type comprehensive emergency treatment system includes at least integrated stretcher, supporting and transporting unit and power supply apparatus. The integrated stretcher and the supporting and transporting unit may be separated and inside the integrated stretcher there are essential first aid equipment and power supply apparatus. The present invention is used for in-situ salvage and monitoring of serious patient and makes it possible to perform interrupted salvage and monitoring in different transportation apparatus.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

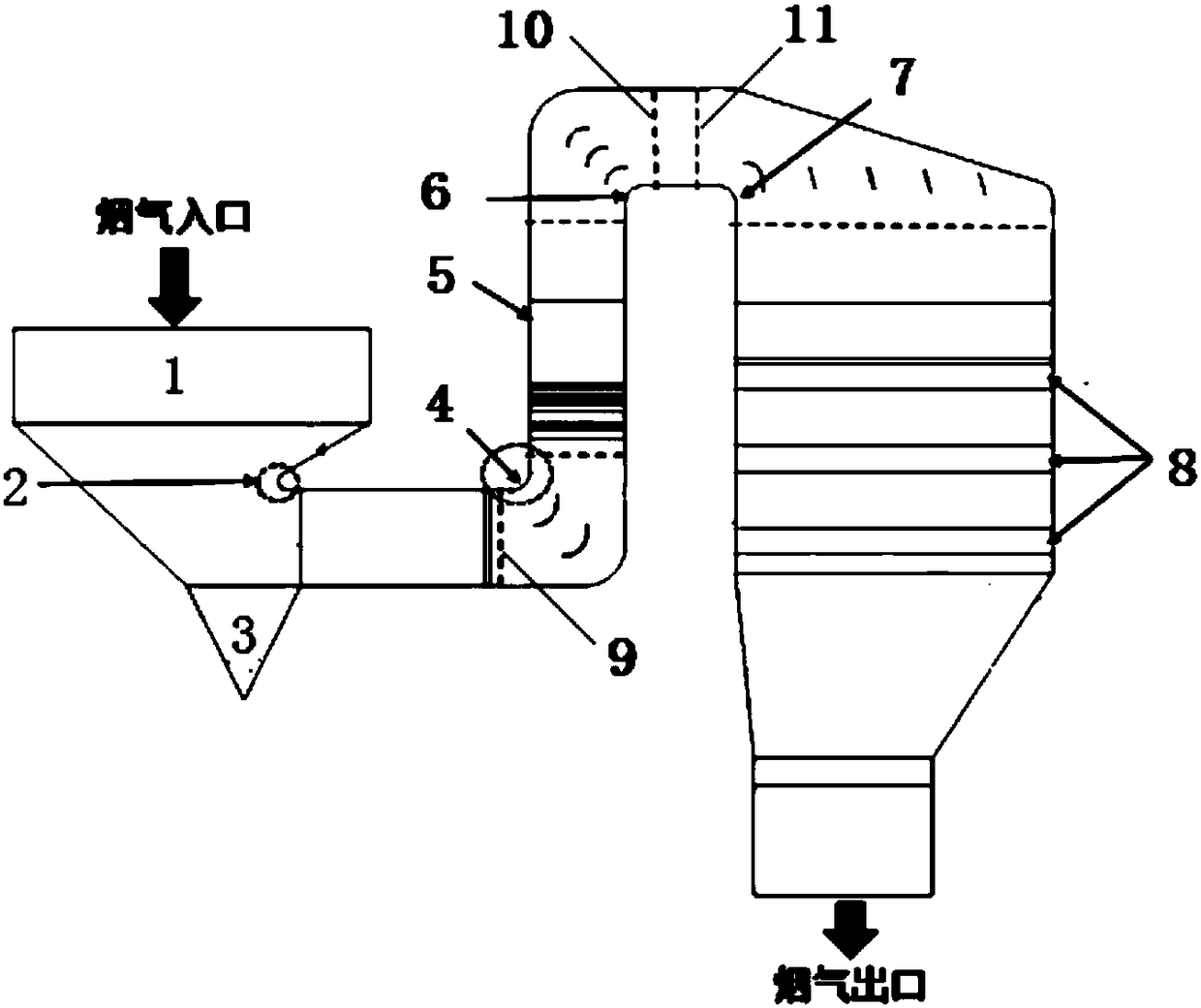

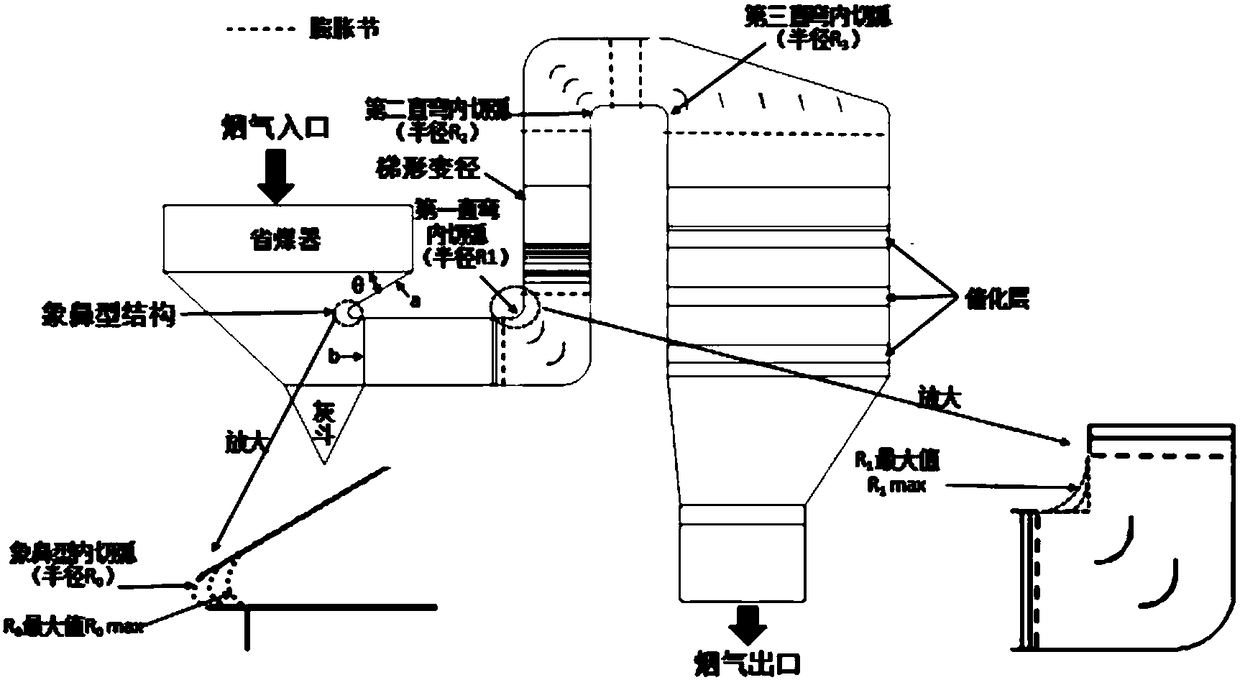

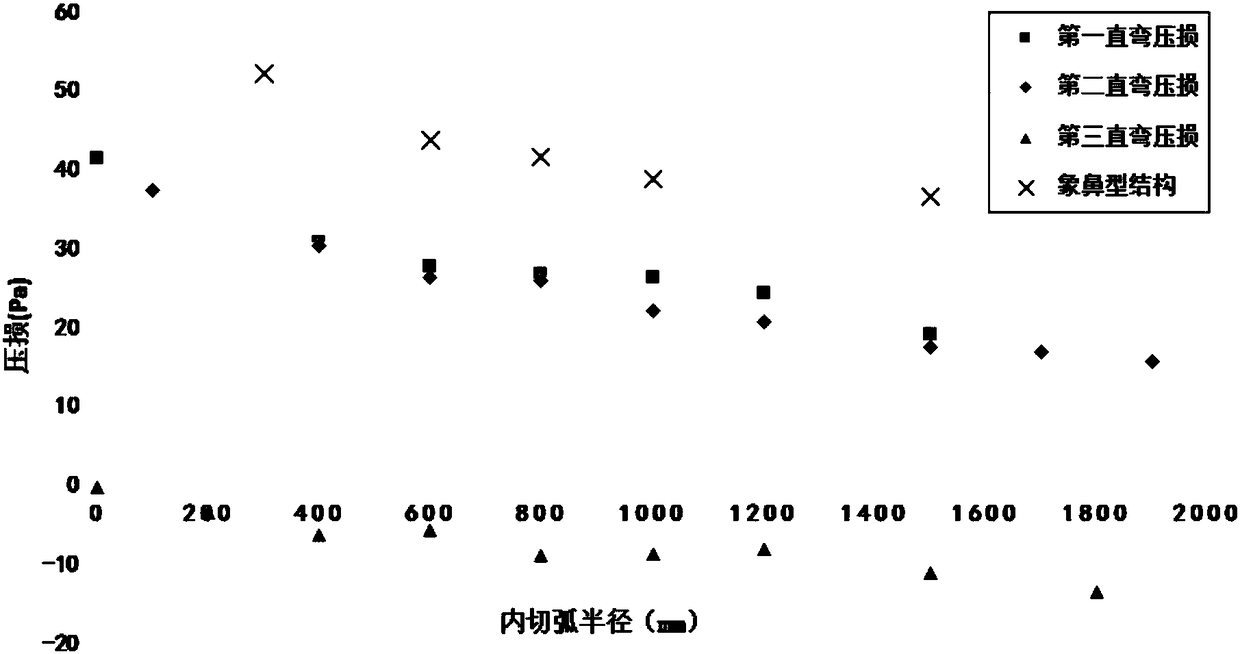

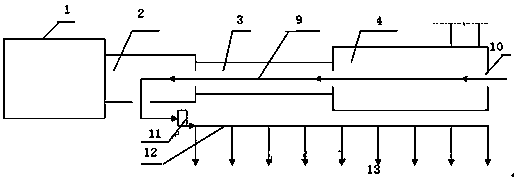

Optimization designing method of flue structure for reducing pressure loss of SCR denitrification device

InactiveCN108187493ADoes not affect velocity field uniformityPotential for reducing self-consumption electricity consumptionGas treatmentDispersed particle separationField uniformityRelative standard deviation

The invention provides an optimization designing method of a flue structure for reducing pressure loss of an SCR denitrification device. According to the method, optimization designing is conducted onthe radius of internally tangent arcs of various bends under the premise that the plane flue gas velocity distribution relative standard deviation above a catalyst layer is sufficiently low, so thatthe pressure loss of each bend is minimized within a given radius range; optimized flue shape parameters comprise the inner tangent arc radius of an elephant-trunk-like structure of an economizer, andthe inner tangent arc radius of first, second, third right-angled bends of a pi-type denitrification device. The pressure loss of the denitrification device is an important indicator affecting the energy consumption of a thermal power induced draft fan, and for a 1000MW unit, every reduced 10Pa of the pressure loss leads to 140,000 kilowatt-hour reduction of the self-use electricity consumption of the induced draft fan every year, so that low-pressure-loss shape designing of the denitrification device has a realistic meaning of energy saving and efficiency enhancing on a power plant; in addition, the optimization designing of the flue gas structure does not generate negative impacts on the flue gas velocity field uniformity above the catalyst layer but increases the uniformity of the fluegas velocity field, which means the velocity distribution standard deviation of the flue gas velocity field is reduced.

Owner:上海电气电站环保工程有限公司 +1

Manufacturing process for antistatic hard coating plastic film

ActiveCN102199305BDoes not change the internal structureNo change in basic performanceElectrically-conductive paintsPolyester coatingsLiquid-crystal displayUltraviolet

Disclosed is a manufacturing process for an antistatic hard coating plastic film, comprising a first step of coating an antistatic hard coating onto the surface of a plastic film substrate and a second step of irradiating the antistatic hard coating with ultraviolet rays so as to react organosilicon with multifunctional acrylate monomers under the condition of an initiator. The antistatic hard coating plastic film provided in the invention has not only excellent antistatic performance, but also good sharpness and scratch resistance. Therefore, such antistatic hard coating plastic films can be used in liquid crystal display devices or be used as films for the protection of various image display devices.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

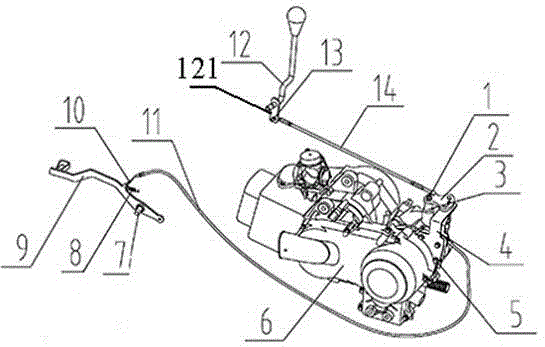

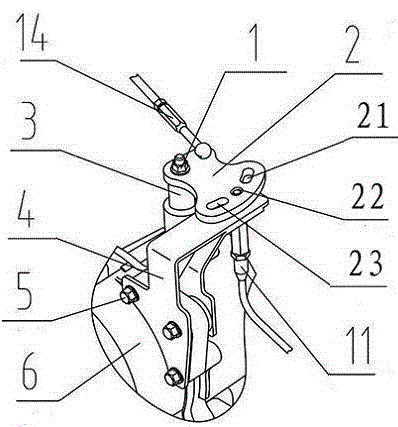

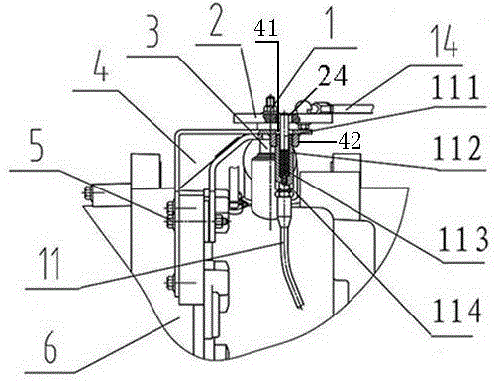

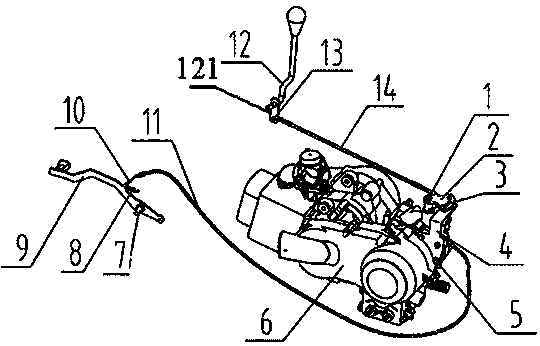

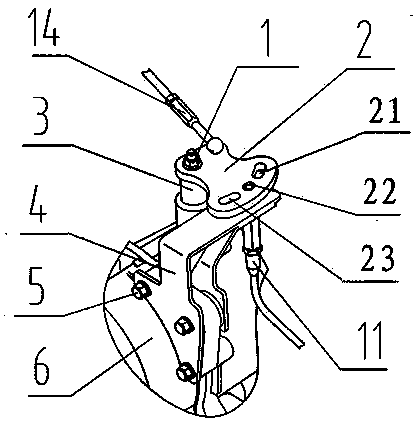

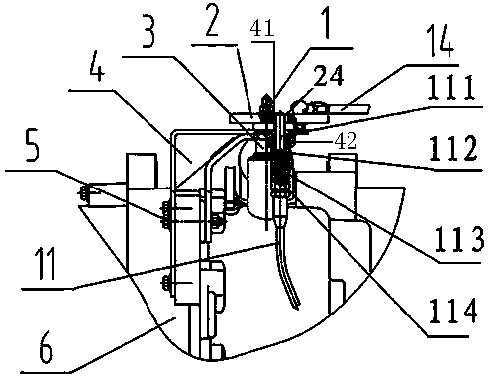

Engine gearbox external gear shifting locking device

ActiveCN105546111AImplement shift lock functionSimple structural designGearing controlVehicle frameLocking mechanism

The invention discloses an engine gearbox external gear shifting locking device which is characterized in that the device comprises an engine (6), a braking limiting mechanism and a gear shifting locking mechanism; the braking limiting mechanism comprises a brake foot lever (9) and a limiting dragline (11); the gear shifting locking mechanism comprises a gear shifting handle (12) rotationally mounted on a vehicle frame, a spline plate (2) and a gear shifting shaft (3); the brake foot lever (9) is in limiting connection with the spline plate (2) through the limiting dragline (11); and the gear shifting handle (12) is sequentially and correspondingly connected with the spline plate (2), the gear shifting shaft (3) and a shifting fork mechanism arranged on a gearbox housing through a gear shifting drawbar (14). The device is reasonable and simple in structural design, low in manufacturing cost, and convenient to mount and use, and is safe and reliable, and effectively realizes the engine gearbox gear shifting locking function.

Owner:JIANGSU LINHAI POWER MACHINERY GROUP

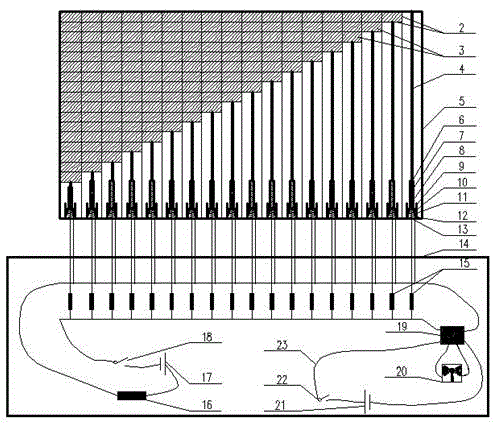

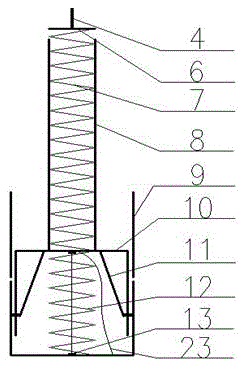

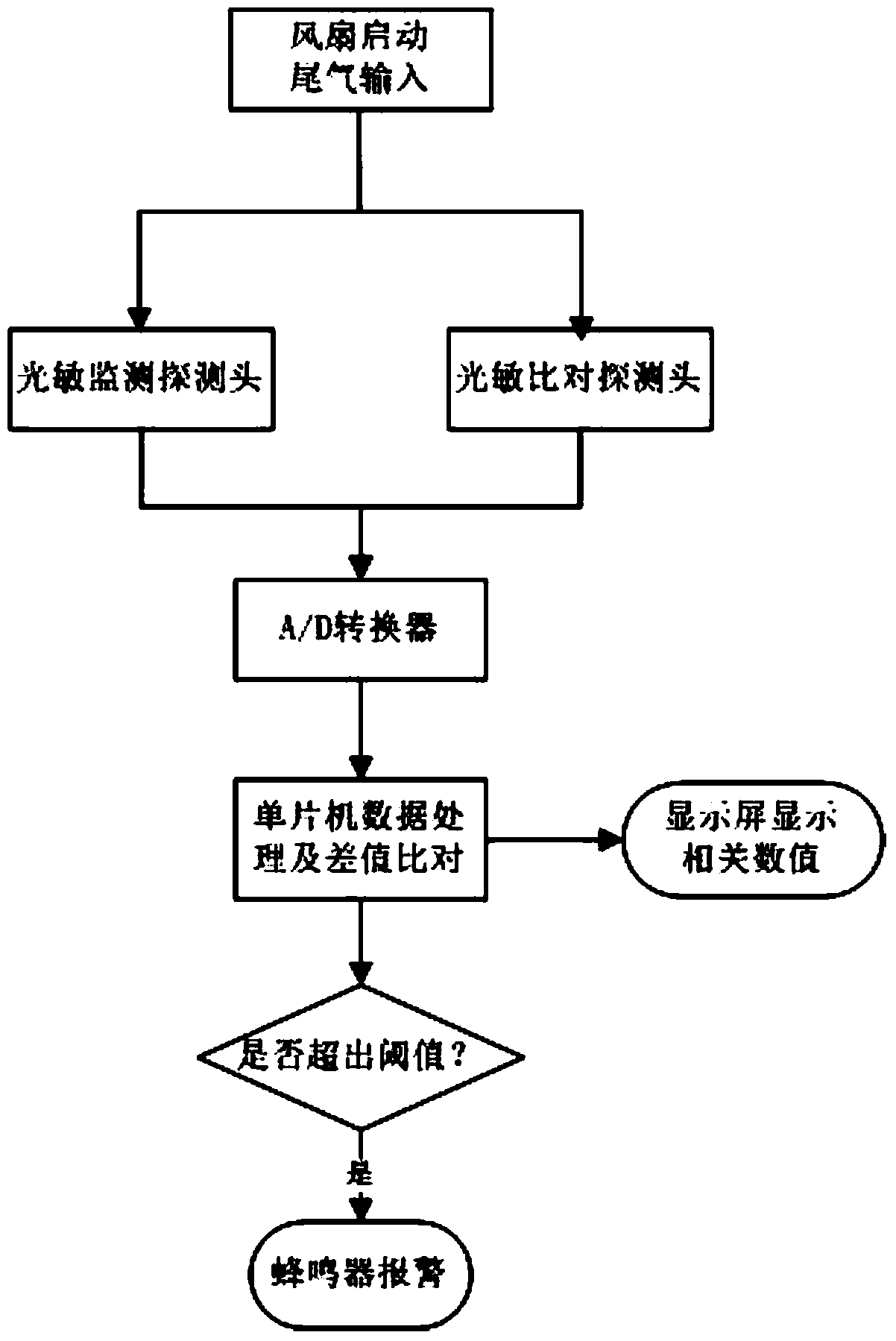

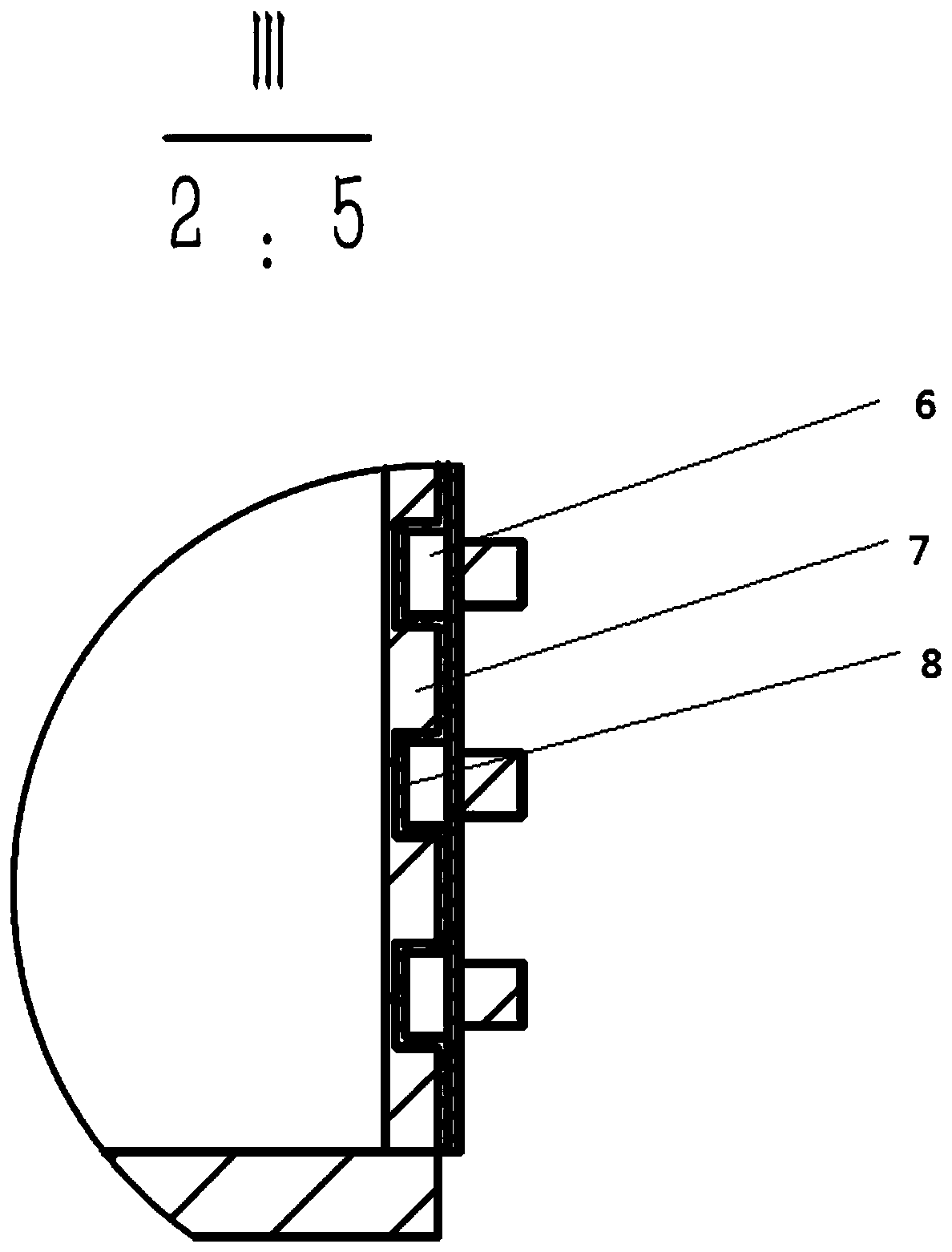

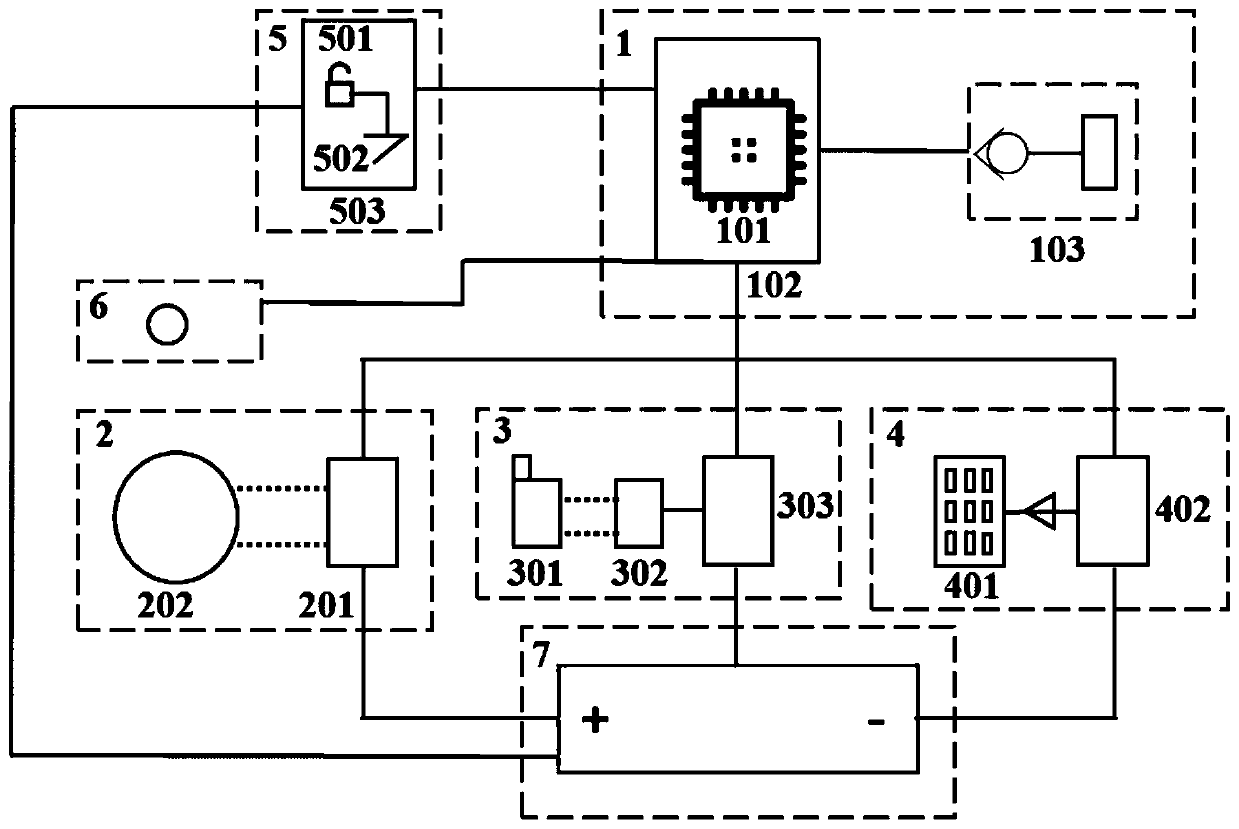

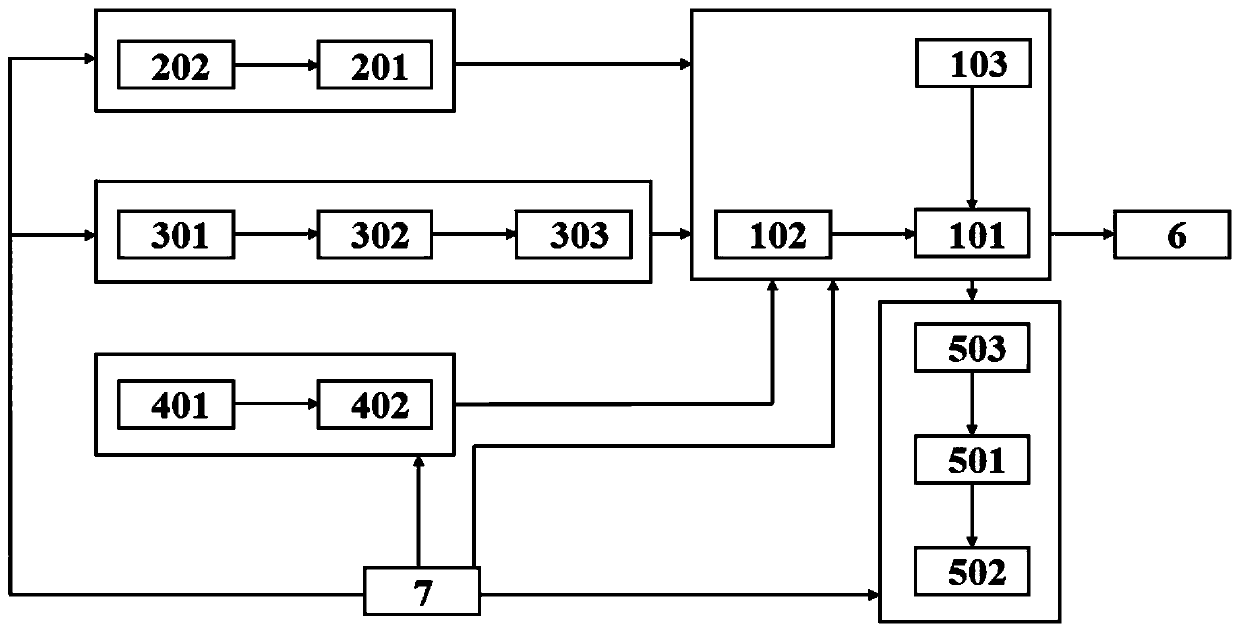

Online real-time shield scraper wear monitoring system

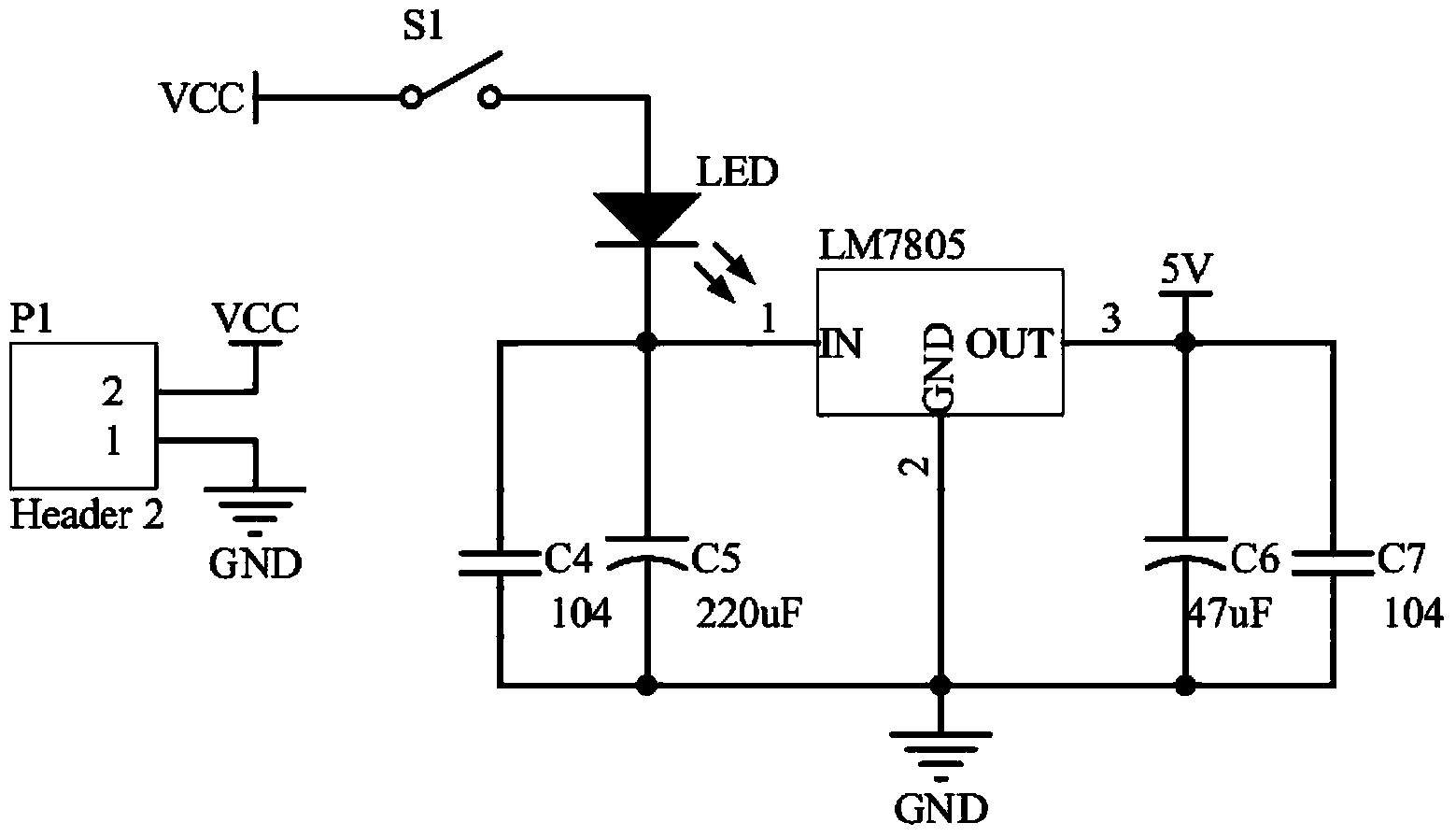

ActiveCN105627899ADoes not change the internal structureMeet the needs of wear monitoringUsing electrical meansMicrocomputerMicrocontroller

The invention discloses an online real-time shield scraper wear monitoring system, which comprises a shield scraper, a wear sensing device, a data acquisition circuit and a data processing module, wherein the wear sensing device comprises a metal box shell, the metal box shell is internally provided with multiple vertical and horizontal equidistantly-arranged steel sheets and spring trigger modules, the metal box shell is fixedly arranged on the back surface of the shield scraper, the horizontal steel sheets are shortened step by step from top to bottom, the lower ends of the spring trigger modules are fixedly connected with the lower end of the metal box shell, and the upper ends of the spring trigger modules abut against the horizontal steel sheets; the data acquisition circuit is formed by multiple parallel resistors, a power supply and a switch in serial connection via wires and each resistor is connected with a movable block in a corresponding spring trigger module via a wire; and the data processing module comprises a single chip microcomputer processor and a wireless transmitting module. Thus, real-time monitoring can be carried out on the wear amount of the shield scraper, the sensitivity and the range are adjustable, intrusion of water and rock slag can be prevented, and the system can be applied to a harsh shield tunneling environment.

Owner:WUHAN UNIV

Degradation early-warming apparatus for diesel engine emission

InactiveCN103398928AReduce volumeLight materialParticle suspension analysisDigital analog converterDisplay device

The invention relates to the field of apparatuses and systems for vehicle emission degradation early-alarming and vehicle exhaust pollution control, and specially relates to a degradation early-warming apparatus for diesel engine emission. The degradation early-alarming apparatus comprises a vehicle-outside main part and a vehicle-inside main circuit board part; the vehicle-outside main part mainly consists of a main pipe, two branch pipes respectively symmetrically fixedly disposed at the exterior of the two through holes on the wall of the main pipe, a comparison-device installing pipe fixedly disposed above the exterior of the main pipe, and two sets of photoelectric coupling signal detectors respectively disposed in the branch pipe and the comparison-device installing pipe; the vehicle-inside main circuit board part mainly consists of a digital-analog converter, a control processor connected with the digital analog converter, and a display and an alarm both connected with the control processor; and the photoelectric coupling signal detectors is connected with the digital analog converter. The apparatus is small in volume, portable in material and low in production cost, and has no influence on vehicle appearance and no influence on vehicle normal use; and the apparatus is disposed on the diesel engine vehicle for real-time monitor, is convenient for problem discovery, and is easy to popularize.

Owner:JILIN UNIV

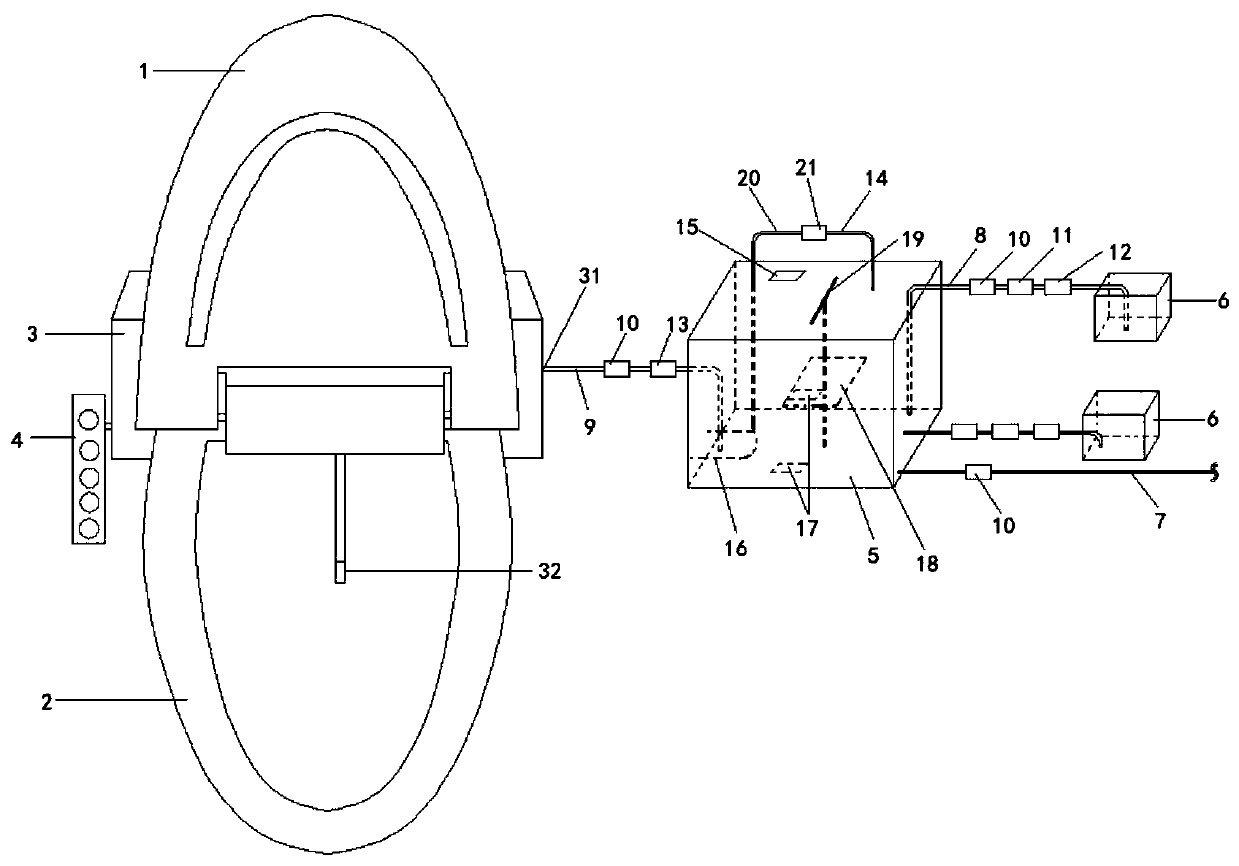

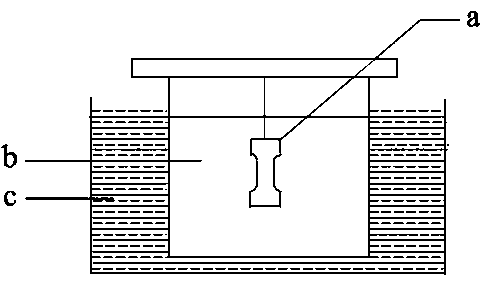

Neutral buoyancy trimming device for realizing wrist structure of underwater mechanical arm

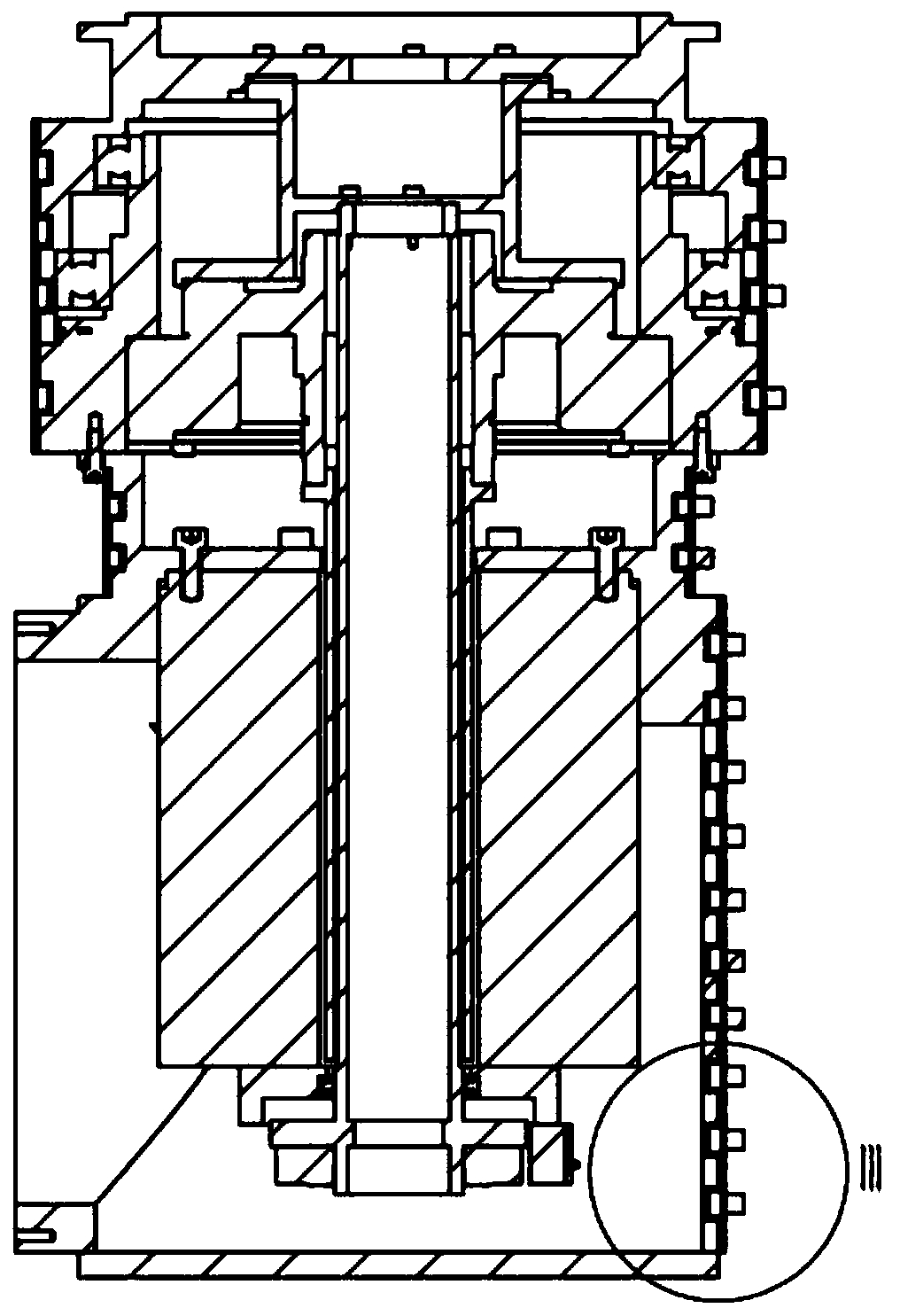

ActiveCN110510086AImprove corrosion resistanceEasy to trimCosmonautic condition simulationsUnderwater vesselsWrist jointsCorrosion

The invention discloses a neutral buoyancy trimming device for realizing a wrist structure of an underwater mechanical arm. The neutral buoyancy trimming device for realizing the wrist structure of the underwater mechanical arm comprises a wrist joint, a silicone shell, chambers and valves; N grooves (N is a natural number which is greater than or equal to 2) are formed in a shell of the wrist joint, the N grooves form the chambers, and the chambers are uniformly distributed along the circumference to form semi-circular and circular closed cavities; and the shell of the wrist joint is coveredwith the silicone shell; the valves are located on the silicone shell and are arranged directly above each chamber for enabling the chambers to be filled with gas or non-Newtonian fluid to adjust volume and density to achieve neutral buoyancy trimming. According to the neutral buoyancy trimming device for realizing the wrist structure of the underwater mechanical arm, the internal structure is notchanged, only the density and volume on the shell are changed to achieve equal gravity and buoyancy, and the center of gravity coincides with the center of buoyancy. The silicone of the device is resistant to corrosion, and the corrosion resistance of the wrist structure is improved; the trimming method is simple, the weight of the device is reduced, and the design cost is reduced; and the tightness of the device is improved, the number of the underwater equipment is effectively reduced, and the entire simulated weightlessness training process is enabled to be more convenient.

Owner:SHANGHAI UNIV

Method for reducing coal consumption by comprehensively and circularly utilizing waste heat of Webster furnace

ActiveCN103411438ASolve the icingImprove efficiencyCombustion processReverberatory furnacePhysical chemistryEngineering

Owner:HEZHANG LINGXUAN ENVIRONMENTAL PROTECTION TECH CO LTD

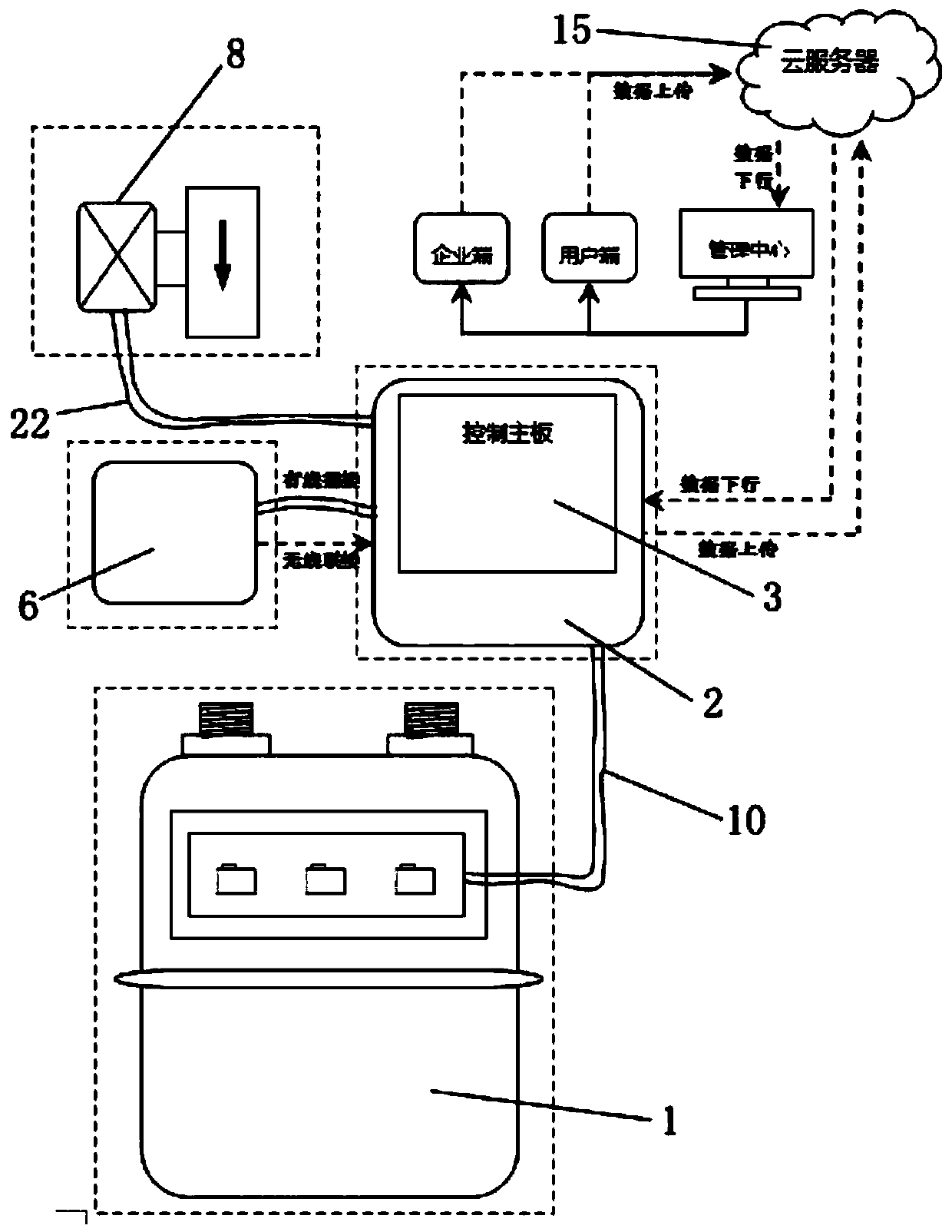

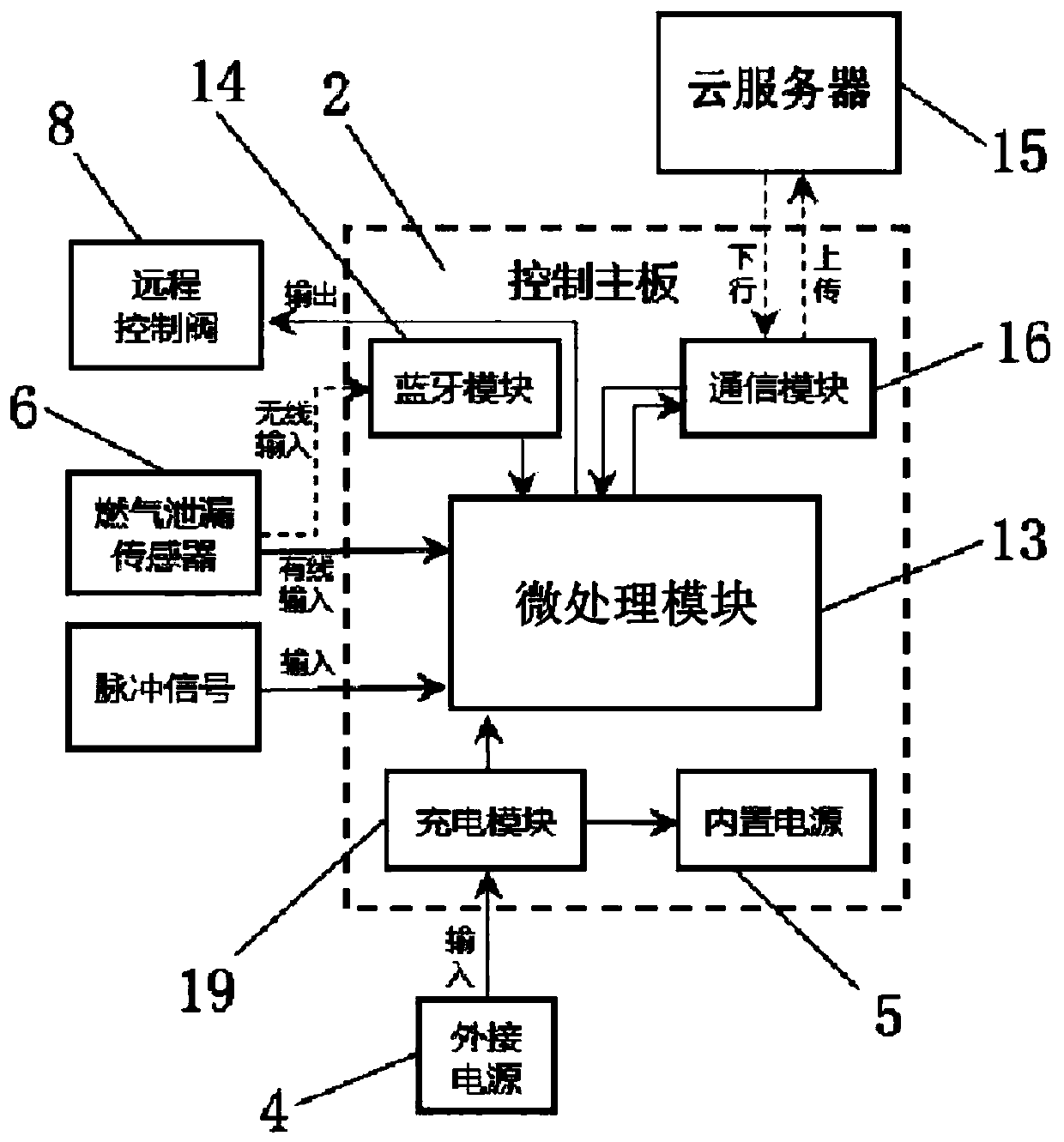

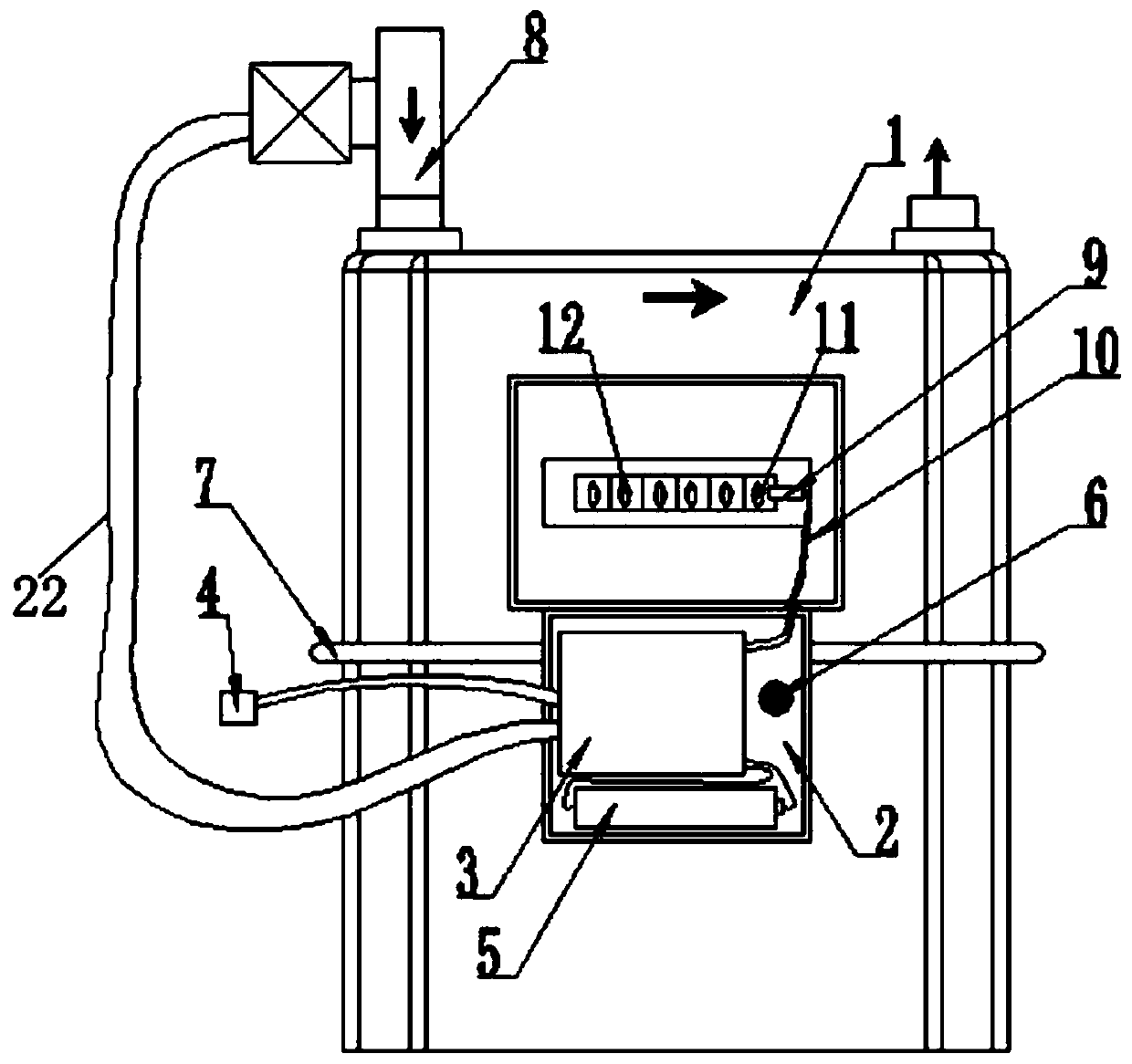

Detachable combined intelligent control gas meter

InactiveCN110686746ARealize data transmission functionImprove the level of intelligent managementElectric signal transmission systemsVolume indication and recording devicesData transmissionInternet of Things

The invention discloses a detachable combined intelligent control gas meter. The gas meter comprises a base meter with a counting bin and an Internet of things control box. The counting bin comprisesa plurality of counting code wheel discs; the base meter is provided with at least one non-mechanical contact sensing element for responding to the rotation of the counting code wheel discs and outputting a pulse signal; the Internet of things control box is used for being connected with a sensing element through a sensing element connecting line; and the Internet of things control box comprises acontrol main board connected with a connecting line of the sensing element, the control main board receives the pulse signal input by the sensing element through a micro-processing module and a communication module, processes data and sends the data to a cloud server through the communication module, and therefore the data transmission function of a mechanical gas meter is achieved. Each part canbe independently detached or combined for use, multiple functions such as data uploading and valve closing are achieved, and the applicability is wider.

Owner:欧健

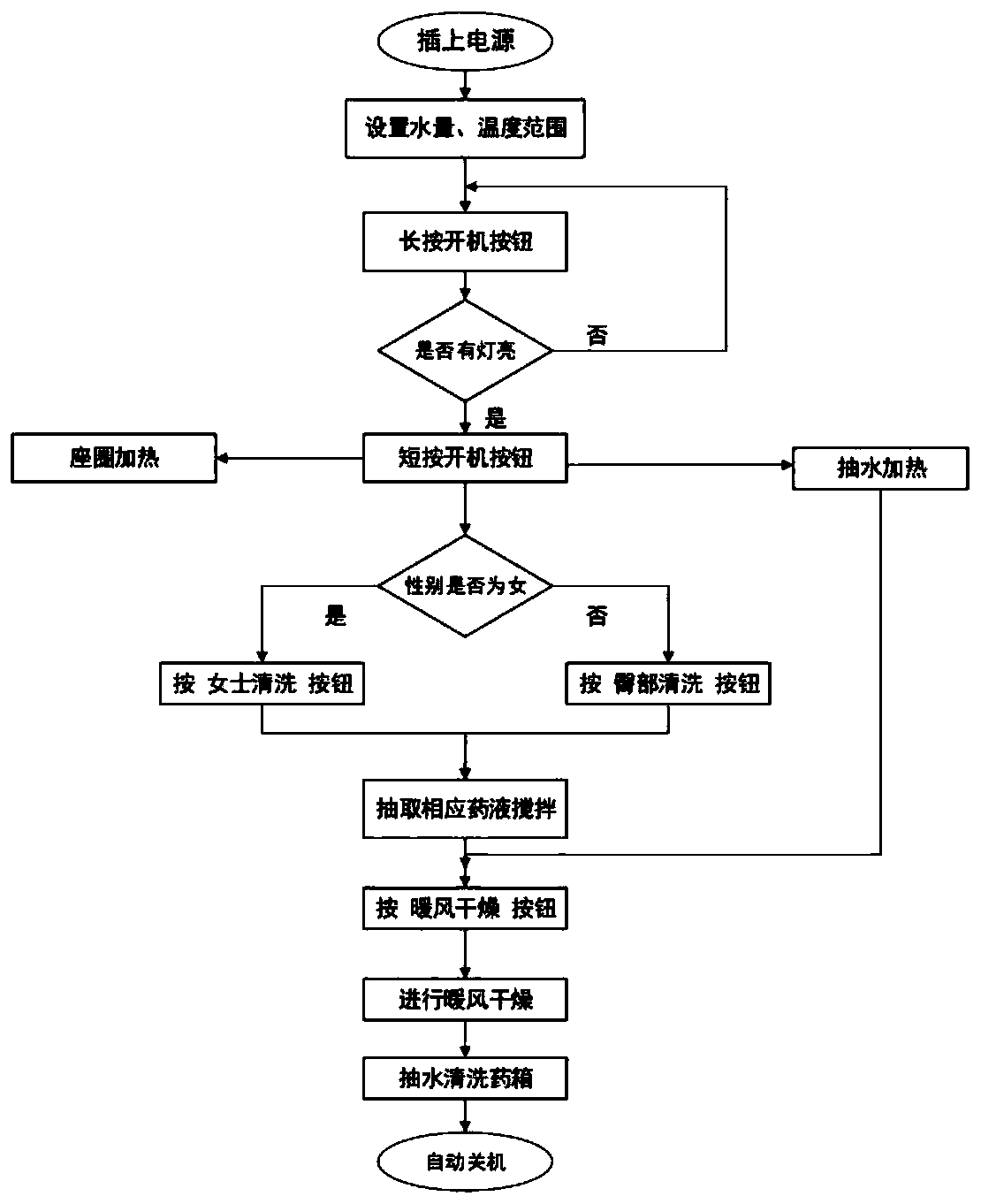

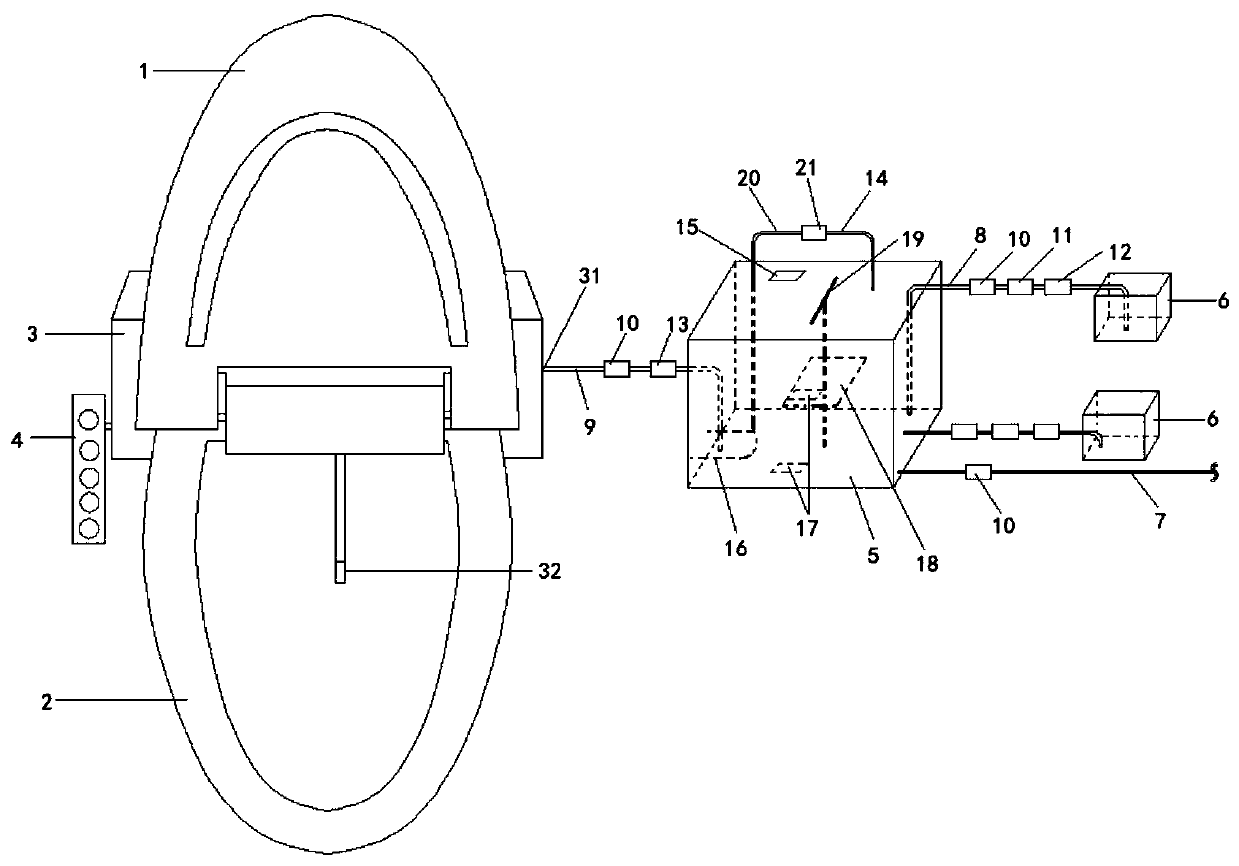

Intelligent toilet cover

InactiveCN109985288ADoes not change the internal structureRealize flushing functionEnemata/irrigatorsWater heatersPeristaltic pumpSolenoid valve

The invention discloses an intelligent toilet cover. The intelligent toilet cover comprises a cover body, a seat ring, a main unit and an operation panel; the operation panel is fixed to one side of the main unit; one side of the main unit is provided with a water inlet, and the bottom of the front surface of the main unit is provided with a retractable nozzle; the intelligent toilet cover furthercomprises a medicine blending box, medicine liquid boxes, a controller and an upper computer; one water inlet of the medicine blending box is connected with a tap water pipeline through a first pipeline, and the other water inlet of the medicine blending box is connected with the liquid medicine boxes through second pipelines; a water outlet of the medicine blending box is connected with the water inlet of the main unit through a third pipeline; the first pipeline is provided with a solenoid valve; each second pipeline is provided with a solenoid valve, a peristaltic pump and a flow meter; the third pipeline is provided with a solenoid valve and a first water pump; the medicine blending box is internally provided with a mixing device; the top of the medicine blending box is further provided with an ultrasonic liquid level sensor; all electronic components are connected with the controller, and the controller is connected with the upper computer. According to the technical scheme, theintelligent toilet cover has a medicine flushing function, and the use convenience is further improved.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

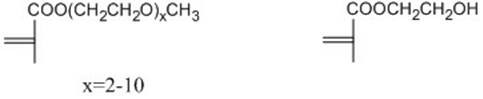

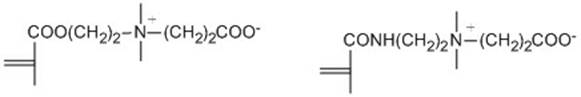

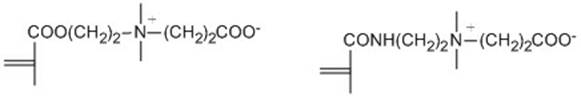

Preparation method of medical polymer material surface antifouling coating

ActiveCN113201164AImprove reaction efficiencyEase of industrial applicationAntifouling/underwater paintsPaints with biocidesBiological macromoleculeBenzyl chloride

The invention discloses a preparation method of a medical polymer material surface antifouling coating, which mainly comprises the following steps of dipping a polymer material in an organic solution containing azodiisobutyronitrile or benzoyl peroxide and vinyl benzyl chloride for a certain time, then taking out the polymer material, and rapidly irradiating the polymer material for 10-500 seconds under the ultraviolet light intensity value of 0.5-50 mW / cm<2> to initiate free radical polymerization, forming a polyvinyl benzyl chloride nano layer on the surface of a polymer material, then taking benzyl chloride as an initiator, grafting hydrophilic antifouling components in a water phase through ATRP, forming a stable antifouling coating, and reducing adsorption of biomacromolecules and bacteria. The method is simple and easy to implement, is suitable for industrial preparation of antibacterial and antifouling coatings on the surfaces of high-molecular medical apparatuses and instruments, and has a very wide application prospect.

Owner:HARBIN INST OF TECH AT WEIHAI

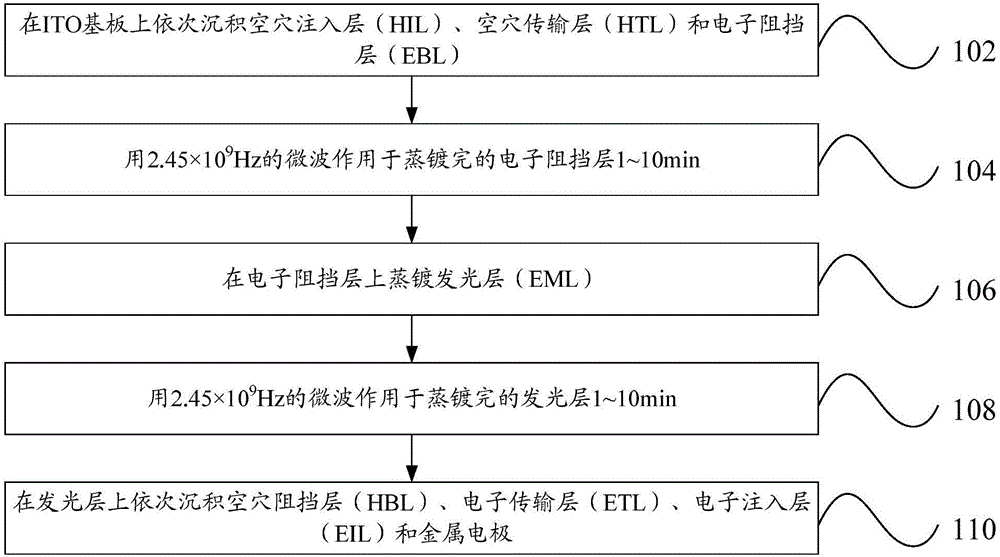

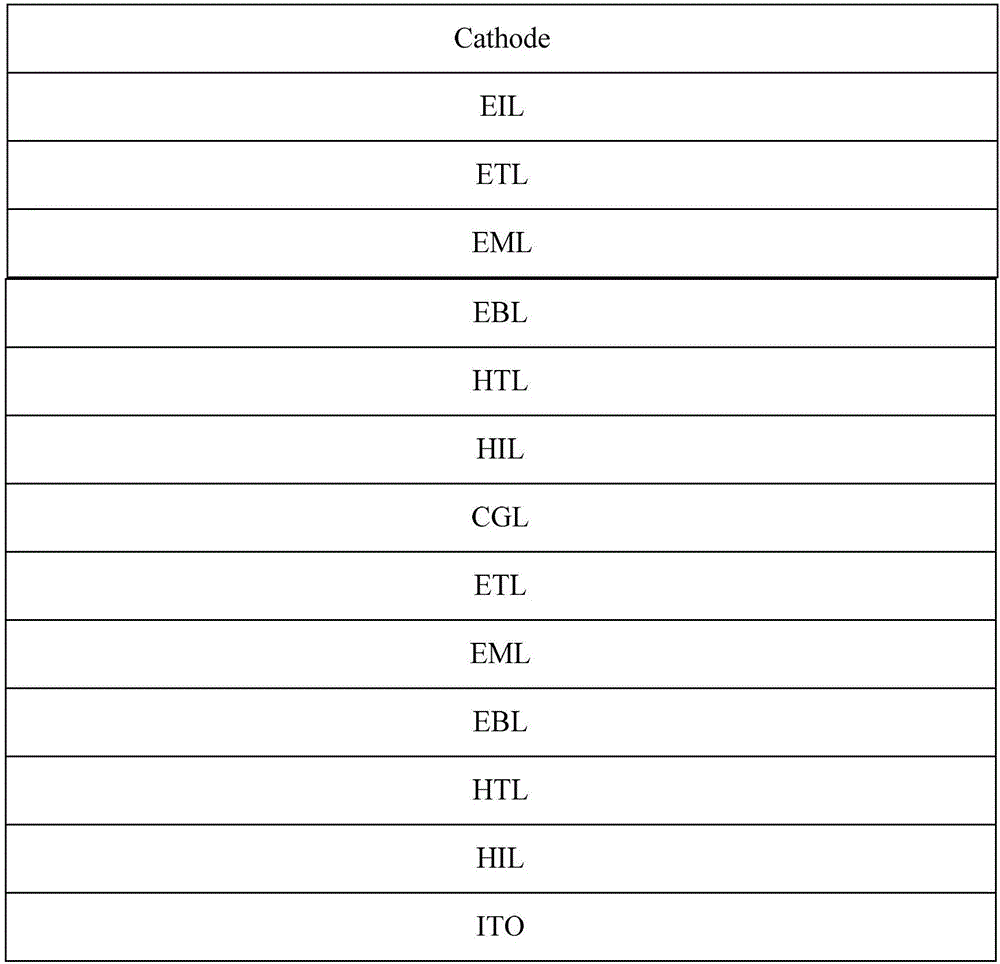

Manufacturing method of OLED device

InactiveCN106654066AExtended service lifeDoes not change the internal structureSolid-state devicesSemiconductor/solid-state device manufacturingDecompositionChemistry

The invention discloses a manufacturing method of an OLED device. The manufacturing method of the OLED device comprises the steps of carrying out microwave resonance water removal on one or multiple organic film layers in the OLED device in a vacuum environment; and carrying out selective heating rapidly on water molecules in the OLED device by adopting microwaves under a vacuum condition so as to remove the water molecules in the OLED device. The internal structures of substance molecules cannot be changed or the chemical bonds of the substance molecules cannot be destroyed in the water molecule removal process, so that the problem of decomposition of an organic material is avoided, and the service lifetime of the OLED device is prolonged efficiently.

Owner:BOE TECH GRP CO LTD

Engine gearbox external shift lock device

ActiveCN105546111BImplement shift lock functionSimple structural designGearing controlVehicle frameLocking mechanism

The invention discloses an engine gearbox external gear shifting locking device which is characterized in that the device comprises an engine (6), a braking limiting mechanism and a gear shifting locking mechanism; the braking limiting mechanism comprises a brake foot lever (9) and a limiting dragline (11); the gear shifting locking mechanism comprises a gear shifting handle (12) rotationally mounted on a vehicle frame, a spline plate (2) and a gear shifting shaft (3); the brake foot lever (9) is in limiting connection with the spline plate (2) through the limiting dragline (11); and the gear shifting handle (12) is sequentially and correspondingly connected with the spline plate (2), the gear shifting shaft (3) and a shifting fork mechanism arranged on a gearbox housing through a gear shifting drawbar (14). The device is reasonable and simple in structural design, low in manufacturing cost, and convenient to mount and use, and is safe and reliable, and effectively realizes the engine gearbox gear shifting locking function.

Owner:JIANGSU LINHAI POWER MACHINERY GROUP

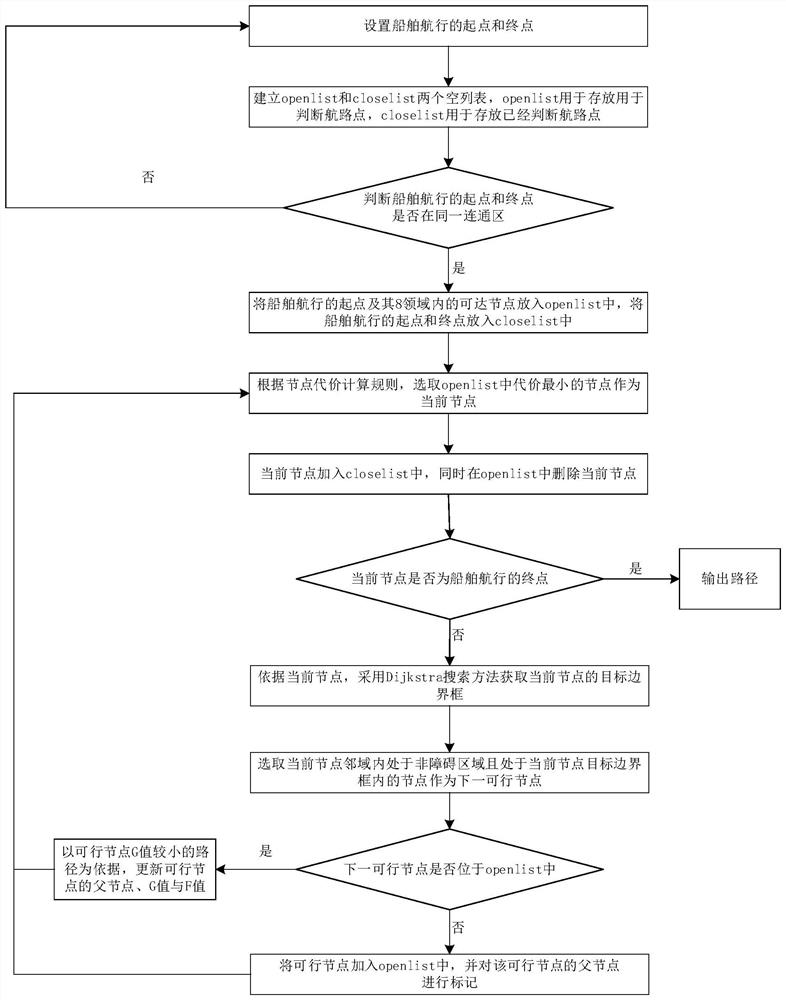

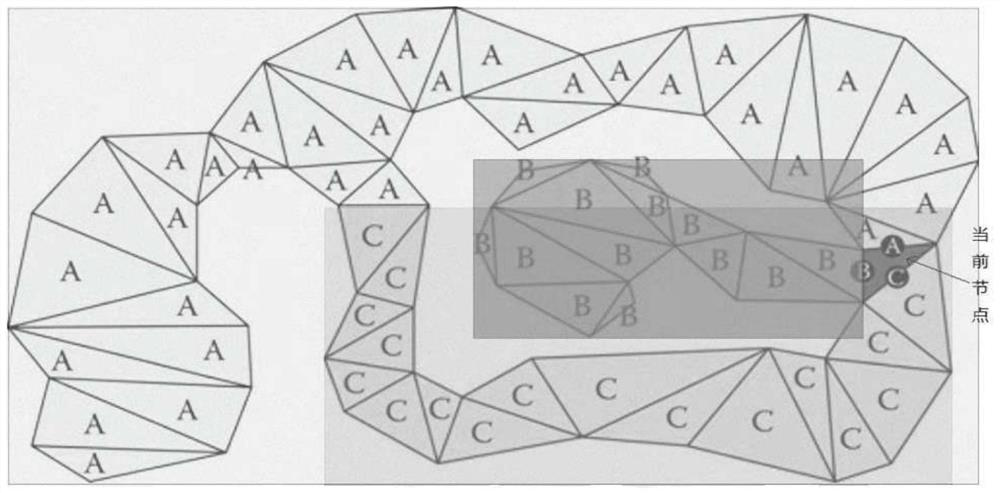

An Optimal Method for Track Planning Algorithm

ActiveCN110006430BAvoid searchingAvoid elevationNavigational calculation instrumentsAlgorithmEngineering

A method for optimizing a track planning algorithm, comprising: S1. According to the current position of the ship and the position of the target point, the track planning algorithm is used to obtain the node set O used to determine the waypoint in the track planning and the node set that has already determined the waypoint C; S2. For each node in the set C, use the Dijkstra search method to obtain the target bounding box of each node; S3. When traversing the neighborhood of each node in the set C to search for the next feasible node, select the current node within the neighborhood of The node in the non-obstacle area and within the target bounding box of the current node is used as the next feasible node; according to the next feasible node, the set O is updated to judge the waypoint; S4, traverse the set C, and obtain the optimal track route. It not only avoids the path planning algorithm to explore redundant and invalid nodes, but also prevents the path planning algorithm from exploring nodes to expand in the wrong direction, thereby speeding up the speed of path finding and improving the efficiency of algorithm operation.

Owner:智慧航海(青岛)科技有限公司

Bus capacitor, capacitor box, controller component and electric vehicle

PendingCN109801786AImprove cooling effectImprove cooling efficiencyCapacitorsElectric/fluid circuitCapacitanceElectric vehicle

The invention discloses a bus capacitor, a capacitor box, a controller component and an electric vehicle. The bus capacitor includes a capacitor body. The capacitor body is provided with a power terminal for connecting external equipment and a radiating surface for conducting heat. The distance between the power terminal and the radiating surface is smaller than the distance between the power terminal and the radiating surface in the existing bus capacitor. Thus, without changing the internal structure of the bus capacitor or adding an additional radiator, the radiating capacity and radiatingefficiency of the bus capacitor can be improved by optimizing the radiating path of a heat source in the bus capacitor and reducing the distance of the radiating path.

Owner:深圳市法拉第电驱动有限公司

A Neutral Buoyancy Trimming Device Realizing the Wrist Structure of an Underwater Manipulator

ActiveCN110510086BDoes not change the internal structureImprove corrosion resistanceCosmonautic condition simulationsUnderwater vesselsSimulated weightlessnessEngineering

The invention discloses a neutral buoyancy trimming device for realizing a wrist structure of an underwater mechanical arm. The neutral buoyancy trimming device for realizing the wrist structure of the underwater mechanical arm comprises a wrist joint, a silicone shell, chambers and valves; N grooves (N is a natural number which is greater than or equal to 2) are formed in a shell of the wrist joint, the N grooves form the chambers, and the chambers are uniformly distributed along the circumference to form semi-circular and circular closed cavities; and the shell of the wrist joint is coveredwith the silicone shell; the valves are located on the silicone shell and are arranged directly above each chamber for enabling the chambers to be filled with gas or non-Newtonian fluid to adjust volume and density to achieve neutral buoyancy trimming. According to the neutral buoyancy trimming device for realizing the wrist structure of the underwater mechanical arm, the internal structure is notchanged, only the density and volume on the shell are changed to achieve equal gravity and buoyancy, and the center of gravity coincides with the center of buoyancy. The silicone of the device is resistant to corrosion, and the corrosion resistance of the wrist structure is improved; the trimming method is simple, the weight of the device is reduced, and the design cost is reduced; and the tightness of the device is improved, the number of the underwater equipment is effectively reduced, and the entire simulated weightlessness training process is enabled to be more convenient.

Owner:SHANGHAI UNIV

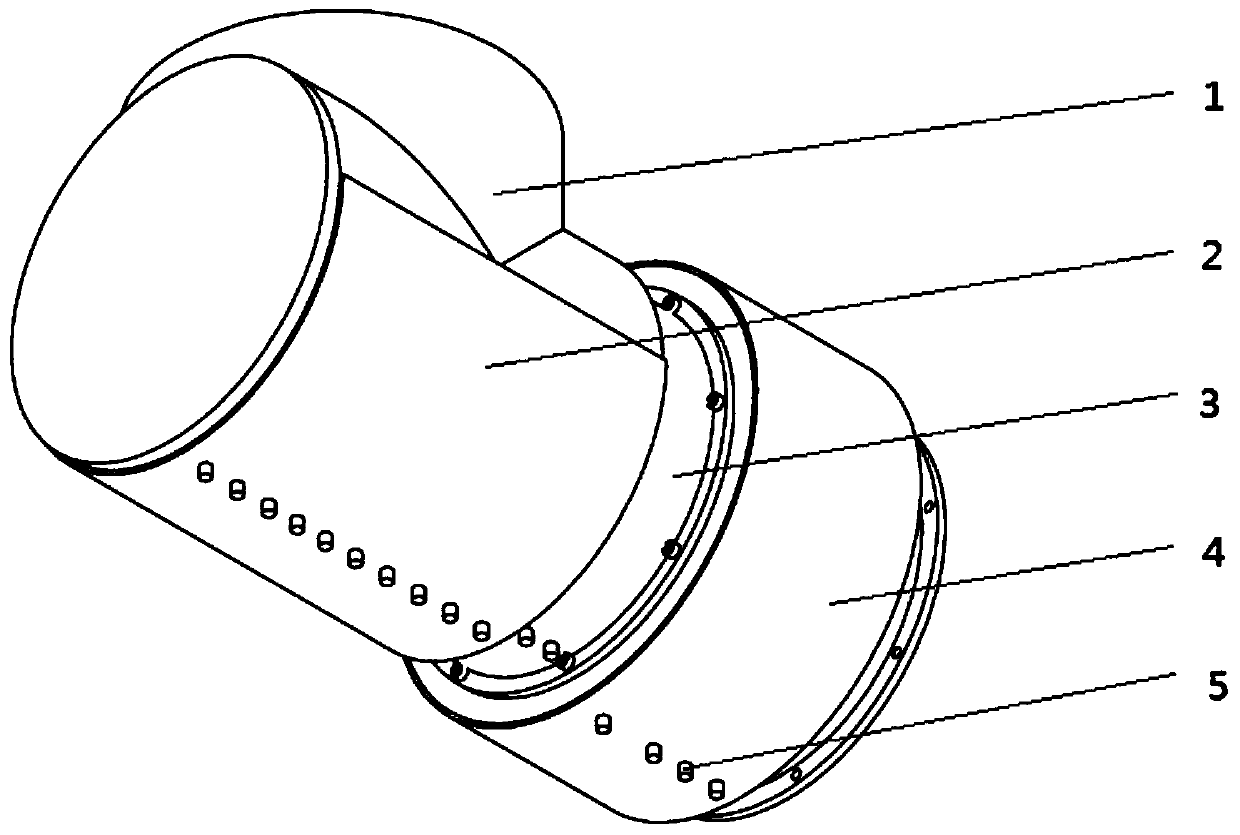

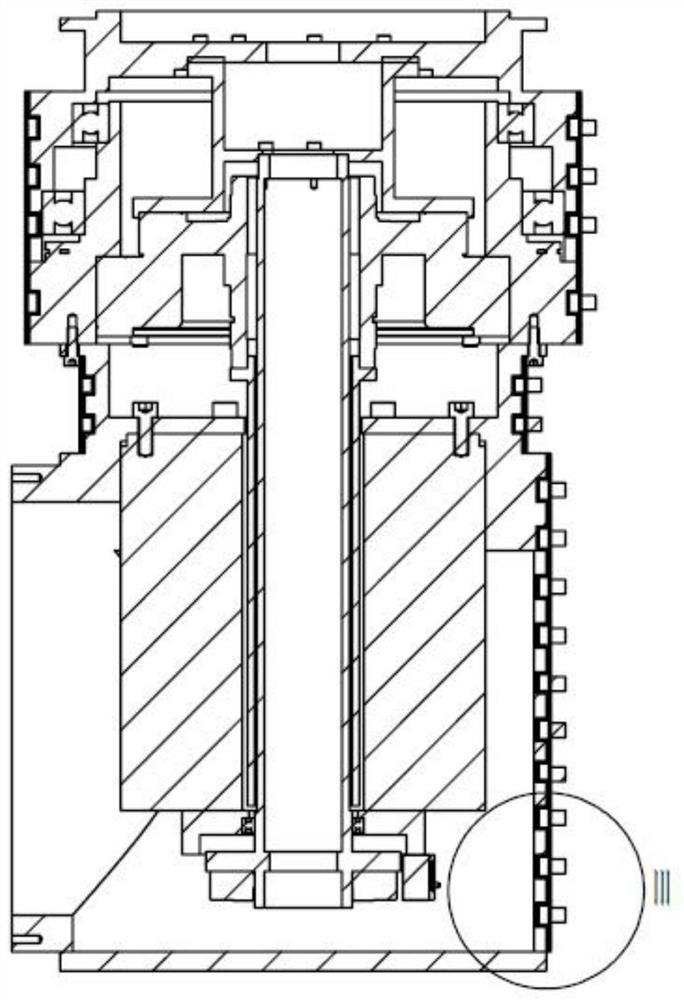

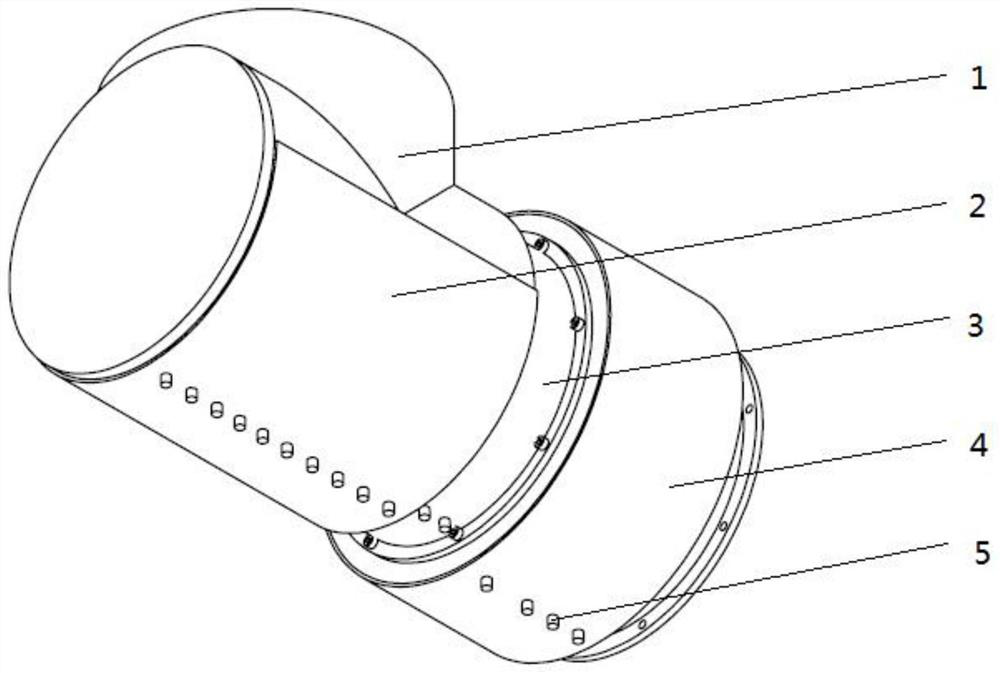

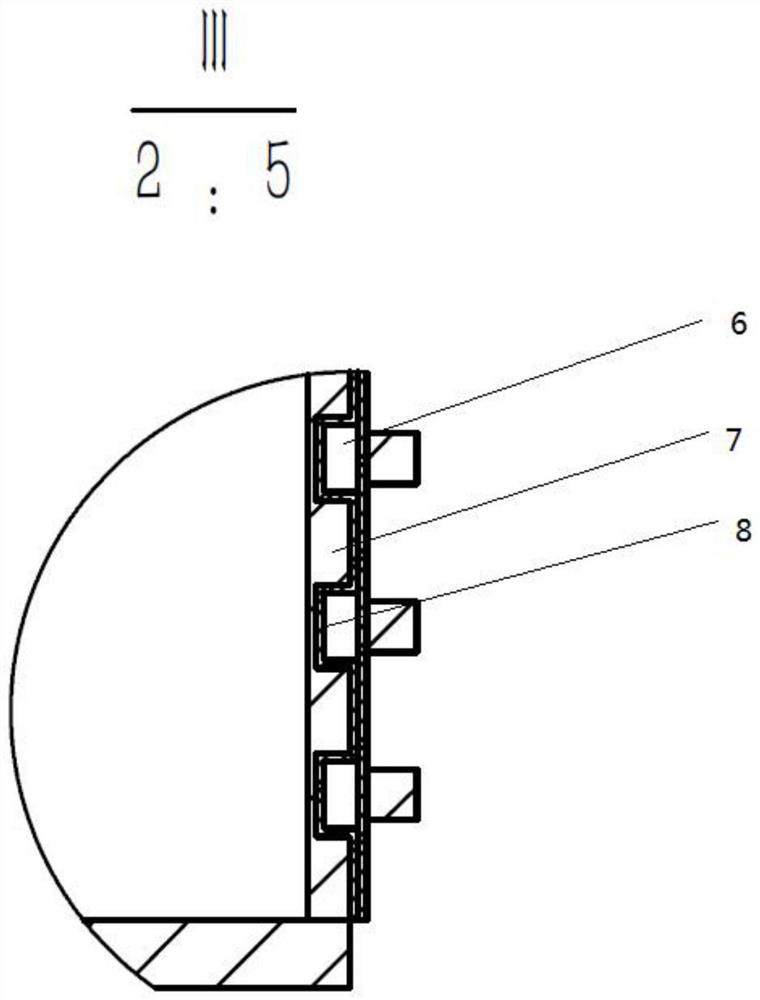

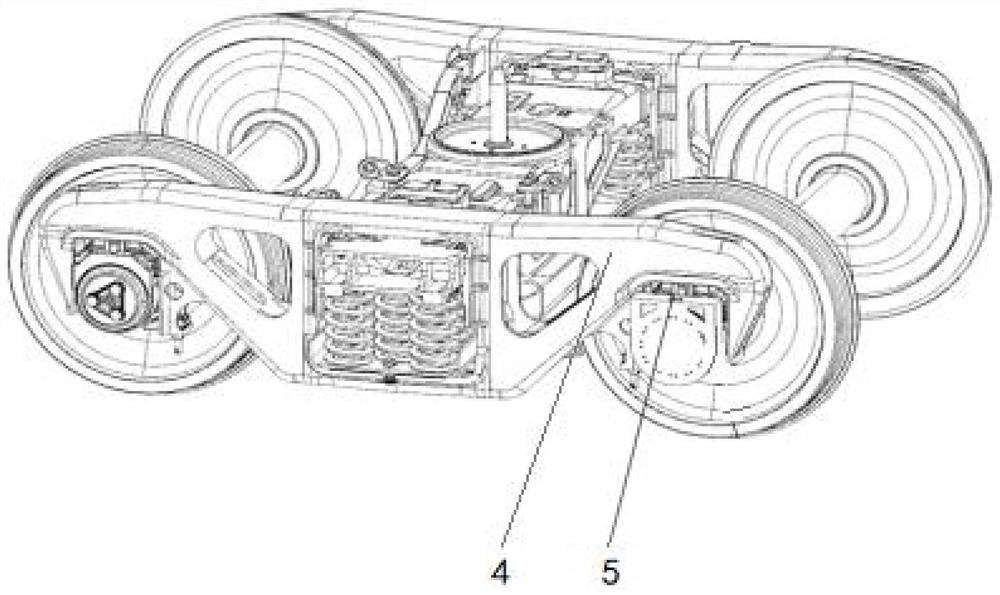

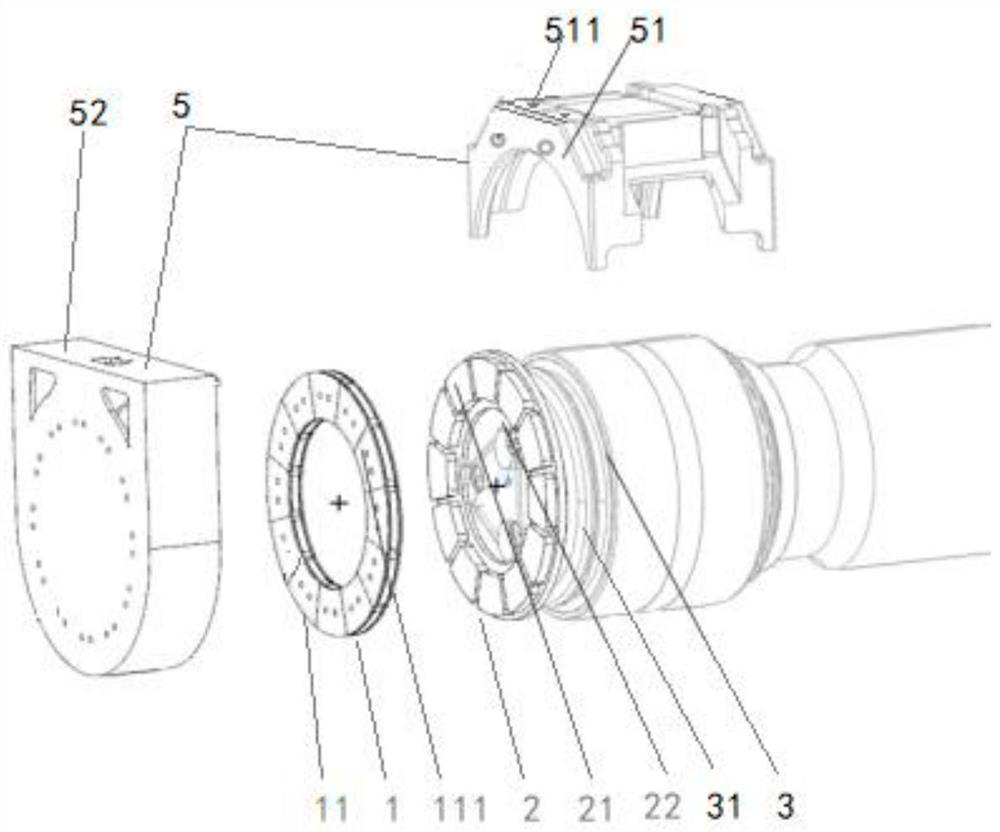

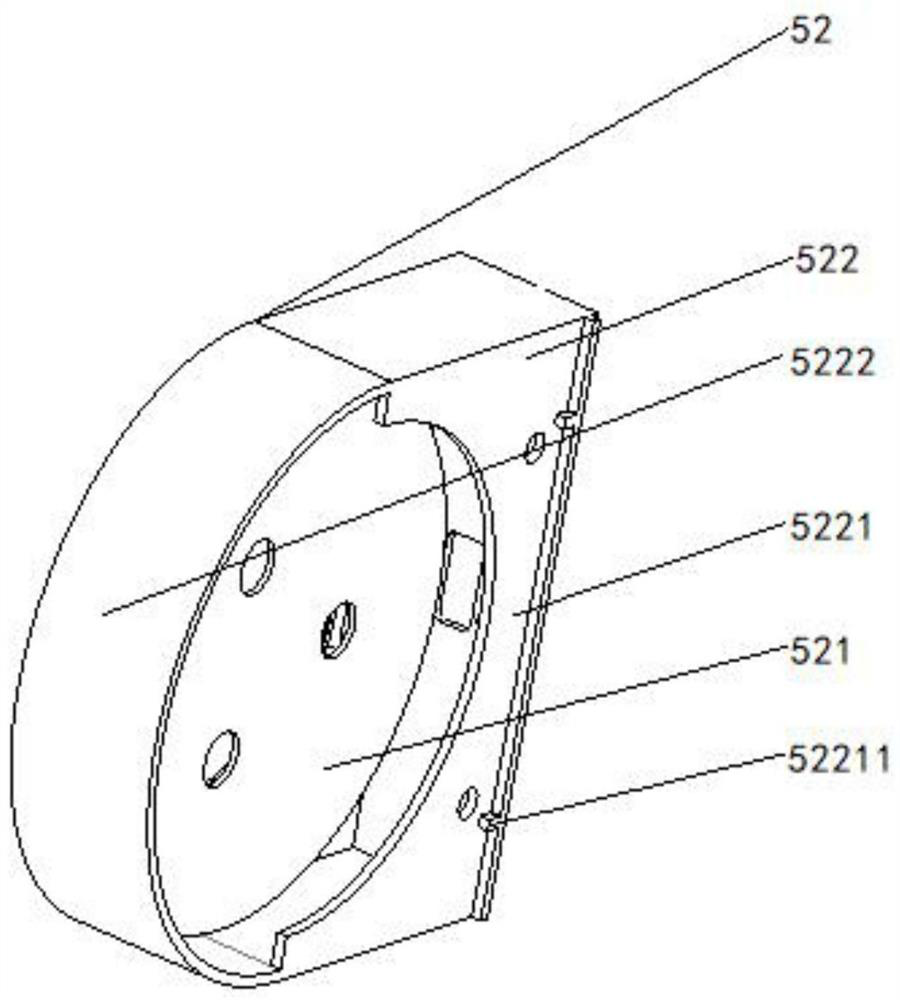

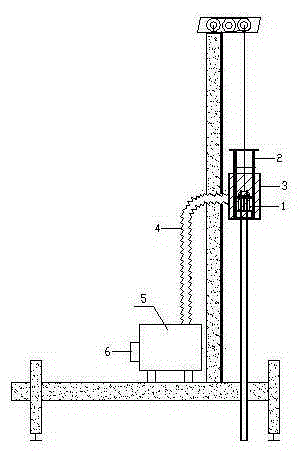

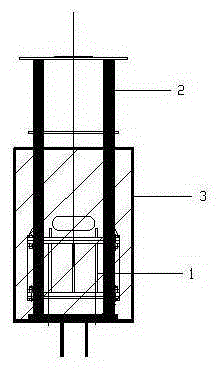

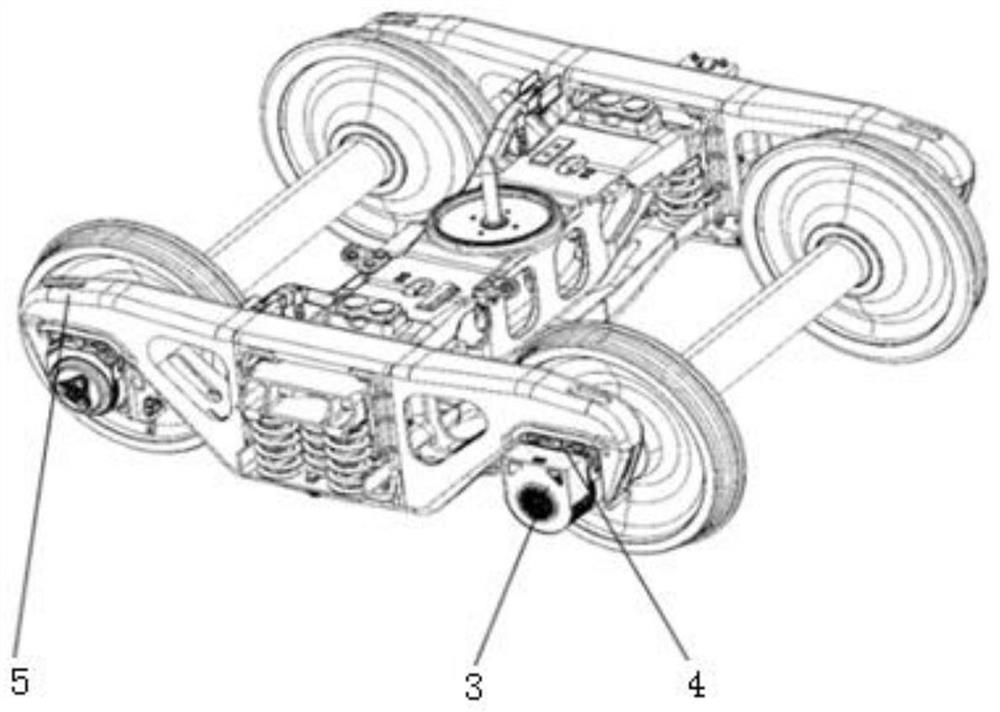

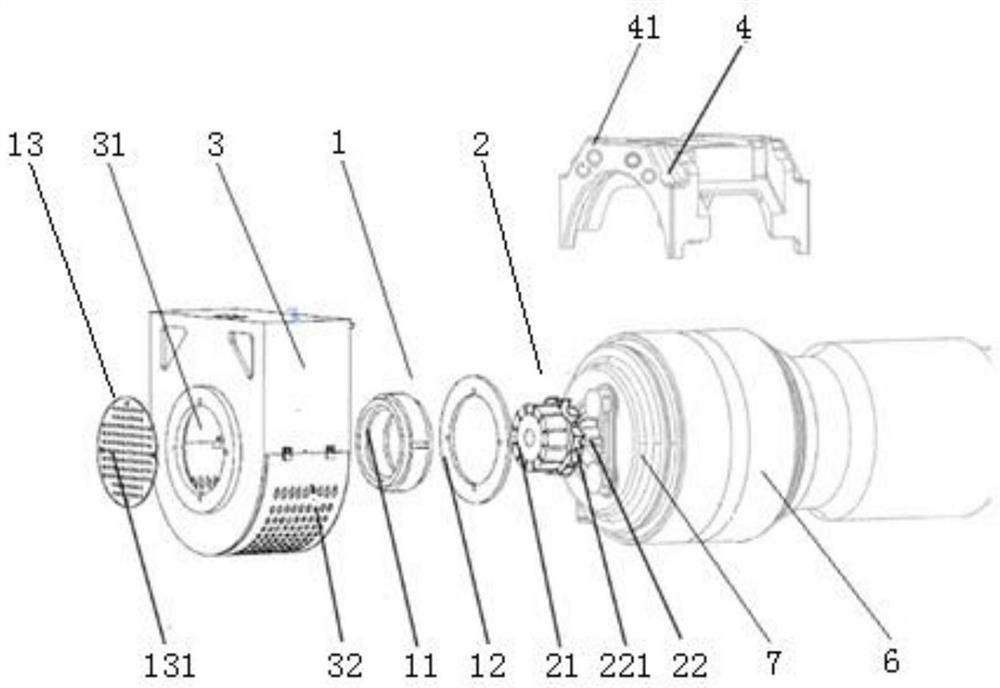

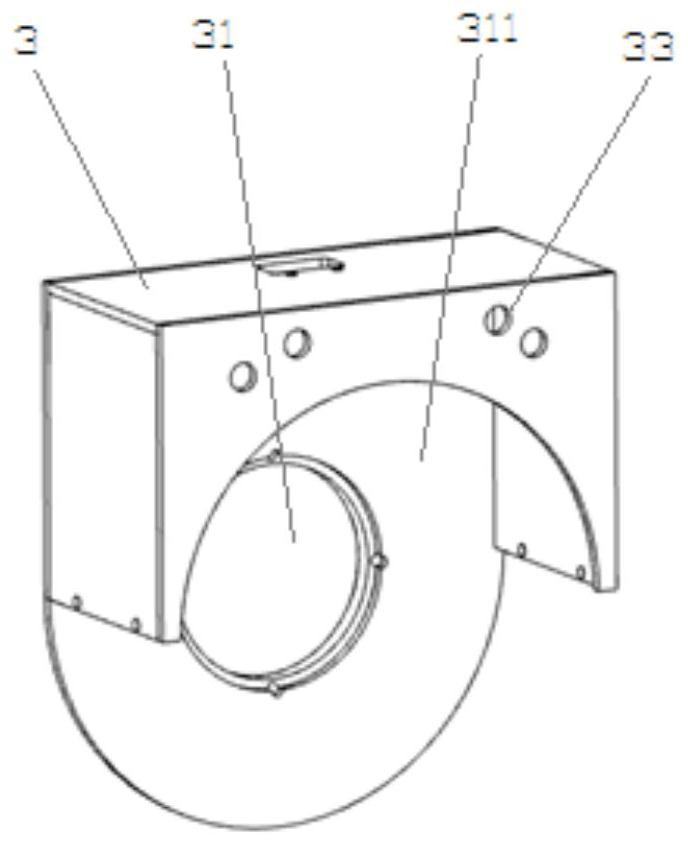

Shaft-end permanent magnet power generation device and bogie comprising same

PendingCN112928883ADoes not change the internal structureReduce axial sizeBatteries circuit arrangementsMagnetic circuit rotating partsElectric energyStator

The invention provides a shaft-end permanent magnet power generation device and a bogie comprising the same. The shaft-end permanent magnet power generation device comprises a stator assembly and a rotor assembly, wherein the rotor assembly is installed at the shaft end of a rotating shaft of the bogie and rotates along with the rotating shaft, the stator assembly is fixedly installed on a frame body of the bogie, a working space with an adjustable radial and / or axial distance is formed between the stator assembly and the rotor assembly, and the relative position of the stator assembly and the rotor assembly meets a corresponding requirement for generating electromagnetic induction current. The shaft-end permanent magnet power generation device of the invention has the advantages of small axial size, small volume, convenience in disassembly and assembly, low production cost, high reliability, simplicity in maintenance, strong practicability, no change of the original internal structure of an axle and the like, and realizes the purpose of converting mechanical energy into electric energy.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

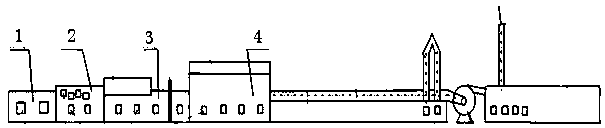

Purification device for diesel hammer construction equipment

InactiveCN105080925ASolve the problem of air pollutionEasy to modifyDirt cleaningCombustionFiltration

The invention provides a purification device for diesel hammer construction equipment. Harmful gas generated when a diesel hammer is used is absorbed, filtered and purified, and thus environmental pollution is effectively avoided. The purification device for the diesel hammer construction equipment is characterized in that an enclosure rod is fixed outside the diesel hammer, the enclosure rod is wrapped in an enclosure cover, an exhaust port formed in the lower portion of the enclosure cover is connected with a soft ventilation pipe, the soft ventilation pipe is connected with a purifier, and a filtering and purifying device and an exhaust fan are arranged in the purifier; one or more of absorptive filtration, adsorptive filtration, mechanical filtration, pulse purification, electrostatic purification, combustion catalytic purification, chemical purification and negative ion purification can be achieved through the filtering and purifying device. The purifier is started while the diesel hammer construction equipment is started, harmful smoke and harmful gas, generated by the diesel hammer, in the enclosure cover are sucked by the purifier and are filtered and purified into smoke-free harmless gas to be exhausted, and pollution to the atmospheric environment is avoided.

Owner:王继忠 +1

Drop-off type fuse grounding device

InactiveCN102354640AChange internal structureEasy to installEmergency protective devicesBare metalTransformer

The invention provides a drop-off type fuse grounding device. By welding a bare metal strip inside a fuse tube supporting frame at the lower end of a main body of a drop-off type fuse, the drop-off type fuse grounding device can directly hang a grounding wire, particularly when a space between the drop-off type fuse and a transformer is relatively narrow.

Owner:STATE GRID SHANDONG NINGYANG COUNTY POWER SUPPLY

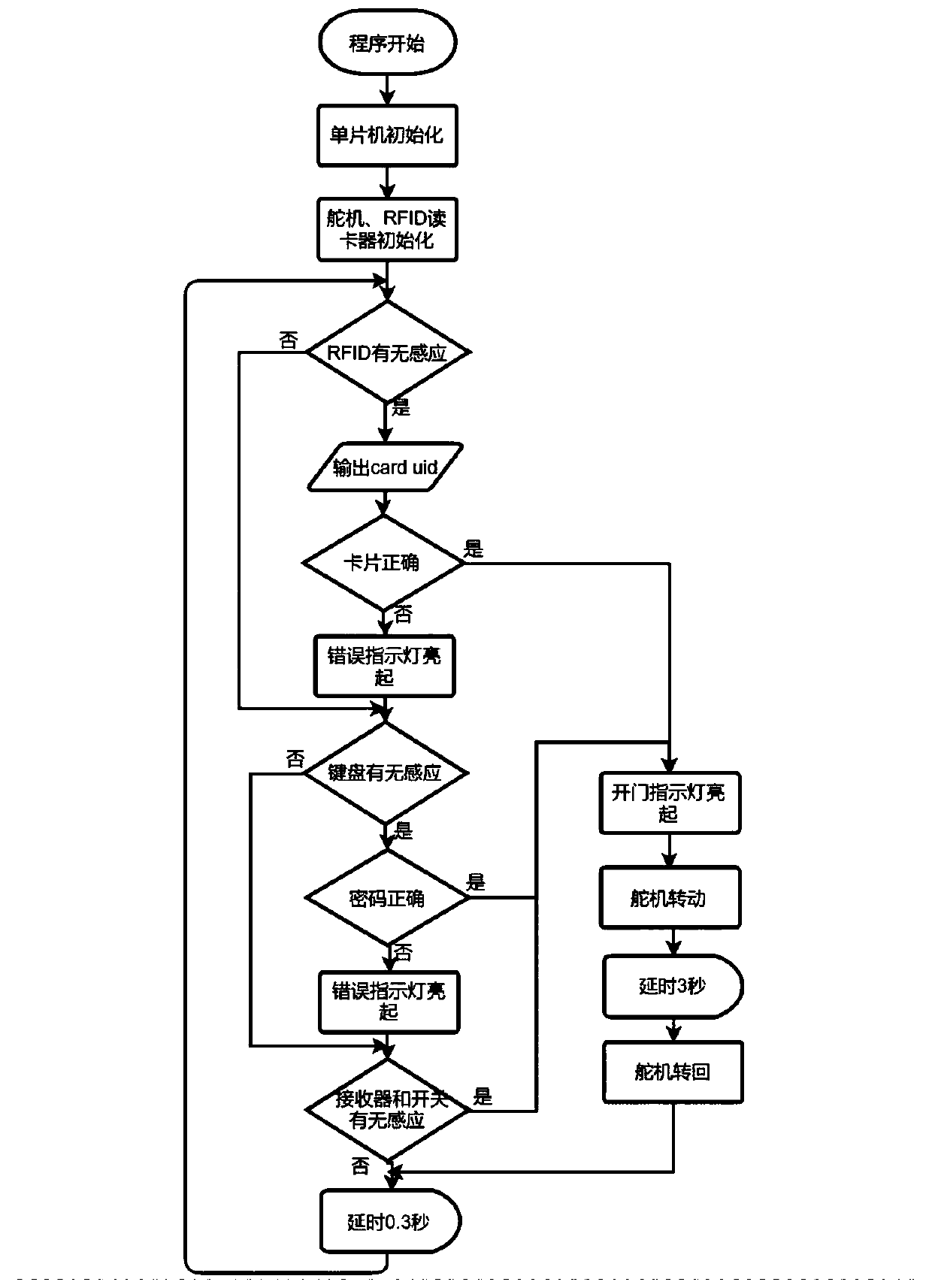

Multifunctional door opening system applied to door lock of student dormitory

InactiveCN110796766ASolve Thickness ProblemsSolve the inconvenience of changing the lock cylinderNon-mechanical controlsElectric permutation locksMicrocontrollerResidence hall

The invention relates to a multifunctional door opening system for a specific using environment, provides a door lock electronic transformation scheme in which price is low, an original door lock structure is not changed and an original door lock function is not influenced, and achieves effects of entering an door by swiping a campus card, entering the door by nfc of a mobile phone, entering the door by a password, remotely controlling the door to be opened in a dormitory and opening the door by a button. The multifunctional door opening system is based on arduino singlechip application, adopts a combination of a steering engine and a rope to pull a door lock open, gives a sufficient movement space to the door lock and keeps original functions; a duel power supply design is adopted, and standby power can keep the system working for three days after a power failure; three difficult problems of small thickness, inconvenience in replacing a lock cylinder and low affordable price of a doorbody of the student dormitory are solved; and the blank of an electronic door lock in the market in the specific using environment of an undergraduate dormitory is filled.

Owner:BEIJING UNIV OF TECH

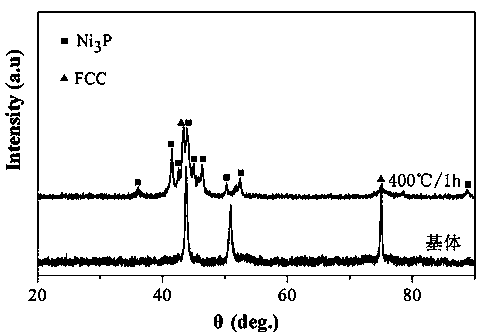

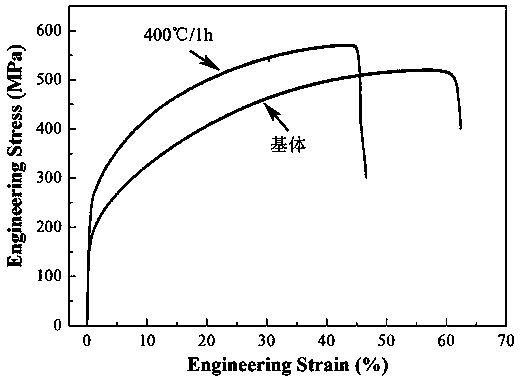

Method for preparing Ni-Mo-P coating on surface of high-entropy alloy

InactiveCN110656327AHigh tensile strength at room temperatureChange structureLiquid/solution decomposition chemical coatingHigh entropy alloysUltimate tensile strength

The invention discloses a method for preparing a Ni-Mo-P coating on the surface of a high-entropy alloy. The method is characterized in that the surface of the high-entropy alloy is plated with a layer of Ni-Mo-P coating, then the bonding force between the coating and the matrix is improved through heat treatment, and the obtained coating improves the room temperature tensile strength of the high-entropy alloy; and finally, the composite material with a sandwich structure of Ni-Mo-P / high-entropy alloy / Ni-Mo-P is formed. According to the method, aiming at the characteristics of low strength of an FCC structure high-entropy alloy, the surface of the high-entropy alloy is plated with the layer of Ni-Mo-P coating, and the bonding force between the coating and the matrix is improved through heat treatment, so that the room temperature tensile strength of the high-entropy alloy is improved; and compared with the high-entropy matrix without coating, the room temperature tensile strength ofthe coated composite material is greatly improved.

Owner:TAIYUAN UNIV OF TECH

Bogie shaft end column type permanent magnet power generation device

InactiveCN112532007ADoes not change the internal structureSmall sizeBatteries circuit arrangementsMagnetic circuit rotating partsBogieMechanical energy

The invention relates to a bogie shaft end column type permanent magnet power generation device. The device comprises a stator assembly, a rotor assembly, a hood and a bearing saddle, wherein the bearing saddle is fixedly installed on a bogie, the rotor assembly is installed on the end face of a shaft end cover of a rotating shaft and concentrically rotates along with the rotating shaft, the stator assembly is installed on the hood, and the hood is installed on the bearing saddle; the stator assembly and the rotor assembly are mutually sleeved and form a radial gap. The device has advantages of being small in axial size, small in size, low in production cost, high in reliability, easy to maintain, high in practicability, capable of not changing the original internal structure of the axle and the like, and a purpose of converting mechanical energy into electric energy is achieved; the hood provided with the electromagnetic coils does not take a rotating shaft as an installation basis, and the sizes of the permanent magnets and the corresponding electromagnetic coils can be increased in a certain space according to the requirement for electric energy; the heat dissipation structure is arranged in the power generation device, heat energy generated in the power generation process is dissipated in time, and the situation that the power generation effect is affected due to too high heat is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com