Fume eject-calcium desulfurizing techinique in pulverized coal fired boiler

A desulfurization process and boiler furnace technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of secondary pollution of by-product gypsum, large investment and high operating costs, and achieve reduced operating costs and desulfurization efficiency. High, simple installation effect

Inactive Publication Date: 2008-11-19

YANKUANG GUOHONG CHEM

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This process has serious problems of large investment, high operating cost and secondary pollution of by-product gypsum

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a desulphurization process of limestone injection into a furnace for a pulverized coal boiler. The desulphurization process is characterized in that desulphurization agent powder with the particle size of 100 to 800 meshes is injected into the furnace from a horizontal flue behind a first-stage steam superheater of the boiler, the desulphurization reaction is carried out in the flue for desulphurization, and the desulphurization agent is limestone powder, lime powder or hydrated lime powder. A device of the invention is simple and has no change of the internal structures of the boiler or the impacts on the operation of the boiler according to normal indicators. The desulphurization efficiency is high, the investment is low, the operation cost is low and the ideal target of low-cost desulphurization is realized, thereby achieving the perfect combination of economic benefits and social effects of environmental protection and emission reduction, and having great popularization value.

Description

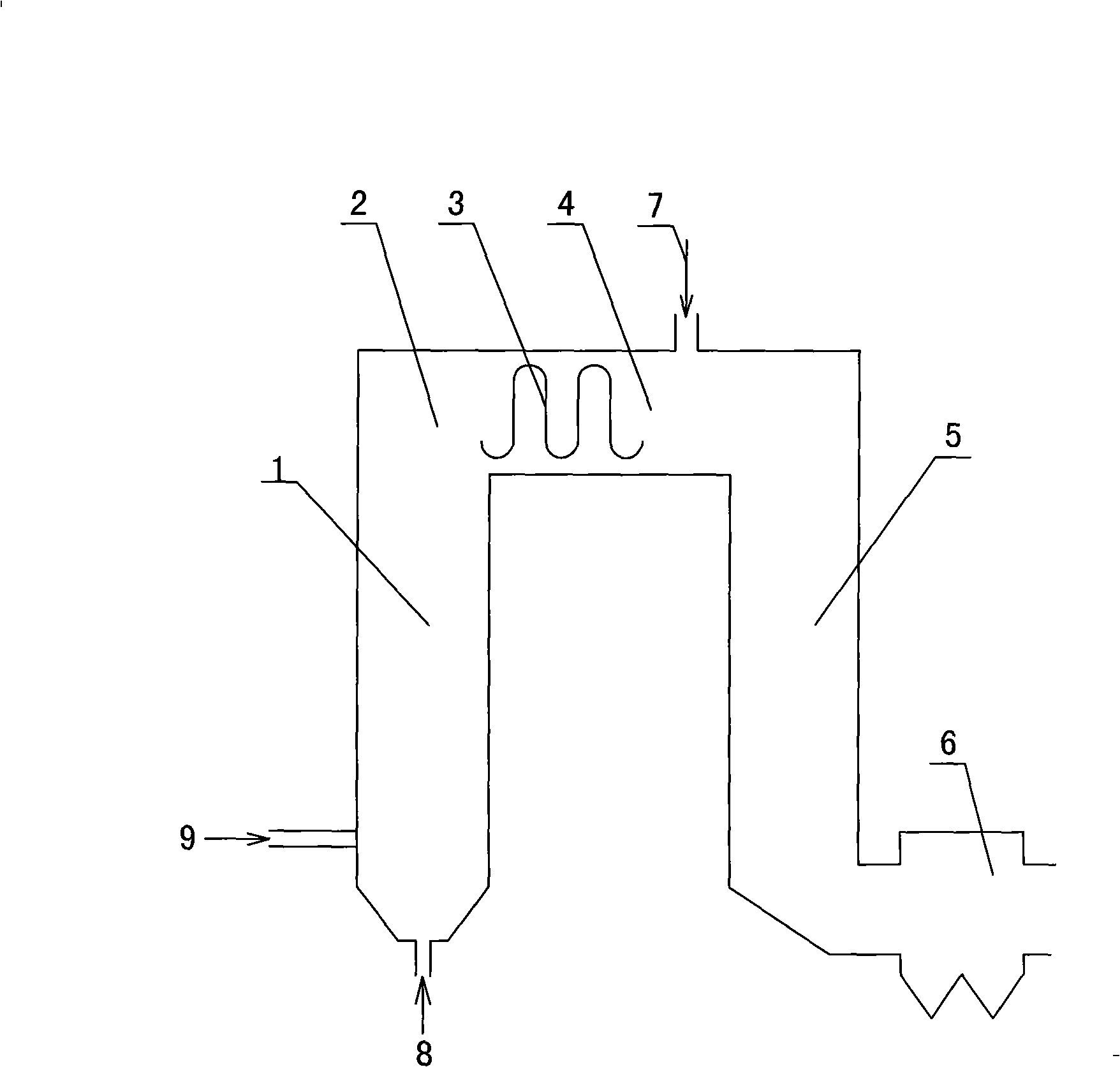

Calcium Injection Desulfurization Process of Flue Gas in Pulverized Coal Boiler technical field The invention belongs to a flue gas desulfurization process in a boiler furnace, in particular to a calcium spraying desulfurization process for flue gas in a pulverized coal boiler furnace. Background technique In various types of thermal power plants in my country, almost all boilers use coal as fuel. Because coal contains ash and mineral sulfur, the combustion process will produce pollutants such as smoke, SO2 and NOX. For pulverized coal boilers, the process of spraying lime powder or milk of lime outside the furnace is currently used for desulfurization. This kind of process has serious problems of large investment, high operating cost and secondary pollution of by-product gypsum. Studies have shown that the critical temperature of the reaction of CaO and SO2 to form CaSO4 is 850°C. When it exceeds 850°C, the reaction will proceed in the opposite direction, that is, in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/50B01D53/81

Inventor 梁道广马训华张鲁生张洪勇

Owner YANKUANG GUOHONG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com