Method for preparing Ni-Mo-P coating on surface of high-entropy alloy

A high-entropy alloy, ni-mo-p technology, applied in the field of materials, can solve the problems of low strength and high plasticity, and achieve the effect of improving the tensile strength at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

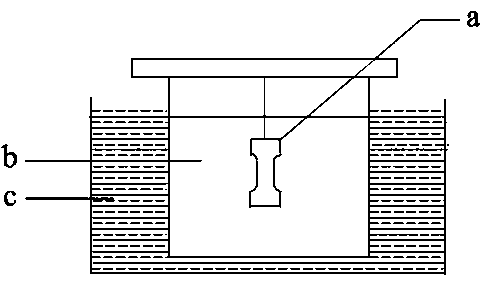

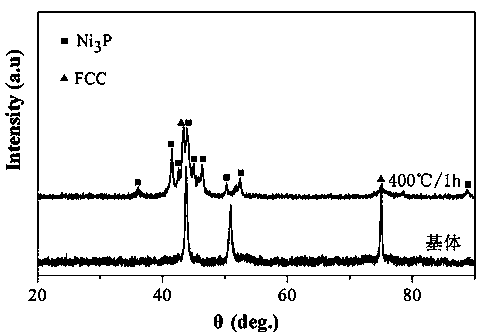

[0032] Traditional high-entropy alloys generally increase their strength by changing the internal structure. The invention breaks the traditional thinking and improves the mechanical properties from the outside without changing the internal structure of the material. The present invention adopts the method of chemical deposition, deposits Ni-No-P coating on the surface of CoCrFeNi high-entropy alloy, and forms Ni-Mo-P / CoCrFeNi / Ni-Mo-P sandwich structure through heat treatment, so as to achieve the purpose of improving the strength of the matrix Purpose.

[0033] The specific implementation process is as follows:

[0034] Step 1, preparation of chemical plating solution

[0035] ①The process formula of each component is as follows:

[0036] Nickel Sulfate (NiSO 4 •6H 2 O) 25g / L

[0037] Sodium hypophosphite (NaH 2 PO 2 •H 2 O) 24g / L

[0038] Sodium molybdate (Na 2 MoO 4 • 2H 2 O) 0.3 g / L

[0039] Sodium citrate (NaC 3 h 5 O7) 25g / L

[0040] Sodium acetate (CH 3...

Embodiment 2

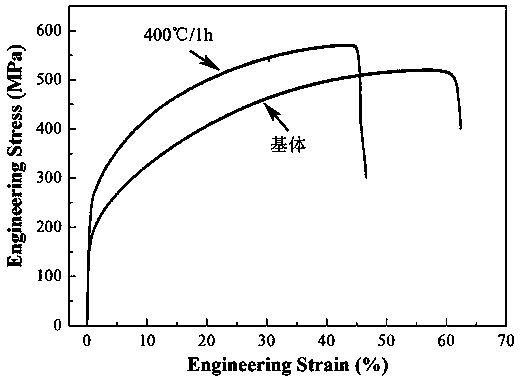

[0069] In addition to the face-centered cubic high-entropy alloy CoCrFeNi in the above-mentioned embodiment 1, the Ni-Mo-P coating also has a strengthening effect on other face-centered cubic high-entropy alloys, such as Al 0.3 CoCrFeNi. In the case of maintaining the preparation method of the high-entropy alloy matrix in the above-mentioned embodiment 1 and other process conditions unchanged, the high-entropy alloy matrix is replaced by Al 0.3 For CoCrFeNi, in order to obtain the effect of different heat treatment times on the mechanical properties of composite materials, the heat treatment times in the experiment were 400 ± 10°C / 1 h, 500 ± 10°C / 3h, 500 ± 10°C / 6h. After the samples under different heat treatment times were cleaned, the tensile mechanical properties at room temperature were tested, and compared with the mechanical properties of the uncoated high-entropy alloy substrate.

[0070] Figure 5 The room temperature tensile engineering stress-strain curves of coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com