Shaft-end permanent magnet power generation device and bogie comprising same

A permanent magnet power generation and bogie technology, which is applied to electromechanical devices, circuit devices, battery circuit devices, etc., can solve the problems of separate shaft design, inability to install bogie power generation devices, and difficulty in matching dynamic parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

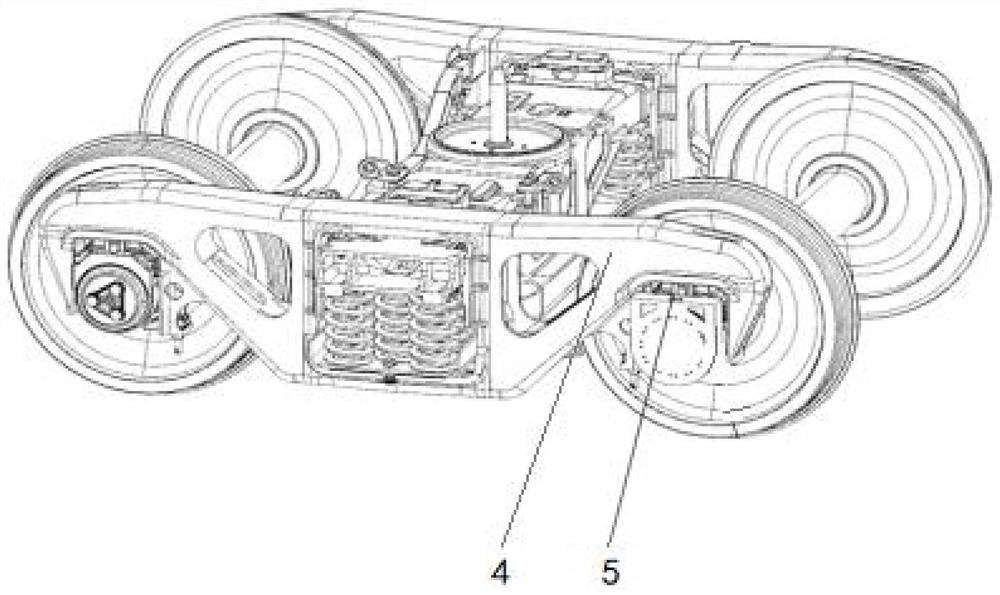

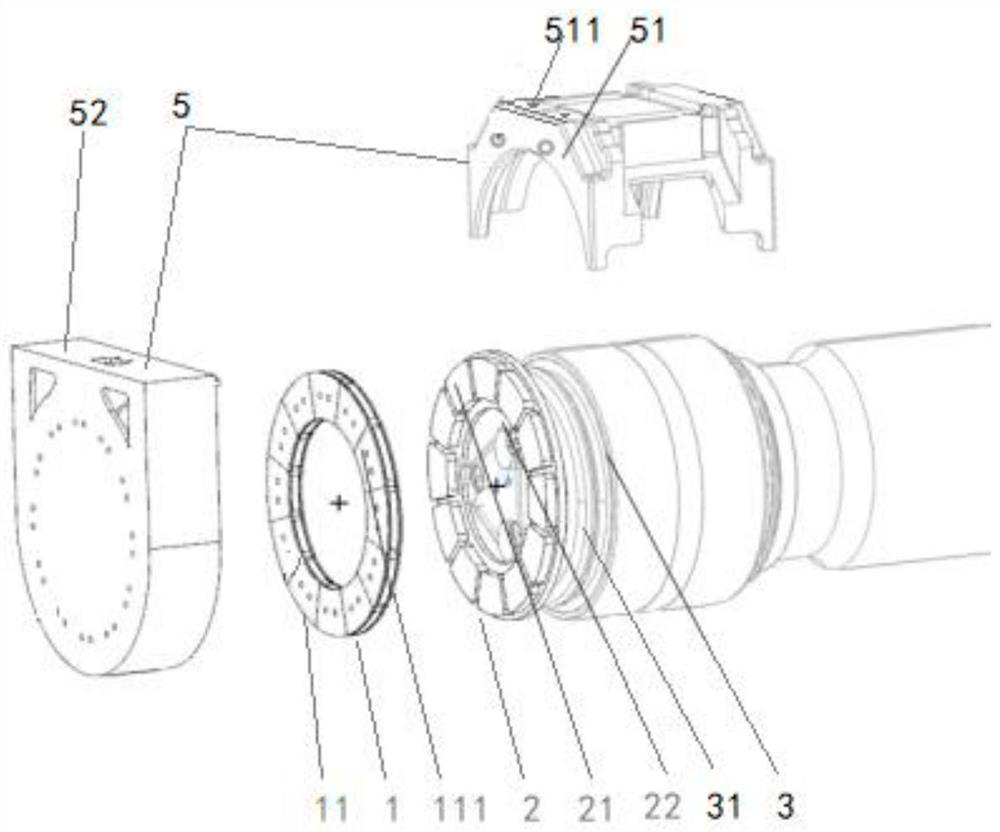

[0038] Such as Figure 1 to Figure 4 As shown, the shaft-end permanent magnet generator of this embodiment includes a stator assembly 1 and a rotor assembly 2. The rotor assembly 2 is installed on the shaft end of the rotating shaft 3 of the bogie and rotates with the rotating shaft 3. The stator assembly 1 is fixed on the bogie. On the frame body 4, a working space with adjustable radial and / or axial distances is formed between the stator assembly 1 and the rotor assembly 2, and the relative position of the stator assembly 1 and the rotor assembly 2 meets the corresponding requirements for generating electromagnetic induction current . When the car body is running normally, the rotating shaft 3 rotates with the rotor assembly 2, and the stator assembly 1 moves to cut the magnetic force line to generate a magnetically induced electromotive force, and then forms a control loop according to the electromagnetic coil terminal of the stator assembly 1, and generates a current. The...

Embodiment 2

[0050] Such as Figure 5 to Figure 8 As shown, the second embodiment of the shaft-end permanent magnet generator of the present invention, the generator is basically the same as the generator of Example 1, the only difference being:

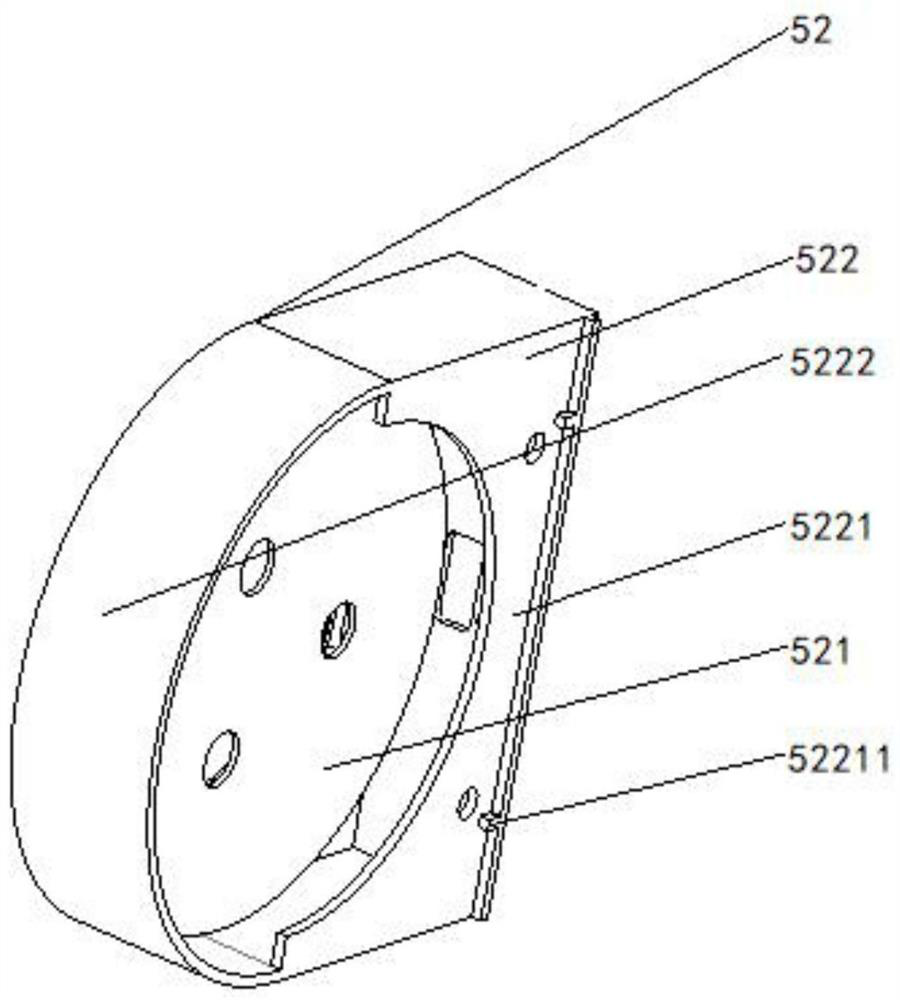

[0051] In this embodiment, the fixing plate 521 is provided with an assembly hole 5211 , the stator assembly 1 is fixed in the assembly hole 5211 and covered by the housing 522 , and the housing 522 is connected with the saddle 51 and forms a shield for the rotor assembly 2 . The housing 522 is detachably connected to the saddle 51 by bolts, the housing 522 is connected to the fixing plate 521 by bolts, the assembly hole 5211 is a through hole, and the stator assembly 1 is embedded in the assembly hole 5211 .

[0052] In this embodiment, the stator assembly 1 includes an electromagnetic coil 12, a coil front gland 13 and a coil rear gland 14. The electromagnetic coil 12 is set in the assembly hole 5211, and the coil front gland 13 and the coil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com