Online real-time shield scraper wear monitoring system

A real-time monitoring system and scraper technology, applied in measuring devices, instruments, electrical devices, etc., can solve problems such as difficulty in implementation, large errors in indirect measurement methods, and inability to realize online real-time monitoring of scrapers, so as to meet monitoring needs and avoid wiring. difficulty, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

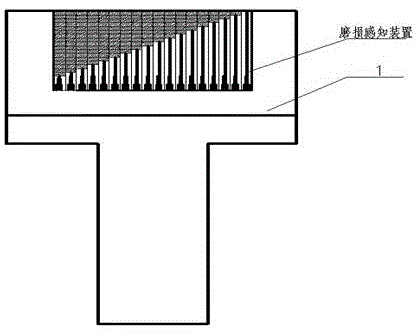

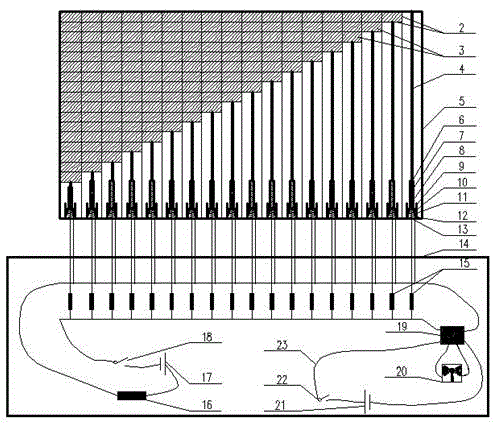

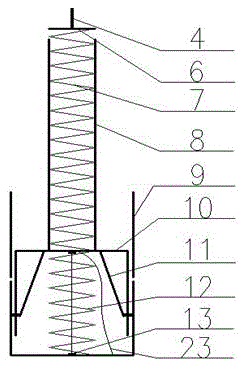

[0021] Such as Figure 1 to Figure 3 An online real-time monitoring system for shield scraper wear is shown, including a shield scraper 1, a wear sensing device, a data acquisition circuit, a data processing module connected to the data acquisition circuit, and a wireless transmission module 20 connected to the data processing module. The wear sensing device includes steel sheets 2 arranged vertically and horizontally, epoxy resin 3, a metal box shell 5 and a spring trigger module. The metal box shell 5 is welded by thick iron plates to protect the internal structure on four sides and welded to the shield scraper 1 Back side; the steel sheets 2 arranged vertically and horizontally are arranged at fixed intervals in the metal box, the horizontal steel sheets 2 become shorter step by step, the vertical steel sheets 2 are arranged all the way, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com