Preparation method of medical polymer material surface antifouling coating

A polymer material, antifouling coating technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of difficult surface functionalization, and achieve easy industrial application and high reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

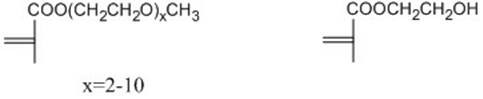

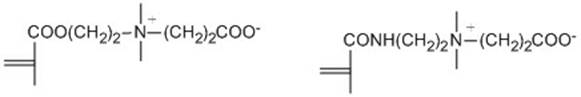

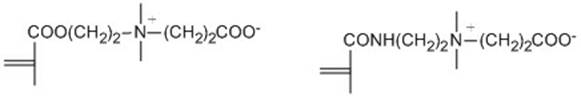

Method used

Image

Examples

Embodiment 1

[0018] Immerse a 2cmx2cm medical polystyrene sheet in a dichloromethane solution of 0.01% azobisisobutyronitrile and 1% vinylbenzyl chloride, take it out after 5 seconds, and irradiate it quickly at an ultraviolet light intensity of 50 mW / cm2 500 seconds, initiate the polymerization of vinylbenzyl chloride, and form a nano-layer of polyvinylbenzyl chloride on the surface of polystyrene; then under nitrogen atmosphere, use 0.001M cuprous chloride catalyst and 0.002M BPY as ligand , 3M aqueous solution of methacryloyl ethyl sulfobetaine is the ATRP reaction system, the above-mentioned medical polystyrene sheet is placed in the system to carry out ATRP grafting of betaine on the surface, at 25 degrees Celsius, the oscillation reaction time is 12 hours, After taking out the polystyrene sheet, immerse it in deionized water for 2 hours to remove copper ions, and measure the contact angle of water to be 30 o (Unmodified polystyrene has a contact angle of 100 o ), so as to obtain the...

Embodiment 2

[0020] Immerse a 2 cmx2 cm medical polypropylene sheet in a chloroform solution of 0.04% benzoyl peroxide and 4% vinylbenzyl chloride, take it out after 60 seconds, and irradiate it quickly at an ultraviolet light intensity of 0.5 mW / cm2 for 10 Seconds, the polymerization of vinyl benzyl chloride is initiated, and a nano-vinyl benzyl chloride layer is formed on the surface of the polypropylene sheet; then, under nitrogen atmosphere, with 0.01M cuprous bromide as the catalyst and 0.02M HMTETA as the ligand, The 3M aqueous solution of 2-methacryloyloxyethylphosphorylcholine is the ATRP reaction system. The above-mentioned medical polypropylene material is placed in the system for surface ATRP grafting reaction. At 90 degrees Celsius, the oscillation reaction time is 8 hours. Take out the medical polypropylene sheet, soak it with deionized water for 2 hours to remove copper ions, and measure the contact angle of water to be 20 o (Note that the contact angle of unmodified polystyr...

Embodiment 3

[0022] Immerse a 2cmx2cm medical polyvinyl chloride sheet in a chloroform solution of 0.02% benzoyl peroxide and 2% vinylbenzyl chloride, take it out after 40 seconds, and irradiate it at an ultraviolet light intensity of 25mW / cm2 for 200 seconds quickly. Initiate the polymerization of vinylbenzyl chloride, and form a nano-layer of polyvinylbenzyl chloride on the surface of the polyvinyl chloride sheet; then, under nitrogen atmosphere, use 0.005M cuprous bromide as the catalyst and 0.01M HMTETA as the ligand, 1M The aqueous solution of hydroxyethyl methacrylate is an ATRP reaction system. The above-mentioned medical polyvinyl chloride material is placed in the system for surface ATRP grafting reaction. At 70 degrees Celsius, the oscillation reaction time is 1 hour, and the medical polyvinyl chloride sheet is taken out. Immerse with deionized water for 2 hours to remove copper ions, and measure the contact angle of water to be 35 o (Note that the contact angle of unmodified pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com