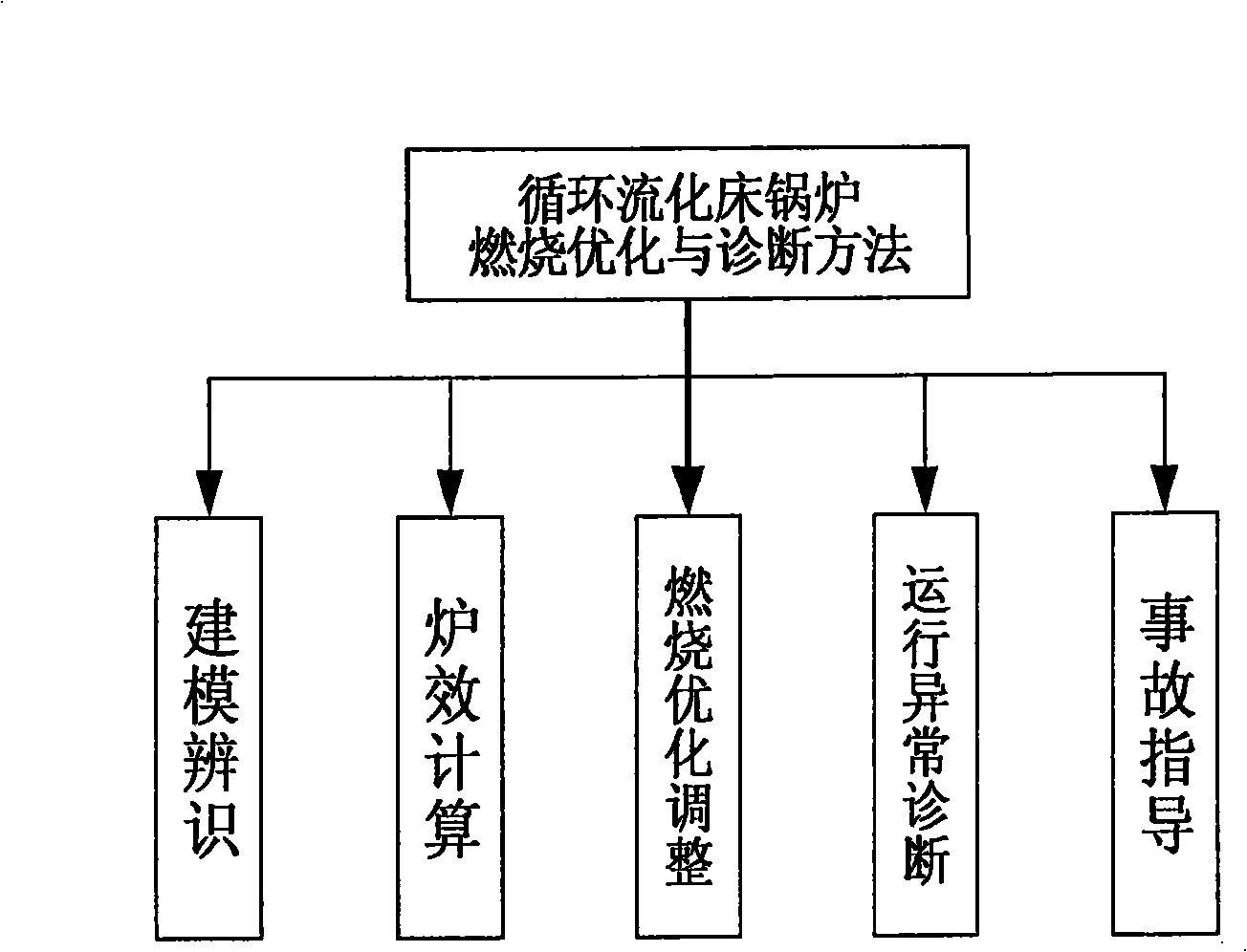

Method for optimizing and diagnosing circulating fluid bed boiler combustion

A circulating fluidized bed and boiler combustion technology, applied in the direction of instruments, adaptive control, electrical testing/monitoring, etc., can solve problems such as economic losses, imperfect operating procedures, production accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] In the present invention, firstly, the operating data of the circulating fluidized bed boiler system are collected and sorted out, and an artificial neural network model is established in which the operating data are mutually restricted.

[0118] Secondly, the present invention adopts the anti-balance algorithm of GB10184-88 to calculate the furnace efficiency, and the data sources are manual input of laboratory test values, field measured values and boiler design values, etc., which are used as important characteristic parameters to evaluate the operation status of the boiler.

[0119] The control principle and strategy that the present invention mainly adopts are specifically set forth as follows:

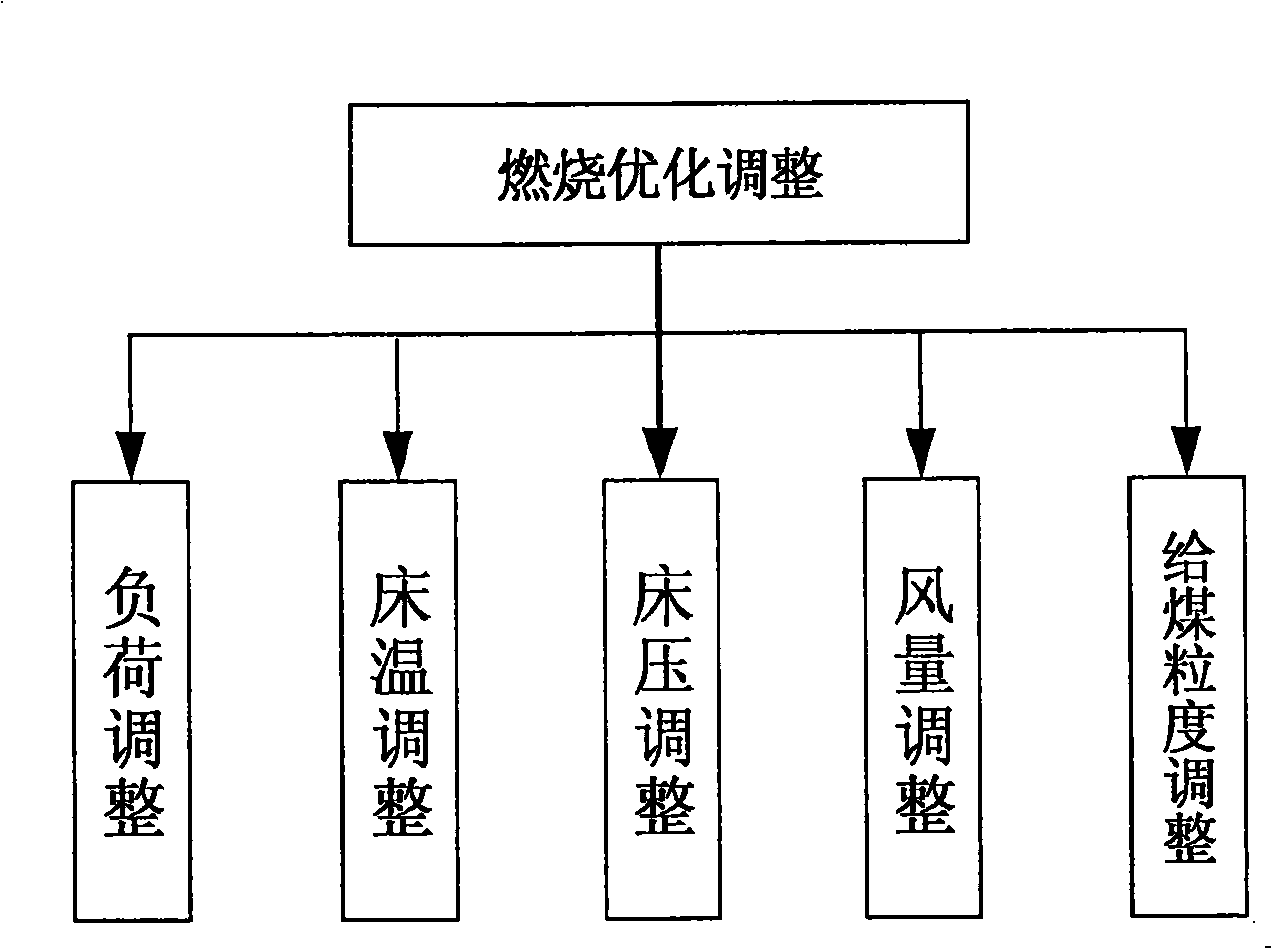

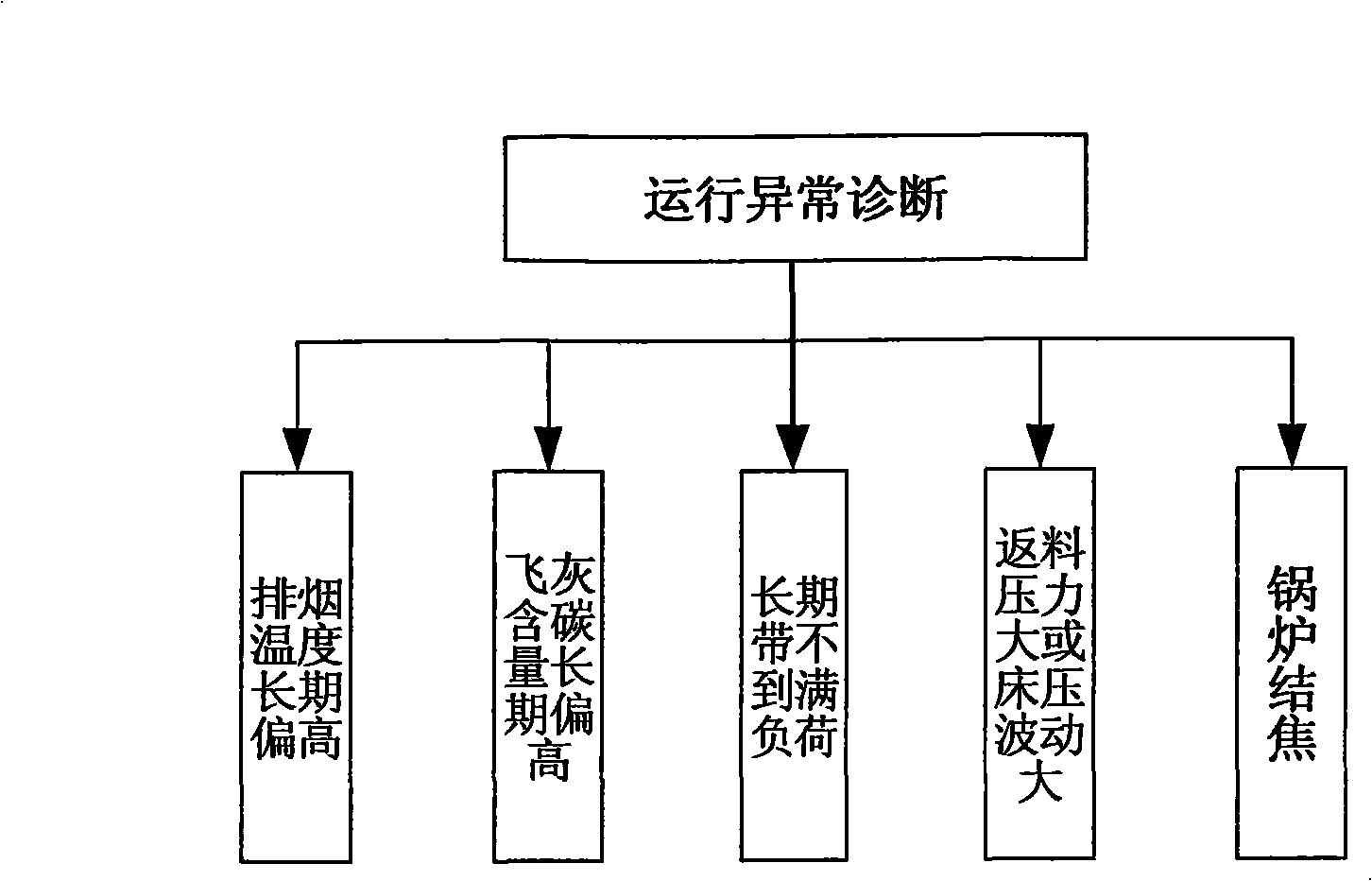

[0120] The combustion optimization module of the present invention summarizes the various experiences and data in the actual operation and control of the circulating fluidized bed boiler according to the established mathematical model of the circulating fluidized bed boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com