Compound desulfurizing process of circulating fluidized bed boiler

A technology of circulating fluidized bed and desulfurization process, which is applied in the direction of fluidized bed combustion equipment, chemical instruments and methods, fuel burned in a molten state, etc. It can solve the problems of desulfurization agent waste, desulfurization efficiency drop, and flying out of the furnace, etc., to achieve Realize the effect of economy, broad application prospect and guarantee of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

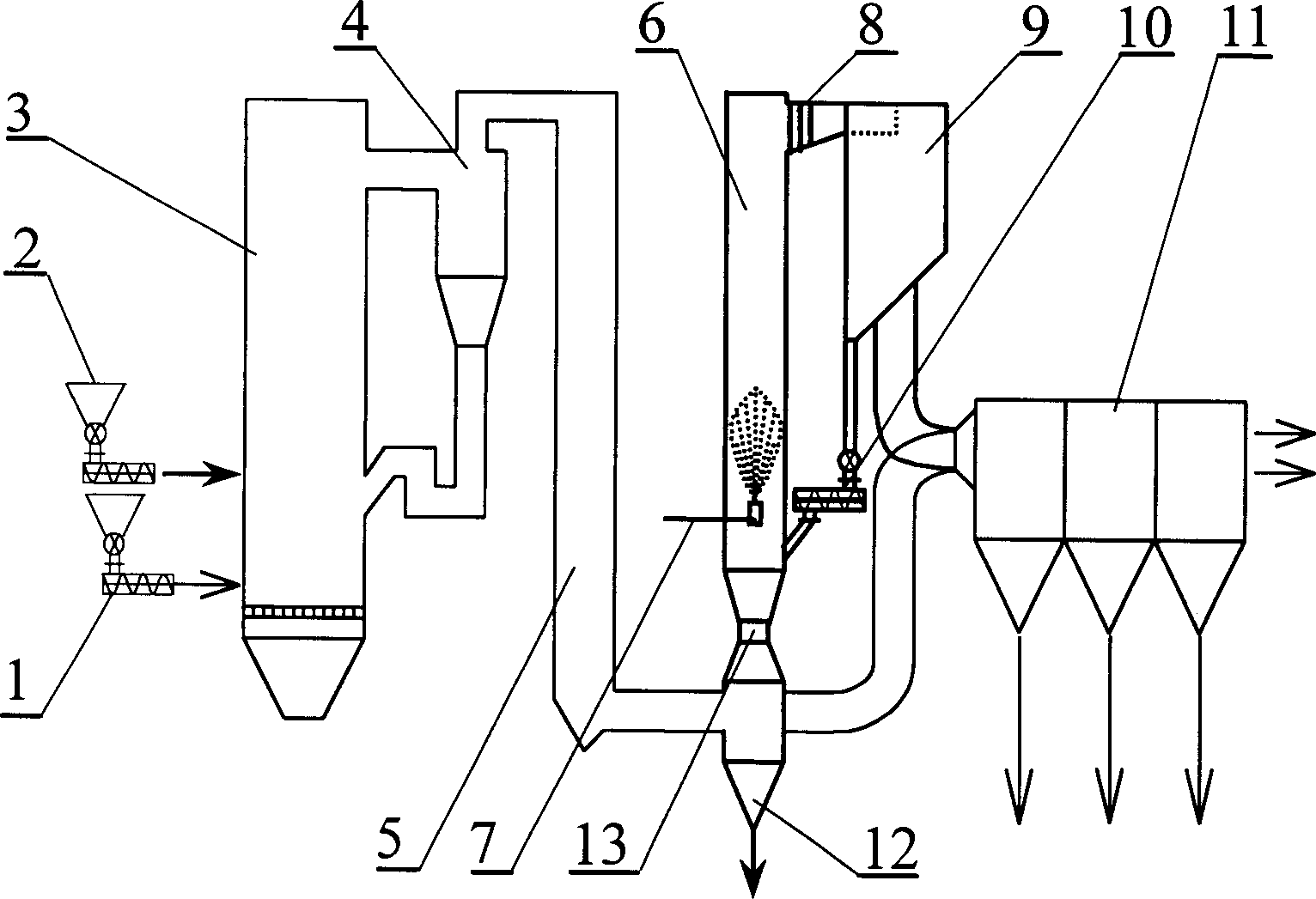

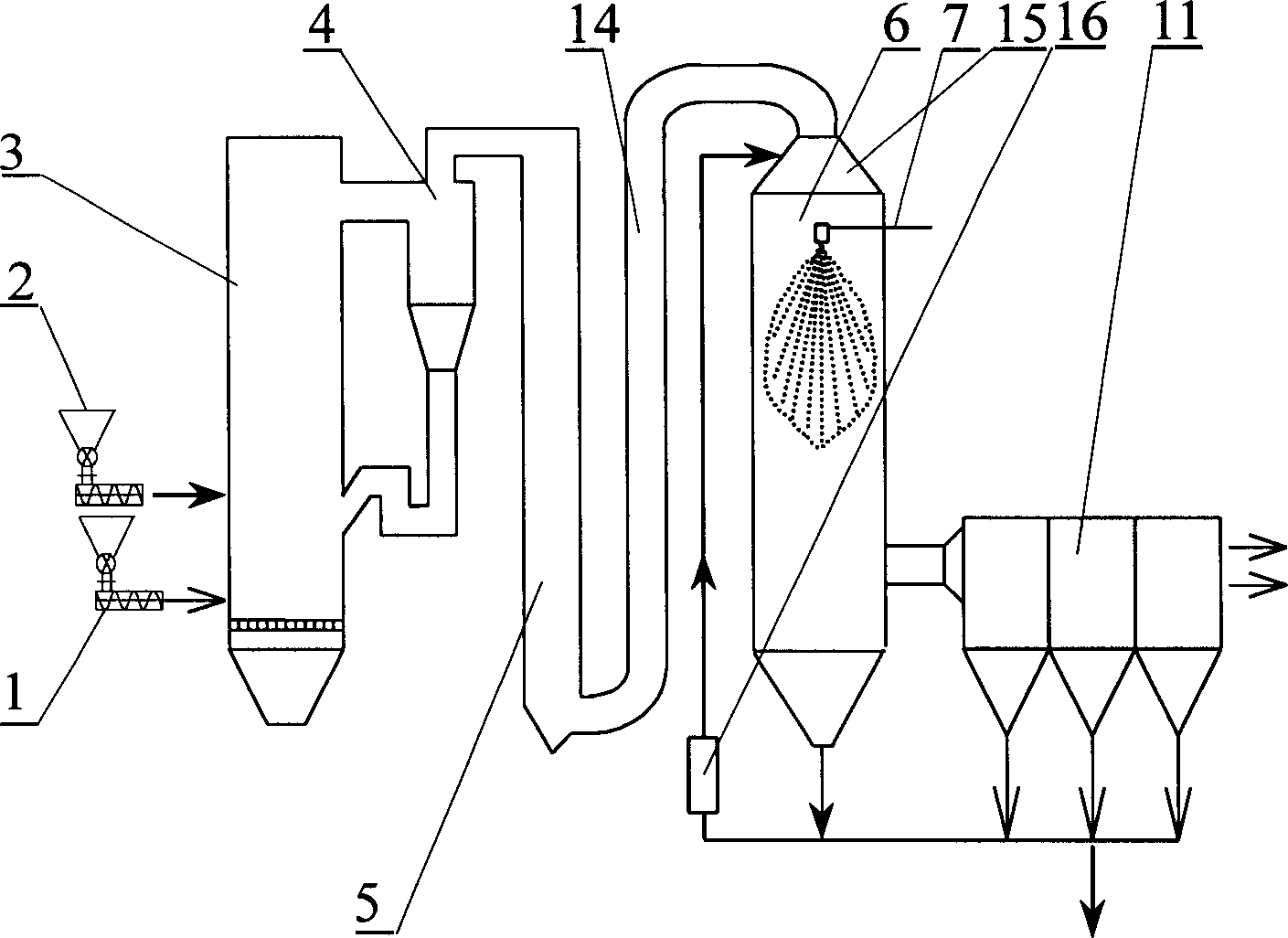

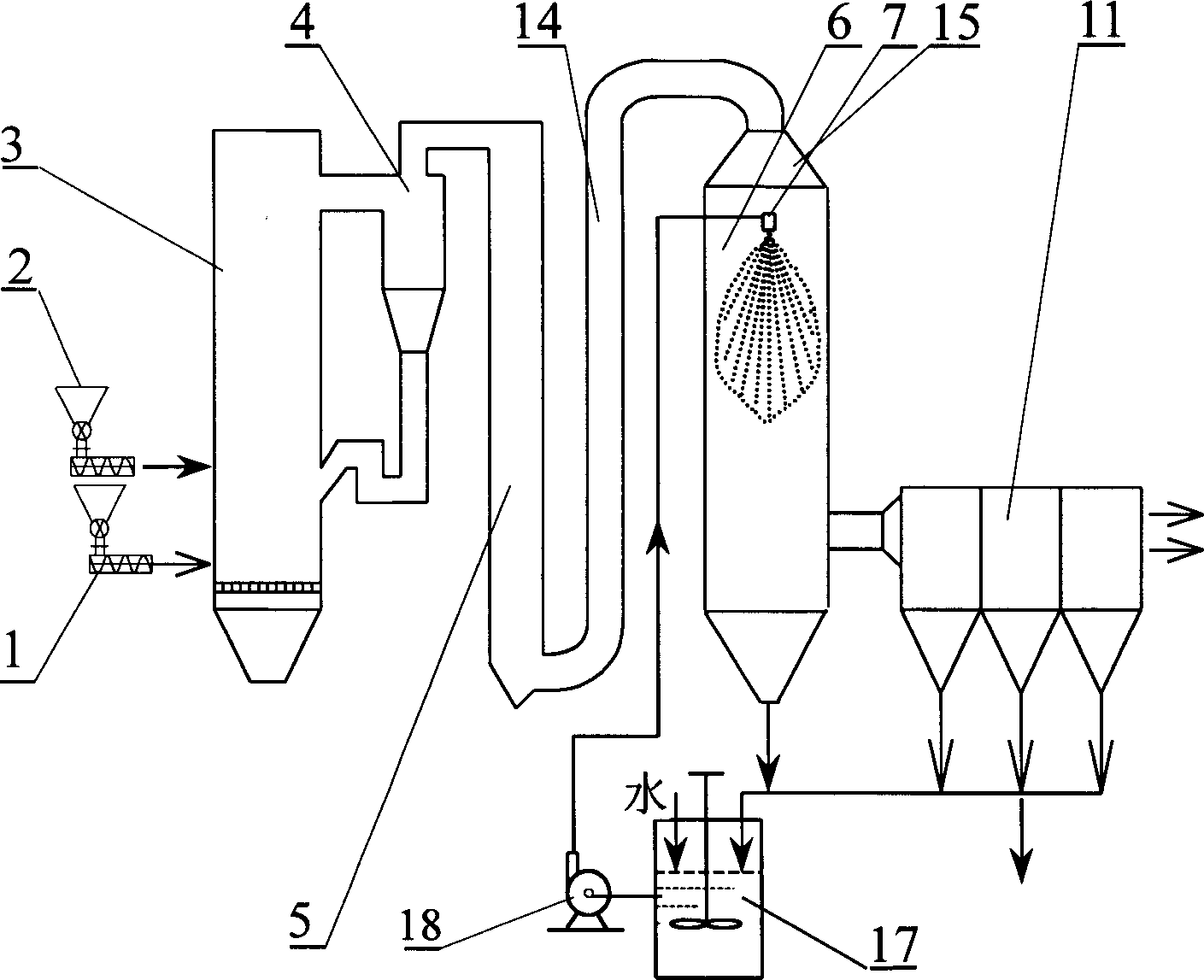

[0017] Attached below figure 1 A preferred embodiment of the present invention is given.

[0018] Limestone particles with a particle size of less than 2mm are sent to the circulating fluidized bed boiler 3 by the limestone feeding device 2, and the CaO particles calcined and decomposed in the furnace undergo a gas-solid reaction with sulfur dioxide at the bed temperature in the furnace, and the larger particles of calcium oxide particles After being separated from the coal-fired particles by the high-temperature separator of the circulating fluidized bed boiler, they enter the bed for further reaction, remove part of the sulfur dioxide and complete the combustion desulfurization process in the bed. Calcium oxide particles with a particle size smaller than the cutting particle size of the high-temperature separator enter the humidification tower 6 through the tail flue 5 and the Venturi 13 with the flue gas, and a water atomization system 7 is arranged on the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com