Circulating fluidized bed boiler ash cement-based self-leveling material

A sulfur-fixing ash, cement-based technology, applied in the field of self-leveling materials for construction and cement-based self-leveling materials for sulfur-fixing ash, can solve the problems of corrosion of iron parts, limited use range, poor water resistance, etc., to save cement consumption, reduce Waste of land resources and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

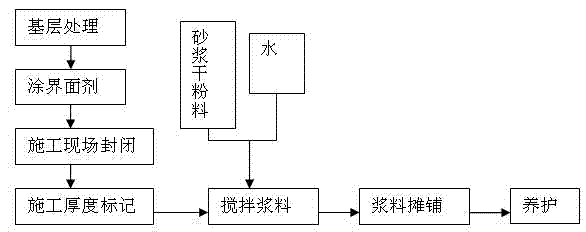

Method used

Image

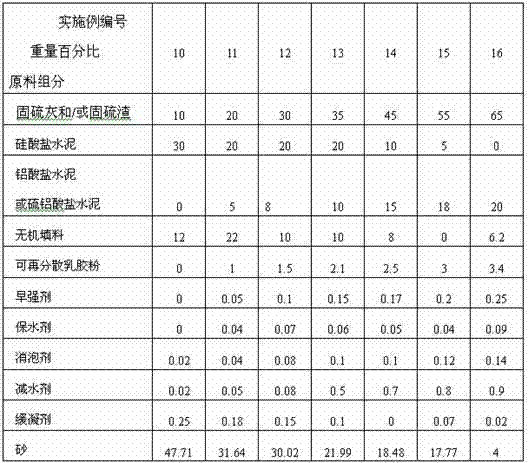

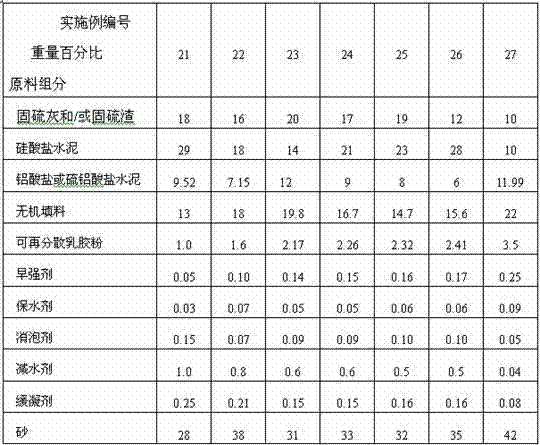

Examples

Embodiment 1

[0049] A kind of sulfur-fixed ash cement-based self-leveling material, its composition and the weight percentage of each component include: 14% of sulfur-fixed ash, 22% of ordinary Portland cement, 9% of aluminate cement, 16.5% of heavy calcium powder, Redispersible latex powder 1.5%, defoamer 0.07%, polycarboxylate superplasticizer 0.07%, lithium carbonate 0.17%, hydroxyethyl methyl cellulose ether 0.06%, citric acid 0.1%, sand 36.53%;

[0050] Wherein: the sulfur-fixing ash is the sulfur-fixing ash discharged from the circulating fluidized bed or the sulfur-fixing ash after grinding by a mill; the sand particle size is controlled at 20-300 mesh; during construction, according to the weight percentage Example ingredients and fully mixed to make mortar dry powder, and then according to the water-material ratio of 0.230 (that is, the weight ratio of water: mortar dry powder is 0.230:1), add water and mix well before construction, that is, after the slurry is paved and maintained...

Embodiment 2

[0052] A kind of sulfur-fixed ash cement-based self-leveling material, its composition and the weight percentage of each component include: 18% of sulfur-fixed ash, 18% of ordinary Portland cement, 8% of aluminate cement, 16% of heavy calcium powder, 0.1% defoamer, 1.5% redispersible latex powder, 0.07% polycarboxylate superplasticizer, 0.17% lithium carbonate, 0.06% methyl hydroxyethyl cellulose ether, 0.1% citric acid, 38% sand;

[0053] Wherein: the sulfur-fixing ash is the sulfur-fixing ash discharged from the circulating fluidized bed or the sulfur-fixing ash after grinding by a mill; the sand particle size is controlled at 20-300 mesh; during construction, according to the weight percentage Example ingredients and fully mixed to make mortar dry powder, then according to the water-material ratio of 0.248 (that is, the weight ratio of water: mortar dry powder is 0.248:1), add water and mix well before construction, that is, after slurry paving and maintenance, performance c...

Embodiment 3

[0055] A kind of sulfur-fixed ash cement-based self-leveling material, its composition and the weight percentage of each component include: sulfur-fixed ash and sulfur-fixed slag (can be mixed in any proportion) 22%, ordinary Portland cement 14%, sulfur-aluminum Salt cement 9%, heavy calcium powder 14.5%, dispersible latex powder 2%, defoamer 0.1%, polycarboxylate superplasticizer 0.08%, lithium carbonate 0.15%, methyl hydroxyethyl cellulose ether 0.05% , citric acid 0.12%, sand 38%;

[0056] Wherein: the sulfur-fixing ash is the sulfur-fixing ash discharged from the circulating fluidized bed or the sulfur-fixing ash after grinding by a mill, and the sulfur-fixing slag is the sulfur-fixing slag after grinding; the sand particle size is controlled at 20 ~300 mesh. During construction, mix the ingredients according to the stated weight percentage and fully mix them to obtain dry mortar powder, then add water and mix well according to the water-material ratio of 0.256 (that is, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com