A membrane-type water-cooled wall four-flue biomass circulating fluidized bed boiler

A circulating fluidized bed and membrane water-cooled wall technology, which is applied in fluidized bed combustion equipment, steam boilers, combustion product treatment, etc. problems, to ensure long-term safe and reliable operation, reduce wear and alkali metal corrosion, and ensure safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

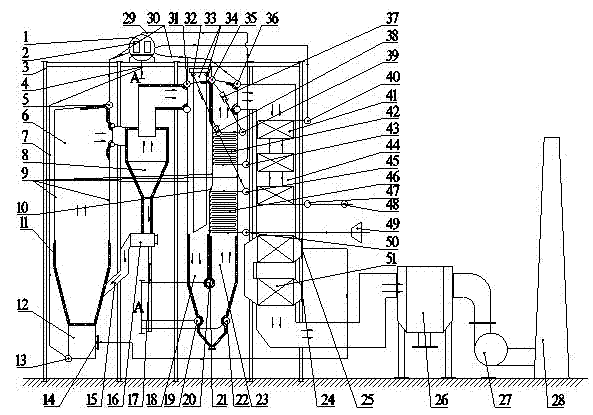

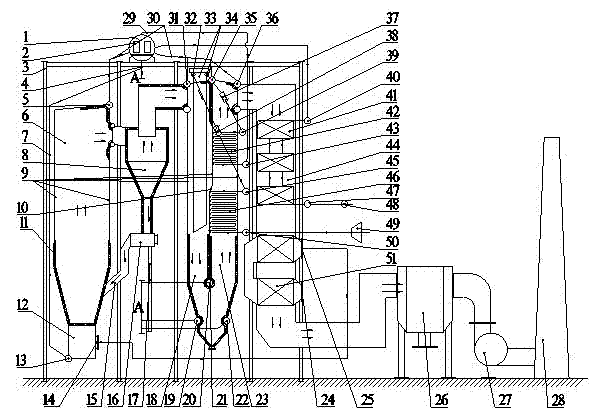

[0009] The high-efficiency biomass circulating fluidized bed boiler with membrane water-cooled wall and four flues of the present invention includes a drum 1 with a steam-water separation device 2 inside, a furnace 6, a cyclone separator 8, a feeder 16, and a second flue 18 , the third flue 23, the fourth flue 44, the low-temperature convection superheater 42, the high-temperature convection superheater 46, the economizer 41, the dust collector 26, the induced draft fan 27 connected to the dust collector 26, the induced draft fan 27 connected to each other chimney28. The furnace 6, the second flue 18 and the third flue 23 are surrounded by a membrane water-cooled wall 9, which can improve the utilization rate of combustion heat energy and reduce the temperature of the flue gas. The drum 1 is set on the top plate of the steel frame 3, the bottom of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com